Metal patterned transparent photosensitive polyimide film, and preparation method and application thereof

A technology of photosensitive polyimide and polyimide film, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of complex manufacturing process, inability to recycle and high cost of flexible circuit boards , to achieve huge economic benefits and environmental protection significance, strong adhesion, fine coating thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

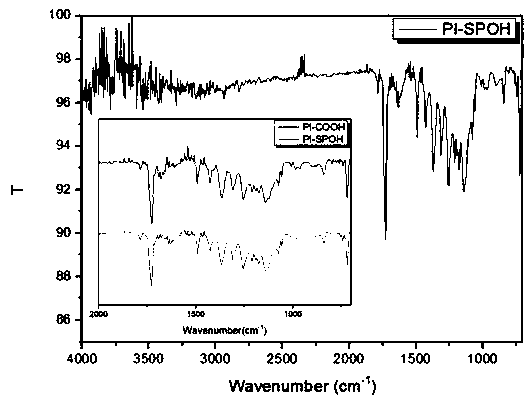

Method used

Image

Examples

Embodiment 1

[0101] This embodiment provides a transparent photosensitive polyimide resin and its film, the preparation process of which is as follows.

[0102] (1) Weigh 40mmol of 2,2'-bis(trifluoromethyl)diaminobiphenyl and 10mmol of 3,5-diaminobenzoic acid monomer into a three-necked flask with nitrogen protection and mechanical stirring , add 150mL of N,N'-dimethylacetamide, stir under dry nitrogen and room temperature for 30min until the raw material is completely dissolved;

[0103] (2), weigh 50mmol of 4,4'-(hexafluoroisopropylene) diphthalic anhydride monomer, add to the above solution in 4 times, the last addition is less than or equal to half of the previous time; Stir at room temperature for 15 hours to obtain polyamic acid;

[0104] The chemical reaction equation of step (1) and (2) is as shown in [1] formula:

[0105]

[0106] (3) Add 8.5mL of acetic anhydride, pyridine and triethylamine to the above polyamic acid; the concentration of acetic anhydride is 0.6mol / L; the conc...

Embodiment 2

[0136] This embodiment provides a transparent photosensitive polyimide resin and its film, the preparation process of which is as follows.

[0137] (1) Weigh 40mmol of 2,2'-bis(trifluoromethyl)diaminobiphenyl and 10mmol of 3,5-diaminobenzoic acid monomer into a three-necked flask with nitrogen protection and mechanical stirring , add 150mL of N,N'-dimethylacetamide, stir for 30min under dry nitrogen and room temperature, until the solid material is completely dissolved;

[0138] (2) Weigh 50 mmol of 3,3',4,4'-benzophenone tetracarboxylic dianhydride monomer, add it to the above solution in 4 times, and the last addition amount is less than or equal to half of the previous one; After adding, stir at room temperature for 20 hours to obtain polyamic acid;

[0139] The chemical reaction equation of step (1) and (2) is as shown in [1] formula:

[0140]

[0141] (3) Add 8.5mL of acetic anhydride, pyridine and triethylamine to the above polyamic acid; the concentration of acetic...

Embodiment 3

[0156] This embodiment provides a transparent photosensitive polyimide resin and its film, the preparation process of which is as follows.

[0157] (1), Weigh 40mmol of 2,2'-bis(trifluoromethyl)diaminobiphenyl and 10mmol of 3.5-diaminobenzoic acid monomer into a three-necked flask with nitrogen protection and mechanical stirring, add Stir 150mL of N,N'-dimethylacetamide under dry nitrogen and room temperature for 30min until the solid material is completely dissolved;

[0158] (2) Weigh 50 mmol of 4,4'-oxydiphthalic anhydride monomer and add it to the above solution in 4 times. The last addition is less than or equal to half of the previous one; Stir for 20 hours to obtain polyamic acid;

[0159] Step (1) and (2) chemical reaction equation is as shown in [1] formula:

[0160]

[0161] (3) Add 8.5mL of acetic anhydride, pyridine and triethylamine to the above polyamic acid; the concentration of acetic anhydride is 0.6mol / L; the concentration of triethylamine is 0.15mol / L; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com