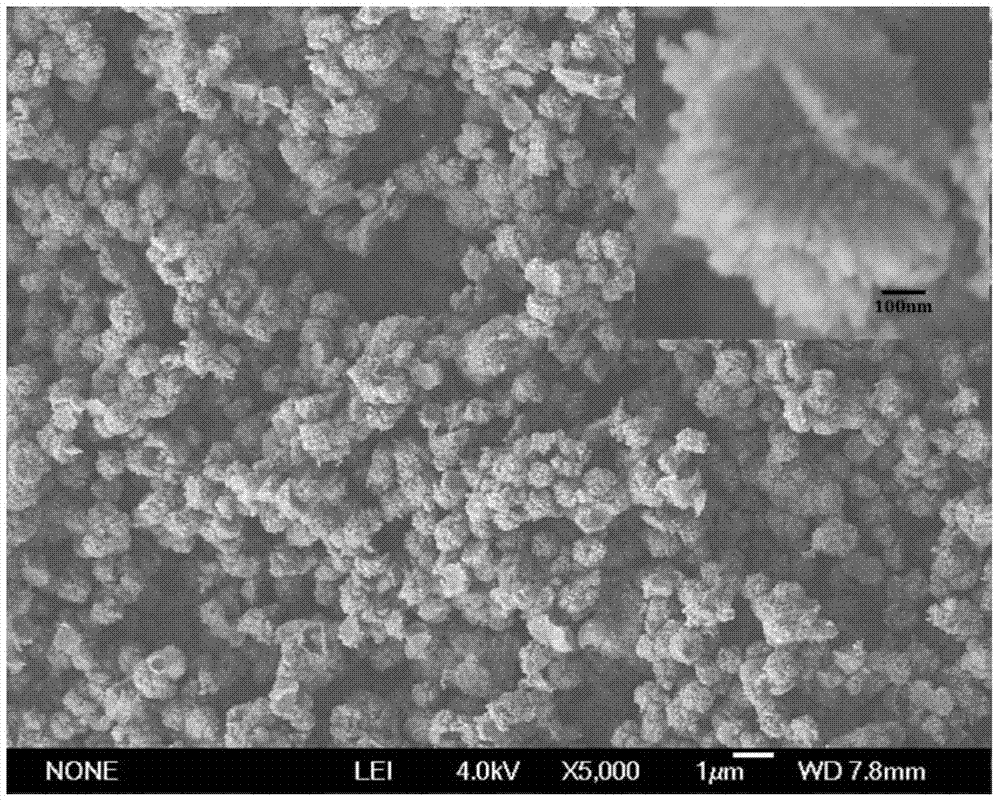

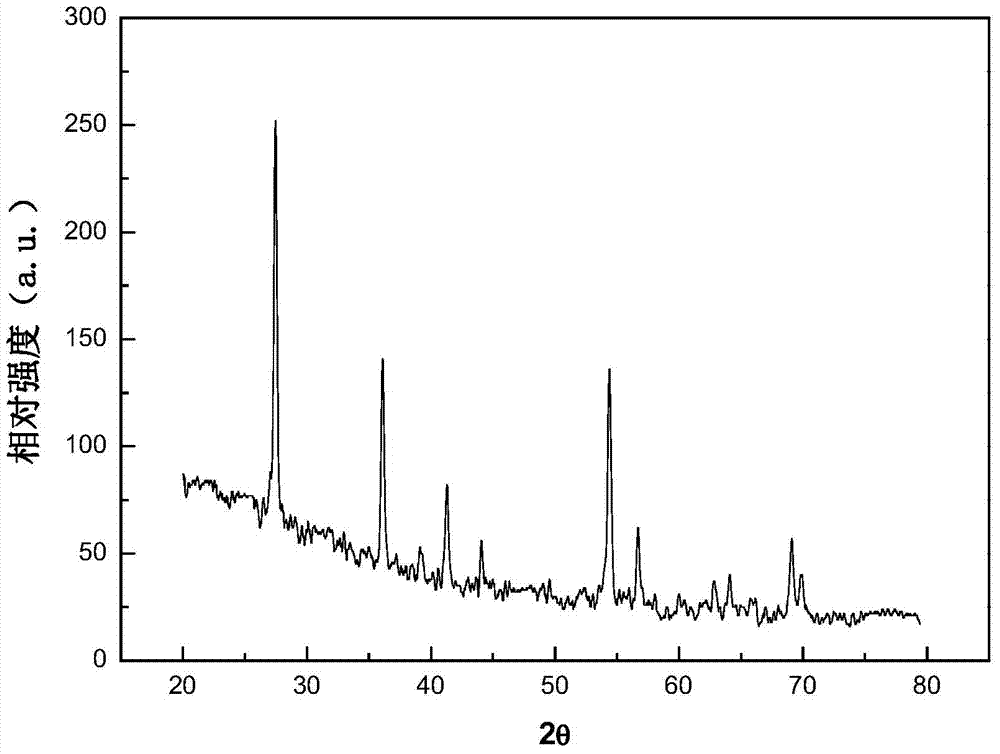

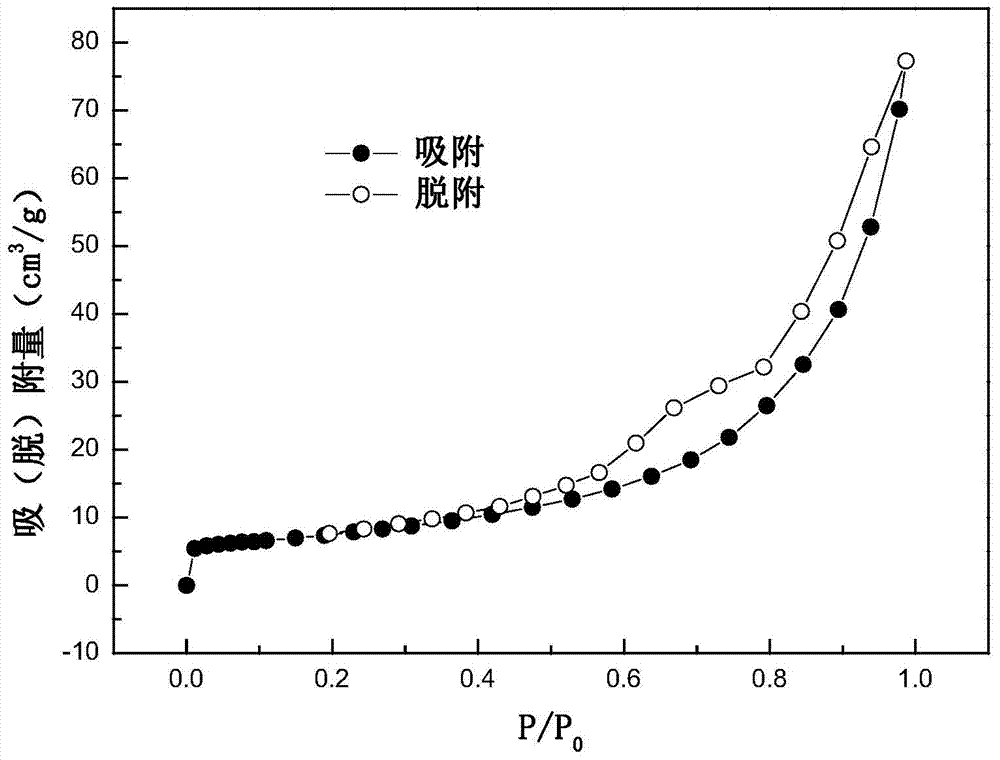

Hierarchical titanium dioxide microspheres based on surface oriented growth nano-rods and preparation method thereof

A titanium dioxide, directional growth technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of unsuitability for large-scale production, low degree of crystallization, poor reproducibility, etc., and achieve good self-settling Performance, good light scattering, excellent performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of graded titanium dioxide microspheres based on surface oriented growth nanorods, comprising the following steps:

[0041] (1) Under the condition of room temperature and constant stirring, the stirring rate is 2000 rpm, and the molar ratio of resorcinol and formaldehyde is 1:8, which are dissolved in water successively, and the amount of water is controlled so that the mass concentration of resorcinol is 1.5%, to get a mixed solution;

[0042] (2) Add titanium trichloride solution dropwise to the resulting mixed solution until the molar ratio of titanium trichloride and resorcinol is 1:8 to obtain a reaction solution; the titanium trichloride solution is dissolved in 3wt % titanium trichloride solution in the hydrochloric acid solution, the concentration of titanium trichloride is 1.5mol / L;

[0043] (3) Transfer the obtained reaction solution into an airtight container, and place it in a constant temperature water bath at 90°C for 2 hours to reac...

Embodiment 2

[0051] A preparation method of graded titanium dioxide microspheres based on surface oriented growth nanorods, comprising the following steps:

