Calcium phosphate biofilm layer and its pulse electrochemical modification method

A biofilm layer, electrochemical technology, applied in electrolytic inorganic material coating and other directions, can solve the problems of low binding force between calcium and phosphorus salt film layer and metal substrate, difficult to achieve industrial application, etc., to improve comprehensive biological performance, morphology and size Controllable and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

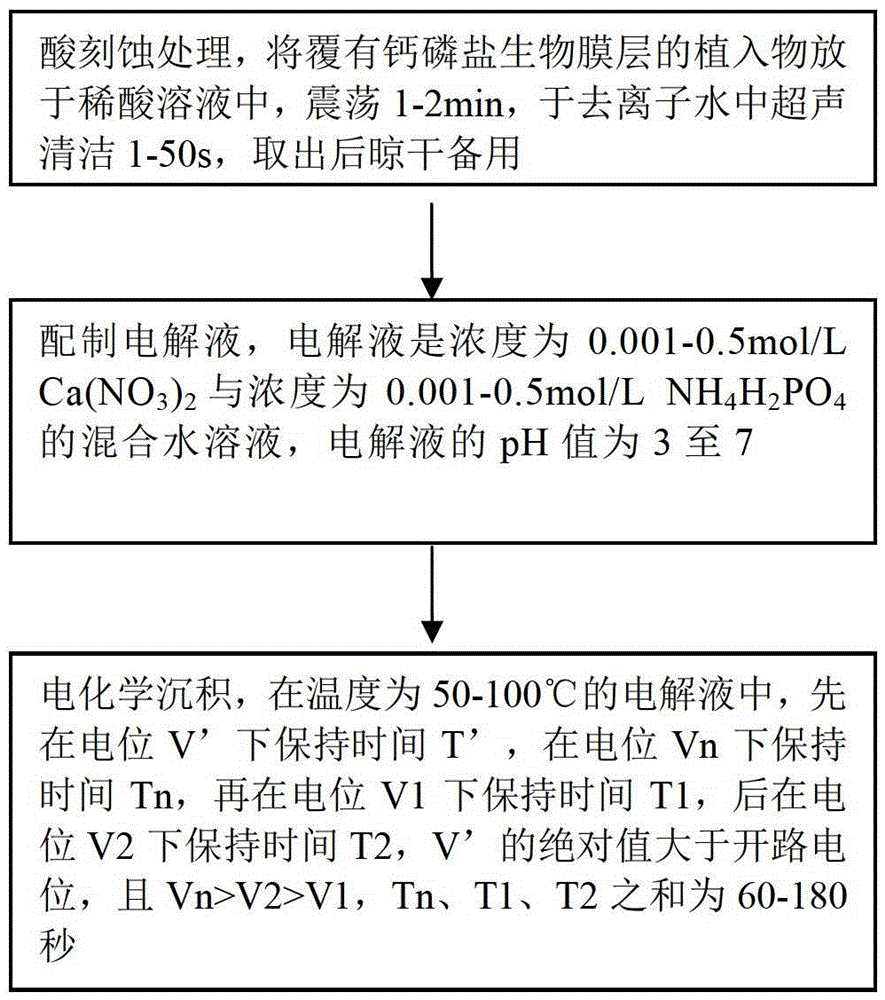

Method used

Image

Examples

Embodiment Construction

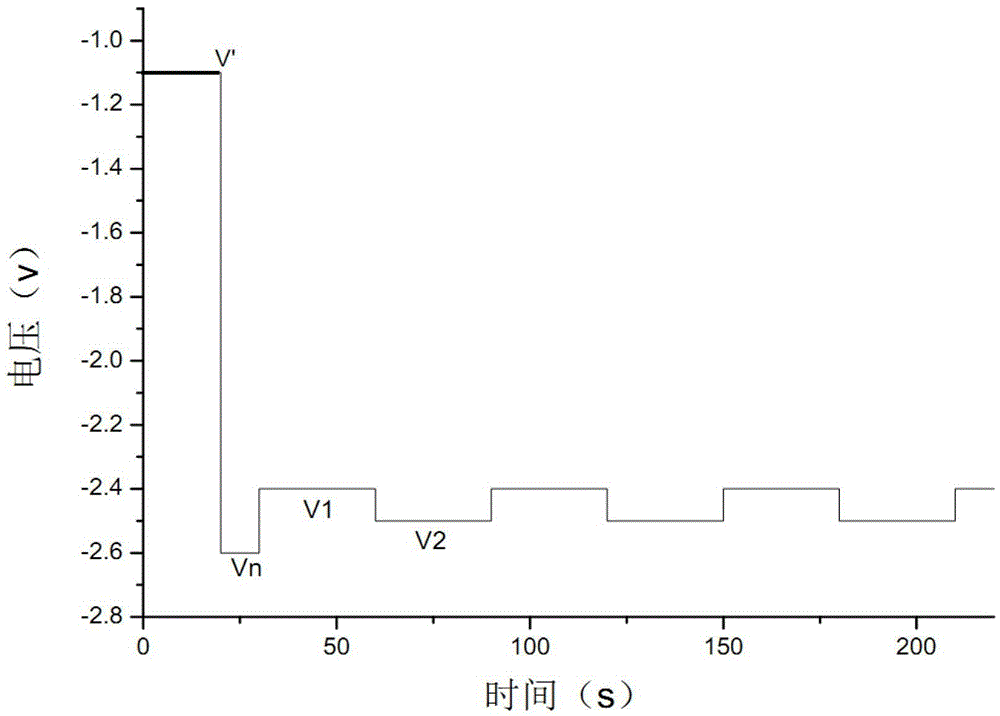

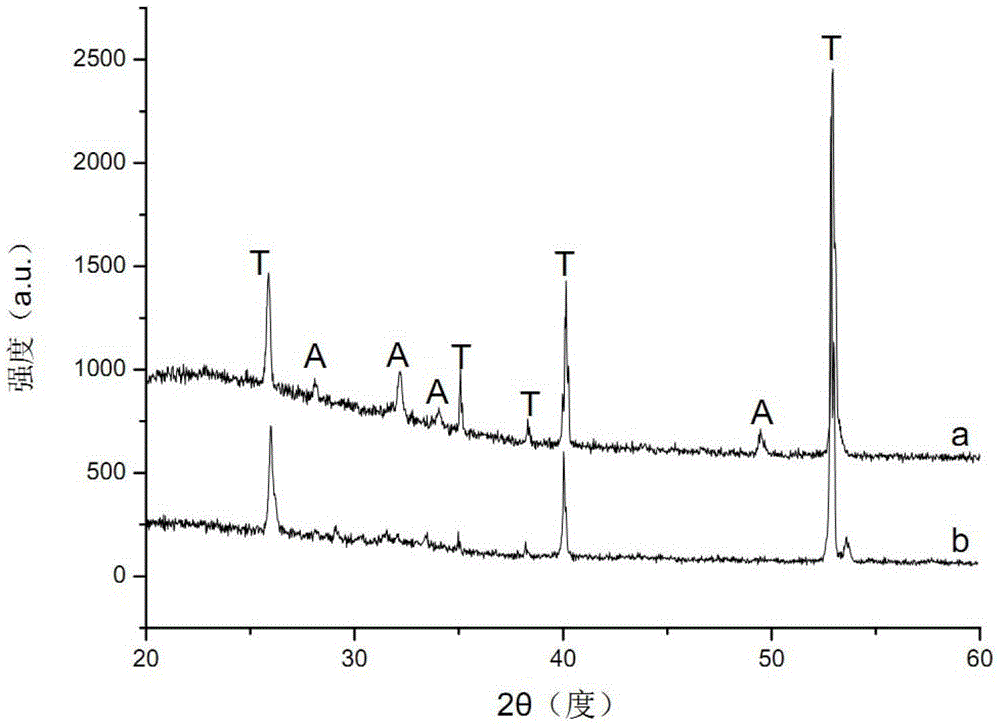

[0028] (1) Example of changing Vn:

[0029] In the electrochemical modification method of this embodiment, the effect of Vn on the microstructure of OCP is mainly observed by changing the value of Vn, which specifically includes the following steps: pretreating the implant and putting the implant into a dilute acid solution Vibrate in the medium for 90 seconds, ultrasonically clean in deionized water for 30 seconds, take it out and dry for later use; prepare the electrolyte, the electrolyte concentration is 0.042mol / LCa(NO 3 ) 2 With a concentration of 0.028mol / LNH 4 H 2 PO 4 The pH value of the electrolyte is 4.2; electrochemical deposition is carried out in the electrolyte at a heating temperature of 80℃, the pretreated implant is used as the cathode, and the platinum electrode is used as the anode. Deposition. Among them, V'is -1.1V, T'is 20 seconds; Vn is -2.7V, -2.5V, -2.0V, -1.5V respectively, keep Tn for 15 seconds; potential V1 is -2.4V, keep T1 as 30 seconds; potential ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com