Copper-silver double-metal nanowire and preparation method thereof

A bimetallic nanometer, copper-silver technology, applied in the fields of transparent conductive films, printed circuits and related electronic products, conductive inks/inks, ultra-long copper-silver bimetallic nanowires and their preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] More specifically, the present invention provides a method for synthesizing copper-silver bimetallic nanowires, the method is as follows:

[0059] Dissolve a cationic surfactant and an organic solvent at 100-250°C to obtain solution A, completely dissolve copper acetylacetonate as a copper source in solution A, and shake well to obtain dark green solution B. Add metal nanoparticles into solution B as a catalyst, react at 120-200°C for 2-15 hours, take out the solution, add silver acetylacetonate as a silver source and mix well, change the temperature to 24-150°C for reaction 10min-10 hours. The reaction system was cooled to room temperature. Wash and disperse with common organic solvents such as ethanol and toluene. After stirring and brief sonication, the nanowires can be uniformly dispersed in the organic solvent.

[0060] The synthesis process is divided into two stages. The first stage temperature is 120-200°C, which is the growth stage of copper nanowires, and t...

Embodiment 1

[0085] 0.5g of cetyltrimethylammonium bromide and 8.0g of hexadecylamine were completely dissolved at 180°C, then 0.2g of copper acetylacetonate was added as a copper source, Pt nanoparticles were used as a catalyst, and the reaction was carried out at 180°C for 10 hour, cooled to 120°C, added 10 mg of silver acetylacetonate as a silver source, and reacted at 120°C for 10 minutes. After cooling to room temperature, the resulting sample was washed several times with toluene. The resulting gray solid was dried under vacuum at 80°C for 2 hours. The diameter of the obtained copper-silver double-metal nanowire is 50-150 nanometers, and the length is 10-100 micrometers.

Embodiment 2

[0087] 0.5g of cetyltrimethylammonium bromide and 8.0g of hexadecylamine were completely dissolved at 180°C, then 0.2g of copper acetylacetonate was added as a copper source, Pt nanoparticles were used as a catalyst, and the reaction was carried out at 180°C for 10 hour, cooled to 120°C, added 20 mg of silver acetylacetonate as a silver source, and reacted at 120°C for 10 minutes. After cooling to room temperature, the resulting sample was washed several times with toluene. The obtained gray solid was vacuum-dried at 80° C. for 2 hours;

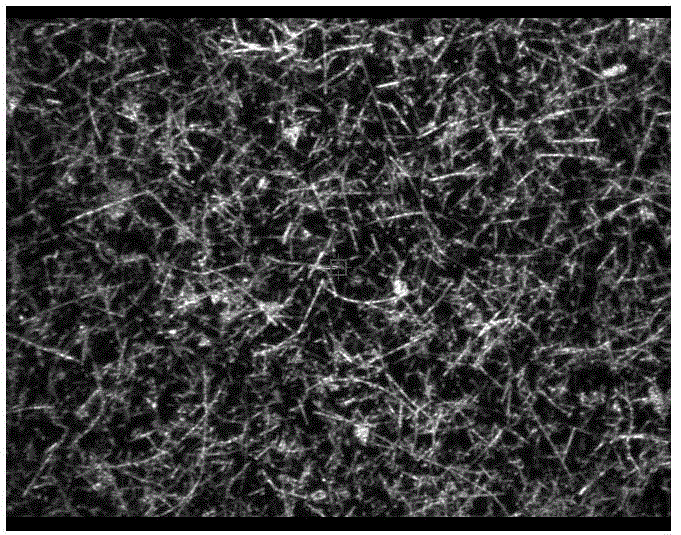

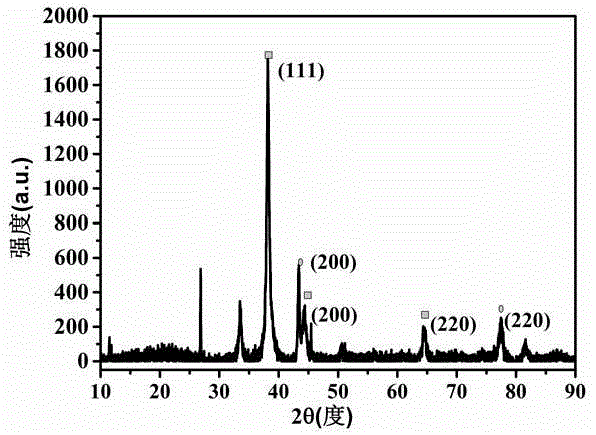

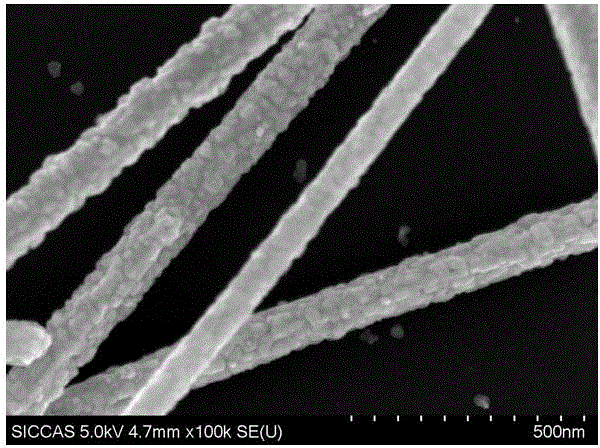

[0088] Depend on figure 1 with image 3 It can be seen that the diameter of the obtained copper-silver bimetallic nanowire is about 50-150 nanometers, and the length is 10-100 microns; figure 2 It is the XRD spectrum of the sample of this embodiment, from which it can be seen that the obtained product contains both silver and copper elements, and the two crystals are good;

[0089] Depend on Figure 4 It can be seen that the silver elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com