Sulfotetraphenyl porphyrin nano luminescent material and preparation method thereof

A technology of sulfonic tetraphenylporphyrin and tetrasulfonic tetraphenylporphyrin, which is applied in the field of porphyrin nano-fluorescent materials and its preparation, and achieves the effects of excellent fluorescence performance, wide chemical stability, and wide spectral response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

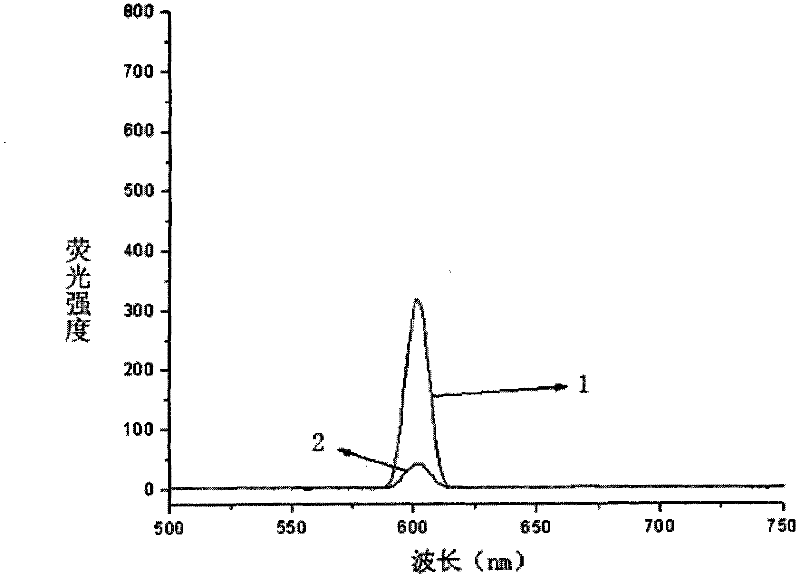

Examples

Embodiment 1

[0036] (1)TPPS 1 Configuration of ethanol solution

[0037] TPPS 1 Place it in a container, add ethanol solution, and stir evenly with a stirrer to prepare TPPS 1 TPPS with mass concentration of 0.58mmol / L 1 Ethanol solution, stored at 3°C in the dark, for later use.

[0038] (2)TPPS 1 Preparation of Nano Fluorescent Material Dispersion System

[0039] After step (1) is completed, press TPPS 1 Ethanol solution: the volume ratio of three distilled water is the ratio of 1:60, the TPPS prepared and preserved in step (1) 1 The ethanol solution is injected into triple distilled water with an initial temperature of 3°C through the injector, then heated and stirred with a constant temperature stirrer and kept at a constant temperature of 80°C, and then stirred at a speed of 1440 rpm for 5 minutes to prepare microemulsion yellow TPPS 1 Nano fluorescent material dispersion system.

[0040] (3) Centrifugal separation

[0041] After the (2) step is completed, the TPPS prepare...