[0052] (1) Under the condition of room temperature and constant stirring, the stirring rate is 500 rpm, and resorcinol and formaldehyde are dissolved in water in a molar ratio of 1:2 in sequence, and the amount of water is controlled so that the mass concentration of resorcinol is 3%, to get a mixed solution;

[0053] (2) Add titanium trichloride solution dropwise to the obtained mixed solution until the molar ratio of titanium trichloride and resorcinol is 1:2 to obtain a reaction solution; the titanium trichloride solution is dissolved in 3wt % titanium trichloride solution in hydrochloric acid solution, the concentration of titanium trichloride is 0.1mol / L;

[0054] (3) Transfer the obtained reaction solution into an airtight container, and place it in a constant temperature water bath at 70°C for 4 hours to react to form a dark r...

Embodiment 3

[0057] A preparation method of graded titanium dioxide microspheres based on surface oriented growth nanorods, comprising the following steps:

[0058] (1) Under the condition of room temperature and constant stirring, the stirring rate is 1000 rev / min, and resorcinol and formaldehyde are dissolved in water in a molar ratio of 1:2 in turn, and the amount of water is controlled so that the mass concentration of resorcinol is 3%, to get a mixed solution;

[0059] (2) Add titanium trichloride solution dropwise to the obtained mixed solution until the molar ratio of titanium trichloride and resorcinol is 1:2 to obtain a reaction solution; the titanium trichloride solution is dissolved in 3wt % titanium trichloride solution in hydrochloric acid solution, the concentration of titanium trichloride is 0.5mol / L;

[0060] (3) Transfer the obtained reaction solution into an airtight container, and place it in a constant temperature water bath at 50°C for 6 hours to generate a dark red g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com