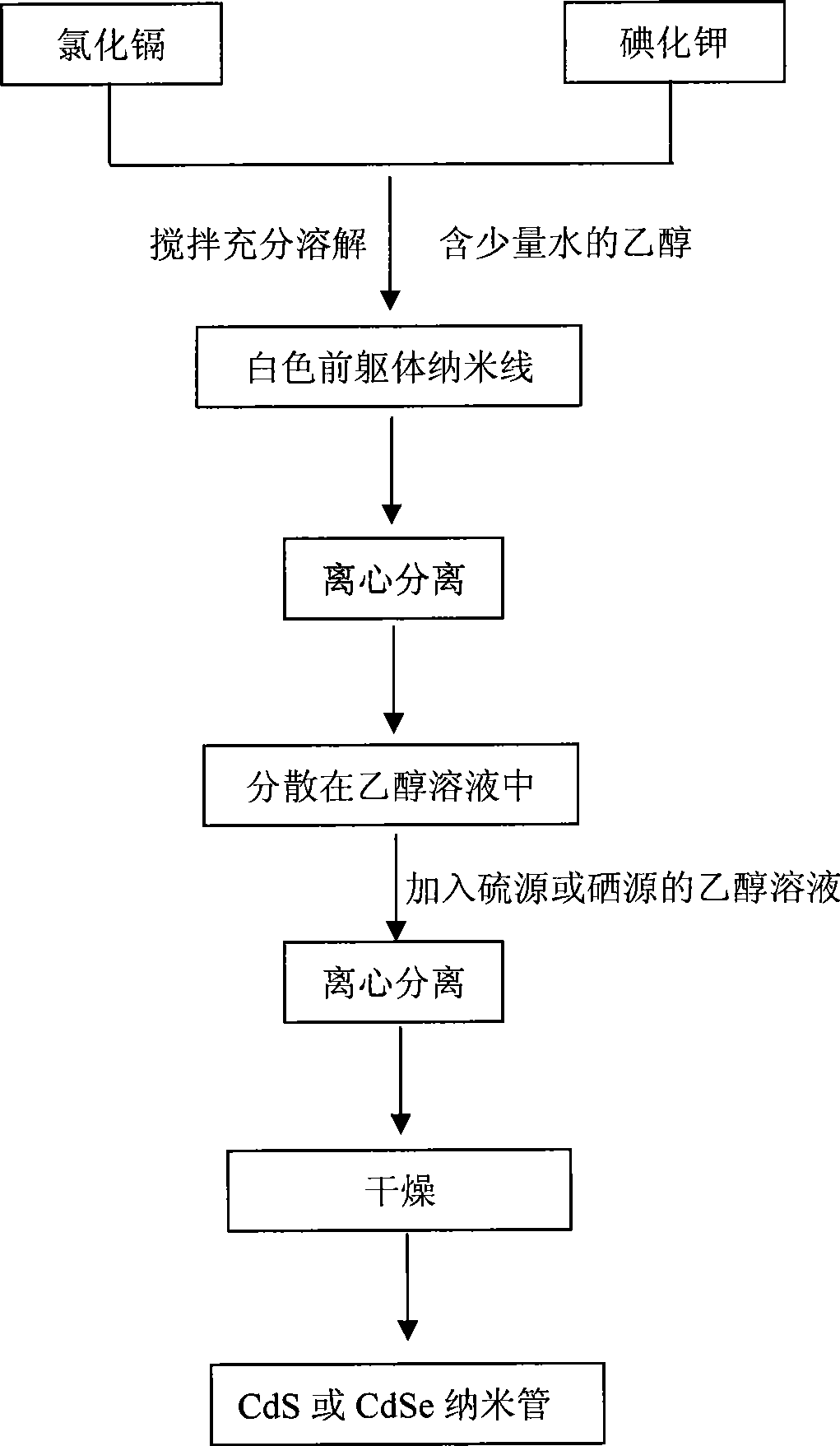

Method for preparing CdS or CdSe nano-tube with KCdCl3 nanowire as template

A technology of nanowires and nanotubes, which is applied in the field of nanomaterial preparation, can solve the problems of not having a layered crystal structure, difficulty in preparing dimensional nanotubes, etc., and achieve the effect of cheap raw materials, high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

