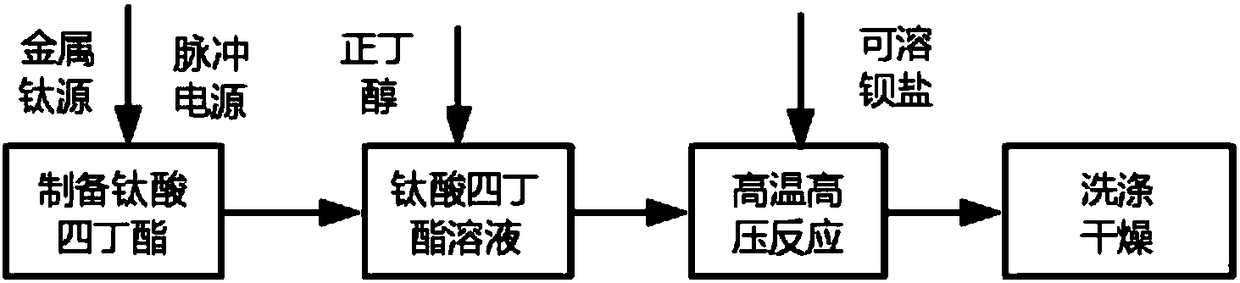

Preparation method of barium titanate nanometer powder

A nano-powder, barium titanate technology, applied in titanate, alkaline earth metal titanate, chemical instruments and methods, etc., can solve the problems of unfavorable clean production, strong corrosion, etc., and achieve controllable shape and size , the mild effect of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

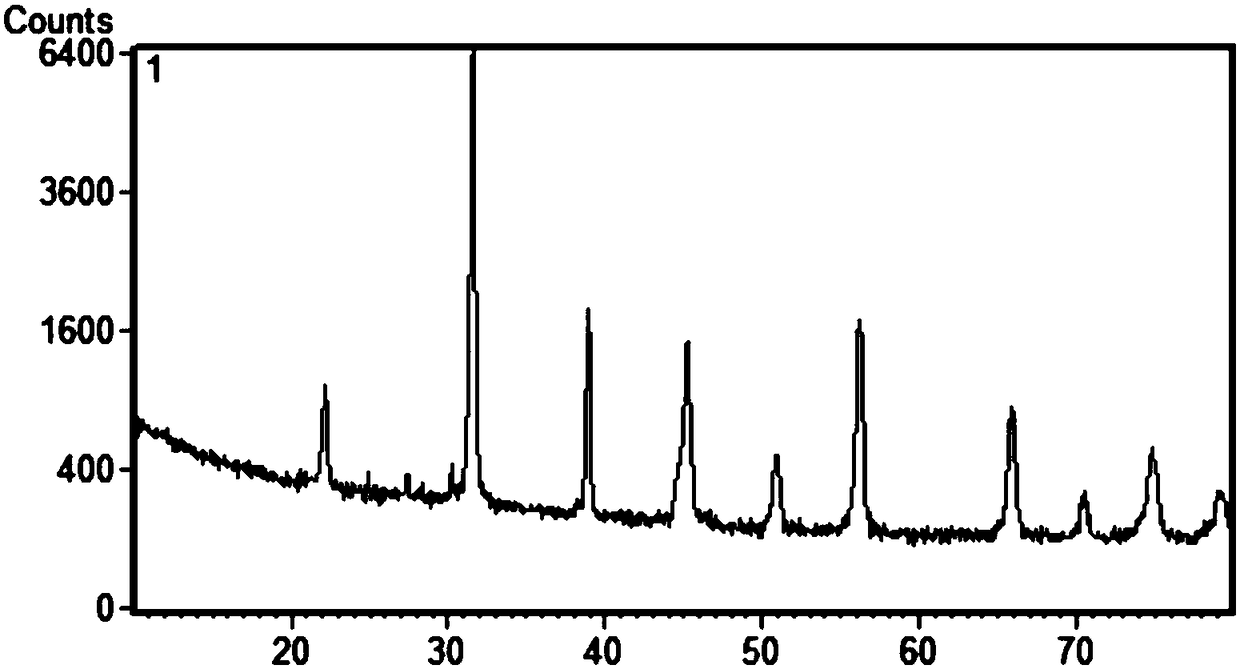

Embodiment 1

[0032] Cut about 700g of high-purity titanium plate and divide it into 3 pieces, each piece is connected in parallel with the negative electrode of the pulse power supply, and inserted as an anode into an electrolytic cell filled with 6kg of n-butanol solution, and a graphite electrode is installed at a distance of 30mm from the anode , and connected to the positive pole of the pulse power supply as the cathode. Add 90% lithium chloride to it, raise the temperature of the electrolytic cell to 70°C, turn on the pulse power supply, and adjust the pulse current density to 3000A / m 2 , the pulse time is 30ms, the duty ratio is 0.25 and the reaction is continued until the anode is completely dissolved, and then the solution is distilled at 130°C for 24h to obtain a tetrabutyl titanate solution.

[0033] Take by weighing 3kg tetrabutyl titanate solution and 9kg (25%) n-butanol solution and add it in the high-pressure enamel reaction kettle, then add 1.8kg barium hydroxide and 18g (1%...

Embodiment 2

[0036] Cut and weigh about 300g of titanium sponge, and divide it into 2 pieces. Each piece will be put into a common can-shaped graphite electrode and connected in parallel with the negative electrode of the pulse power supply, and inserted as an anode into an electrolytic cell filled with 4kg of n-butanol solution. Set a graphite electrode at a distance of 10 mm from the anode, and connect it to the positive pole of the pulse power supply as the cathode. Add 4g of ammonium bromide to it again, raise the temperature of the electrolytic cell to 105°C, turn on the pulse power supply, and adjust the pulse current density to 400A / m 2, the pulse time is 150 ms, the duty ratio is 0.5 and the reaction is continued until the anode is completely dissolved, and then the solution is distilled at 130° C. for 24 h to obtain a tetrabutyl titanate solution.

[0037] Weigh 1kg tetrabutyl titanate solution and 19kg (5%) n-butanol solution and add it in the high-pressure enamel reaction kettle...

Embodiment 3

[0040] Cut and weigh about 700g of titanium sponge, and divide it into 3 pieces. Each piece will be put into a common can-shaped graphite electrode and connected in parallel with the negative electrode of the pulse power supply, and inserted as an anode into an electrolytic cell filled with 6kg of n-butanol solution. Set a graphite electrode at a distance of 15 mm from the anode, and connect it to the positive pole of the pulse power supply as the cathode. Add 60g of ammonium chloride to it again, raise the temperature of the electrolytic cell to 95°C, turn on the pulse power supply, and adjust the pulse current density to 1500A / m 2 , the pulse time is 100ms, the duty ratio is 0.25 and the reaction is continued until the anode is completely dissolved, and then the solution is distilled at 130°C for 24h to obtain a tetrabutyl titanate solution.

[0041] Take by weighing 3kg tetrabutyl titanate solution and 17kg (15%) n-butanol solution and add it in the high-pressure enamel rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com