Nano nickel-sulfur compound based on eutectic solvent one-step synthesis method

A technology of deep eutectic solvent and sulfur compound is applied in the field of preparing nano-nickel sulfur compound by one-step synthesis method of deep eutectic solvent, which can solve the problems of expensive equipment, high impurity content and high reaction temperature, and achieves low price, high purity, The effect of low temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

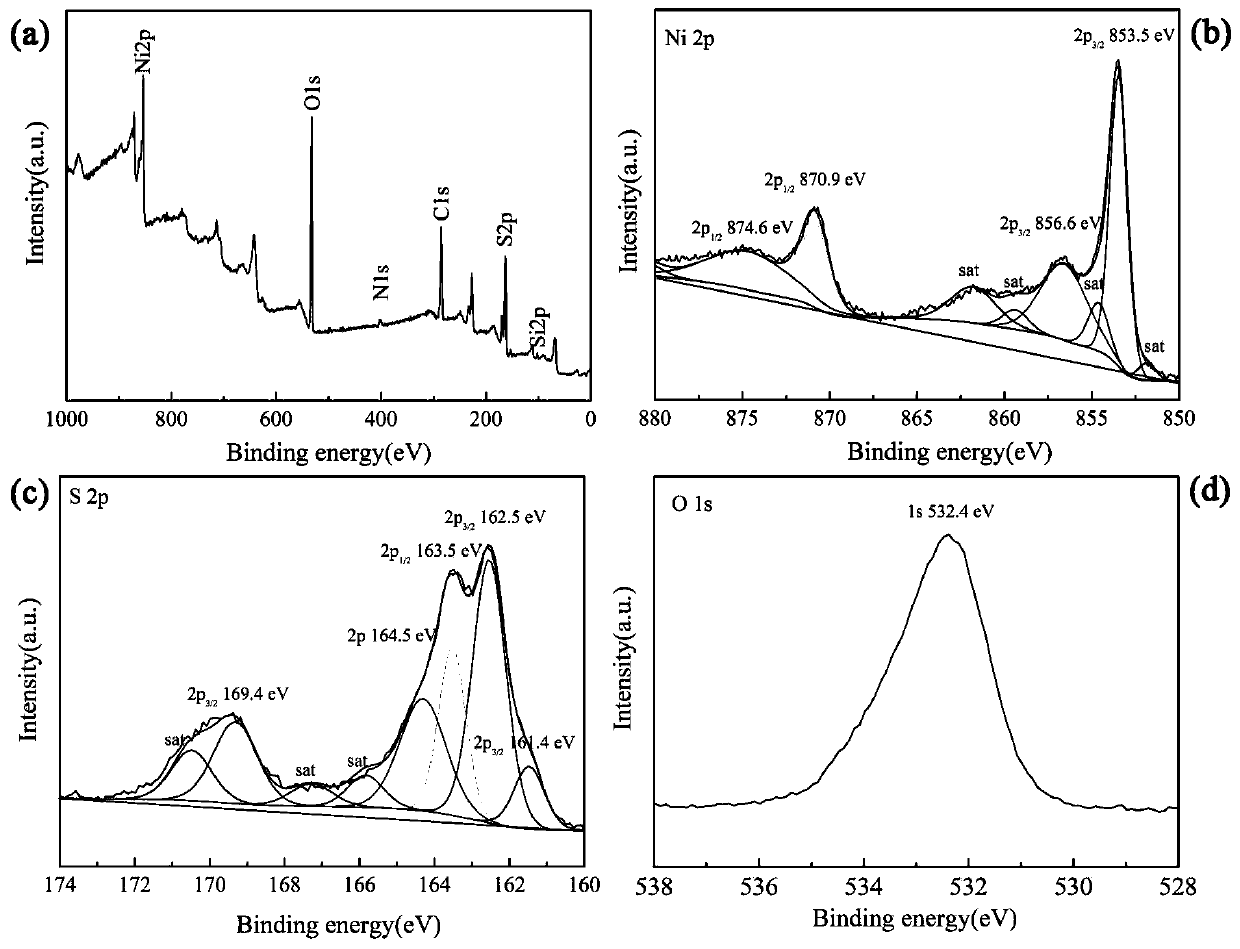

[0048] Deep eutectic solvent one-step synthesis method prepares the method for nano-nickel-sulfur compound, and its specific steps are as follows:

[0049] (1) First, choline chloride and glycerol are placed in a beaker to mix uniformly according to a molar ratio of 1:3 to form a deep eutectic solvent as a solvent to be used;

[0050] (2) Then add a certain amount of 0.02mol / L nickel chloride, 0.04mol / L sodium thiosulfate and 0.01mol / L sublimed sulfur powder into the deep eutectic solvent, and stir at a temperature of 25°C until completely dissolve;

