Catalyst used for methanol ammoxidation and preparation and forming method thereof

A technology of oxidation reaction and molding method, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. problems such as poor particle size controllability and poor particle size control, to achieve the effect of good popularization and application value, controllable morphology and size, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

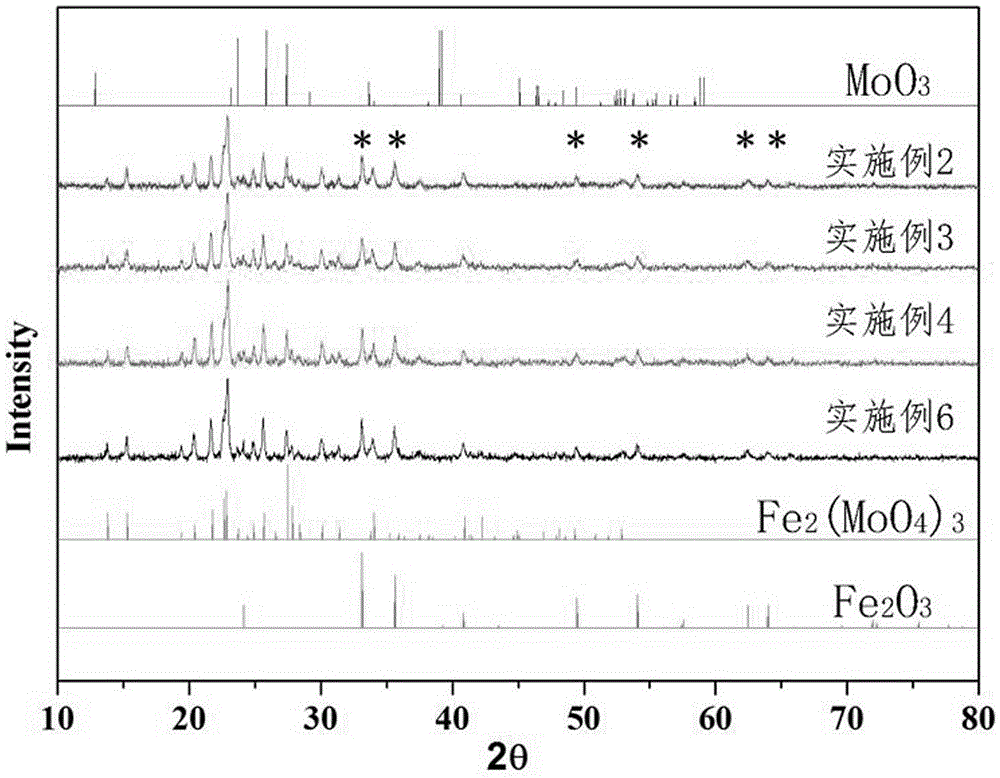

[0029] A catalyst for methanol ammoxidation, the chemical composition of the active ingredient of the catalyst is Fe a MoO b , where a=0.5, its preparation method is as follows:

[0030] (1) Dissolve 12.35g of ammonium molybdate tetrahydrate powder in 40g of deionized water and 7g of ammonia water with a mass fraction of 25%, stir for 10 minutes and dissolve to form an ammonium molybdate solution. 14.14 g of ferric nitrate nonahydrate were dissolved in 20 g of deionized water. Under rapid stirring, the ammonium molybdate solution is slowly added dropwise to the ferric nitrate solution, and the drop rate is controlled to complete the dropwise addition within 0.5 to 1 hour. After the dropwise addition, the pH was adjusted to 2.5 with ammonia water. Then raise the temperature to 100°C and heat to reflux for 2 to 3 hours. The temperature was then lowered to 80° C., and stirring was stopped overnight.

[0031] (2) Slowly add 40g of acidic silica sol with a mass fraction of 30%...

Embodiment 2

[0034] A catalyst for methanol ammoxidation, the chemical composition of the active ingredient of the catalyst is Fe a MoO b , where a=1, its preparation method is as follows:

[0035] (1) Dissolve 12.35g of ammonium molybdate tetrahydrate powder in 40g of deionized water and 7g of ammonia water with a mass fraction of 25%, stir for 10 minutes and dissolve to form an ammonium molybdate solution. 28.28 g of ferric nitrate nonahydrate were dissolved in 30 g of deionized water. Under rapid stirring, the ammonium molybdate solution is slowly added dropwise to the ferric nitrate solution, and the drop rate is controlled to complete the dropwise addition within 0.5 to 1 hour. After the dropwise addition, the pH was adjusted to 2.5 with ammonia water. Then raise the temperature to 100°C and heat to reflux for 2 to 3 hours. The temperature was then lowered to 80° C., and stirring was stopped overnight.

[0036] (2) Slowly add 50g of acidic silica sol with a mass fraction of 30% d...

Embodiment 3

[0039] A catalyst for methanol ammoxidation, the chemical composition of the active ingredient of the catalyst is Fe a MoO b , where a=1.5, its preparation method is as follows:

[0040] (1) Dissolve 12.35g of ammonium molybdate tetrahydrate powder in 40g of deionized water and 7g of ammonia water with a mass fraction of 25%, stir for 10 minutes and dissolve to form an ammonium molybdate solution. 42.42 g of ferric nitrate nonahydrate were dissolved in 45 g of deionized water. Under rapid stirring, the ammonium molybdate solution is slowly added dropwise to the ferric nitrate solution, and the drop rate is controlled to complete the dropwise addition within 0.5 to 1 hour. After the dropwise addition, the pH was adjusted to 2.5 with ammonia water. Then raise the temperature to 100°C and heat to reflux for 2 to 3 hours. The temperature was then lowered to 80° C., and stirring was stopped overnight.

[0041] (2) Slowly add 60g of acidic silica sol with a mass fraction of 30%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com