Preparation method of carbon nitride/nanometer zinc oxide ultraviolet shielding agent close to skin color

A nano-zinc oxide, ultraviolet shielding agent technology, applied in skin care preparations, chemical instruments and methods, zinc oxide/zinc hydroxide and other directions, can solve the problems of paleness and unnaturalness, easy precipitation of pigments, affecting performance, etc. To achieve the effect of simple preparation process, simple post-processing and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

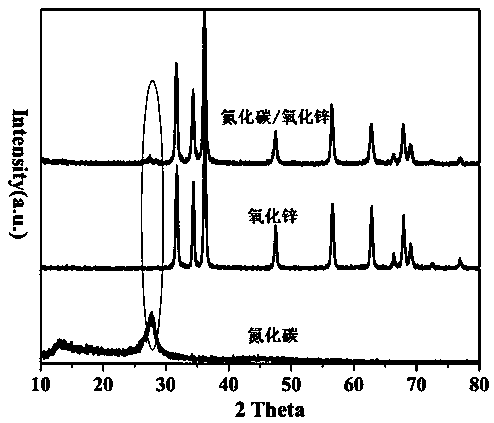

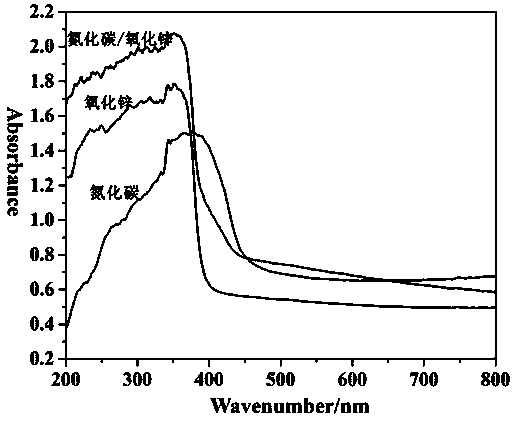

[0022] The preparation method of the near skin color carbon nitride / nano-zinc oxide ultraviolet shielding agent of the present embodiment, the steps are as follows:

[0023] (1) Dissolve melamine and thiourea in deionized water at a ratio of 1:0.1 (molar ratio), stir evenly, transfer the above solution to a reaction kettle at 180°C for 12 hours, cool to room temperature and filter, and filter the obtained The cake was calcined at 520°C for 3 hours to obtain carbon nitride;

[0024] (2) Fully grind the carbon nitride and zinc chloride obtained above (the mass ratio of carbon nitride to zinc chloride is 5%) in an agate mortar, put the ground powder in a crucible, and heat at 350°C Calcining at low temperature for 2 hours, you can get nano carbon nitride / zinc oxide UV shielding agent with close skin color.

Embodiment 2

[0026] The preparation method of the near skin color carbon nitride / nano-zinc oxide ultraviolet shielding agent of the present embodiment, the steps are as follows:

[0027] (1) Dissolve melamine and thiourea in deionized water at a ratio of 1:3 (molar ratio), stir evenly, transfer the above solution to a reaction kettle at 180°C for 12 hours, cool to room temperature and filter, and filter the obtained The cake was calcined at 520°C for 3 hours to obtain carbon nitride;

[0028] (2) Fully grind the carbon nitride and zinc chloride obtained above (the mass ratio of carbon nitride to zinc chloride is 25%) in an agate mortar, put the ground powder in a crucible, and heat at 400°C Calcining at low temperature for 2 hours, the carbon nitride / nanometer zinc oxide ultraviolet shielding agent with close skin color can be obtained.

Embodiment 3

[0030] The preparation method of the near skin color carbon nitride / nano-zinc oxide ultraviolet shielding agent of the present embodiment, the steps are as follows:

[0031] (1) Dissolve melamine and thiourea in deionized water at a ratio of 1:6 (molar ratio), stir evenly, transfer the above solution to a reaction kettle at 180°C for 12 hours, cool to room temperature and filter, and filter the obtained The cake was calcined at 520°C for 3 hours to obtain carbon nitride;

[0032] (2) Fully grind the carbon nitride and zinc chloride obtained above (the mass ratio of carbon nitride to zinc chloride is 50%) in an agate mortar, put the ground powder in a crucible, and heat at 500°C Calcining at low temperature for 2 hours, the carbon nitride / nanometer zinc oxide ultraviolet shielding agent with close skin color can be obtained.

[0033] As a comparison (relative to Example 1), without adding carbon nitride, fully grind zinc chloride in an agate mortar, place the ground powder in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com