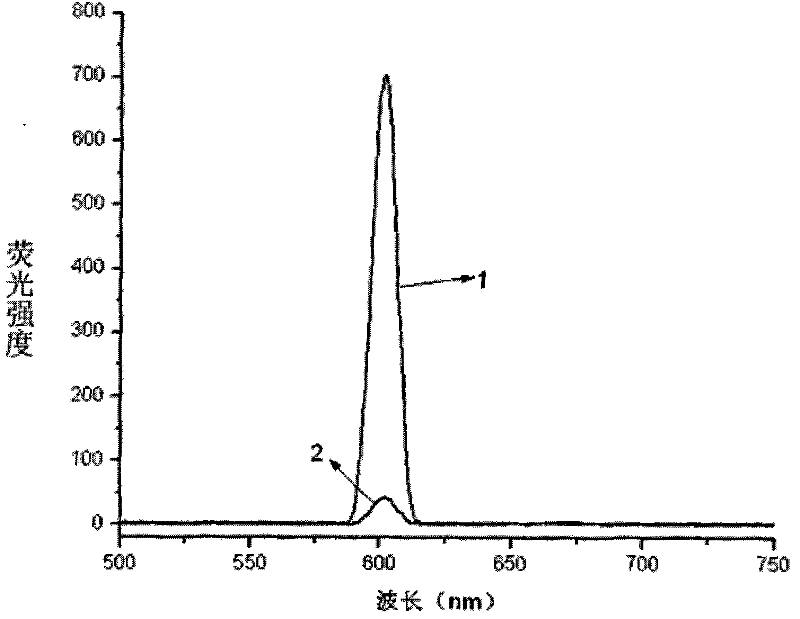

Embodiment 2

[0047] (1)TPPS 1 Configuration of ethanol solution

[0048] With embodiment 1, feature is: prepare TPPS 1 The mass concentration is 0.43mmol / L, and the storage temperature in the dark is 4°C.

[0049] (2)TPPS 1 Preparation of nano-fluorescent materials

[0050] With embodiment 1, feature is: TPPS 1 The volume ratio of ethanol solution: triple distilled water is 1:50, the initial temperature of triple distilled water is 4°C, the temperature of the mixture is 70°C, the stirring speed is 1600rpm, and the stirring time is 10 minutes.

[0051] (3) Centrifugal separation

[0052] With embodiment 1, feature is: the speed of centrifugation is 13000 rev / mins, and centrifugation time is 30min.

[0053] (4) dry

[0054] With embodiment 1, feature is: drying temperature is 85 ℃, and drying time is 24 hours, and the powdery material prepared is the TPPS of long 350~450nm, wide 150~300nm 1 Fluorescent nano sheets and fluorescent nano strips with a length of 500-850nm and a width of ...

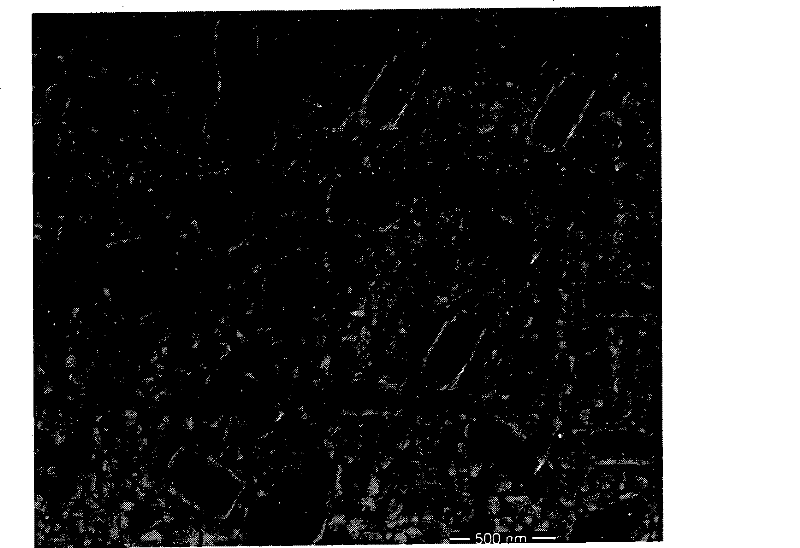

Embodiment 3

[0058] (1)TPPS 1 Configuration of ethanol solution

[0059] With embodiment 1, feature is: prepare TPPS 1 The mass concentration is 0.50mmol / L, and the storage temperature in the dark is 4°C.

[0060] (2)TPPS 1 Preparation of nano-fluorescent materials

[0061] With embodiment 1, feature is: TPPS 1 The volume ratio of ethanol solution: triple distilled water is 1:70, the initial temperature of triple distilled water is 4°C, the temperature of the mixed solution is kept constant at 4°C, the stirring speed is 1550rpm, and the stirring time is 15 minutes.

[0062] (3) Centrifugal separation

[0063] With embodiment 1, feature is: the speed of centrifugation is 14000 rev / mins, and centrifugation time is 20min.

[0064] (4) dry

[0065] Same as Example 1, the features are: the drying temperature is 84° C., the drying time is 25 hours, and the prepared powdery substance is a fluorescent nanosheet with a length of 350-400 nm and a width of 150-250 nm.

[0066] Example 4

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com