Lithium intercalation manganese dioxide-titanium nitride nanotube composite material and preparing method and application thereof

A technology of manganese dioxide and composite materials, which is applied in the manufacture of hybrid/electric double-layer capacitors, double-layer capacitors, hybrid capacitors, etc., can solve the problems of electrode material conductivity and storage performance to be further improved, and achieve high conductivity , high power storage performance, high current charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Lithium intercalation manganese dioxide-titanium nitride nanotube composite material, its preparation method comprises the following steps:

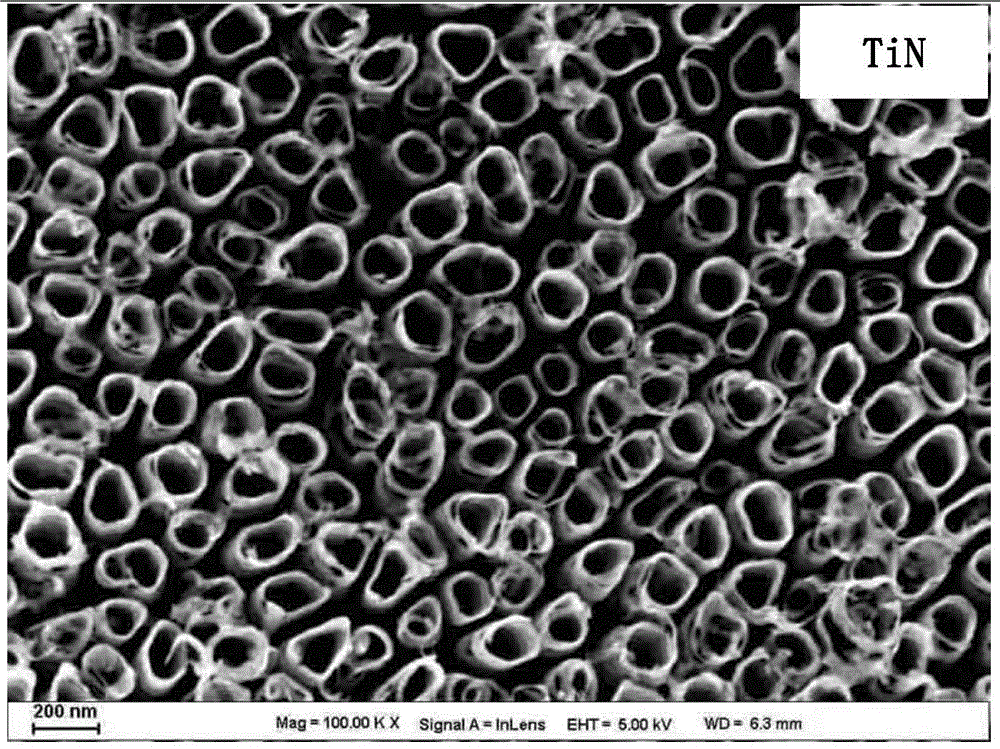

[0034] (1) Preparation of titanium nitride nanotube electrode matrix material: 0.2mol / L ammonium fluoride, 0.5mol / L phosphoric acid and 9.0mol / L ethylene glycol solution are used as the reaction electrolyte solution, and the anodic oxidation synthesis method is adopted, and the working voltage is 30V, and the reaction time was 3h to obtain titanium dioxide nanotubes. Then, they were calcined at 450° C. for 2 hours in an air atmosphere and 800° C. for 2 hours in an ammonia atmosphere to obtain titanium nitride nanotube electrode matrix materials.

