Expandable polystyrene beads prepared from expandable few-layer graphene and preparing method of expandable polystyrene beads

A technology of expandable polystyrene and few-layer graphene, applied in the field of polystyrene foam materials, can solve the problems of high preparation cost, complicated process, unsatisfactory flame retardant and heat insulation performance, and achieve good heat insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

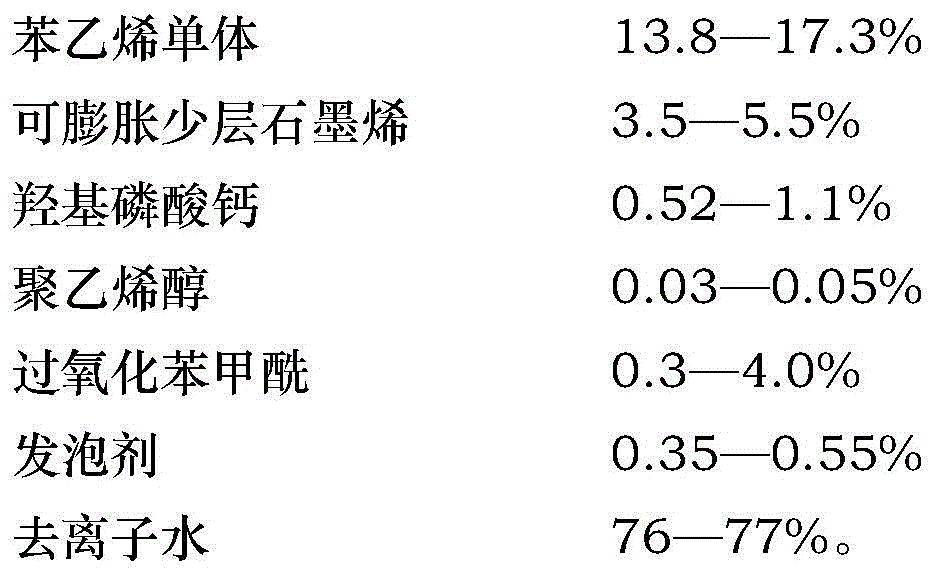

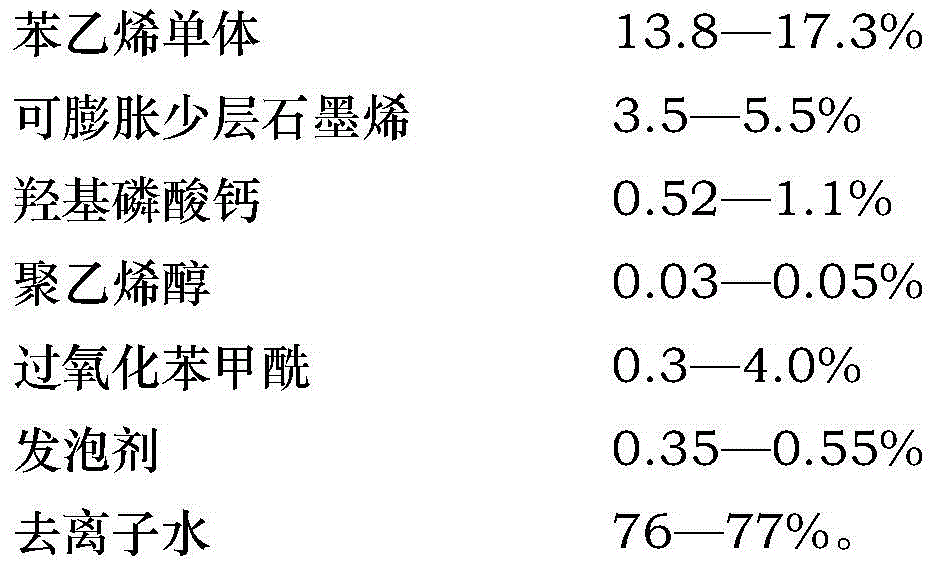

[0023] The preparation method of the expandable polystyrene beads of expandable few-layer graphene comprises the following steps:

