Metallic oxide nanowire coil/active carbon fiber composite electrode material and preparation thereof

A technology of activated carbon fiber and composite electrode, applied in the fields of materials and electrochemistry, can solve the problems of low energy density of supercapacitors, and achieve the effects of being conducive to rapid migration, high power storage capacity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

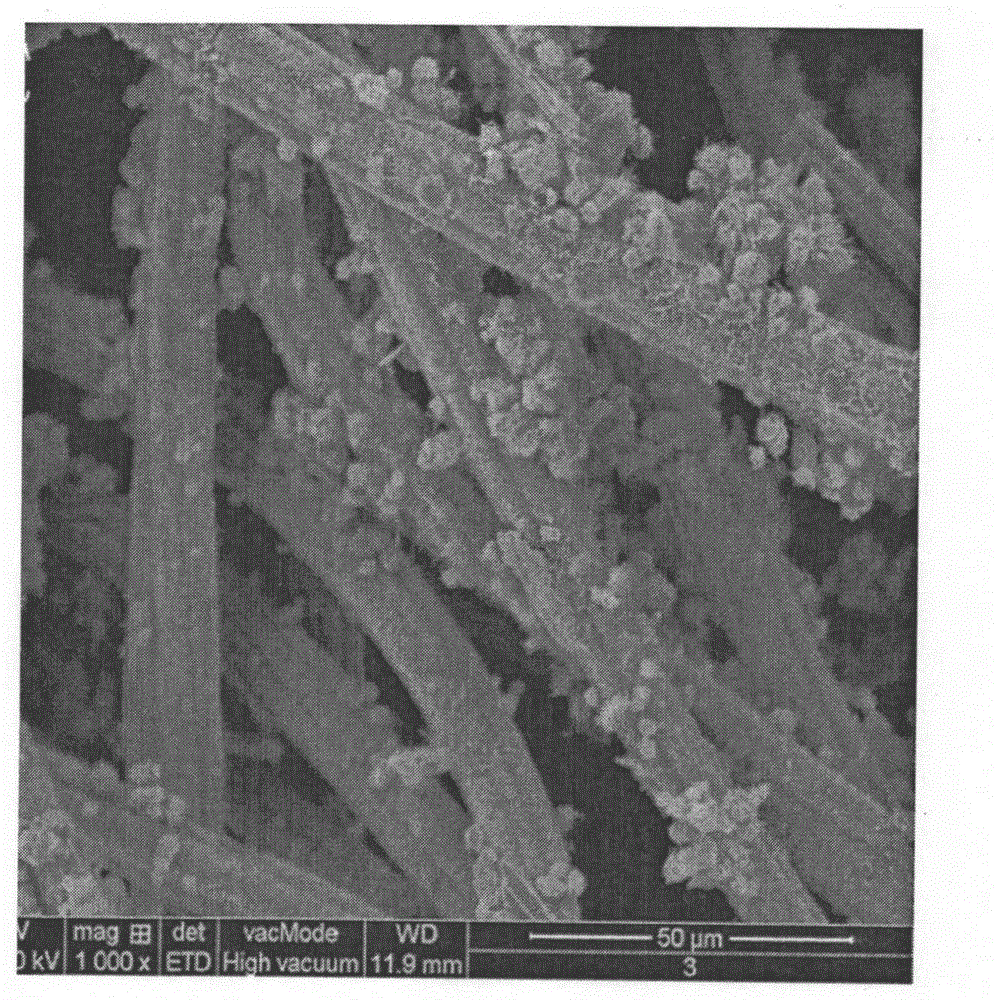

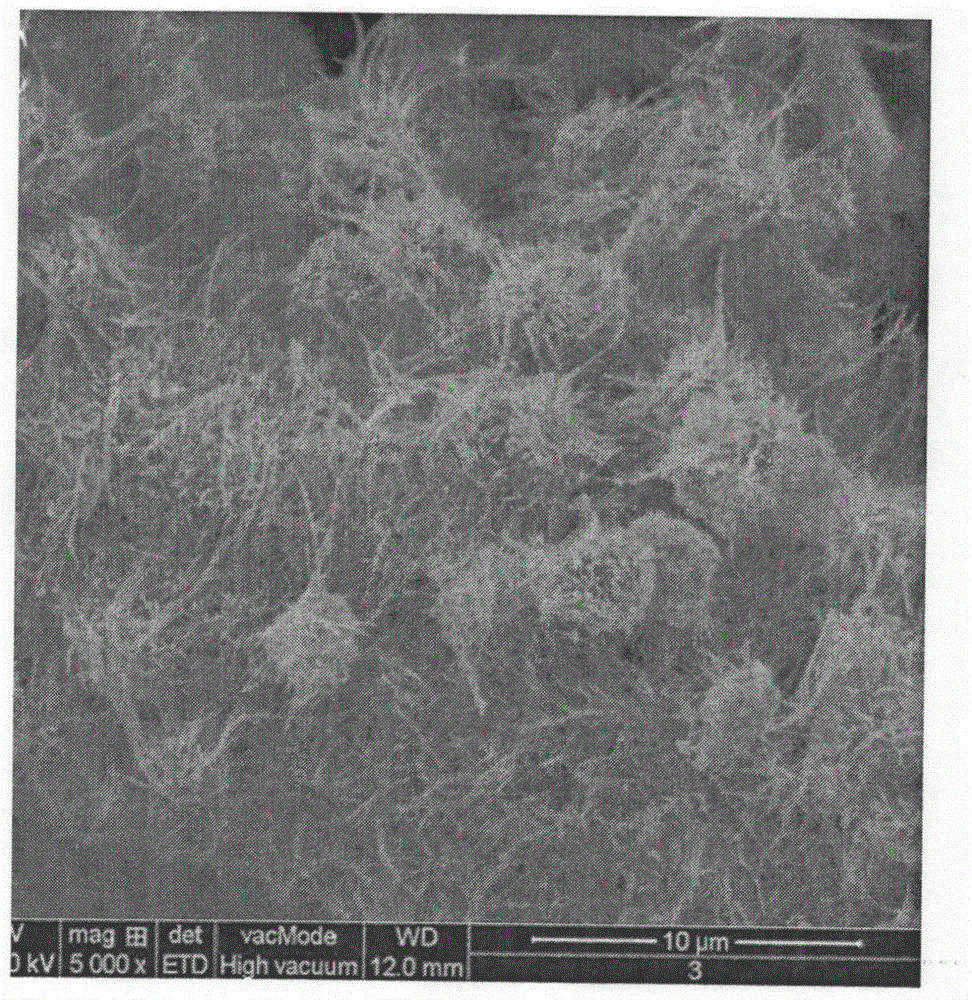

[0025] A metal oxide nanocoil / activated carbon fiber composite electrode material, comprising activated carbon fibers, cobalt and nickel oxides, the cobalt and nickel oxides are coated and grown on the activated carbon fibers in the form of nanowires or nanocoils surface.

[0026] The present invention also provides a preparation method of the above-mentioned metal oxide nanocoil / activated carbon fiber composite electrode material, the specific steps are:

[0027] Step 1: adding cobalt sulfate and nickel acetate into water to make a mixed aqueous solution containing 0.5% cobalt sulfate and 0.3% nickel acetate with a weight concentration, the common industrial activated carbon fiber needle felt (such as the product of Anhui Jialiqi Carbon Fiber Co., Ltd. ) washed with dilute hydrochloric acid and deionized water, dried and then immersed in the mixed aqueous solution of the above-mentioned cobalt sulfate and nickel acetate for 1 hour, then transferred to the hydrothermal reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com