Method for preparing nano-porous structure based on nano-particle self-assembly and application thereof

A nanoporous and nanoparticle technology, applied in the field of nanopores, can solve the problems of difficult preparation of small pore size, expensive instruments, and high technical requirements, and achieve the effects of mature processing technology, simple method and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

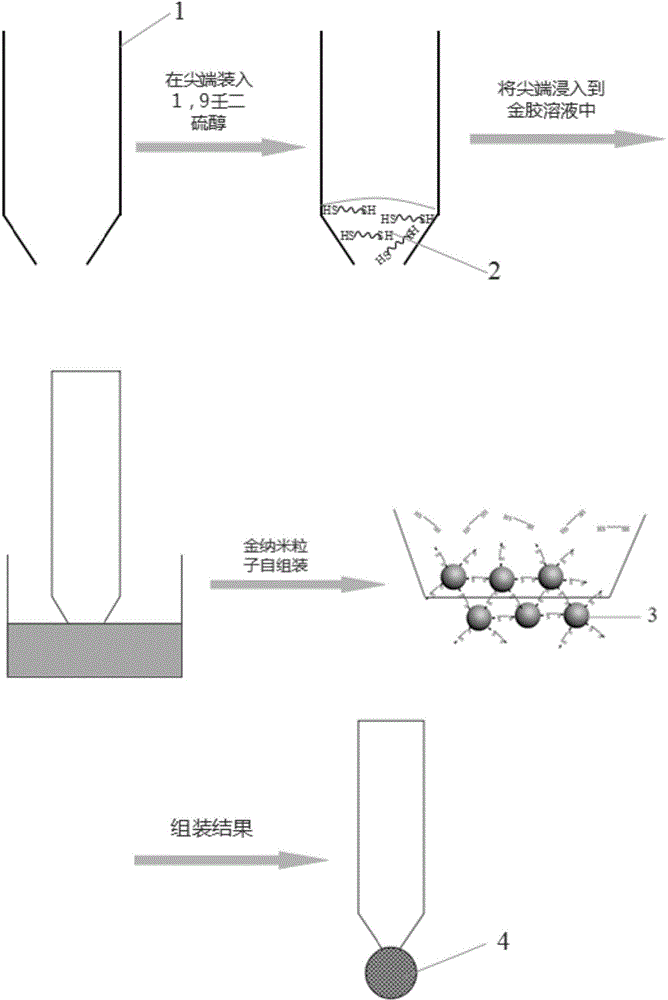

[0041] figure 1 It is a schematic diagram of the formation of the nanoporous structure of the present invention. Such as figure 1As shown, the method (technology) for preparing a nanoporous structure by self-assembly of nanoparticles includes a nano-glass capillary 1 as a support, and gold nanoparticles 3 capable of self-assembly under the action of 1,9 nonaneedithiol 2 . Add 1,9 nonanedithiol 2 to the tip of the nano glass capillary 1, and then immerse the tip into a monodisperse gold nanoparticle solution (prepared by Example 7), due to diffusion, 1,9 nonanedithiol Alcohol is in contact with gold nanoparticles 3, and the thiol groups at both ends of a dithiol molecule are bonded to two gold nanoparticles 3 respectively. After such continuous self-assembly, a regular nanoporous structure 4 (gold balls) is finally formed. ), the pore size is jointly regulated by the nanoparticle size and the crosslinker molecules.

