Method for preparing graphene

A technology of graphene and graphite rods, which is applied in the field of material science and engineering, and can solve problems such as the thickness of graphene sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

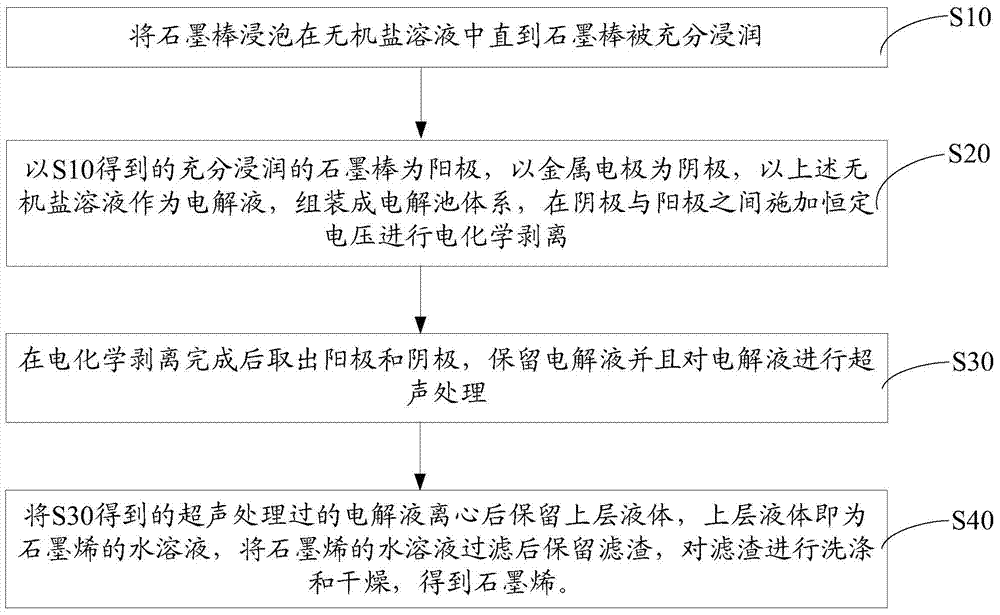

[0025] Such as figure 1 The preparation method of the graphene of one embodiment shown, comprises the steps:

[0026] S10. Soak the graphite rod in the inorganic salt solution until the graphite rod is fully soaked.

[0027] The material of the graphite rod may be spectroscopically pure graphite with a particle size of 0.01 mm to 5 mm. The graphite rods can be pretreated, that is, the surface of the graphite rods is polished and decontaminated with sandpaper.

[0028] The inorganic salt solution is selected from sodium stannate (Na 2 SnO 3 ) solution and potassium stannate (K 2 SnO 3 ) in one of the solutions. The anion stannate ion contained in sodium stannate and potassium stannate (SnO 3 2- ) is equivalent to the distance (0.34nm) between the graphite flakes, which can intercalate between the graphite flakes to reduce the Van der Waals force between the graphite flakes, which is beneficial to stripping and obtaining thin-layer graphene.

[0029] The concentration o...

