A kind of cellulose type II nanocrystalline particle and its preparation method and application

A cellulose and nanocrystal technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of inability to accurately control product crystallinity, crystallographic defects, difficult to control the surface properties of cellulose nanocrystals, and cellulose nanocrystals. The crystal stays at the research level and other issues to achieve the effect of avoiding excessive degradation, high crystallinity, and high integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] 1. Preparation method of cellulose type II nanocrystalline particles

[0061] Raw materials containing cellulose

[0062] In the present invention, "cellulose-containing raw material" or "cellulose raw material" can be a cellulose-containing material in any physical state, preferably purified cellulose or cellulose slurry isolated from plants, animals, algae, bacteria, Preference is given to refined cellulose or cellulose pulp of vegetable origin. In the present invention, "plant", "animal", "algae" and "bacteria" all have common meanings in this field, such as plants can include bryophytes, ferns, seed plants, etc., such as trees, bamboo, cotton , grass, hemp, etc.

[0063] In the present invention, "refined cellulose" refers to a cellulose-containing material with an increased cellulose content obtained through pretreatment of the cellulose raw material. The pretreatment or refining of the cellulose raw material can use techniques known in the art, for example, the ...

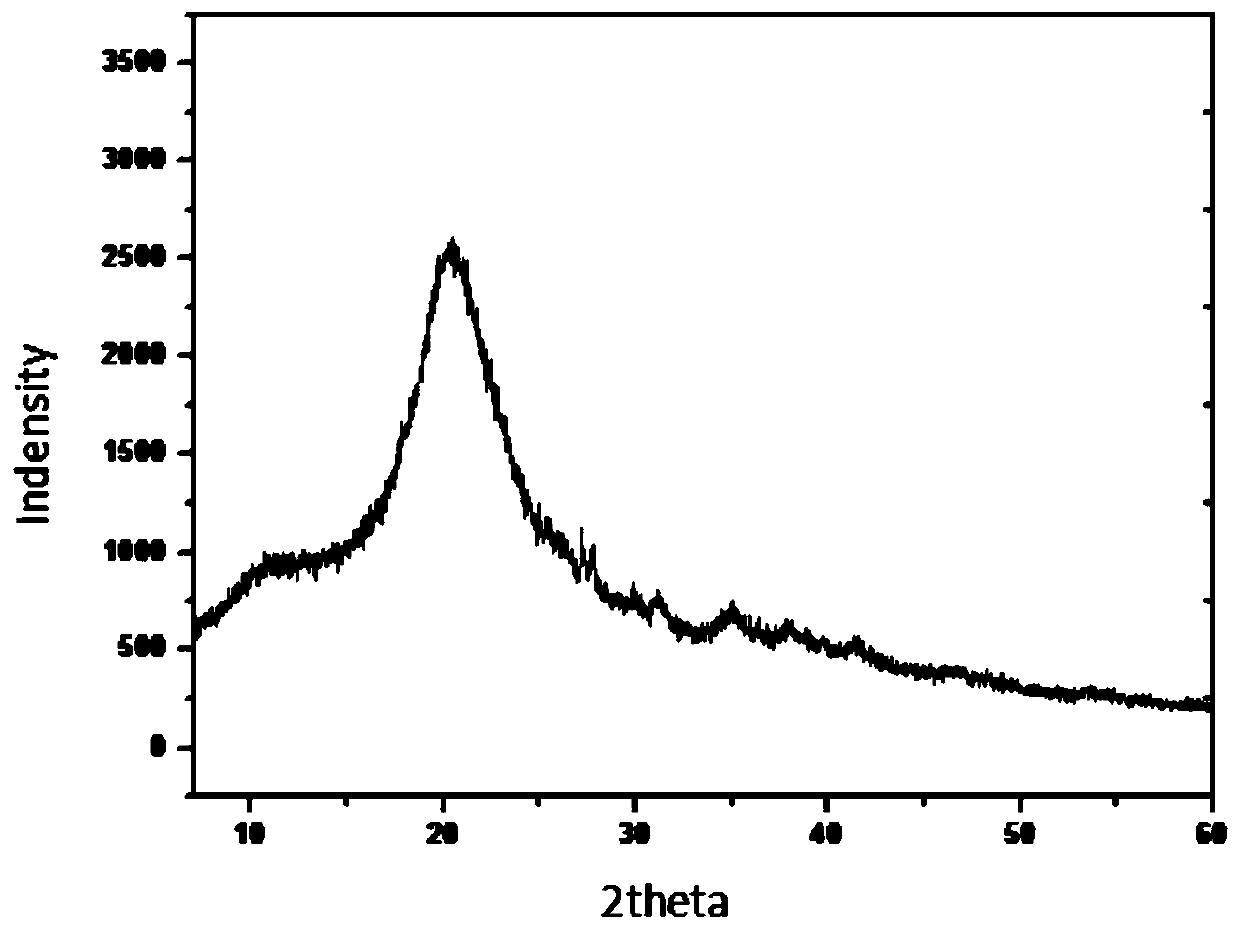

Embodiment 1

[0087] Step 1, amorphization and reconstitution of cellulose raw materials: use the straw refined cellulose obtained after successively refluxing the straw through an aqueous solution of 5wt% NaOH, an aqueous solution of 1wt% HCl, and an aqueous solution of 1wt% sodium hypochlorite as the cellulose-containing cellulose of the present invention. Raw material of cellulose. A solvent system composed of 8.3wt% NaOH, 10wt% urea and the rest of water was added and stirred to obtain 50g of 5wt% straw cellulose solution. During stirring, ethanol is added until the cellulose is completely precipitated, and the precipitated amorphous reconstituted cellulose is washed with ethanol and dried.

