Method for processing high-toxicity high-concentration highly salt-containing organic waste water with biochemistry combination process of catalytic oxidation

A technology of catalytic oxidation and combined process, applied in the field of water treatment, can solve the problems of high treatment cost, difficult biological treatment to play a role, huge treatment facilities, etc., to achieve the effect of improving the degree of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: The ultra-high salinity pesticide wastewater with a salinity of 10% first enters the three-effect vacuum distillation desalter treatment unit in the combined treatment technology, the pressure of the first distillation tower is 10kg, and the temperature is 90°C ;The pressure of the second distillation tower is 7kg and the temperature is 75°C; the pressure of the third distillation tower is 3kg and the temperature is 60°C; The effluent of the device ensures that the salt content is 0.9%, and the crystallized salt is recycled and reused. After testing, the water quality changes after treatment by this treatment unit are shown in the table below:

[0037] serial number

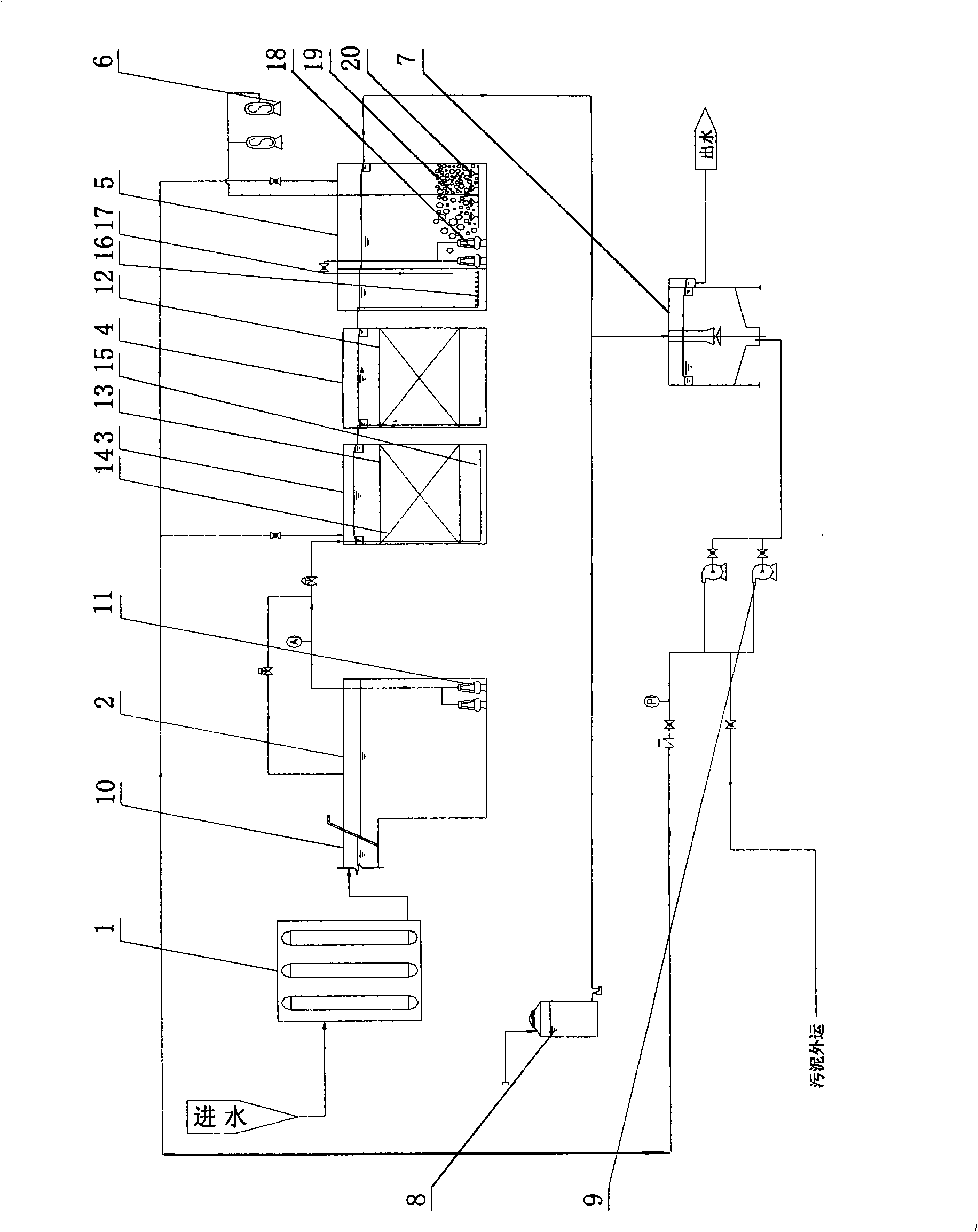

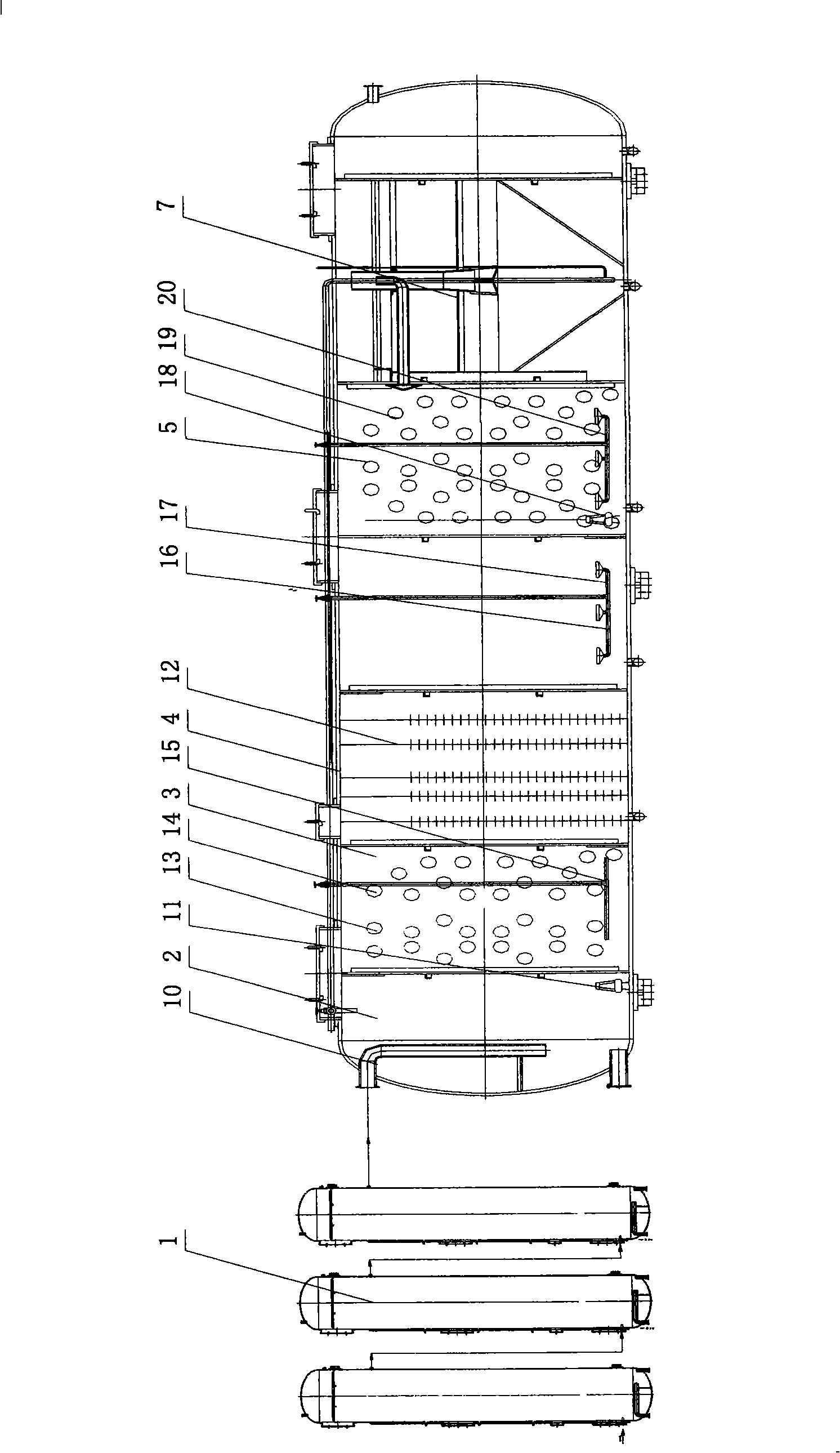

[0038] The waste water with a salt content of 0.9% from the three-effect distillation desalter 1 is pretreated by the grid well 10 and the regulating pool 2, and then lifted into the micro-electrolytic catalytic oxidation pool 3 by the submersible lift pump 11, and the residence time o...

Embodiment 2

