Preparation method of iron/carbon composite material

A carbon composite material and iron source technology, applied in the field of materials, can solve the problems of high requirements for experimental instruments, low product output, and long synthesis time, and achieve the effects of reducing risk, reducing raw material costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

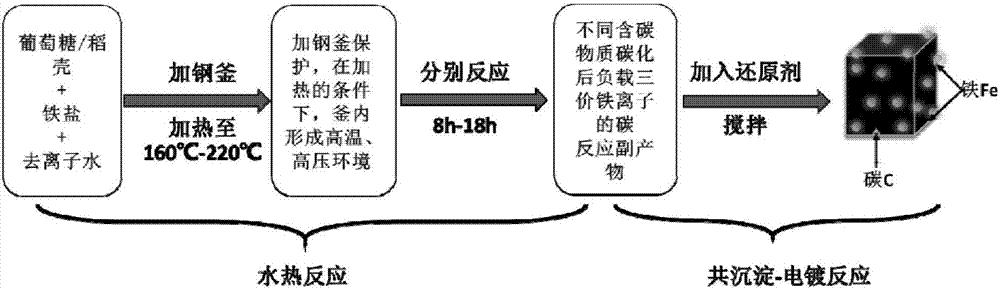

[0040] The preparation method of embodiment 1 iron / carbon composite material

[0041] (1), carbonization of organic matter by hydrothermal method

[0042] Take 2g of rice husk, wash it with water several times to remove surface impurities, and then dry it at about 60°C; add the pretreated raw material into a polytetrafluoroethylene autoclave with an effective volume of 25mL, and add 0.005mol Iron nitrate (Fe(NO 3 ) 3 9H 2 0) solid, add 15mL deionized water, then fully stir to make the reactants fully mix, because the density of the rice husk is small, it is easy to float on the solution, so the rice husk should be fully soaked in clear water before the reaction to make it Can be fully dispersed in the liquid phase, add a steel kettle to the high-pressure reaction kettle filled with reactants, put the steel kettle into an electric blast drying oven, set the reaction temperature to 180°C, and control the appropriate reaction time: 8 hours when rice husk is the carbon source....

Embodiment 2

[0048] The steps are the same as in Example 1, except that 0.01 mol of glucose is used as the carbon source, and in the hydrothermal carbonization step (1), the reaction time is 12 hours.

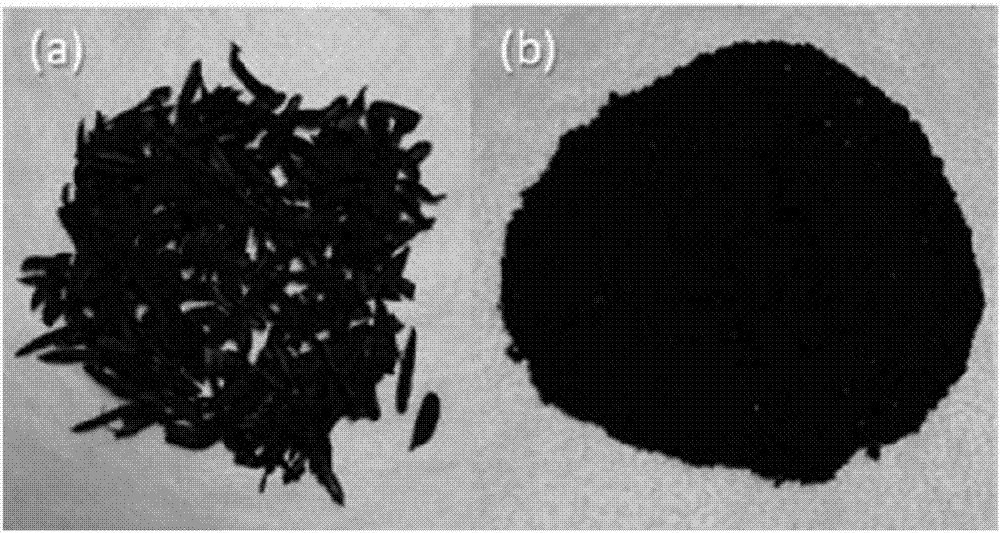

[0049] From figure 2 It can be seen that the iron / carbon material synthesized with rice husk as a carbon source is black and bright, basically maintaining the original shape of rice husk; the iron / carbon material synthesized with glucose as a carbon source is black powder.

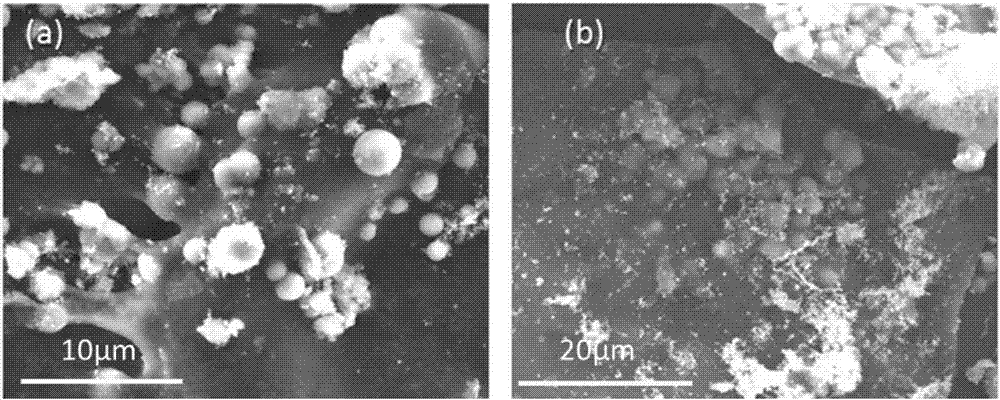

[0050] 1. The material was characterized by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS).

[0051] Taking iron / carbon composites synthesized with glucose as carbon source, the materials were pretreated before characterization. Take a small amount of synthetic product, sprinkle it lightly and evenly on the conductive adhesive used for testing, and then blow the surface of the conductive adhesive with a nitrogen stream to blow away the excess material that is not in contact with the conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com