A kind of preparation method of transition group metal/carbon tube/graphene electrocatalyst for hydrogen evolution reaction

A transition metal, hydrogen evolution reaction technology, applied in the fields of materials and energy, can solve the problems of reduced catalytic activity and stability, large size of metal particles, cumbersome preparation process, etc., to achieve inhibition of agglomeration, excellent electrical conductivity, high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

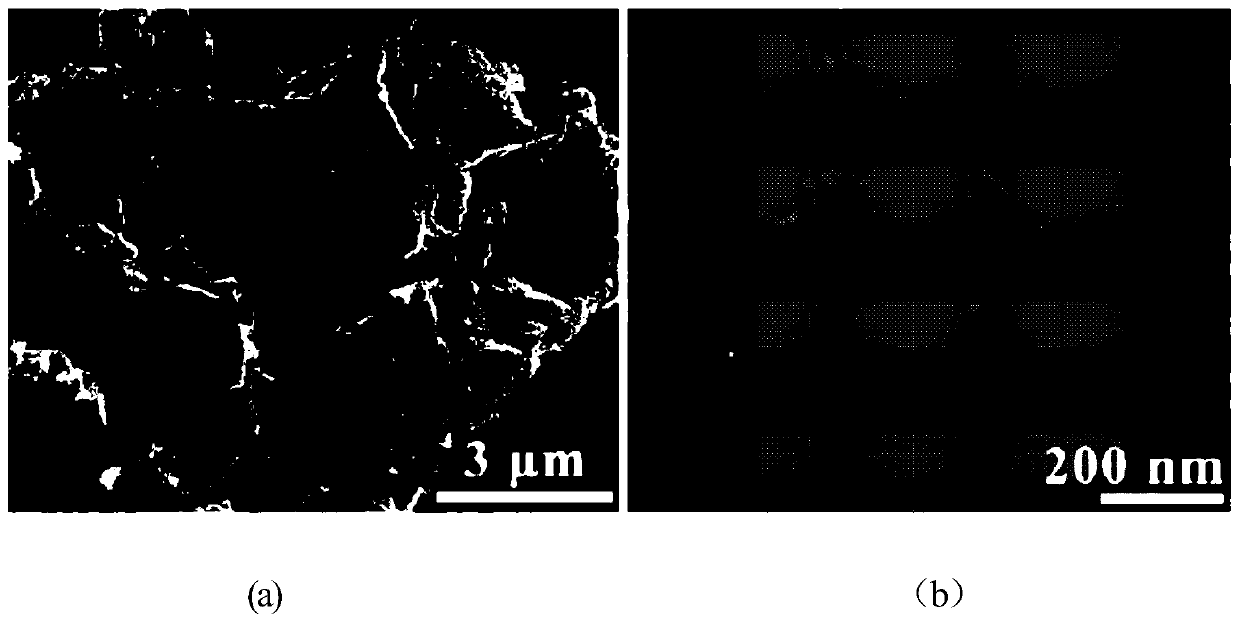

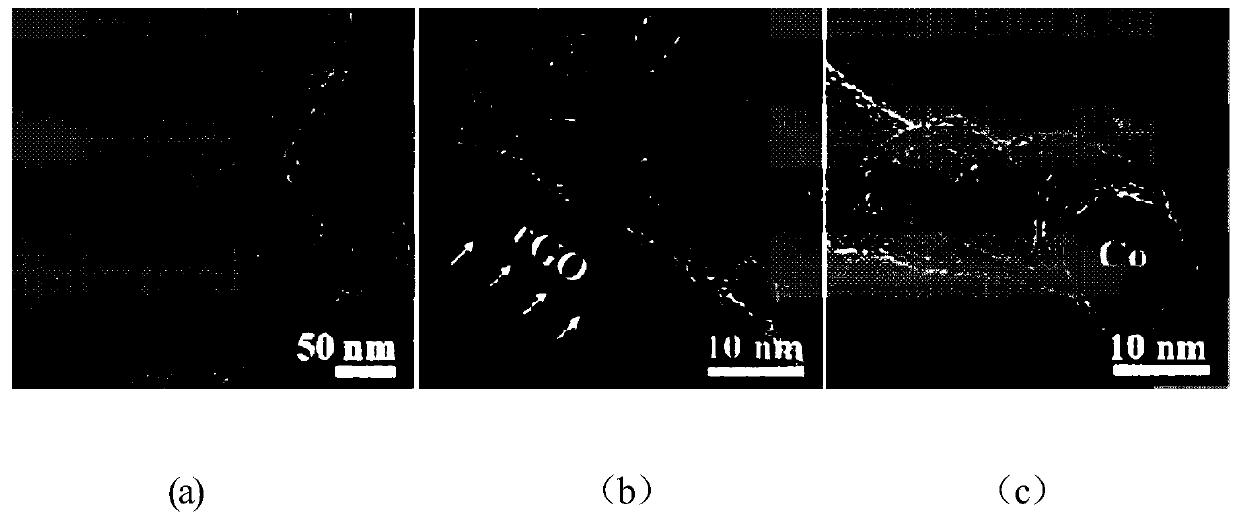

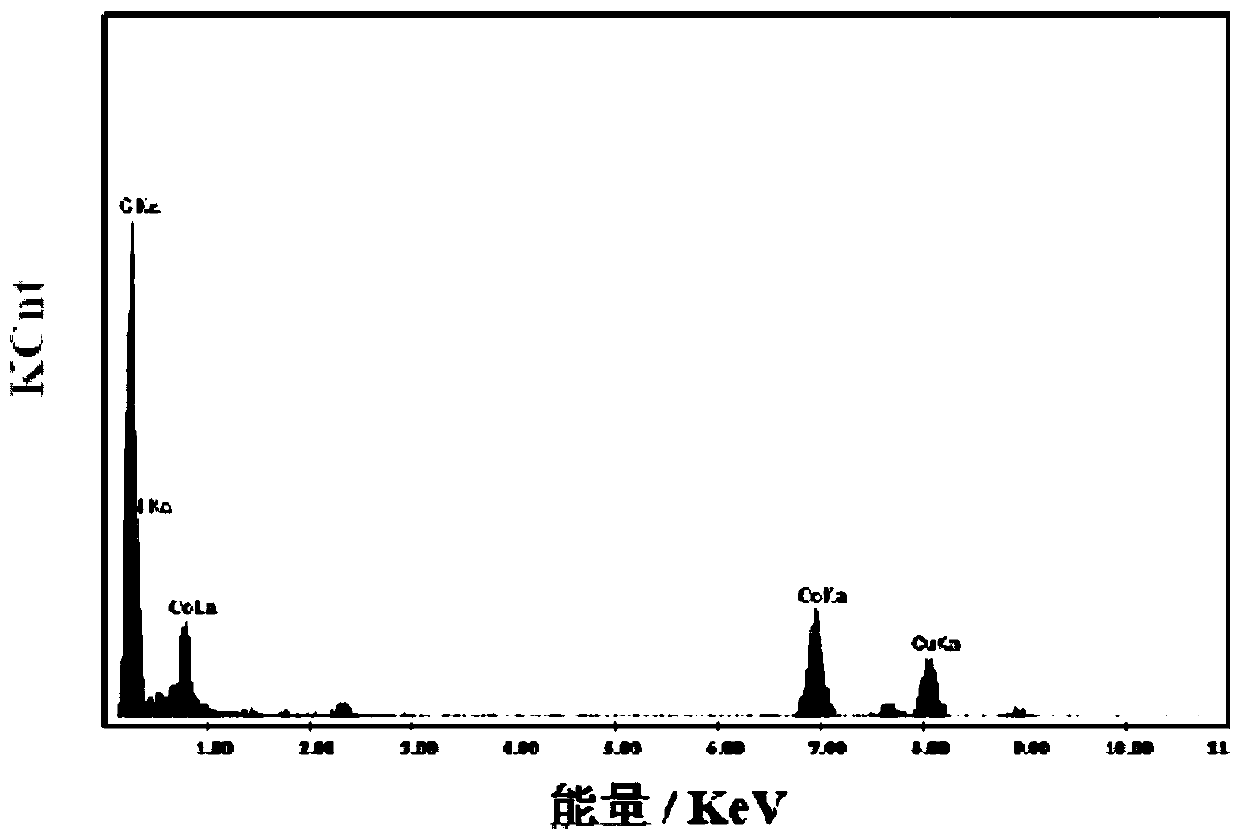

[0021] Embodiment 1, Co@N-CNTs@rGO composite material and its preparation method and application, including the following steps:

[0022] (1) The cubic ZIF-8 template (ZIF-8@GO) of composite graphene was prepared by co-precipitation method: 150–300 mg of Zn(NO 3 ) 2 ·6H 2 0 and 5 mg of CTAB were added to 10 mL of graphene oxide suspension, fully stirred to obtain a mixed solution; the mixed solution was added to 40 mL of 2-methylimidazole solution, stirred at room temperature for 30 min, the product was separated by centrifugation, washed with ethanol solution for 3-4 times, and finally placed in a freeze dryer at -50 °C, and freeze-dried for 36-72 h, and the obtained product was ZIF-8@GO;

