Carbon-supported core-shell type platinum cobalt-platinum catalyst for fuel cells and preparation method for carbon-supported core-shell type platinum cobalt-platinum catalyst

A fuel cell and platinum catalyst technology, applied in the field of electrochemistry, can solve the problems of low catalytic activity and low utilization rate of platinum, and achieve the effects of promoting further development, reducing preparation cost, and improving utilization rate and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

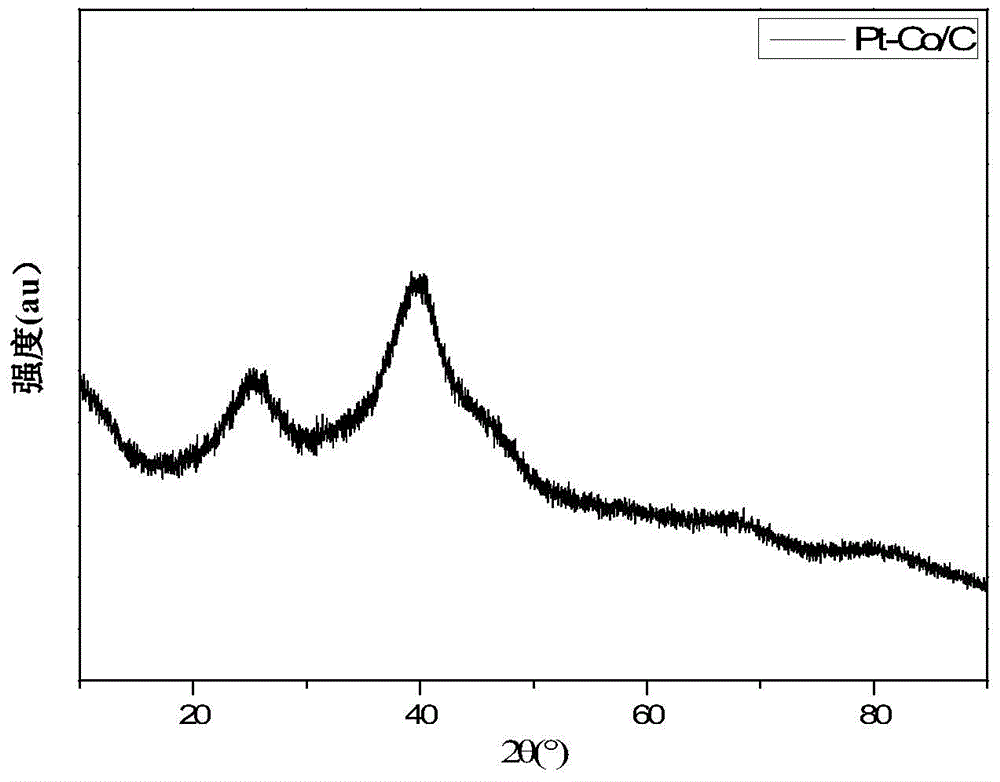

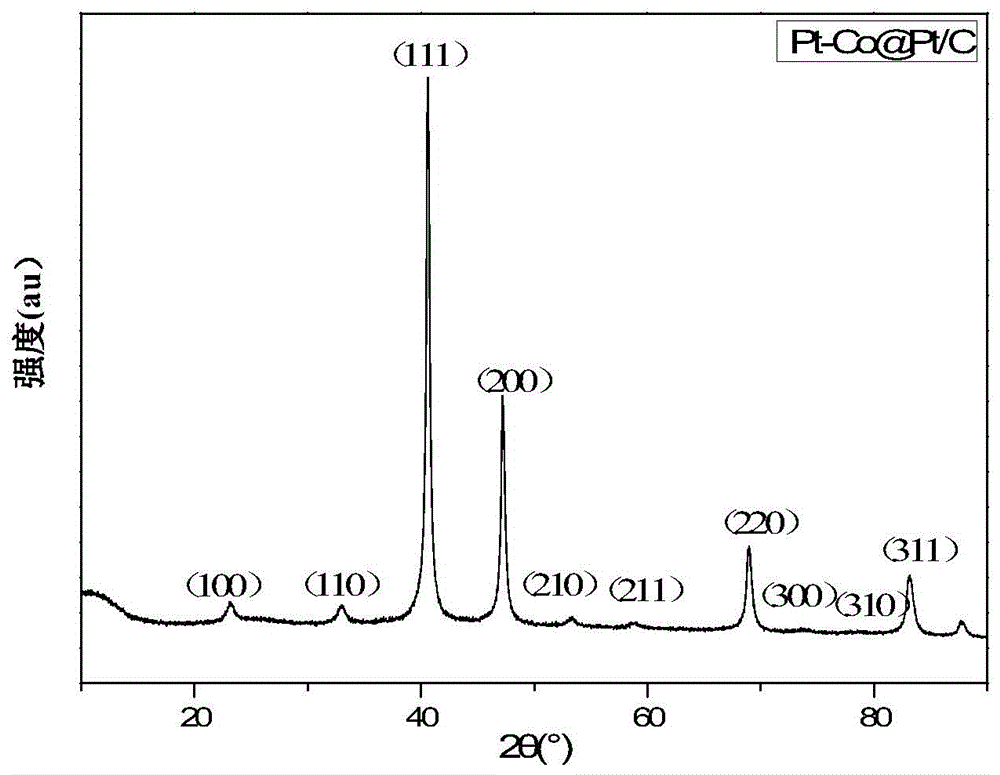

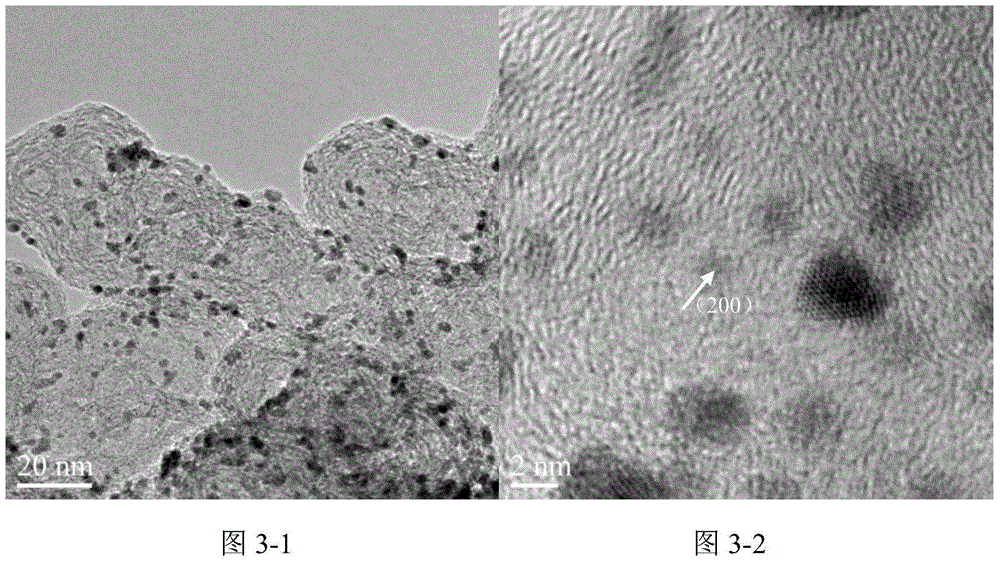

[0034] The preparation method of the core-shell platinum-cobalt-platinum catalyst for fuel cells of the present invention comprises two major steps. First, a co-reduction method is used to synthesize a carbon-supported cobalt-platinum alloy Pt- Co / C catalyst; then, the catalyst obtained in the previous step was 2 Structurally ordered core-shell platinum-cobalt-platinum catalyst prepared by annealing at high temperature. Specific steps are as follows:

[0035] (1) Weigh 60-90 mg of carbon spheres and place them in a tripod flask, add 30-50 ml of ethylene glycol (EG), ultrasonically disperse at room temperature for 0.5-1 h, and then add ethylene glycol (EG) of soluble cobalt salt under stirring Alcoholic solution and ethylene glycol solution of chloroplatinic acid, so that the mass ratio of carbon, cobalt ion and platinum ion in the mixed solution is 6~9:1.5:3, magnetically stirred for 3h;

[0036] (2) Use potassium hydroxide solution dissolved in ethylene glycol to adjust the...

Embodiment 1

[0041] (1) Weigh 80mg of carbon powder (XC-72 carbon black, the same below) into a conical flask, add 40ml of ethylene glycol, and ultrasonicate at room temperature for 1 to 2 hours to evenly disperse the carbon powder in ethylene glycol;

