Porous nanometer zero-valent iron and porous nanometer zero-valent iron composite material

A technology of nano-zero-valent iron and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of easy agglomeration of products, high production costs, small specific surface area, etc., and achieve Low production cost, not easy to agglomerate, large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

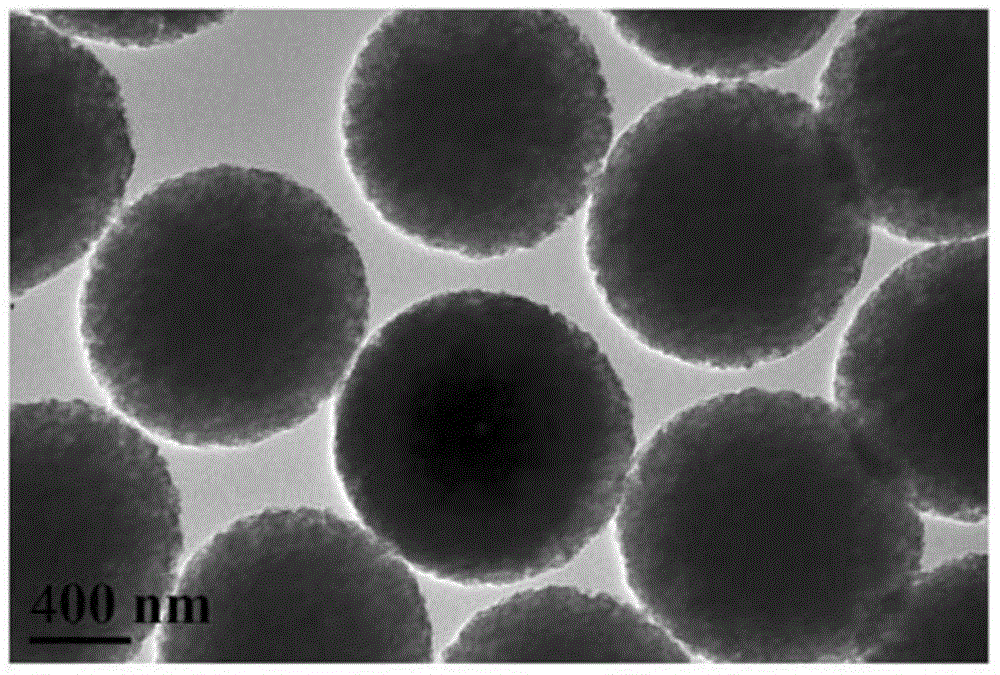

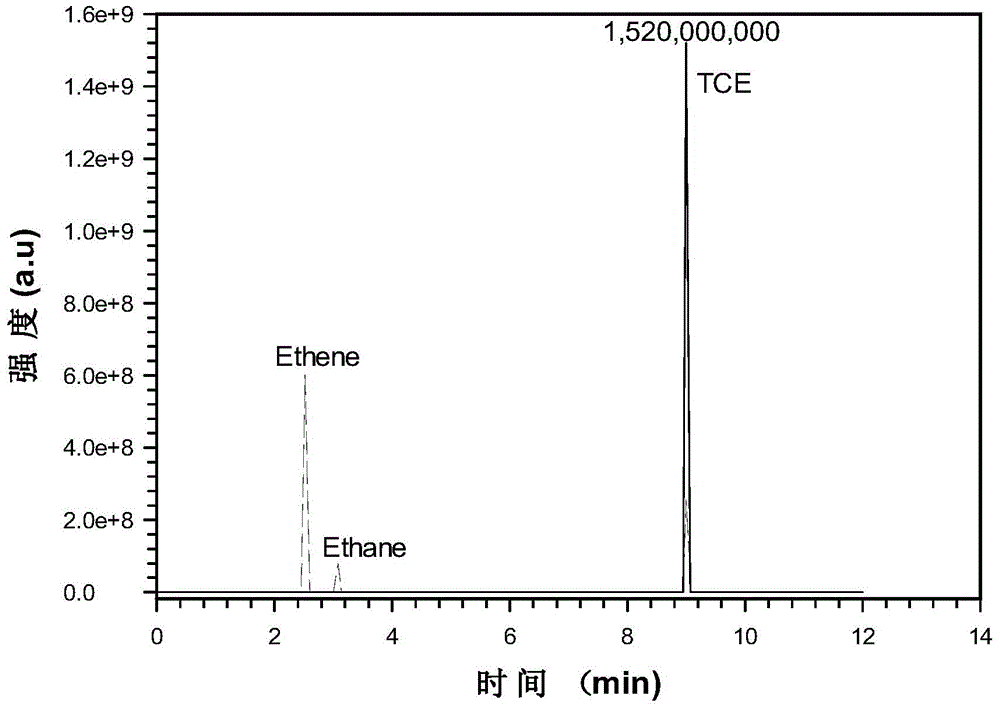

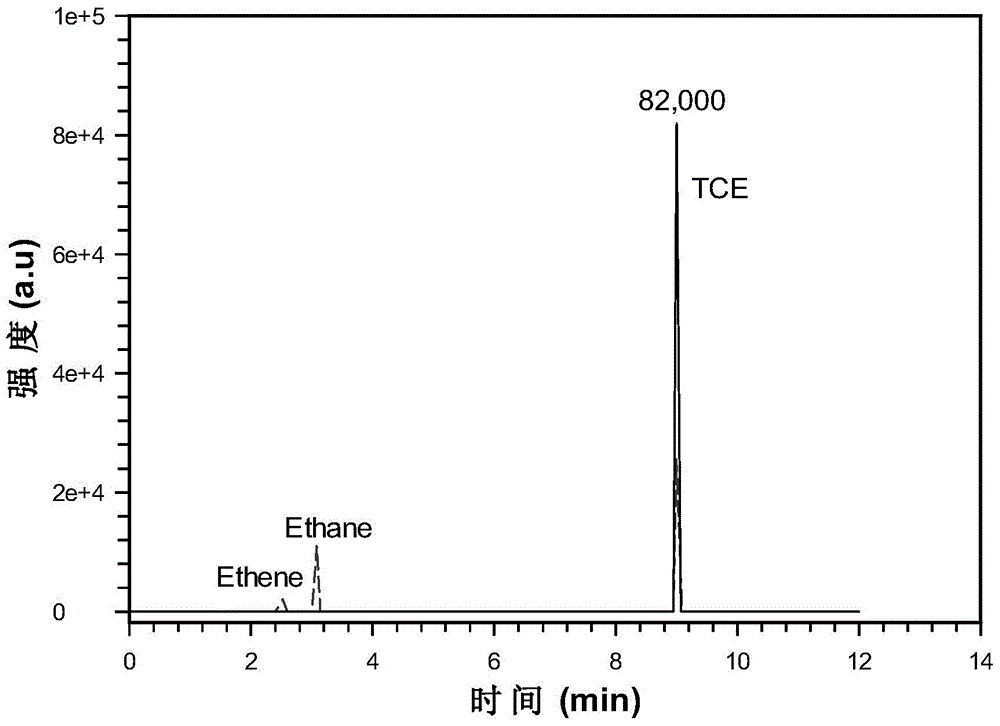

[0072] Embodiment 1. Utilize Al-Fe-Ni porous nano-zero valent iron composite to eliminate trichlorethylene in water

[0073] Contain 46% aluminium, the preparation method of the nano-alloy particle of 50% iron and 4% nickel is: with iron powder, aluminum powder and nickel powder (the average particle diameter of three kinds of powders is 300 orders, purchased from Beijing Gaodewei company) as The raw materials are mixed according to the above weight ratio, after being melted, superheated at 50°C, passed through high-pressure water mist and dried to obtain the above-mentioned ternary alloy particles with a particle size of 0.6-5.8 μm, and the powder is added to a high-energy ball mill (SPEX8000M single-grinding pot high-energy ball mill) Among them, the ball-to-material ratio is 25:1-50:1, sealed under argon protection, and after ball milling for 48 hours, an Al-Fe-Ni ternary alloy powder with an average particle size of 600-800nm is obtained (see Wang Yanxing, et al., Prepar...

Embodiment 2

[0075] Embodiment 2. Utilize Al-Fe-Pd nano zero valent iron composite to eliminate trichlorethylene in soil

