Preparation method for synthesizing MoS2/Fe3O4 nano composite material

A nanocomposite material, fe3o4 technology, applied in the direction of microsphere preparation, inorganic material magnetism, microcapsule preparation, etc., to achieve the effect of simple process, good crystallinity, and controllable shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

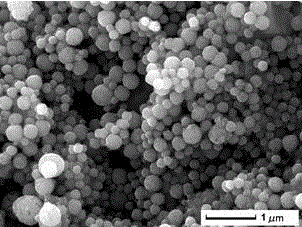

[0025] (a) Preparation of nano-Fe 3 o 4 Particles: FeCl 3 ·6H 2 O was dissolved in 80mL of ethylene glycol to make a solution with a concentration of 0.1 mol / L, and stirred for 10 minutes. During the stirring process, trisodium citrate and anhydrous sodium acetate were added at a concentration of 0.15 mol / L and 0.6 mol / L, respectively. L, then pour the solution into a 100mL polytetrafluoroethylene reactor and put it in an oven. The reaction temperature is 200°C, and the reaction time is 8 hours. After the reaction is completed, the reactor is cooled to room temperature, and the upper layer solution in the reactor is poured into In the beaker, the Fe in the solution is 3 o 4 Adsorption deposition was carried out, and the obtained product was repeatedly washed with alcohol, and the product was dried at 60°C for 2 h to obtain Fe 3 o 4 nanoparticles, as a result figure 1 As shown, the product is spherical particles.

[0026] (b) Add 0.5g Fe 3 o 4 , 1.5g NaMoO 4 2H2O, 0....

Embodiment 2

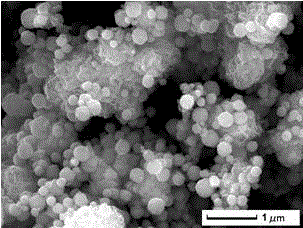

[0028] 0.5g Fe 3 o 4 , 1g NaMoO 4 2H2 O, 0.4g NaCl, 0.25g CTAB, and 1.6g NaSCN were put into a 100ml reactor in turn, added 80ml of distilled water, stirred evenly, adjusted the pH of the reaction solution to 3, put the reactor into an oven, and reacted at 160°C After 36 hours, the obtained product was washed 2-3 times with distilled water and ethanol, and the sample was placed in an oven and dried at 60°C for 2 hours to obtain MoS 2 / Fe 3 o 4 Nanocomposite material, carry out scanning electron microscope to the product of this embodiment to observe its microscopic appearance, the result is as follows figure 2 As shown, the product consists of MoS 2 Nanoflowers and spherical Fe 3 o 4 Particle composition.

Embodiment 3

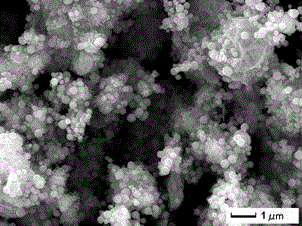

[0030] 1g Fe 3 o 4 , 1.8g NaMoO 4 Put 2H2O, 0.6g NaCl, 0.35g CTAB, 1.5g NaSCN into a 100ml reaction kettle in turn, add 80ml of distilled water, stir evenly, adjust the pH of the reaction solution to 4, put the reaction kettle into an oven, React for 24 hours. After the reaction is over, wash the obtained product with distilled water and ethanol 2-3 times, put the sample in an oven, and dry it at 60°C for 2 hours to obtain MoS 2 / Fe 3 o 4 Nanocomposite material, carry out scanning electron microscope to the product of this embodiment to observe its microscopic appearance, the result is as follows Figure 4 As shown, the product consists of MoS 2 flake and spherical Fe 3 o 4 Particle composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com