[0042] (2) 7.39mg cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and 48.27mg chloroplatinic acid (H 2 PtCl 6 ·H 2 O) Dissolve in ethylene glycol and sonicate for 1 h to make it homogeneous. Then, under strong stirring at room temperature, the above-mentioned precursors of Pt and Co were added dropwise and stirred for 3 h;

[0043] (3) Under room temperature and magnetic stirring, adjust the pH of the above reaction slurry to 10 with 1M KOH / EG solution, and stabilize it for 0.5h;

[0044] (4) Under nitrogen atmosphere protection and magnetic stirring, utilize oil bath to heat the above-mentioned reaction liquid, make its temperature reach 80 ℃, then slowly add 15ml of sodium borohydride (NaBH) dissolved in ethylene glycol dropwise 4 / EG,...

Embodiment 2

[0048] (1) Weigh 90mg of carbon powder into a conical flask, add 40ml of ethylene glycol, and ultrasonicate for 1-2 hours at room temperature, so that the carbon powder is evenly dispersed in ethylene glycol;

[0049] (2) 3.70mg cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and 23.14mg chloroplatinic acid (H 2 PtCl 6 ·H 2 O) Dissolve in ethylene glycol and sonicate for 1 h to make it homogeneous. Then, under strong stirring at room temperature, the above-mentioned precursors of Pt and Co were added dropwise and stirred for 3 h;

[0050] (3) Under room temperature and magnetic stirring, adjust the pH of the above reaction slurry to 10 with 1M KOH / EG, and stabilize it for 0.5h;

[0051] (4) Under nitrogen atmosphere protection and magnetic stirring, utilize oil bath to heat the above-mentioned reaction liquid, make its temperature reach 80 ℃, then slowly add 15ml of sodium borohydride (NaBH) dissolved in ethylene glycol dropwise 4 / EG, 2M) solution, make it react 3h;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com