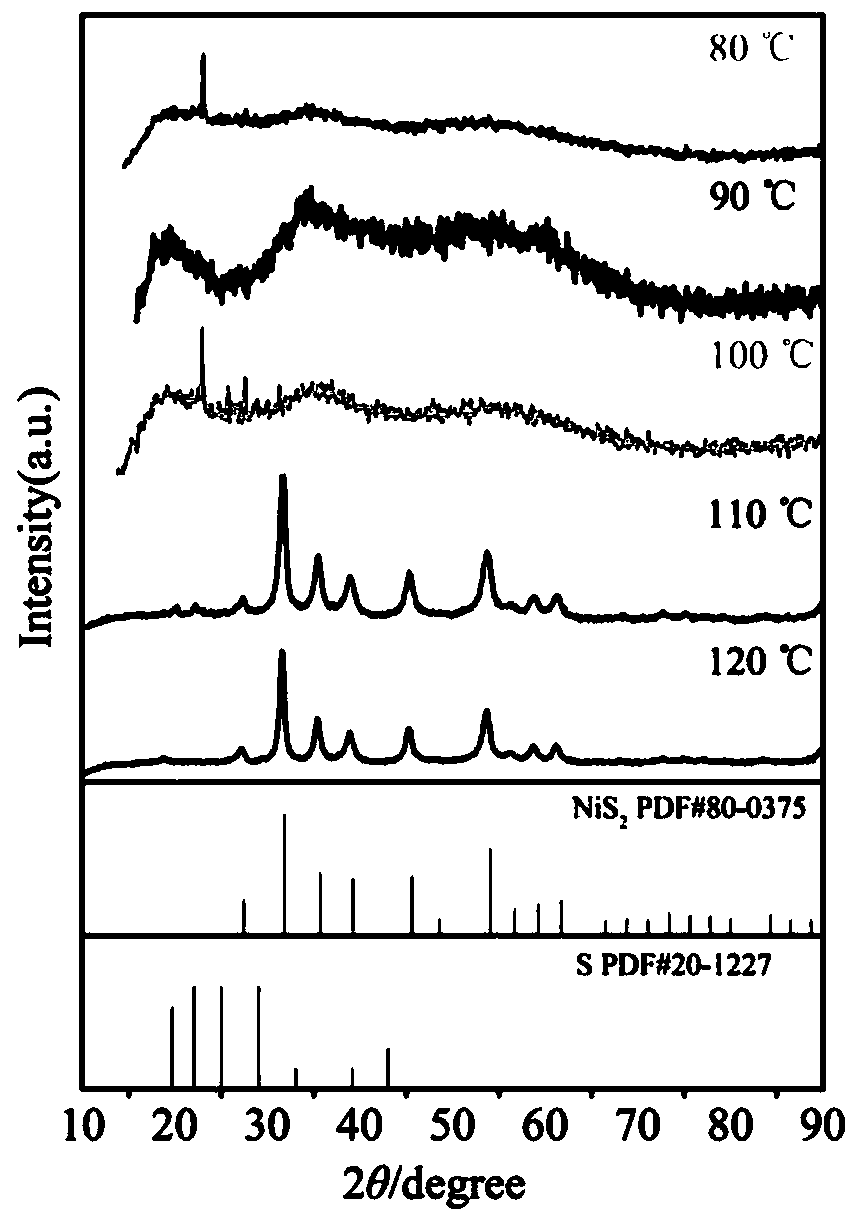

[0051] (3) Stir and heat the deep eutectic solvent in which nickel source, sulfur source and reactants are completely dissolved, the stirring speed is controlled at 100 rpm, the temperature is 110°C, and the reaction time is 6h;

[0052] (4) Finally, the generated powder is ultrasonically washed with distilled water, washed with alcohol, and dried in vacuum to obtain high-purity nano-NiS 2 pink.

[0053] The nano-NiS prepared ...