[0047] Embodiment 2: the organic wastewater with a salt content of 6% first enters the three-effect vacuum distillation desalter treatment unit in the combined treatment technology, the pressure of the first distillation tower is 9kg, and the temperature is 85°C; the second distillation The pressure of the tower is 6.5kg and the temperature is 70°C; the pressure of the third distillation tower is 3.5kg and the temperature is 55°C; in this treatment unit, the ultra-high salt content is removed, and the effluent of the desalter after treatment ensures The salt content is 0.6%, and the crystallized salt is recycled and reused. After testing, the water quality changes after treatment by this treatment unit are shown in the table below:

[0048] serial number

Indicator name

The processing unit is flooded

The treatment unit effluent

Removal rate

Remark

1

salt content

6%

0.6%

90%

2

COD Cr

4000mg / l

2...

Embodiment 3

[0062] Embodiment 3: process high salinity (CaCl 2 be the main salt) the organic waste water technology of 3% salinity, the specific implementation is expressed as follows: high salinity (CaCl 2is the main salt) organic wastewater technology first enters the three-effect distillation desalter treatment unit in the combined treatment technology, the pressure of the first distillation tower is 8kg, and the temperature is 85°C; the pressure of the second distillation tower is 5kg, and the temperature is 65°C; the pressure of the third distillation tower is 3kg, and the temperature is 50°C; in this treatment unit, the ultra-high salt content is removed, and the salt content of the treated desalter effluent is guaranteed to be 0.5%, and the crystallized salt is processed Recycle and reuse. After testing, the water quality changes after treatment by this treatment unit are shown in the table below:

[0063] serial number

Indicator name

The processing unit is flood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com