Preparation method of bismuth sulfide/bismuth molybdenum oxide heterojunction photocatalytic composite material

A molybdenum bismuth oxide, composite material technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

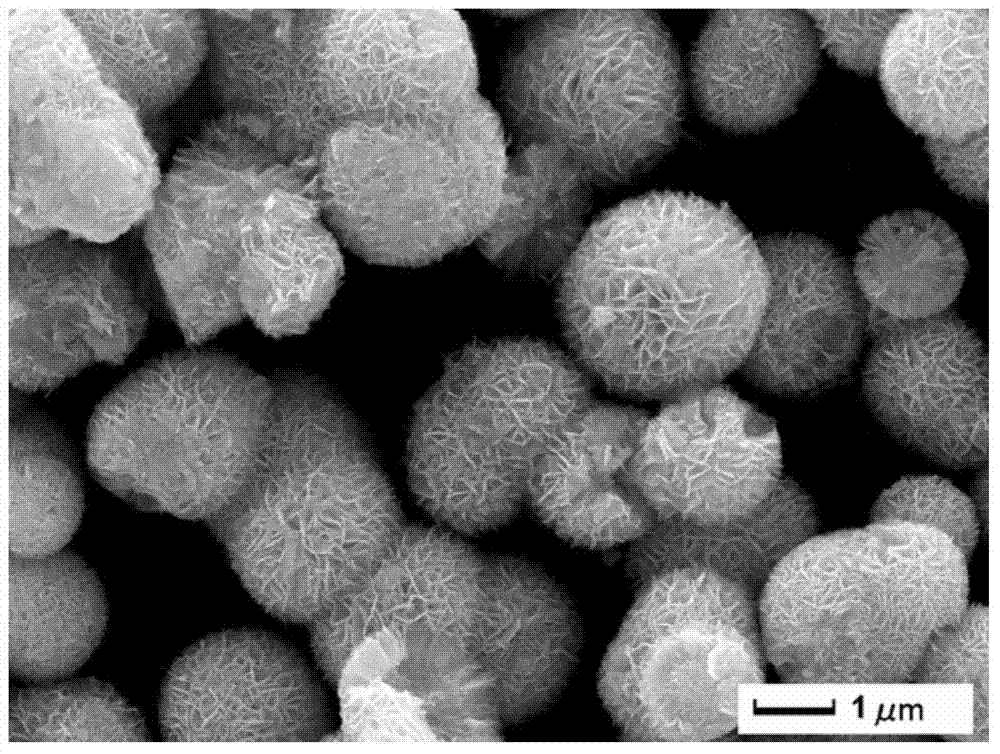

[0023] (1) Preparation of BiOBr microspheres: Bi(NO3) 3 ·5H 2 O was dissolved in ethylene glycol monomethyl ether to make a solution with a concentration of 0.03-0.04mol / L and stirred evenly. During the stirring process, cetyltrimethylammonium bromide (CTAB) was added to ensure a concentration of 0.2 -0.3mol / L, then pour the solution into a polytetrafluoroethylene reactor and put it in an oven, the reaction temperature is 150-200°C, and the reaction time is 8-12 hours. After the reaction was completed, the reactor was cooled to room temperature and washed repeatedly with deionized water and alcohol. Put the washed BiOBr solution into an oven at 60° C. to dry to obtain dried BiOBr microparticles.

