Super-long silver nanowire and preparation method thereof

A silver nanowire, ultra-long technology, applied in the field of its preparation, ultra-long silver nanowire, can solve the problem of complex preparation methods of silver nanowire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention relates to a silver nanowire and a preparation method thereof, in particular to an ultra-long silver nanowire and a preparation method thereof, as well as a conductive ink / ink, a transparent conductive film, a printed circuit and related electronic products prepared therefrom.

[0039] The invention provides a method for preparing ultra-long silver nanowires, the method comprising:

[0040] a) dissolving the cationic surfactant in the organic reducing agent to form an organic reducing system;

[0041] b) adding silver salt as a silver source to the organic reducing system obtained in step a), and reacting at a first specified temperature.

[0042] In the present invention, in the process of synthesizing ultra-long silver nanowires, a typical reaction system composed of an organic reducing agent and an organic surfactant is used. After the system is melted to form a transparent solution, an organic silver salt is added to the system as a silver source. . ...

Embodiment 1

[0082] 0.5 g of cetyltrimethylammonium bromide and 8.0 g of hexadecylamine were completely dissolved at 180° C., then 50 mg of silver acetylacetonate was added as a silver source, and reacted at 140° C. for 10 hours. The resulting sample was washed several times with toluene after cooling to room temperature. The obtained silver-white solid was vacuum-dried at 80°C for 2 hours;

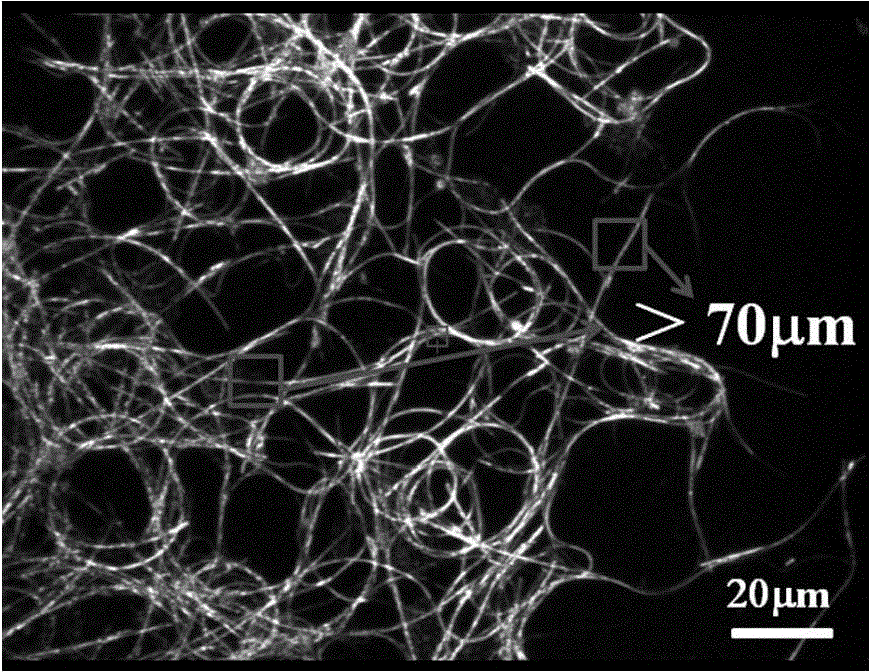

[0083] figure 1 It can be seen that the diameter of the obtained silver nanowire is about 50-100 nanometers, and its length exceeds 70 microns on average;

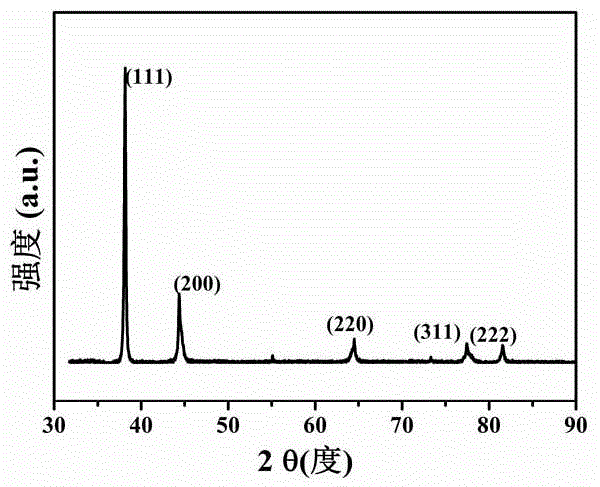

[0084] figure 2 For the XRD spectrum of the sample prepared in this embodiment, it can be seen that the product is a pure silver nanowire;

[0085] Depend on image 3 It can be seen that the nanowires have good crystallinity and smooth surface.

Embodiment 2

[0087] 0.5 g of hexadecyltrimethylammonium bromide and 8.0 g of hexadecylamine were completely dissolved at 180° C., then 50 mg of silver acetylacetonate was added as a copper source, and reacted at 150° C. for 10 hours. The resulting sample was washed several times with toluene after cooling to room temperature. The obtained silver-white solid was vacuum-dried at 80° C. for 2 hours. The obtained silver nanowires have a diameter of about 50-100 nanometers and an average length of more than 70 micrometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com