Catalyst and preparation method and application thereof

A catalyst and production method technology, applied in molecular sieve catalysts, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of reducing dehydration activity and selectivity, reducing selectivity of conversion rate, prolonging residence time, etc. performance, avoid secondary side reactions, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

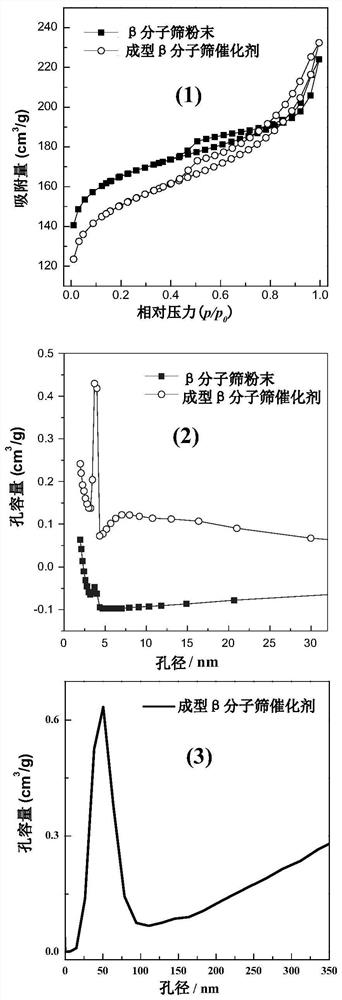

Embodiment 1

[0156] The micron Hβ molecular sieve powder is fully mixed with citric acid and 5% of citric acid and 5% of polyacrylonitrile-based activated carbon fibers with a fiber length of 3 mm and a diameter of 10 microns, which account for the mass percentage of the wet plastomer after kneading. After kneading, the wet plastomer mass percentage of 35% aluminum sol (aluminum hydroxide mass percentage of 30%) is fully stirred and kneaded to obtain a plastic molded body; with an all-stainless steel kneading extruder, it is extruded through an orifice plate of Φ1.5mm. The wet elongated solid cylinder was dried in an oven at 40°C for 10h, then in an air atmosphere, at a heating rate of 2°C / min to 550°C, and calcined at 550°C for 12h to obtain a cylindrical bar-shaped catalyst sample C, Mesopore and macropore volume in total pore volume increased by 14.6% compared to sample A.

[0157] Wherein, the source of the micron Hβ molecular sieve powder described in this example refers to Comparativ...

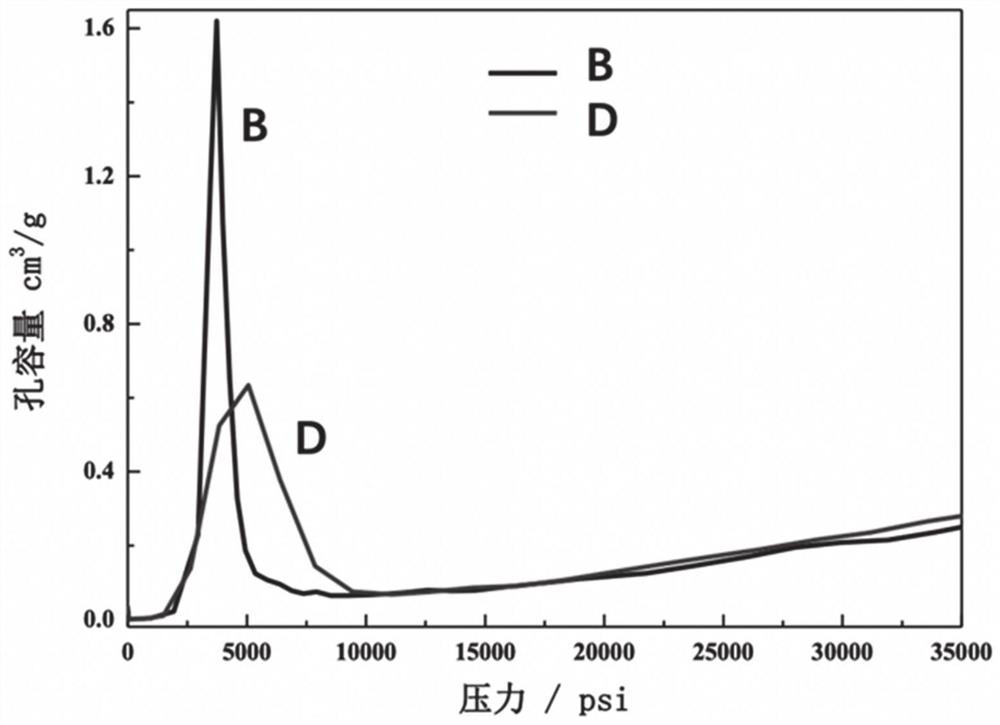

Embodiment 2

[0159] Example 1 was repeated, but the micron Hβ molecular sieve powder was replaced with nano Hβ molecular sieve powder to obtain a shaped catalyst sample D, whose mesopore and macropore volume in the total pore volume increased by 18.5% compared with that of sample B.

[0160] Wherein, the source of the nano Hβ molecular sieve powder described in this example refers to Comparative Example 2.

Embodiment 3

[0162] Repeat Example 1, change the addition amount of polyacrylonitrile-based activated carbon fibers, and change the mass percentage of polyacrylonitrile-based activated carbon fibers in the wet plastomer after kneading to 1%, 2%, 15% and 20%, and obtain samples in turn For E, F, G and H, the mesopore and macropore volumes in the total pore volume increased by 8.1%, 24.5%, 27.6% and 29.3%, respectively, compared with sample A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com