High-combination leather fatting agent and preparing method thereof

A kind of leather fatliquor and combination technology, which is applied in the field of high combination leather fatliquor and its preparation, can solve the problems of restricting the wide use of products, high proportion of unreacted monomers, poor product performance, etc., and achieve the combination ability Strong, environmentally friendly and economical production process, overcome the effect of acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a high-binding leather fatliquoring agent specifically comprises the following steps:

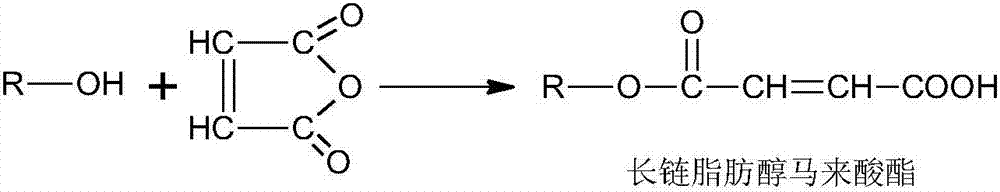

[0036] (1) Add 0.5 mol of dodecyl alcohol and 1 mol of maleic anhydride into the reactor, heat up to 90° C., perform esterification reaction for 2 hours, and obtain intermediate product A;

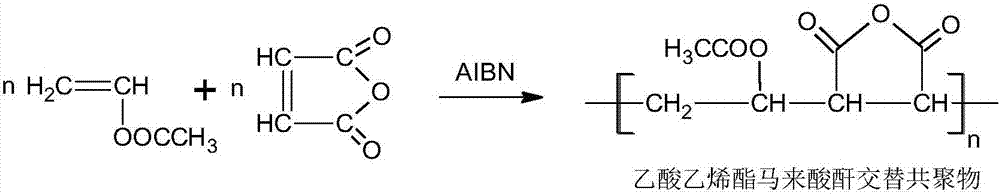

[0037] (2) The intermediate product A was cooled to 70°C, added 3.82g of azobisisobutyronitrile, and slowly added dropwise 0.5mol of vinyl acetate for 1.5-2.0h. After the dropwise addition, the temperature was raised to 80°C, and the reaction was kept for 2h. Obtain intermediate product B;

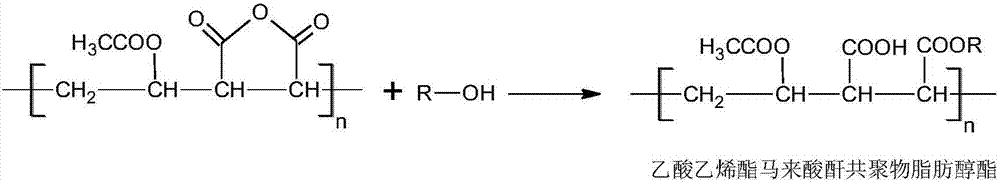

[0038] (3) Intermediate product B was heated to 100°C, 0.5 mol of dodecanol was added, and intermediate product C was obtained by reacting at 100°C for 2 hours.

[0039] (4) The intermediate product C was cooled to 65°C, and the pH was neutralized to 7.0 with 133g of a 30% aqueous sodium hydroxide solution, and then 173g of a 30% aqueous sodium bisulfite solution was added, and reacte...

Embodiment 2

[0041] A preparation method of a high-binding leather fatliquoring agent specifically comprises the following steps:

[0042] (1) Add 0.5 mol of cetyl alcohol and 1 mol of maleic anhydride into the reactor, raise the temperature to 90° C., perform esterification reaction for 2 hours, and obtain intermediate product A;

[0043] (2) The intermediate product A was cooled to 70°C, added 3.82g of azobisisobutyronitrile, and slowly added dropwise 0.5mol of vinyl acetate for 1.5-2.0h. After the dropwise addition, the temperature was raised to 80°C, and the reaction was kept for 2h. Obtain intermediate product B;

[0044] (3) Intermediate product B was heated to 100°C, 0.5 mol of cetyl alcohol was added, and reacted at 100°C for 2 hours to obtain intermediate product C.

[0045] (4) The intermediate product C was cooled to 65°C, and the pH was neutralized to 7.0 with 133g of a 30% aqueous sodium hydroxide solution, and then 173g of a 30% aqueous sodium bisulfite solution was added, a...

Embodiment 3

[0047] A preparation method of a high-binding leather fatliquoring agent specifically comprises the following steps:

[0048] (1) Add 0.5 mol of stearyl alcohol and 1 mol of maleic anhydride into the reactor, heat up to 90° C., perform esterification reaction for 2 hours, and obtain intermediate product A;

[0049] (2) The intermediate product A was cooled to 70°C, added 3.82g of azobisisobutyronitrile, and slowly added dropwise 0.5mol of vinyl acetate for 1.5-2.0h. After the dropwise addition, the temperature was raised to 80°C, and the reaction was kept for 2h. Obtain intermediate product B;

[0050] (3) Intermediate product B was heated to 100°C, 0.5 mol of octadecyl alcohol was added, and reacted at 100°C for 2 hours to obtain intermediate product C.

[0051] (4) The intermediate product C was cooled to 65°C, and the pH was neutralized to 7.0 with 133g of a 30% aqueous sodium hydroxide solution, and then 173g of a 30% aqueous sodium bisulfite solution was added, and react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com