Digital guniting decorative ceramic tile and production device and production method thereof

A production device and a technology of ceramic tiles, applied in the field of ceramics, can solve problems such as difficulty in pattern control of glazing process, serious homogeneity of products, and insufficient natural and rich patterns, etc., to achieve expansion of potential possibilities, economic and environmental protection, and process controllability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096] (a) Preparation of ceramic brick powder.

[0097] (b) Preparation of cosmetic soil slurry; the fineness of the cosmetic soil powder in the cosmetic soil slurry is 325 mesh standard sieve residue is 0.3-0.8%, and the specific gravity of the cosmetic soil slurry is 1.70-1.90g / cm³, The viscosity is 700-1000mPa·s.

[0098] (c) Preparation of basic slurry: the powder of the basic slurry includes the following components: SiO 2 : 62%~70%, Al 2 o 3 : 15%~21%, MgO+CaO: 1%~4%, K 2 O+Na 2 O: 5%~8%, ZnO: 0.5%~5%, TiO 2 : 0.1% ~ 3%, the balance is trace components and impurities; the fineness of the powder of the base slurry is 325 mesh standard sieve, the balance is within 0.5%, the specific gravity of the base slurry is 1.70 ~ 1.90g / cm³, and the viscosity is 700~1000mPa·s.

[0099] (d) Preparation of decorative paste: decorative paste includes various ceramic pastes for blanks and glazes, containing pigments, additives, etc. The fineness of the powder of the decorative pas...

Embodiment 1

[0132] Example 1 (Mobile digital spraying machine is located directly above the shower bell)

[0133] A digital shotcrete decorative ceramic tile, such as Figure 7 As shown, it includes: a base layer 100, a makeup soil layer 400 arranged on the upper surface of the base layer, a base glaze layer 500 arranged on the upper surface of the base layer; Decorative paste layer 200.