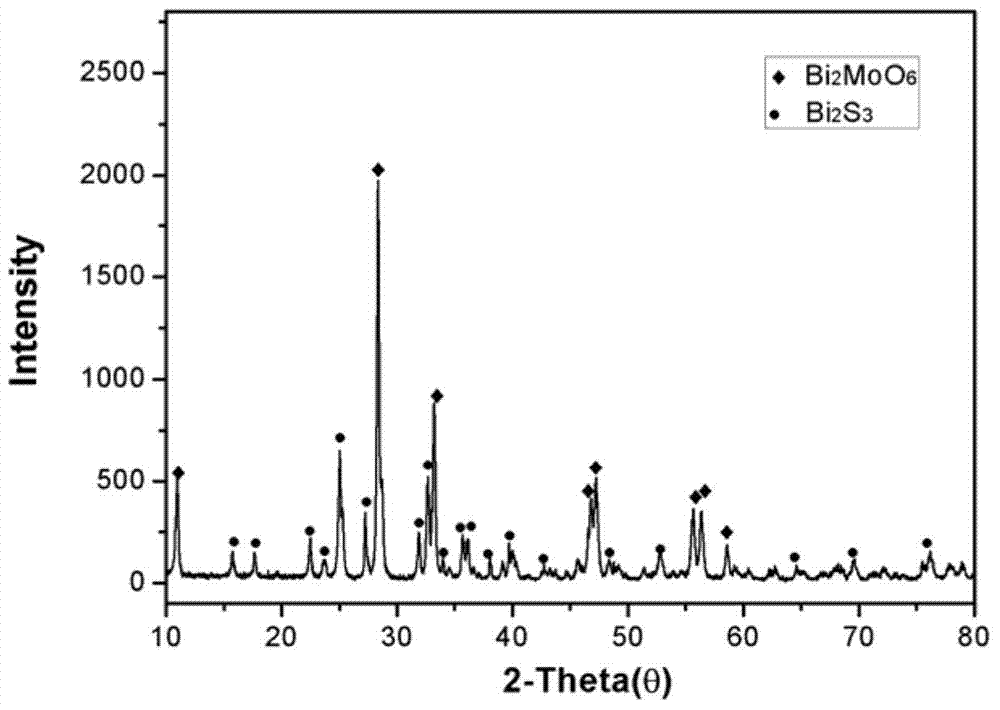

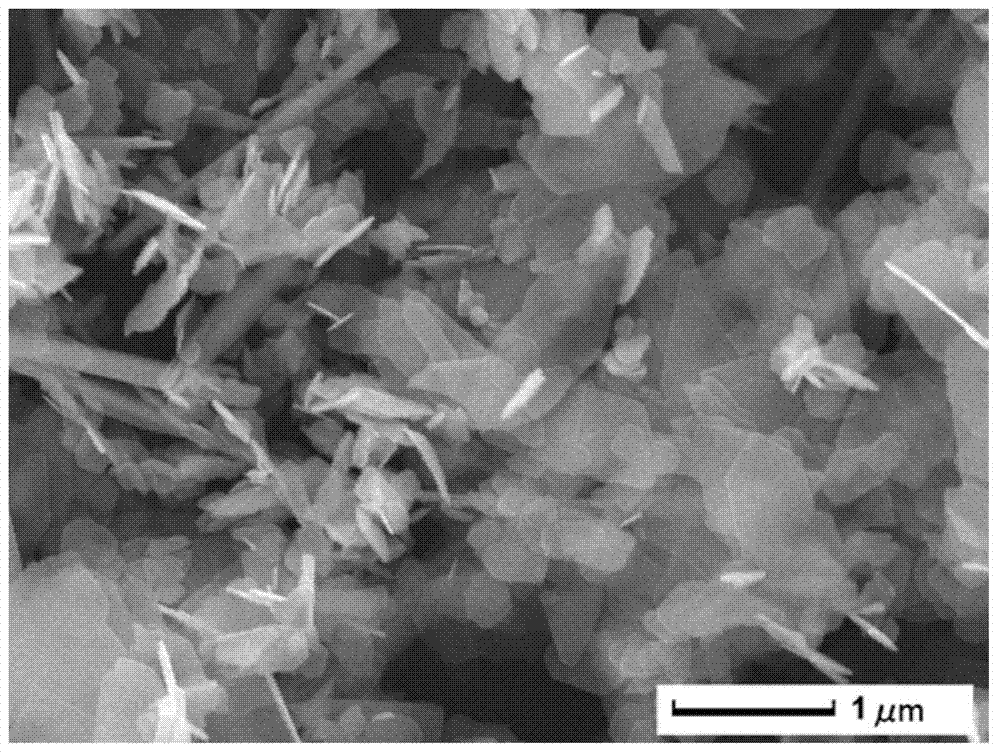

[0024] (2) Preparation of Bi 2 S 3 / Bi 2 MoO 6 Heterojunction photocatalytic composite material: weighed 0.462g BiOBr microparticles, 0.3g NaMoO 4 2H 2 O, 0.12g NaCl, 0.09g CTAB, and 0.3g NaSCN were put into a 100ml reaction kettle in sequence, and at the same time, 60ml of d...

Embodiment 2

[0026] The preparation process of the BiOBr microspheres of this embodiment is the same as that of Embodiment 1.

[0027] The difference is that the content of step (2) is as follows: Weigh 0.462g BiOBr, 0.36g NaMoO 4 2H 2 O, 0.15g NaCl, 0.108g CTAB, and 0.33g NaSCN were put into a 100ml reaction kettle in turn, and at the same time, 60ml of distilled water was weighed with a measuring cylinder and added to the reaction kettle and stirred for 45 minutes. Adjust the pH of the reaction solution to 3, put the reaction kettle into an oven at a temperature of 180° C., and react for 36 hours. After the reaction is finished, the reaction kettle is lowered to room temperature, and washed by a centrifuge. The washing solution is distilled water and absolute ethanol. The number of centrifuges is 3 to 5 times. The sample is put into an oven and dried at 60°C. to get Bi 2 S 3 / Bi 2 MoO 6 Heterojunction Photocatalytic Composite Materials.

Embodiment 3

[0029] The preparation process of the BiOBr microspheres of this embodiment is the same as that of Embodiment 1.

[0030] The difference is that the content of step (2) is as follows: Prepare the weighed 0.462g BiOBr, and weigh 0.42g NaMoO 4 2H 2 O, 0.18g NaCl, 0.12g tetrabutylammonium bromide, and 0.36g NaSCN were successively put into a 100ml reaction kettle, and at the same time, 60ml of distilled water was weighed with a graduated cylinder and added to the reaction kettle and stirred for 60 minutes. Adjust the pH of the reaction solution to 4, put the reaction kettle into an oven at a temperature of 200° C., and react for 48 hours. After the reaction is finished, the reaction kettle is lowered to room temperature, and washed by a centrifuge. The washing solution is distilled water and absolute ethanol. The number of centrifuges is 3 to 5 times. The sample is put into an oven and dried at 60°C. to get Bi 2 S 3 / Bi 2 MoO 6 Heterojunction Photocatalytic Composite Materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com