Embodiment 1

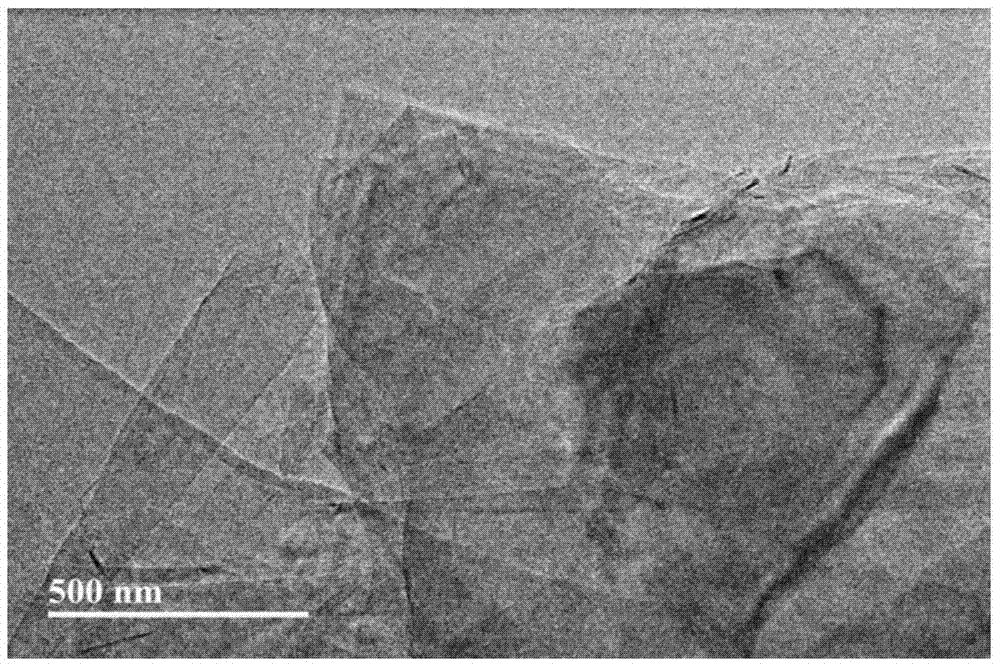

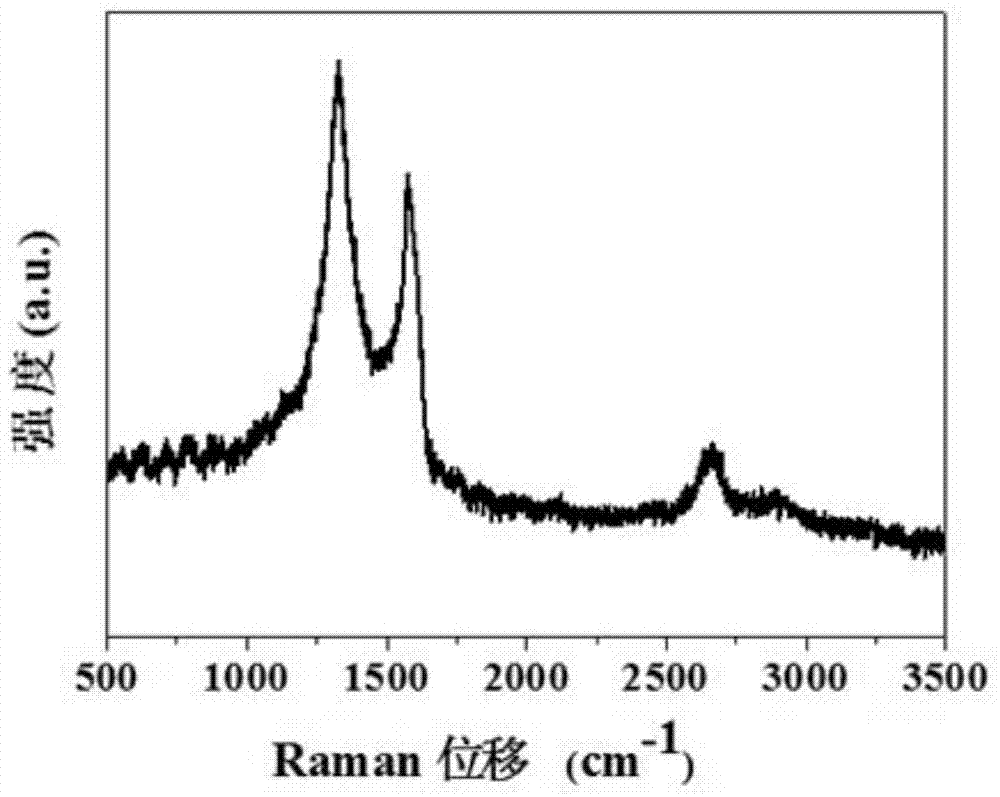

[0045] Take the graphite rod, polish and decontaminate its surface with sandpaper and keep it for later use. Prepare 100 mL of Na with a concentration of 0.1 mol / L 2 SnO 3 solution, soak the graphite rod in Na 2 SnO 3 After the graphite rod is fully infiltrated by the solution for 1 h, the fully infiltrated graphite rod is used as the anode, the platinum sheet electrode is used as the cathode, and the Na 2 SnO 3 The solution is an electrolyte, which is assembled into an electrolytic cell system. A working voltage of 10V was applied between the cathode and the anode, and the electrochemical stripping was continued for 120min, and then the power was turned off to stop the stripping. After taking out the cathode and anode, the electrolyte was ultrasonically treated for 1 hour, and then centrifuged at 3000rmp / min for 20 minutes, and the remaining upper liquid was the graphene aqueous solution. The graphene aqueous solution is sequentially subjected to suction filtration, was...

Embodiment 2

[0050] Take the graphite rod, polish and decontaminate its surface with sandpaper and keep it for later use. Prepare 100 mL of Na with a concentration of 0.2 mol / L 2 SnO 3 solution, soak the graphite rod in Na 2 SnO 3 After the graphite rod is fully infiltrated by the solution for 2 hours, the fully infiltrated graphite rod is used as the anode, the platinum sheet electrode is used as the cathode, and the Na 2 SnO 3 The solution is an electrolyte, which is assembled into an electrolytic cell system. A working voltage of 10V was applied between the cathode and the anode, and the electrochemical stripping was continued for 30min, and then the power was turned off to stop the stripping. After taking out the cathode and anode, the electrolyte was ultrasonically treated for 1 hour, and then centrifuged at 3000rmp / min for 20 minutes, and the remaining upper liquid was the graphene aqueous solution. The graphene aqueous solution is sequentially subjected to suction filtration, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com