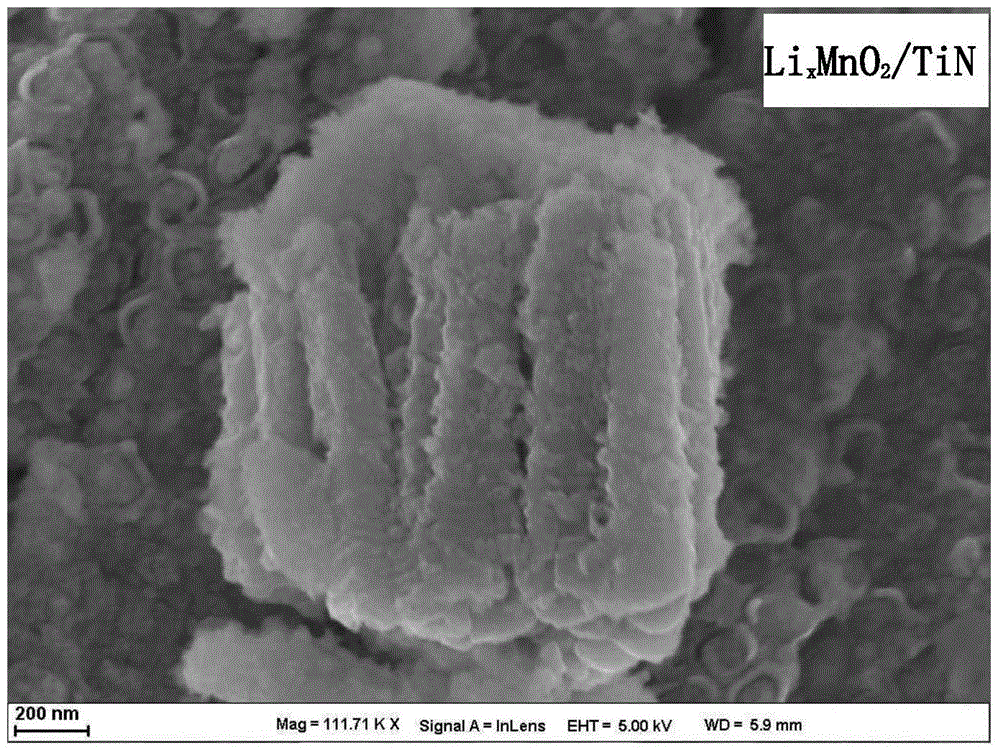

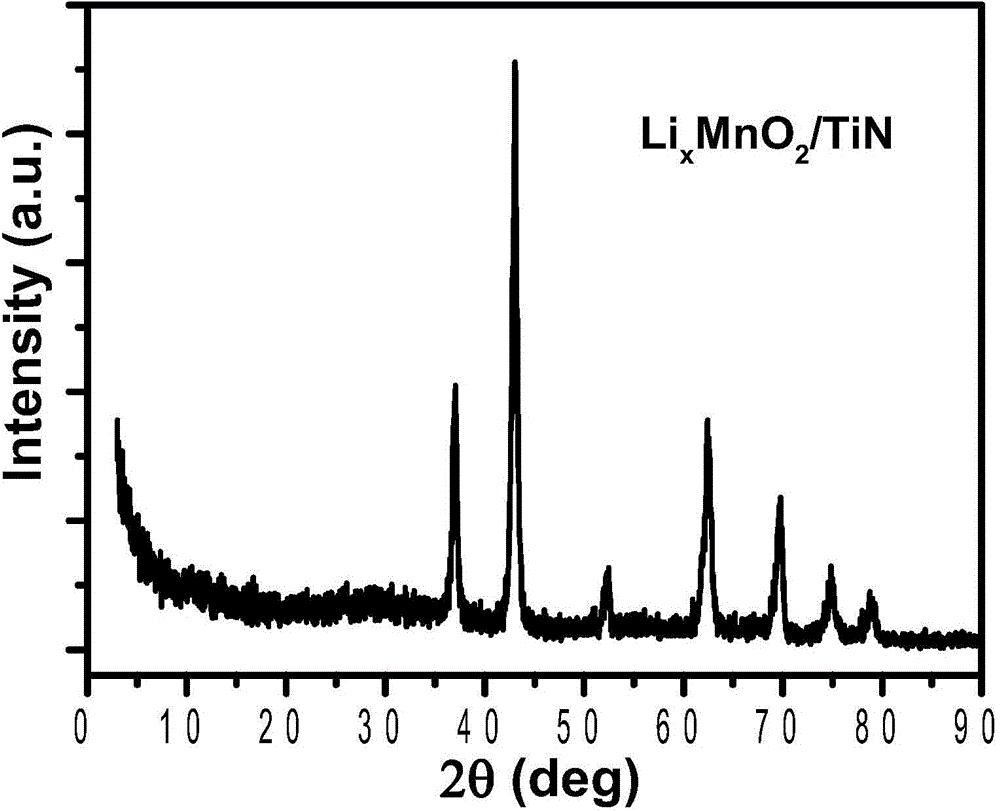

[0035] (2) Lithium intercalated manganese dioxide-titanium nitride nanotube electrode material preparation: using titanium nitride nanotube as working electrode, platinum sheet as auxiliary electrode, saturated calomel Hg / Hg 2 Cl 2 As a reference electrode, lithium intercalated mangane...

Embodiment 2

[0040] Lithium intercalation manganese dioxide-titanium nitride nanotube composite material, its preparation method comprises the following steps:

[0041] (1) Preparation of titanium nitride nanotube electrode matrix material: 0.1mol / L ammonium fluoride, 0.4mol / L phosphoric acid and 8.0mol / L ethylene glycol solution are used as the reaction electrolyte solution, and the anodic oxidation synthesis method is adopted, and the working voltage is 25V, and the reaction time was 4h to obtain titanium dioxide nanotubes. Then, they were calcined at 400° C. for 3 hours in an air atmosphere and 750° C. for 3 hours in an ammonia atmosphere to obtain a titanium nitride nanotube electrode base material.

[0042] (2) Lithium intercalated manganese dioxide-titanium nitride nanotube electrode material preparation: using titanium nitride nanotube as working electrode, platinum sheet as auxiliary electrode, saturated calomel Hg / Hg 2 Cl 2 As a reference electrode, lithium intercalated manganes...

Embodiment 3

[0047] Lithium intercalation manganese dioxide-titanium nitride nanotube composite material, its preparation method comprises the following steps:

[0048] (1) Preparation of titanium nitride nanotube electrode matrix material: 0.3mol / L ammonium fluoride, 0.5mol / L phosphoric acid and 10.0mol / L ethylene glycol solution are used as the reaction electrolyte solution, and the anodic oxidation synthesis method is adopted, and the working voltage is 35V, and the reaction time was 2h to obtain titanium dioxide nanotubes. Then, they were calcined at 500° C. for 1 h in an air atmosphere and calcined at 850° C. for 1 h in an ammonia atmosphere to obtain a titanium nitride nanotube electrode base material.

[0049] (2) Lithium intercalated manganese dioxide-titanium nitride nanotube electrode material preparation: using titanium nitride nanotube as working electrode, platinum sheet as auxiliary electrode, saturated calomel Hg / Hg 2 Cl 2 As a reference electrode, lithium intercalated man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com