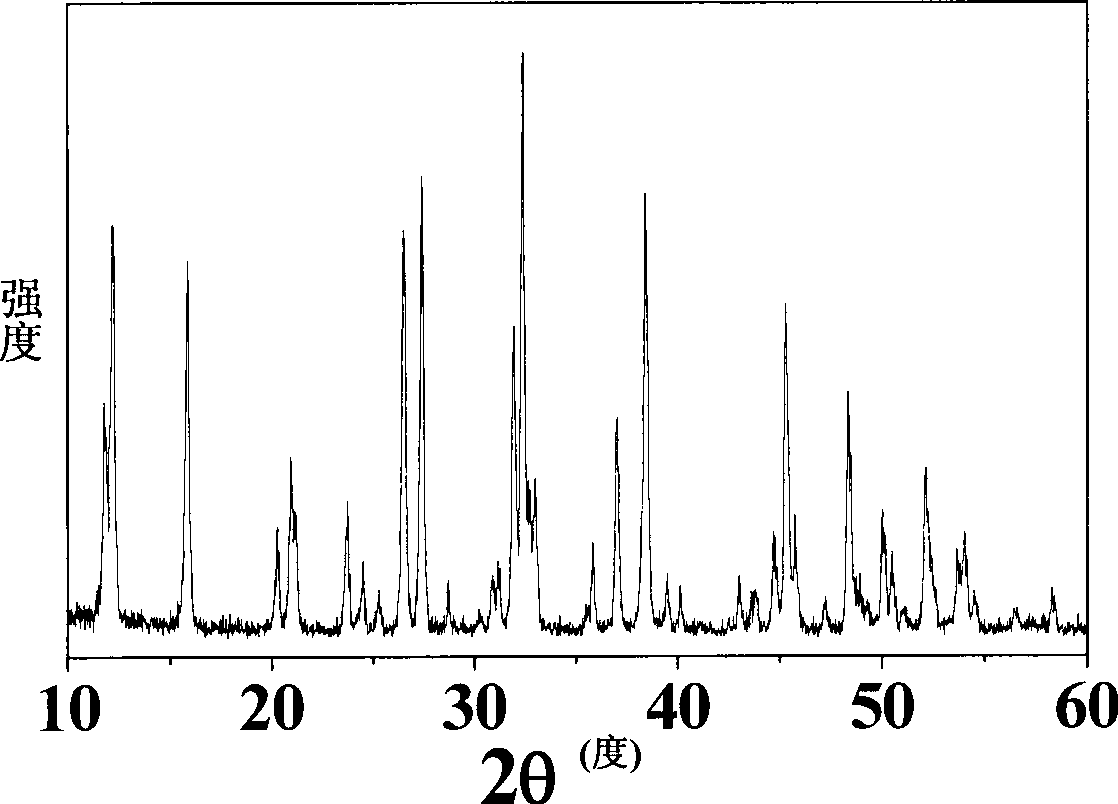

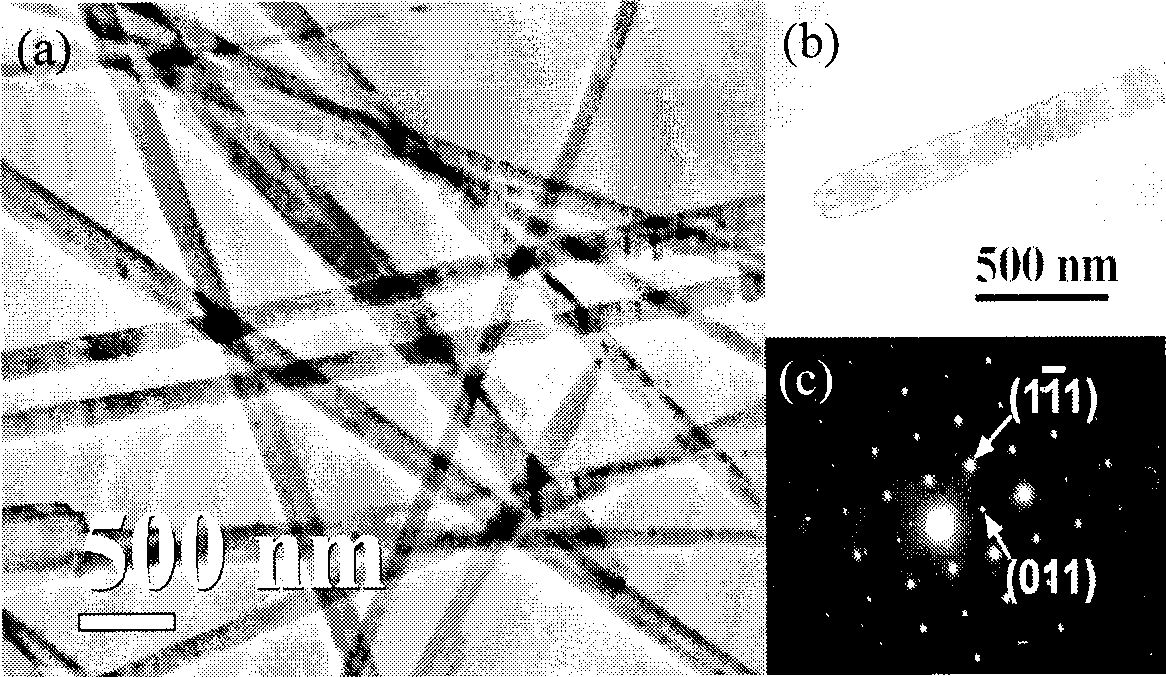

[0024] Under magnetic stirring at room temperature, dissolve 0.456g of cadmium chloride and 0.042g of potassium iodide in 3mL of deionized water, add this solution into 30mL of absolute ethanol, and immediately generate a white product, continue to stir for 20 minutes to make the reaction complete, and centrifuge After the nanowire product was separated and collected by the method, it was washed with absolute ethanol and dried in vacuum at 60°C. X-ray diffraction pattern and transmission electron microscope photo show that the product is KCdCl 3 Nanowires( figure 2 , image 3 ). KCdCl 3 The nanowires were dispersed in 20 mL of absolute ethanol. Prepare a sulfur source solution containing 0.096 g of sodium sulfide and 5 mL of absolute ethanol. The precursor solution and the sulfur source solution were mixed and reacted at room temperature for 30 minutes to obtain a yellow product. The product was separated by centrifugation, and the separated product was washed three tim...

Embodiment 2

[0026] At room temperature, the precursor KCdCl was prepared according to Example 1 3 nanowires and dispersed them in 20 mL of absolute ethanol. Prepare a serving containing 0.031g Se powder, 0.060g NaBH 4 and 5 mL of selenium source solution in absolute ethanol. The precursor solution and the selenium source solution were mixed and reacted for 30 minutes to obtain a black product. The product was separated by centrifugation, and the separated product was washed three times with absolute ethanol and deionized water respectively, and dried under vacuum at 60°C. X-ray diffraction figure and transmission electron microscope photo illustrate that this black product is the cadmium selenide nanotube ( Figure 5 , Image 6 b).

Embodiment 3

[0028] At room temperature, the precursor KCdCl was prepared according to Example 1 3 nanowires, and the KCdCl 3 The nanowires were dispersed in 20 mL of absolute ethanol. Prepare a sulfur source solution containing 0.24 g of sodium sulfide and 5 mL of absolute ethanol. The precursor solution and the sulfur source solution were mixed and reacted at room temperature for 30 minutes to obtain a yellow product. The product was separated by centrifugation, and the separated product was washed three times with absolute ethanol and deionized water respectively, and vacuum-dried at 60° C. to obtain cadmium sulfide nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com