[0076] With reference to the method of Example 1, the Al-Fe-Pd ternary alloy powder (the mass ratio of aluminum-iron-palladium is 55:44.9:0.1) with an average particle diameter of 600-800nm was prepared, and the ternary alloy powder was prepared by 1g:100mL Ratio, immersed in 4mol / L NaOH and 2mol / L sodium methoxide solution with oxygen content less than 0.5mg / L (NaOH:sodium methoxide=5:1 (volume ratio)), in N 2 Under protection at a rotating speed of 1500rpm, magnetically stirred for 3 hours, filtered, rinsed with distilled water with an oxygen content of less than 0.5mg / l to neutrality (pH=7.2-7.6), and then dried under vacuum conditions (vacuum degree 200Pa), That is, porous nano-scale zero-valent iron composite particles containing trace aluminum impurities and palladium were prepared. The average particle size of this particle was 755nm, the porosity was 50.8%, a...

Embodiment 3

[0078] Embodiment 3. Utilize Si-Fe-Cu porous nano-zero valent iron composite to eliminate trichlorethylene in water

[0079] With reference to the method of Example 1, the Si-Fe-Cu ternary alloy powder (mass ratio is 60:35:5) with an average particle diameter of 600-800nm was prepared, and the ternary alloy powder was immersed in the ratio of 1g:100mL containing In 4mol / L NaOH and 2mol / L sodium methoxide solution (NaOH:sodium methoxide = 5:1 volume ratio) with oxygen content less than 0.5mg / L, in N 2 Under protection at a speed of 1500rpm, magnetically stirred for 3 hours, filtered, rinsed with distilled water with an oxygen content of less than 0.5mg / L to neutrality (pH=7.2-7.6), and then dried under vacuum conditions (vacuum degree 200Pa), That is, Fe / Cu bimetallic nanoparticles containing a small amount of Si were prepared, and the porosity of the particles was 58.6%. The specific surface area of Fe / Cu bimetallic nanoparticles is about 211m 2 / g, the average particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com