Preparation method for three-element oxide composite material and application

A ternary oxide and composite material technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of long time required, inability to mass-produce, complicated preparation methods, etc., reaching time-consuming The effect of short, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

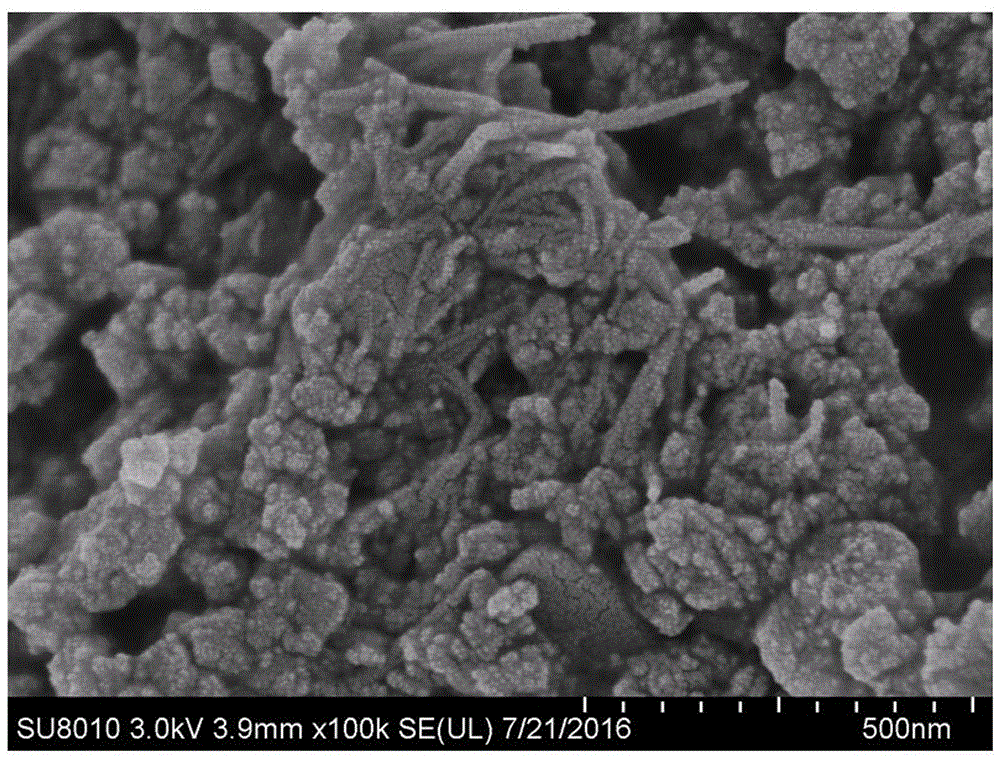

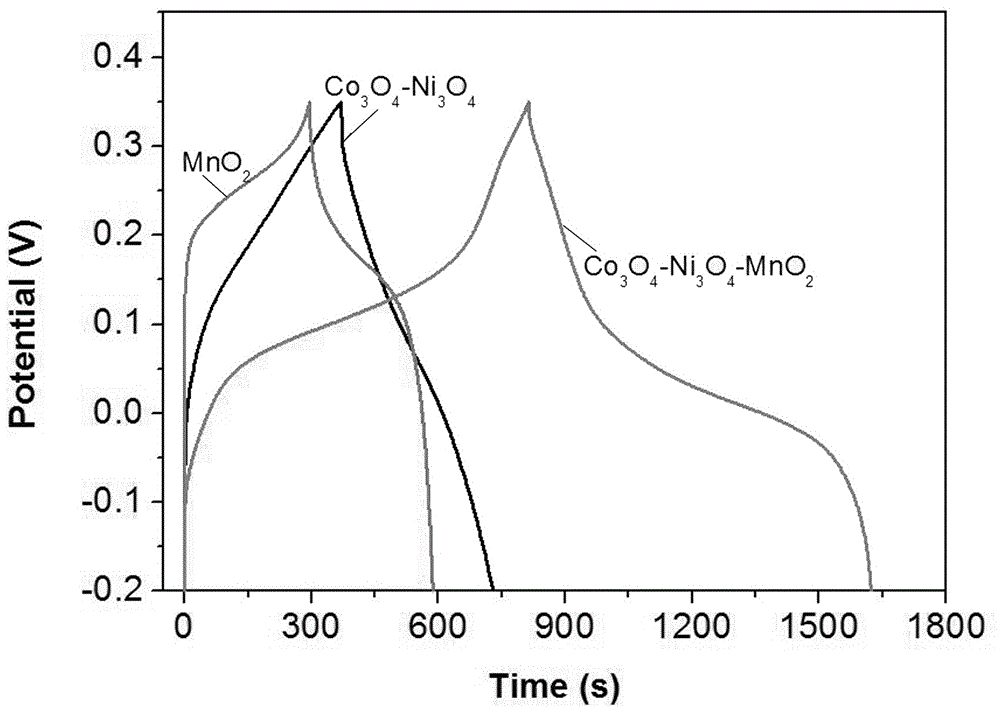

[0031] Preparation of Co 3 o 4 -Ni 3 o 4 -MnO 2 Ternary oxide composite materials:

[0032] (1) Take 50 g CoSO 4 , 5 g NiSO 4 Dissolve in 100 mL of water;

[0033] (2) Weigh 2 g NaBH 4 , and then added to water to give NaBH 4 aqueous solution;

[0034] (3) NaBH from step (2) 4 The aqueous solution is slowly added dropwise to the aqueous solution of step (1);

[0035] (4) After the dropwise addition is completed, let the solution react for 2 hours, filter, wash, and dry to obtain powder;

[0036] (5) Add the powder obtained in step (4) to 1 g / L potassium permanganate aqueous solution to react; filter, wash, and dry to obtain Co 3 o 4 -Ni 3 o 4 -MnO 2Ternary oxide composite materials;

[0037] (6) Weigh 0.008 g Co-Ni-W alloy oxide-graphene composite material, 0.001 g acetylene black (produced in Tianjin, 90%) and 0.001 g polytetrafluoroethylene micropowder (produced in Tianjin, 90%), place in Add a few drops of ethanol (produced in Tianjin, AR) to a small agate...

Embodiment 2

[0042] Preparation of Co 3 o 4 -Ni 3 o 4 -MnO 2 Ternary oxide composite materials:

[0043] (1) Take 50 g CoSO 4 , 5 g NiSO 4 Dissolve in 100 mL of water;

[0044] (2) Weigh 1 g NaBH 4 , and then added to water to give NaBH 4 aqueous solution;

[0045] (3) NaBH from step (2) 4 The aqueous solution is slowly added dropwise to the aqueous solution of step (1);

[0046] (4) After the dropwise addition is completed, let the solution react for 2 hours, filter, wash, and dry to obtain powder;

[0047] (5) Add the powder obtained in step (4) to 3 g / L potassium permanganate aqueous solution to react, filter, wash, and dry to obtain Co 3 o 4 -Ni 3 o 4 -MnO 2 Ternary oxide composite materials;

[0048] (6) Weigh 0.008 g Co-Ni-W alloy oxide-graphene composite material, 0.001 g acetylene black (produced in Tianjin, 90%) and 0.001 g polytetrafluoroethylene micropowder (produced in Tianjin, 90%), place in Add a few drops of ethanol (produced in Tianjin, AR) to a small agat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com