Dendritic PdPt nanoparticle for electrocatalytic methanol oxidization and preparation method of dendritic PdPt nanoparticle

A methanol oxidation and nanoparticle technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of large particle size of precious metals, difficult process control, and particle shape damage, etc., and achieve easy Preparation, low cost, and the effect of improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Mix palladium salt (palladium chloride powder with a mass fraction of 99% (Pd% is 59%)) and hydrochloric acid (hydrogen chloride) in a molar ratio of 1:2 to obtain a palladium precursor solution with a concentration of 10 mM;

[0027] 2) Weigh 0.085g of tannic acid, drop into 1mL 10mM palladium precursor aqueous solution, 3mL 5mM chloroplatinic acid aqueous solution and 26mL deionized water in sequence, the dropping rate is 8 drops / min, and the total volume is 30mL;

[0028] 3) The mixed solution obtained in step 2) was continuously stirred at room temperature for 15 minutes, then transferred to a stainless steel autoclave, heated at 120 °C for 6 hours, cooled to room temperature in a furnace, and the cooling rate was 3 °C / min to obtain a black mixed solution ;

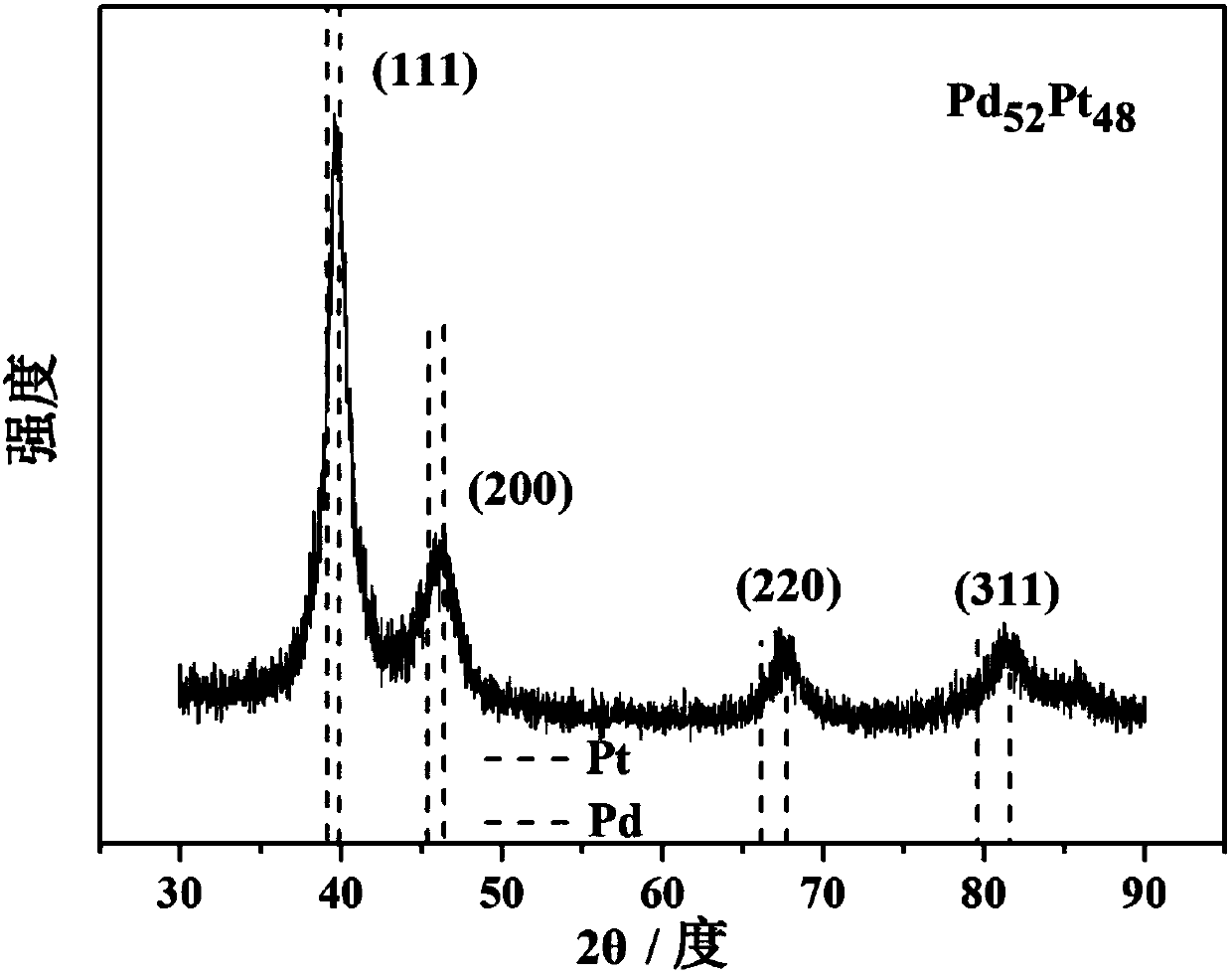

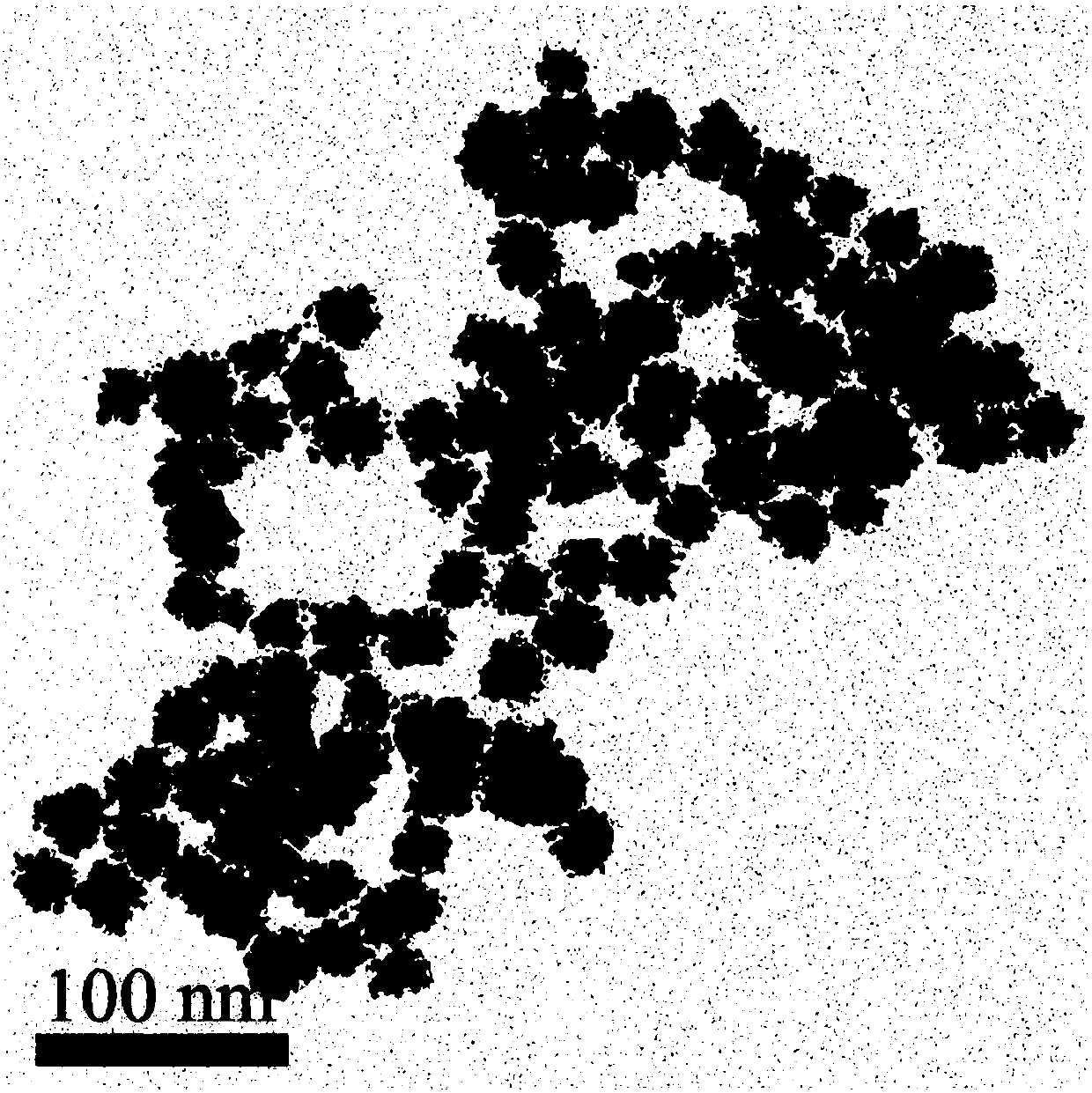

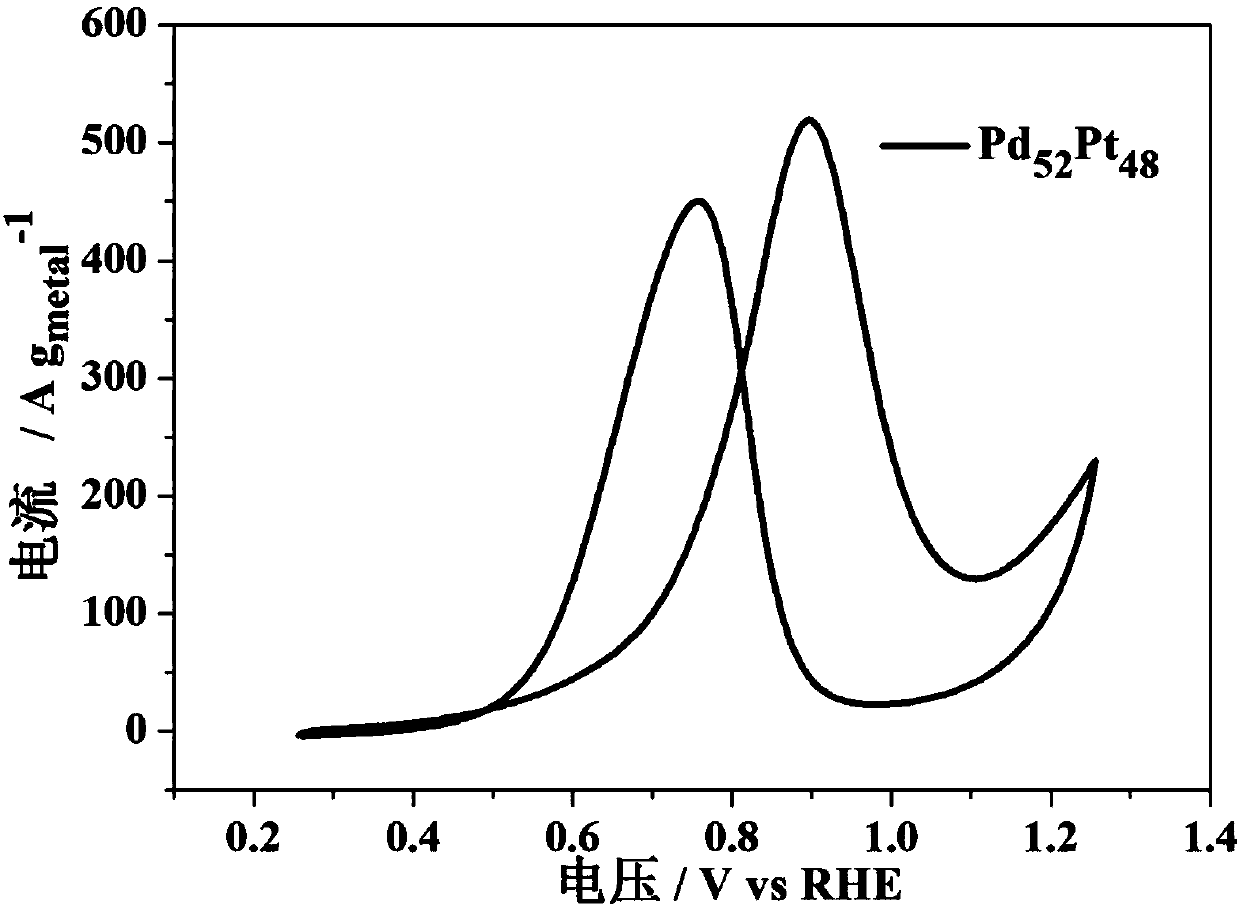

[0029] 4) The mixed solution obtained in step 3) is centrifuged at 18,000 rpm for 10 min by a centrifuge, and washed with a mixture of deionized water and ethanol to finally obtain dendritic Pd 52 Pt 48 na...

Embodiment 2

[0033] 1) Mix palladium salt (palladium chloride powder with a mass fraction of 99% (Pd% is 59%)) and hydrochloric acid in a molar ratio of 1:2 to obtain a palladium precursor solution with a concentration of 10mM;

[0034] 2) Weigh 0.102g of tannic acid, drop into 0.5mL 10mM palladium precursor solution, 4mL 5mM chloroplatinic acid solution and 25.5mL deionized water in sequence, the dropping rate is 5 drops / min, and the total volume is 30mL;

[0035] 3) The mixed solution obtained in step 2) was continuously stirred at room temperature for 12 minutes, then transferred to a stainless steel autoclave, heated at 150°C for 4h, and cooled to room temperature in a furnace at a cooling rate of 5°C / min to obtain a black mixed solution ;

[0036] 4) The mixed solution obtained in step 3) is centrifuged at 15,000 rpm for 12 min by a centrifuge, and washed with a mixture of deionized water and ethanol to finally obtain dendritic Pd 36 Pt 64 nanoparticles.

[0037] Figure 4 For the...

Embodiment 3

[0039] 1) Mix palladium salt (palladium chloride powder with a mass fraction of 99% (Pd% is 59%)) and hydrochloric acid in a molar ratio of 1:2 to obtain a palladium precursor solution with a concentration of 10mM;

[0040] 2) Weigh 0.077g of tannic acid, drop into 1.5mL 10mM palladium precursor solution, 2mL 5mM chloroplatinic acid solution and 26.5mL deionized water in sequence, the dropping rate is 10 drops / min, and the total volume is 30mL;

[0041] 3) The mixed solution obtained in step 2) was continuously stirred at room temperature for 18 minutes, then transferred to a stainless steel autoclave, heated at 100°C for 8h, and cooled to room temperature by furnace cooling at a cooling rate of 1°C / min to obtain a black mixed solution ;

[0042] 4) The mixed solution obtained in step 3) was centrifuged at 20,000 rpm for 8 min by a centrifuge, and washed with a mixture of deionized water and ethanol to finally obtain dendritic Pd 69 Pt 31 nanoparticles.

[0043] Figure 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Peak current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com