[0088] Step 2, crystallization and acid hydrolysis of amorphized and restructured cellulose: add the amorphized and restructured cellulose obtained in step 1 to the water / ethanol / ethylene glycol mixed solution, add hydrochloric acid to the solution, and hydrochloric acid The concentration is 0.1 m...

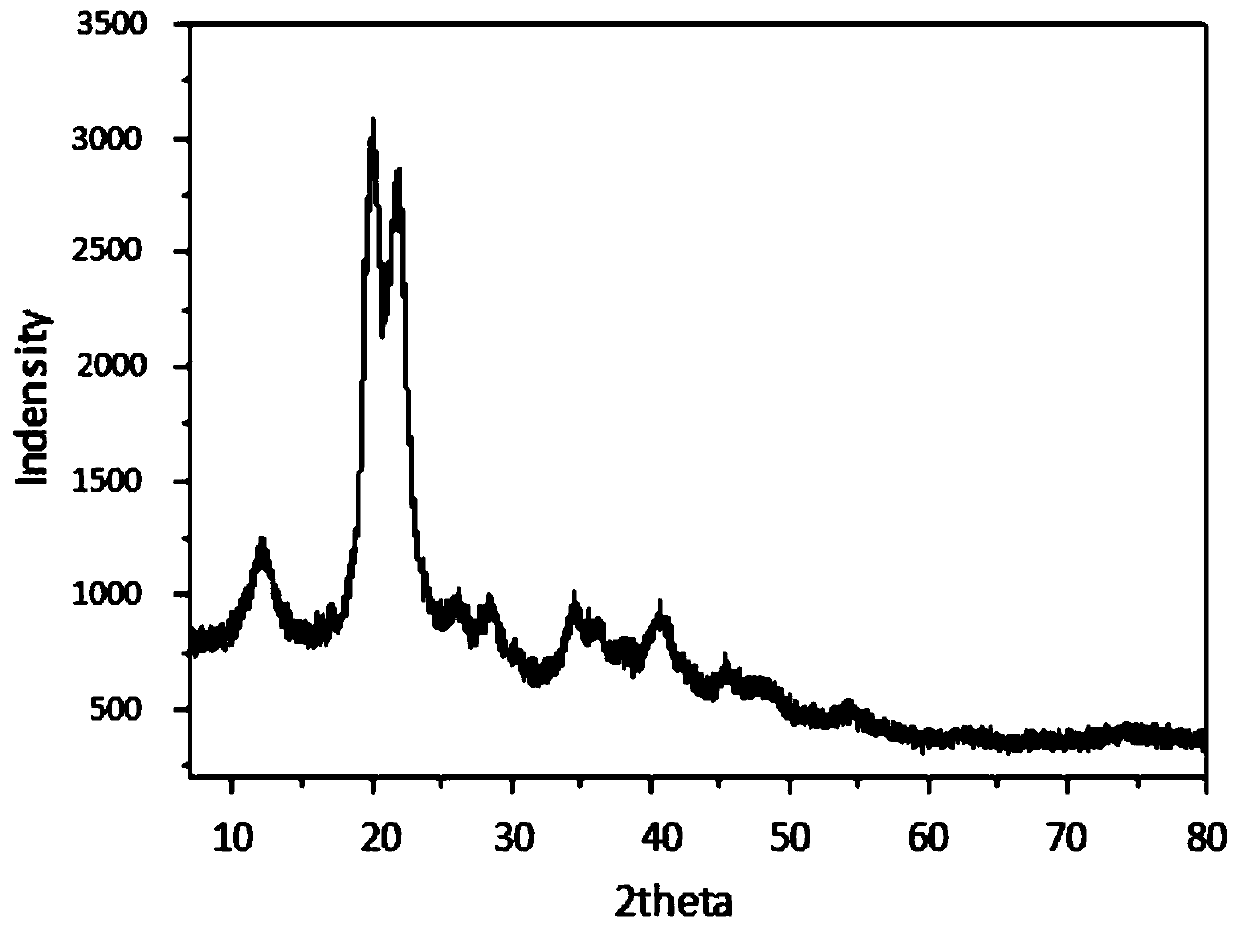

Embodiment 2

[0096] Step 1, amorphization and reconstitution of cellulose raw materials: use the straw refined cellulose obtained after successively refluxing the straw through an aqueous solution of 5wt% NaOH, an aqueous solution of 1wt% HCl, and an aqueous solution of 1wt% sodium hypochlorite as the cellulose-containing cellulose of the present invention. Raw material of cellulose. A solvent system composed of 8.3wt% NaOH, 10wt% urea and the rest of water was added and stirred to obtain 50g of 5wt% straw cellulose solution. While stirring, methanol was added until the cellulose was completely precipitated, and the precipitated amorphous reconstituted cellulose was washed with methanol and dried.

[0097] Step 2, crystallization acid hydrolysis of the restructured amorphous cellulose: add the restructured amorphous cellulose obtained in step 1 to the water / tetrahydrofuran mixed solution, add sulfuric acid to the solution, the concentration of sulfuric acid is 1mol / L, heated to reflux fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com