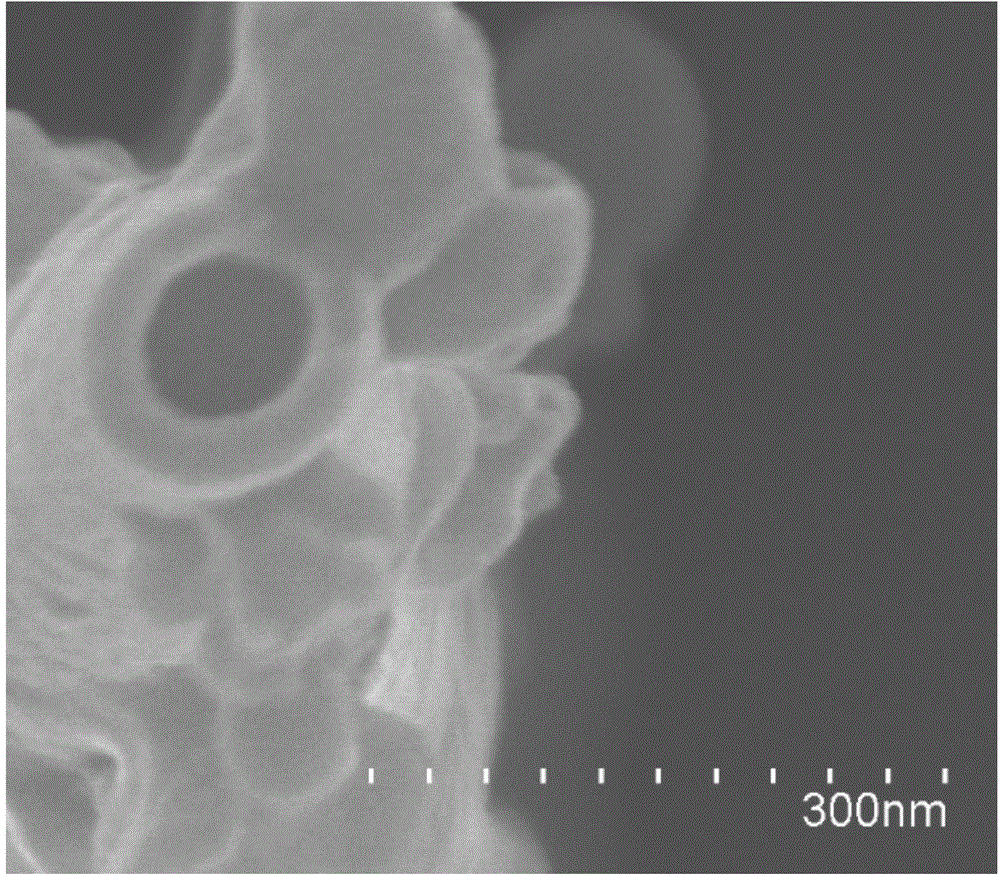

[0042] figure 2 is the electron micrograph of a single ...

Embodiment 2

[0046] The support used in Example 1 is a glass capillary. In Example 2, the support is replaced by a quartz capillary, and other conditions remain unchanged. A nanoporous structure (gold ball) of several microns is formed by the self-assembly of gold colloidal nanoparticles. .

Embodiment 3

[0048] Self-assembly of gold nanoparticles with 1,9 nonaneedithiol in solution. When the gold nanoparticle solution is mixed with the 1,9 nonanedithiol solution, the gold nanoparticles are connected to each other through the dithiol. This assembly process is to simulate the self-assembly process of the gold nanoparticles and the dithiol at the tip of the glass capillary.

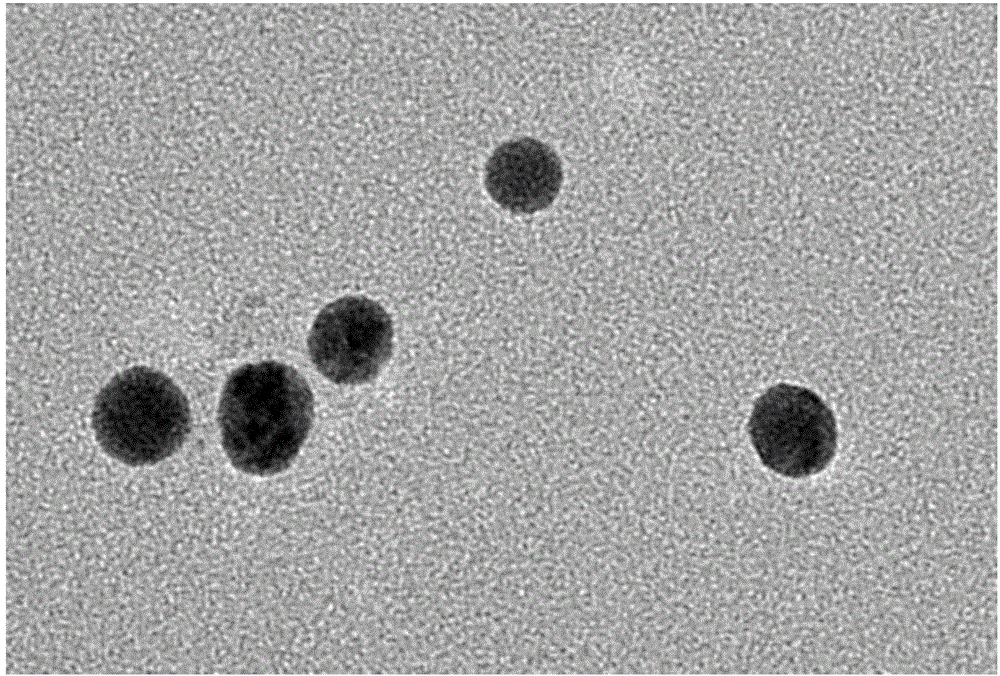

[0049] Figure 5 It is the electron micrograph of self-assembly of gold colloid in dithiol solution, from Figure 5 It can be seen that the gold colloid has self-assembled in the dithiol solution, and the gap between the nanoparticles is about 1 nanometer. Compared with the porous structure obtained in Example 1, this technical solution is to simulate the assembly of Example 1 at the tip of the capillary The process further illustrates the cross-linking process of gold nanoparticles and 1,9 nonaneedithiol in Example 1. It is proved from examples that a multi-nanopore structure is formed after self-assembl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com