Graphene and preparation method thereof

A graphene and graphite rod technology, applied in the field of electrochemistry, can solve problems such as higher requirements for production equipment, limitation of graphene performance, human body and environmental hazards, etc., to achieve easy large-scale industrial production, realize large-scale industrial production, improve energy storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

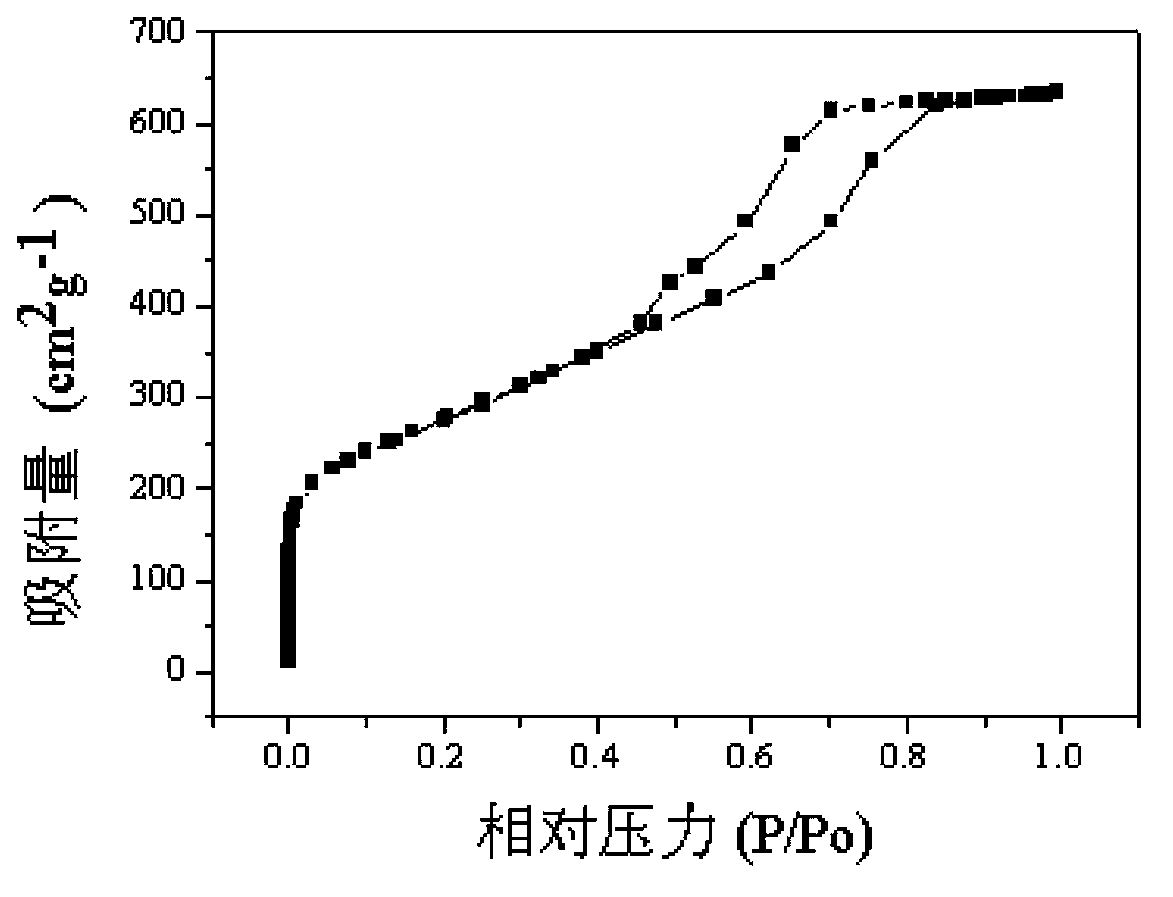

Image

Examples

preparation example Construction

[0016] The preparation process of graphene of the present invention is roughly divided into the following steps:

[0017] 1. Take graphite with a purity of 99.5% to make a graphite rod, use the graphite rod as the positive electrode and the platinum rod as the negative electrode, and connect them to the two poles of the external power supply respectively, so as to apply an external voltage to the positive and negative electrodes in the subsequent steps;

[0018] 2. Then insert the positive graphite rod and the negative platinum rod into the electrolyte solution, apply a small voltage of 0.8V~1.5V between the positive and negative electrodes, keep it for 1~5 minutes and stop, and then apply 10V~15V between the positive and negative electrodes. High voltage and keep it for 4~15 minutes to stop, then filter the electrolyte solution and dry it;

[0019] The purpose of this step is to use the principle of chemical intercalation, first apply a small voltage to lightly intercalate gr...

Embodiment 1

[0026] The preparation steps of graphene in the present embodiment are as follows:

[0027] 1. Graphite rods with a purity of 99.5% are made of graphite rods, and the graphite rods are used as positive electrodes and platinum rods as negative electrodes, which are respectively connected to the two poles of the external power supply;

[0028] 2. Insert the positive and negative electrodes into the electrolyte. The electrolyte is mixed with 1 g of deionized water and 1 g of 1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt. A voltage of 1.2V was applied between the positive and negative electrodes for 5 minutes, and then a voltage of 10V was applied between the positive and negative electrodes for 5 minutes. After 5 minutes, the electrolyte solution was filtered, and the solid product was placed in a vacuum oven at 60°C for 48 hours. Vacuum dry for 12 hours.

[0029] 3. Put the dried solid product in an argon atmosphere with a flow rate of 400ml / min, and use 4×10 1...

Embodiment 2

[0032] The preparation steps of graphene in the present embodiment are as follows:

[0033] 1. Graphite rods with a purity of 99.5% are made of graphite rods, with graphite rods as positive electrodes and platinum rods as negative electrodes, respectively connected to the two poles of the external power supply, so as to apply external voltages to the positive and negative electrodes in subsequent steps;

[0034] 2. Insert the positive and negative electrodes into the electrolyte mixed with 2g of deionized water and 1g of 1-ethyl-3-methylimidazole bis-trifluoromethanesulfonimide salt, and apply a voltage of 1V between the positive and negative electrodes for a continuous period of time. 4 minutes, then apply 12V voltage between positive and negative electrodes, after lasting 4 minutes, the electrolyte solution is filtered, and the solid product is placed in the vacuum oven of 100 ° C for 24 hours;

[0035] 3. Put the dried solid product under the protection of argon with flow r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com