example 2

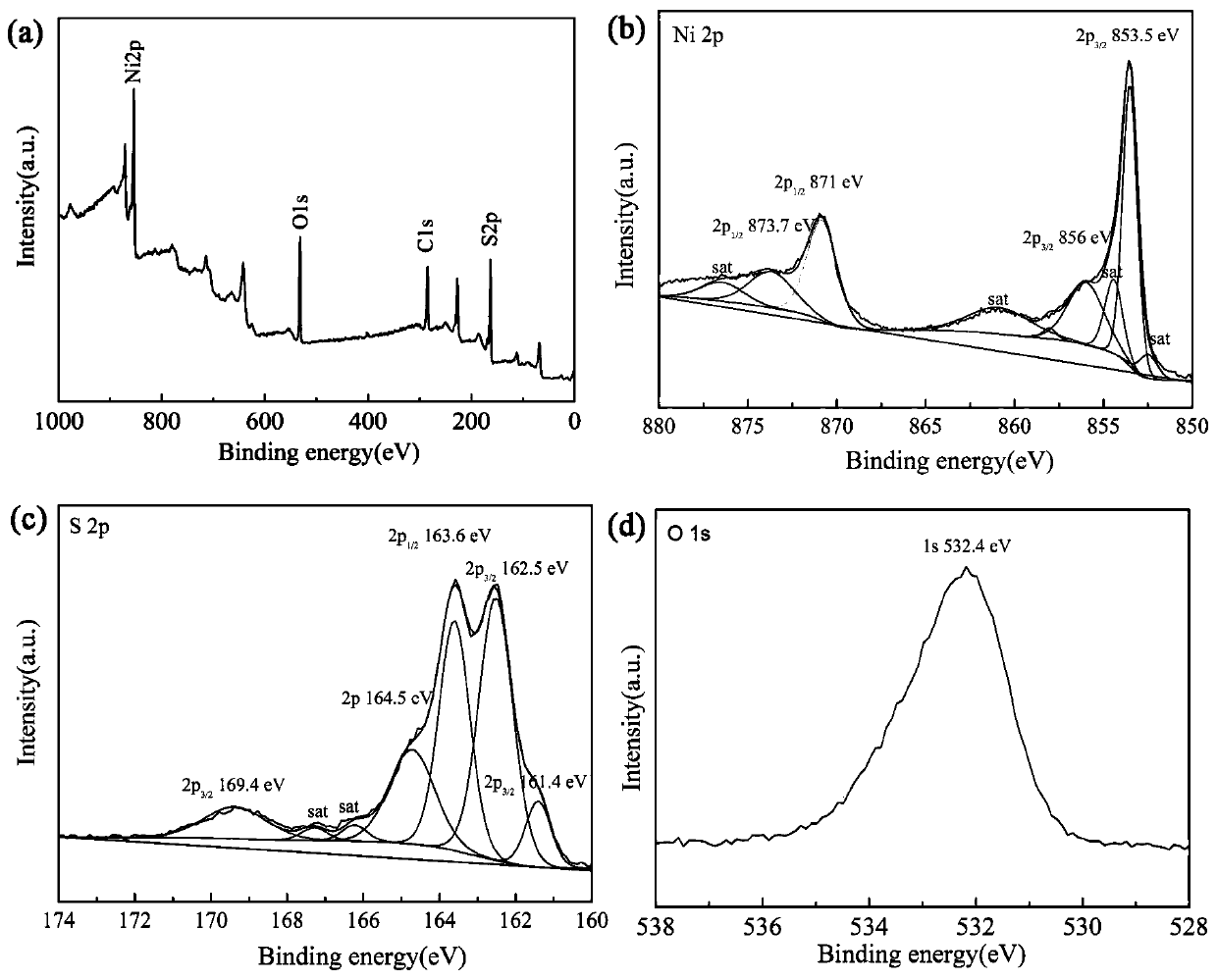

[0055] Deep eutectic solvent one-step synthesis method prepares the method for nano-nickel-sulfur compound, and its specific steps are as follows:

[0056] (1) choline chloride and propylene glycol are placed in a beaker to mix uniformly according to a molar ratio of 1:4 to form a deep eutectic solvent as a solvent to be used;

[0057] (2) Then add 0.05mol / L of nickel sulfate, 0.1mol / L of sodium thiosulfate and 0.005mol / L of ethylenediaminetetraacetic acid into the deep eutectic solvent, and stir at a temperature of 10°C until completely dissolved ,;

[0058] (3) Stir and heat the deep eutectic solvent that dissolves the nickel source, sulfur source, and reactants again, the stirring speed is controlled at 200 rpm, the temperature is 110°C, and the reaction time is 12h;

[0059] (4) Finally, the generated powder is ultrasonically washed with distilled water, washed with alcohol, and vacuum-dried to obtain high-purity nano-Ni 3 S 4 pink.

[0060] Ni was prepared in this exa...

example 3

[0062] Deep eutectic solvent one-step synthesis method prepares the method for nano-nickel-sulfur compound, and its specific steps are as follows:

[0063] (1) First, choline chloride and urea are placed in a beaker in a molar ratio of 1:2 and mixed evenly to form a deep eutectic solvent as a solvent to be used;

[0064] (2) Then add 0.1mol / L nickel acetate, 0.2mol / L thiourea and 0.05mol / L sublimed sulfur powder into the deep eutectic solvent, and stir at 0°C until completely dissolved;

[0065] (3) Stir and heat the fully dissolved eutectic solvent of nickel source, sulfur source, and reactant again, the stirring speed is controlled at 400 rpm, the temperature is 120°C, and the reaction time is 18h;

[0066] (4) The resulting powder can be ultrasonically washed with distilled water, washed with alcohol, and dried in vacuum to obtain NiS 2 and Ni 3 S 4 pink.

[0067] The XRD of the nano nickel sulfur compound that this example prepares is as follows Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com