Method for preparing high-dispersity spherical nano lead powder through lead-bearing soldering tin in electronic waste

A nano-lead powder and high-dispersibility technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of complex process and low output of chemicals, and achieve short process and high form. The effect of controllable size and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

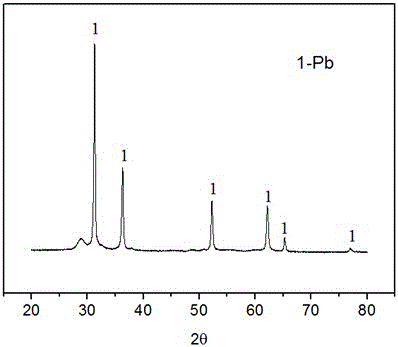

[0035] The method for preparing high-dispersibility spherical nano-lead powder by recycling lead-containing solder in electronic waste mainly includes the following steps:

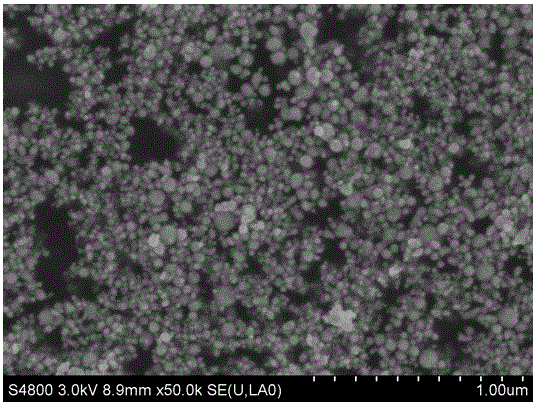

[0036] The solder in the waste circuit board is separated from the bare board and electronic components by a certain method to obtain the waste solder, and the other parts are collected to avoid polluting the environment. Weigh 20 g of the obtained waste solder and place it in an alumina crucible, and then put the crucible into the heating chamber of a tube-type vacuum furnace. After sealing the system, the vacuum unit pumps the system pressure to 1Pa to remove the air in the vacuum furnace and avoid the oxidation of metal during heating and evaporation. Then nitrogen gas was introduced to keep the system pressure at 5000 Pa, and at the same time, the heating device was turned on, and the evaporation chamber was heated to 950 °C at a heating rate of 10 °C / min and kept for 60 min. The evaporated lead vapor...

Embodiment 2

[0038] The method for preparing high-dispersibility spherical nano-lead powder by recycling lead-containing solder in electronic waste mainly includes the following steps:

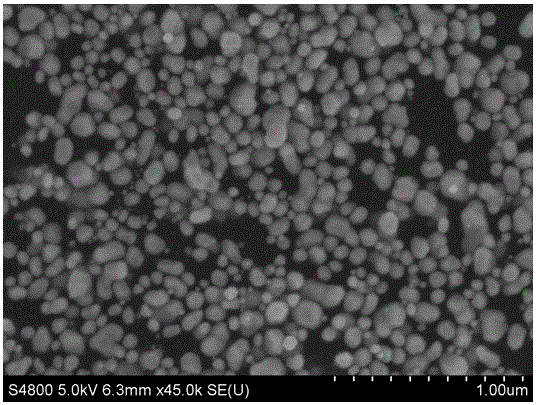

[0039] The solder in the waste circuit board is separated from the bare board and electronic components by a certain method to obtain the waste solder, and the other parts are collected to avoid polluting the environment. Weigh 20 g of the obtained waste solder and place it in a corundum crucible, and then put the crucible into the heating chamber of a tube-type vacuum furnace. Put a quartz tube in the condensation chamber as the condensation substrate. After sealing the system, the vacuum unit pumps the system pressure to 1Pa to remove the air in the vacuum furnace and avoid the oxidation of metal during heating and evaporation. Then nitrogen was introduced to keep the system pressure at 1000 Pa, and at the same time, the heating device was turned on, and the evaporation chamber was heated to 900 °C at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com