[0023] (2) Preparation of graphene-wrapped core-shell bimetallic zeolite imidazole-based framework (ZIF-67@ZIF-8@GO): Weigh 100 mg of ZIF-8@GO obtained in step (1) and uniformly disperse in methanol solution, sonicate for 20 min, then add 3ml of 2-methylimidazole solution to the resulti...

Embodiment 2

[0027] Embodiment 2, Co@N-CNTs@rGO composite material and its preparation method and application, including the following steps:

[0028] (1) The cubic ZIF-8 template of composite graphene (ZIF-8@GO) was prepared by co-precipitation method: 300–400 mg of Zn(NO 3 ) 2 ·6H 2 0 and 5 mg of CTAB were added to 10 mL of graphene oxide suspension, fully stirred to obtain a mixed solution; the mixed solution was added to 40 mL of 2-methylimidazole solution, stirred at room temperature for 30 min, the product was separated by centrifugation, washed with ethanol solution for 3-4 times, and finally placed in a freeze dryer at -50 °C, and freeze-dried for 36-72 h, and the obtained product was ZIF-8@GO;

[0029] (2) Preparation of graphene-wrapped core-shell bimetallic zeolite imidazole-based framework (ZIF-67@ZIF-8@GO): Weigh 100 mg of ZIF-8@GO obtained in step (1) and uniformly disperse in 23 mL of methanol solution, sonicated for 20 min, then added 3 ml, 895 mg of 2-methylimidazole so...

Embodiment 3

[0033] Embodiment 3, Co@N-CNTs@rGO composite material and its preparation method and application, including the following steps:

[0034] (1) The cubic ZIF-8 template of composite graphene (ZIF-8@GO) was prepared by co-precipitation method: 82.5 mg of Zn(NO 3 ) 2 ·6H 2 The CTAB of 0 and 5 mg was added respectively in the graphene oxide suspension of 10 mL, fully stirred, obtained mixed solution; Said mixed solution was joined in 40 mL, in the 2-methylimidazole solution of 2.825 g, at room temperature After stirring at low temperature for 30 min, the product was centrifuged, washed 3-4 times with ethanol solution, and finally placed in a freeze dryer at -50 °C, and freeze-dried for 72 h. The obtained product was ZIF-8@GO;

[0035] (2) Preparation of graphene-wrapped core-shell bimetallic zeolite imidazole-based framework (ZIF-67@ZIF-8@GO): Weigh 50 mg of ZIF-8@GO obtained in step (1), and evenly disperse in 23 mL In methanol solution, sonicate for 20 min, then add 3 ml of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com