Uranium (U) and plutonium (Pu) separation technology in Purex process

A process and process technology, applied in the field of nuclear fuel reprocessing, can solve the problems of unspecified process conditions and inapplicable actual operation process, etc., and achieve the effect of not being easy to acidolysis, strong complexation ability, and strong reduction ability

Active Publication Date: 2013-12-18

CHINA INSTITUTE OF ATOMIC ENERGY

View PDF7 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] published "Reduction Kinetics of Formaldoxime and Pu(IV)" in Volume 44, No. 2, "Nuclear Chemistry and Radiation Chemistry" in 2010 and No. 2010 "Formaldoxime and HNO2 Redox Reaction Kinetics" published in Volume 32, Issue 1 of "Nuclear Chemistry and Radiation Chemistry" respectively discloses the relationship between formaldoxime and Pu(IV) and HNO2 Basic research on reaction kinetics has obtained some process conditions, but the disclosed process conditions are not suitable for the actual operation process of uranium and plutonium separation. Process conditions for practical application in the separation process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0017] Example 2

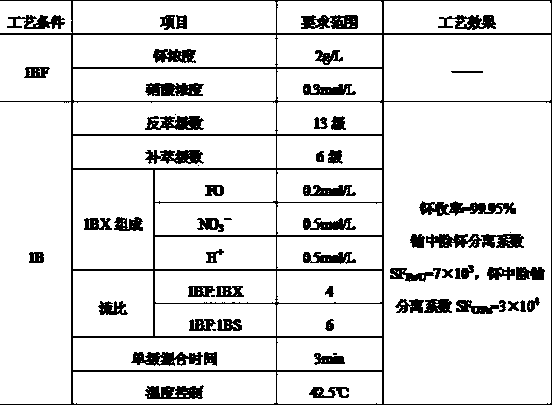

[0018] Identical with the method used in embodiment 1, difference is process condition, and process condition used and corresponding result are as table 2:

Embodiment 2

[0020] Example 3

[0021] Identical with the method used in embodiment 1, difference is process condition, and process condition used and corresponding result are as table 3:

Embodiment 3

[0023]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of nuclear fuel postprocessing, and discloses a uranium (U) and plutonium (Pu) separation technology in a Purex process. According to the uranium and plutonium separation technology, Pu (IV) in 1BF material flow is reduced to Pu (III) in 1B tank by use of reducing agent 1BX and supplement extractant 1BS to enable plutonium to get into an aqueous phase and uranium to be retained in an organic phase, and uranium and plutonium separation is realized. The reducing agent 1BX which is used comprises 0.1-0.2 mol / L of formaldoxime, 0.35-0.5 mol / L of NO<3-> and 0.35-0.5 mol / L of H<+>; the flow ratio of 1BF:1BX is 1-4, and the flow ratio of 1BF:1BS is 4-6. The uranium and plutonium separation technology has the characteristics that the plutonium recovery rate is high, and the purification coefficients of removal of plutonium from uranium and removal of uranium from plutonium are large.

Description

technical field [0001] The invention belongs to the technical field of nuclear fuel reprocessing, and in particular relates to a process for separating uranium and plutonium in the Purex process. Background technique [0002] The separation of uranium and plutonium is an important process in the Purex process. Its main task is to use a reducing agent to convert the Pu(IV) Reduction to Pu(Ⅲ), which is extremely difficult to be extracted, makes plutonium enter the water phase while uranium remains in the organic phase, realizing the separation of uranium and plutonium. Because organic chemical reagents have the characteristics of fast reaction speed, good selectivity, no introduction of salt, and easy destruction, a lot of research has been carried out in the application of uranium and plutonium separation. Among them, N, N-dimethylhydroxylamine, N, N-ethyl hydroxyethyl hydroxylamine, hydroxyurea, acetohydroxamic acid, etc. can be used as reducing agents in the separation of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B60/02C22B60/04G21F9/06B01D11/04

Inventor 肖松涛刘协春罗方祥杨贺兰天孟照凯

Owner CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com