[0024] A, the preparation of graphite intercalation compound: take the natural flake graphite of 1000-5000 order as the anode with the average particle diameter, the metal titanium flake is as the cathode, and the concentrated sulfuric acid with the concentration of 98% is the intercalation agent, under 1.8V voltage. Chemical intercalation, the intercalation time is 0.5-2.0 hours, and the graphite interlayer compound is prepared;

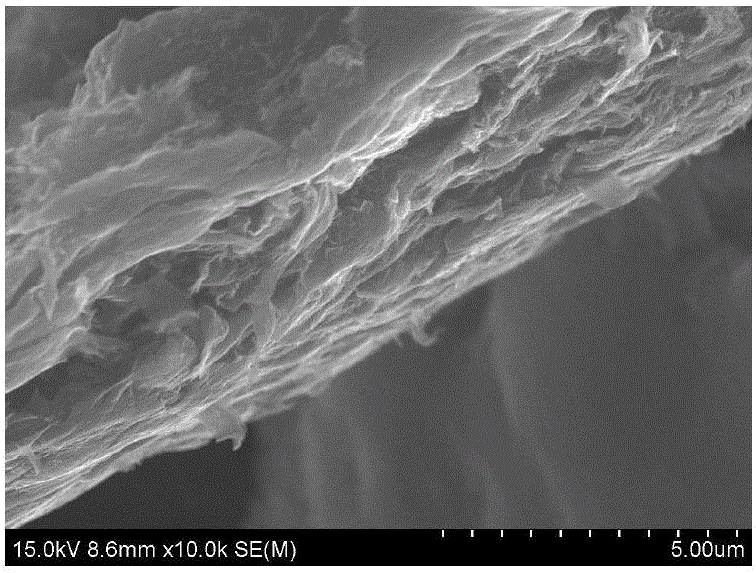

[0025] B, the preparation of few-layer graphene: above-mentioned graphite interlayer compound is in the concentrated sulfuric acid solution that concentration is 98%, implements ultrasonic vibration stripping 05-1.5 hour under 1000W power, makes few-layer graphene;

[0026] C, the preparation of expandable few-layer graphene: take the concentrated sulfuric acid of concentration 98% as intercalation agent, the hydrogen p...

Embodiment 1

[0029] A, the preparation of graphite interlayer compound: the average particle size is 1000 mesh natural flake graphite as the anode, the metal titanium sheet as the cathode, and the concentrated sulfuric acid with a concentration of 98% as the intercalation agent, and the electrochemical intercalation is carried out at a voltage of 1.8V layer, the intercalation time is 2.0 hours, and the graphite intercalation compound is obtained.

[0030] B. Preparation of few-layer graphene: the above-mentioned graphite interlayer compound was peeled off by ultrasonic vibration for 1.5 hours at a power of 1000W in a concentrated sulfuric acid solution with a concentration of 98%, to prepare few-layer graphene.

[0031] C, the preparation of expandable few-layer graphene: use the concentrated sulfuric acid of concentration 98% as intercalation agent, the hydrogen peroxide of concentration 30% is as oxidizing agent, carry out chemical method secondary intercalation to above-mentioned obtaine...

Embodiment 2

[0034] A. Preparation of graphite intercalation compound: take natural flake graphite with an average particle size of 3000 meshes as the anode, metal titanium sheet as the cathode, and use concentrated sulfuric acid with a concentration of 98% as the intercalation agent, and perform electrochemical intercalation at a voltage of 1.8V layer, the intercalation time is 1.0 hour, and the graphite intercalation compound is prepared.

[0035] B. Preparation of few-layer graphene: the above-mentioned graphite interlayer compound was peeled off by ultrasonic vibration for 1.0 hour at a power of 1000W in a concentrated sulfuric acid solution with a concentration of 98%, to prepare few-layer graphene.

[0036] C, the preparation of expandable few-layer graphene: use the concentrated sulfuric acid of concentration 98% as intercalation agent, the hydrogen peroxide of concentration 30% is as oxidizing agent, carry out chemical method secondary intercalation to above-mentioned obtained few-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com