Antibacterial and low-odor decorative polypropylene material used in saloon car and preparation method thereof

A polypropylene material, low odor technology, applied in the field of antibacterial, low odor polypropylene material for car interior and its preparation, can solve the problems of short validity period and high cost, and achieve no secondary pollution, strong bactericidal power and durability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

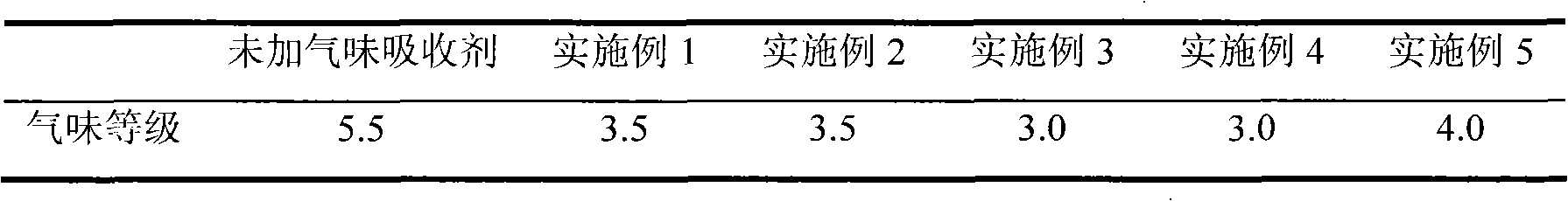

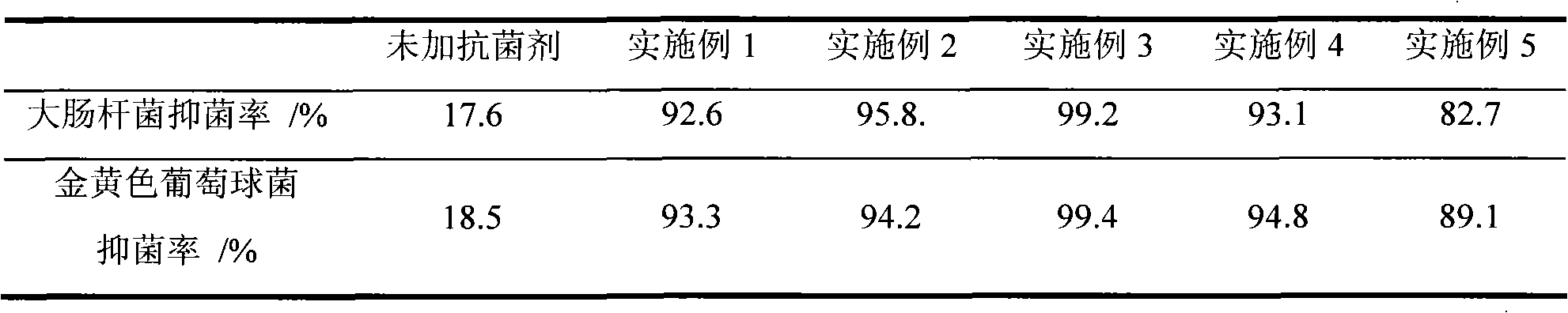

Embodiment 1

[0033] An antibacterial, low-odor polypropylene material for car interiors, which is composed of the following raw materials in weight percentage: polypropylene (brand: AP3N) 60%; elastomer 20%; talcum powder 16%; photocatalytic micropowder 2%; 0.5% antibacterial agent, 0.5% odor absorber, 0.4% antioxidant; 0.3% processing aid; 0.3% white mineral oil.

[0034] The talcum powder mesh number is 3000 mesh. The elastomer is selected from ethylene-octene copolymer. The photocatalytic micropowder is loaded with Ag + TiO 2 . The antibacterial agent is ultrafine ZnO 0.3% and CuO 0.2%. The odor absorbent is 0.3% molecular sieve and 0.2% zeolite. The antioxidants are three (2,4-di-tert-butylphenyl) phenyl phosphite 0.2% and tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid) Pentaerythritol esters 0.2%. Described processing aid is ethylene bis stearamide.

[0035] The preparation method is as follows: (1) firstly add white mineral oil to the mixture of polypropylene ...

Embodiment 2

[0038] An antibacterial, low-odor polypropylene material for car interiors, which is composed of the following raw materials in weight percentage: polypropylene (brand: K7726) 80%; elastomer 5%; talcum powder 10%; photocatalytic micropowder 2%; Antibacterial agent 0.8%, odor absorber 0.7%, antioxidant 0.8%; processing aid 0.5%; white mineral oil 0.2%.

[0039] The talcum powder mesh number is 1250 mesh. The elastomer is selected from ethylene-butene copolymer. The photocatalytic micropowder is loaded with Cu 2+ TiO 2 . The antibacterial agent is Ag 2 O 0.3% and CuO 0.5%. The odor absorbent is 0.4% molecular sieve and 0.3% hydroxyapatite. Described antioxidant is two (2.4-di-tert-butylphenyl) pentaerythritol diphosphite 0.4% and four (beta-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol Esters 0.4%. The processing aid is composed of 0.2% ethylene bis stearamide and 0.3% calcium stearate.

[0040] The preparation method is as follows: (1) firstly add whi...

Embodiment 3

[0043] An antibacterial, low-odor polypropylene material for car interiors, consisting of the following raw materials in weight percentage: polypropylene (brand: K7760) 61%; talcum powder 30%; photocatalytic micropowder 5%; antibacterial agent 1.4%, Odor absorbent 1.0%, antioxidant 0.6%; processing aid 0.6%; white mineral oil 0.4%.

[0044] The talcum powder mesh number is 5000 mesh. The photocatalytic micropowder is anatase TiO 2 2% and loaded with Ag + TiO 2 3%. The antibacterial agent is 0.7% of silver-based inorganic antibacterial powder and 0.7% of CuO. The odor absorbing agent is 0.4% of molecular sieve and 0.6% of silicate mineral. The antioxidant is N, N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine 0.3% and tetrakis(β-(3,5 -di-tert-butyl-4-hydroxyphenyl)propionate)pentaerythritol ester 0.3%. The processing aid is composed of 0.3% polyethylene wax and 0.3% calcium stearate.

[0045] The preparation method is as follows: (1) firstly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com