Binder-free porous silicon/carbon composite electrode and application thereof

A binder-free, porous silicon technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of insignificant improvement in conductivity, shedding of active components, and deterioration of electrode performance, and achieve excellent electronic conductivity and environmental protection. The effect of small influence and excellent binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] First, use sandpaper with gradient particle size (400#, 600#, 1000#) to polish the copper foil or nickel foil substrate in turn until it is bright without obvious scratches, remove the surface oxide with 1mol / L dilute hydrochloric acid, and then use absolute ethanol and deionized water in order to degrease and wash, then dry with hot air; gradually add 50mL of absolute ethanol, 50mL of 0.05mol L to the beaker -1 Potassium nitrate, 1mL orthomethyl silicate (TMOS), with 2.0mol·L -1 HNO 3 Adjust the pH to about 6.0, and stir at room temperature for 6 h for later use. Polished copper foil or nickel foil cathode, 2*2cm 2 The platinum sheet is used as the anode, the Ag / AgCl is used as the reference electrode, the distance between the electrodes is controlled at 1cm, and the current density is controlled at -0.1mA·cm -2 Electrodeposition was performed, and the deposition time was 1000s. After the deposition was completed, the working electrode was rinsed with deionized wate...

Embodiment 2

[0044] First, use sandpaper with gradient particle size (400#, 600#, 1000#) to polish the copper foil or nickel foil substrate in turn until it is bright without obvious scratches, remove the surface oxide with 1mol / L dilute hydrochloric acid, and then use absolute ethanol and deionized water in order to degrease and wash, then dry with hot air; gradually add 50mL of absolute ethanol, 50mL of 1.0mol L to the beaker -1 Potassium nitrate, 5mL tetraethyl orthosilicate (TEOS), with 0.5mol·L -1 Adjust the pH to about 2.0 with HAc, stir at room temperature for 2 h and set aside. Use polished copper foil or nickel foil as the cathode, 2*2cm 2 Platinum sheet is the anode, Ag / AgCl is the reference electrode, the electrode spacing is controlled at 10cm, and the current density is controlled at -5mA cm -2 Electrodeposition was carried out, and the deposition time was 30s. After the deposition was completed, the working electrode was rinsed with deionized water and then dried at 40° C. ...

Embodiment 3

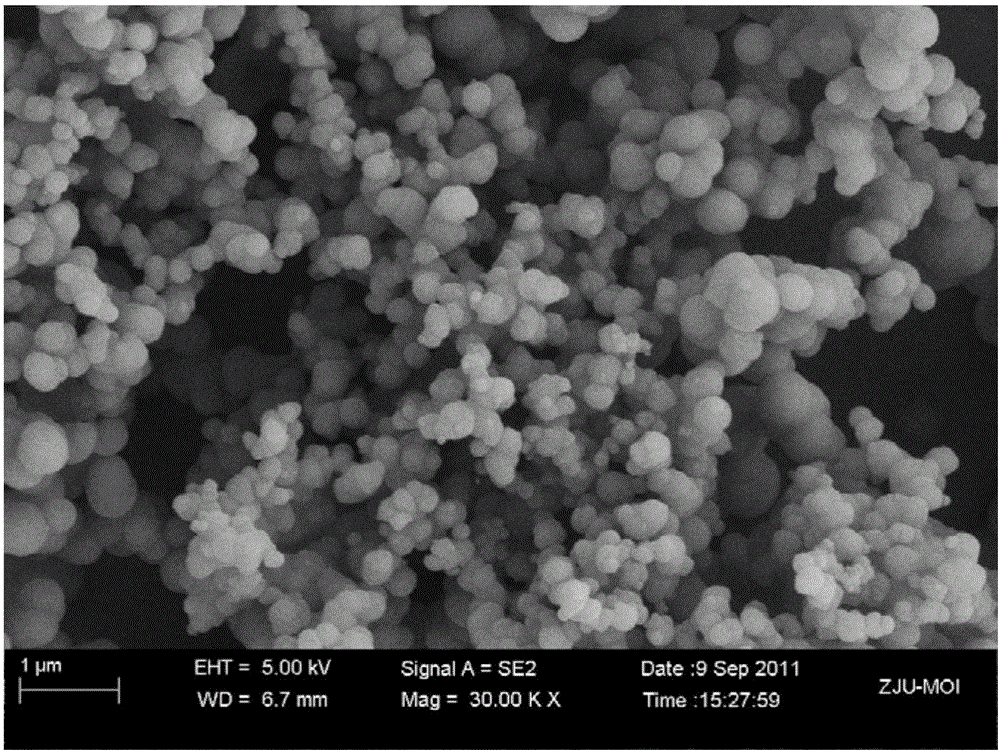

[0048] First, use sandpaper with gradient particle size (400#, 600#, 1000#) to polish the copper foil or nickel foil substrate in turn until it is bright without obvious scratches, remove the surface oxide with 1mol / L dilute hydrochloric acid, and then use absolute ethanol and deionized water in order to degrease and wash, then dry with hot air; gradually add 100mL absolute ethanol, 100mL0.2mol·L -1 Sodium nitrate, 10mL orthomethyl silicate (TMOS), with 1.0mol·L -1 Adjust the pH to about 6.0 with HCl, stir at room temperature for 6 h and set aside. Use polished copper foil or nickel foil as the cathode, 2*2cm 2 Platinum sheet is the anode, Ag / AgCl is the reference electrode, the electrode spacing is controlled at 1cm, and the current density is controlled at -1mA cm -2 Electrodeposition was performed, and the deposition time was 600s. After the deposition was completed, the working electrode was rinsed with deionized water and then dried at 40° C. to obtain a micronano oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com