Nanometer zero-valent iron-biochar composite material, and preparation method and application thereof

A technology of nano-zero-valent iron and composite materials, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problem of reducing specific surface area and reactivity, prone to agglomeration, performance degradation, etc. problems, to achieve excellent adsorption, stable properties, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

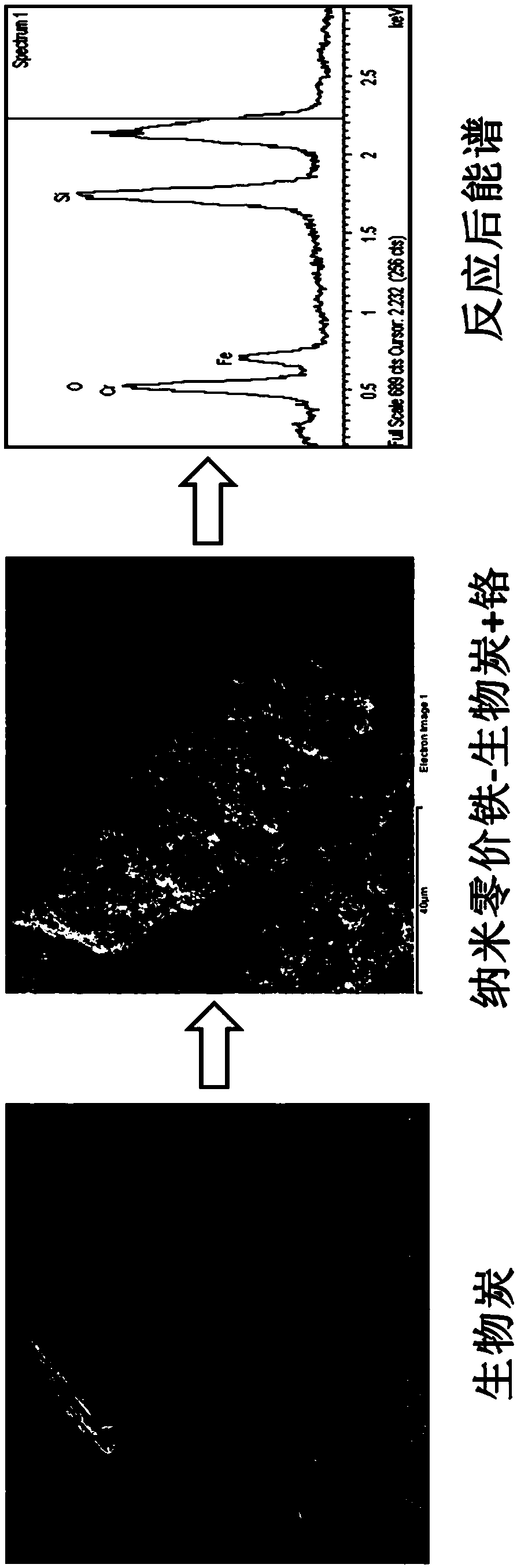

[0016] Preparation and application of a nano-zero-valent iron-biochar composite material. Using rice straw as biomass and biochar (BC100) produced by pyrolysis at a cracking temperature of 100°C as the carrier, the nano-zero-valent iron-biochar composite was prepared by liquid reduction method material, and used for the removal of Cr(Ⅵ), its preparation process and removal process include the following steps:

[0017] First prepare the rice straw biochar sample (BC100), weigh 50g of the biomass powder passed through a 0.154 mm sieve into a 250mL crucible, cover it after compaction, place it in a muffle furnace at 100°C for 6 hours, and cool to Take it out after room temperature, grind it through a 0.154 mm sieve with a mortar, and put it in a brown bottle. The prepared biochar is recorded as: BC100.

[0018] 2.0g FeSO 4 . 7H 2 O and 400 mg BC100 were dissolved in 100 mL of aqueous solution, adjusted to pH 4.5, and placed in a shaker at 25°C for 1 h. Then add 100mL of abso...

Embodiment 2

[0021] Preparation and application of a nano-zero-valent iron-biochar composite material. Using rice straw as biomass and biochar (BC300) produced by pyrolysis at 300°C as the carrier, the nano-zero-valent iron-biochar composite was prepared by liquid reduction method material, and used for the removal of Cr(Ⅵ), its preparation process and removal process include the following steps:

[0022] First prepare the rice straw biochar sample (BC300), weigh 50g of the biomass powder passed through a 0.154mm sieve into a 250mL crucible, cover it after compaction, place it in a muffle furnace at 300°C for 6 hours, and cool to Take it out after room temperature, grind it through a 0.154 mm sieve with a mortar, and put it in a brown bottle. The prepared biochar is recorded as: BC300.

[0023] 1.0g FeSO 4 . 7H 2 O and 200 mg BC300 were dissolved in 50 mL of aqueous solution, adjusted to pH 4.5, and placed in a shaker at 25°C for 1 h. Then add 50mL of absolute ethanol, transfer the wh...

Embodiment 3

[0026] Preparation and application of a nano-zero-valent iron-biochar composite material. Using rice straw as biomass and biochar (BC400) produced by pyrolysis at 400°C as the carrier, the nano-zero-valent iron-biochar composite was prepared by liquid reduction method material, and used for the removal of Cr(Ⅵ), its preparation process and removal process include the following steps:

[0027] First prepare the rice straw biochar sample (BC400), weigh 50g of the biomass powder passed through a 0.154 mm sieve into a 250mL crucible, compact it, cover it, place it in a muffle furnace at 400°C for 6 hours, and cool it to Take it out after room temperature, grind it through a 0.154 mm sieve with a mortar, and put it in a brown bottle. The prepared biochar is recorded as: BC400.

[0028] 1.0g FeSO 4 . 7H 2 O and 50 mg BC400 were dissolved in 50 mL of aqueous solution, adjusted to pH 4.0, and placed in a shaker at 25°C for 1 h. Then add 50 mL of absolute ethanol, transfer the who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com