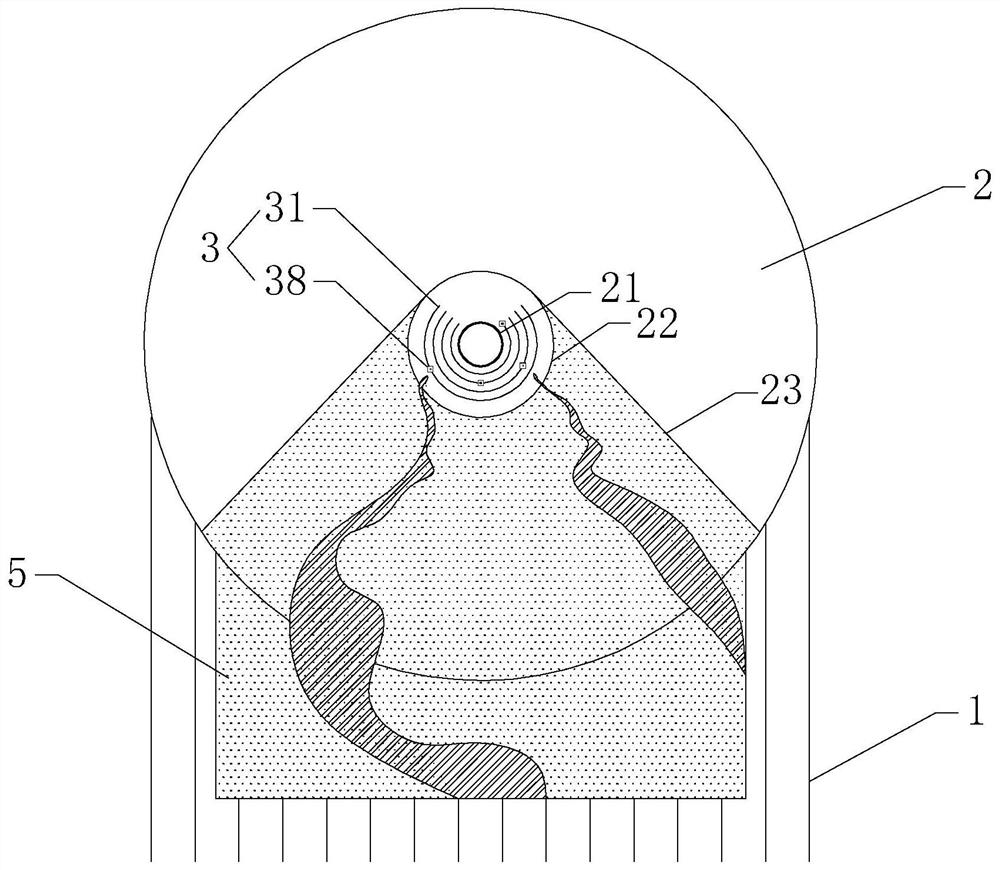

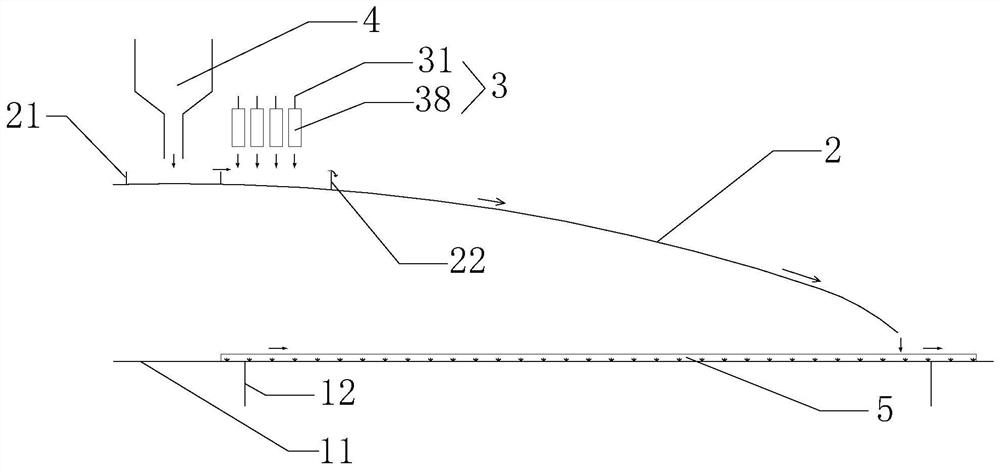

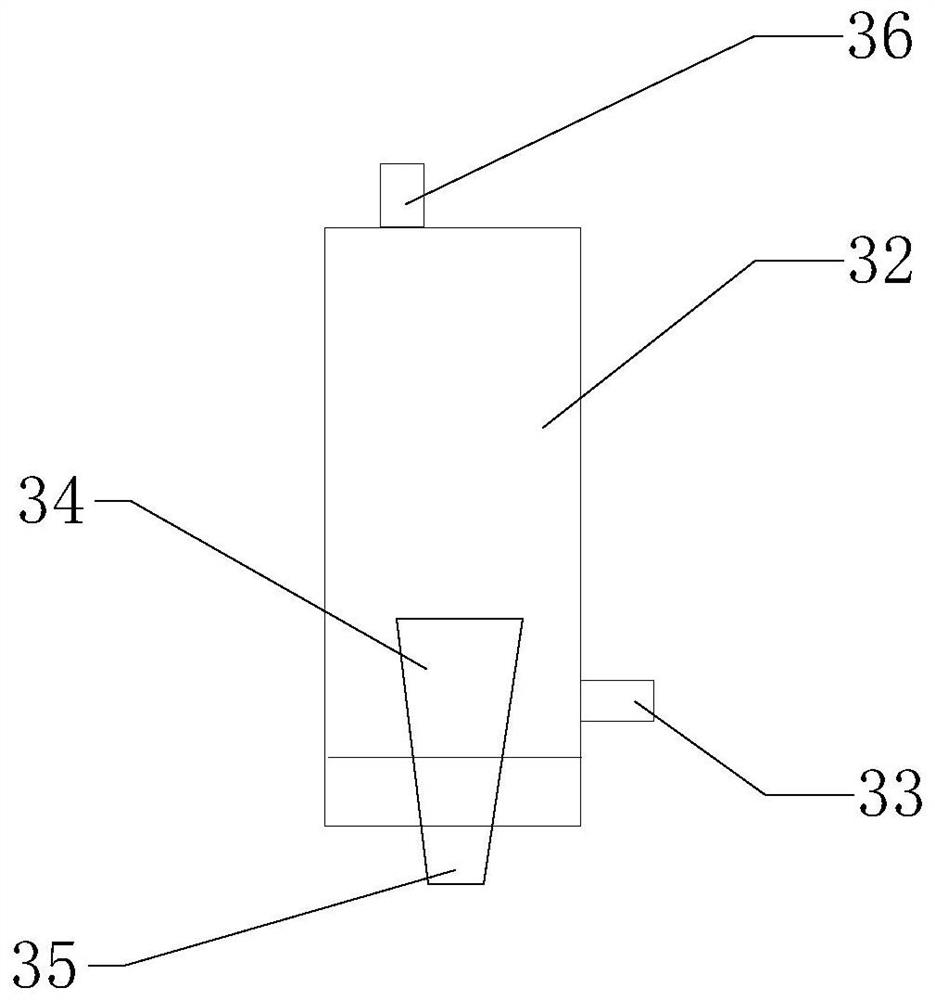

[0134] Such as Figure 1-2 and Figure 4 As shown, a production device for digital spraying decorative ceramic tiles includes: a ceramic brick conveying mechanism 1 , a shower bell 2 , a basic slurry applying mechanism 4 and a movable digital spraying mechanism 3 . specifically:

[0135] The ceramic tile conveying mechanism includes a conveying motor, a conveying belt 11 and a support 12; the conveying belt is arranged on the support, and the conveying motor is used to drive the conveying belt.

[0136] The upper surface of the shower bell is an arc surface, and the arc surface is provided with a b...

Embodiment 2

[0150] Example 2 (Mobile digital spraying machine is located upstream of the shower bell)

[0151] A digital shotcrete decorative ceramic tile, such as Figure 8 As shown, it includes: a base layer 100, a makeup soil layer 400 arranged on the upper surface of the base layer, an inkjet printing layer 300 arranged on the upper surface of the makeup soil layer, and a local inkjet printing layer arranged on the upper surface of the inkjet printing layer. The decorative paste layer 200 in the area; the basic glaze layer 500 provided on the upper surface of the inkjet printing layer and the decorative paste layer.

[0152] Different from Example 1, as Figure 5 As shown, in the production device of this embodiment, the movable digital spraying mechanism is located above the ceramic tile conveying mechanism and upstream of the shower bell, and the decorative paste is output by the movable digital spraying mechanism and applied on the surface of the ceramic tile. , and the basic slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com