A method for removing benzene group hydrocarbons in coke oven gas

A technology for coke oven gas and benzene hydrocarbons, which is applied in the fields of combustible gas purification, climate sustainability, combustible gas purification/reconstruction, etc. It can solve the problems of low solubility and absorption rate, only applicable, and high cost of cooling equipment heat exchangers , to achieve the effect of economical saving and reducing volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

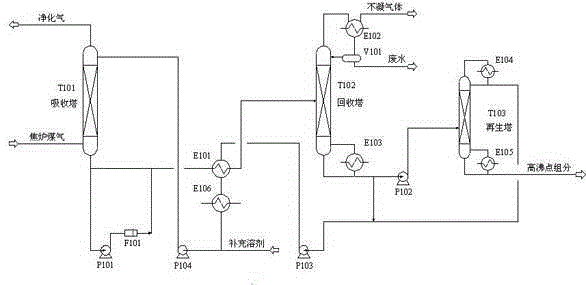

Method used

Image

Examples

Embodiment 1

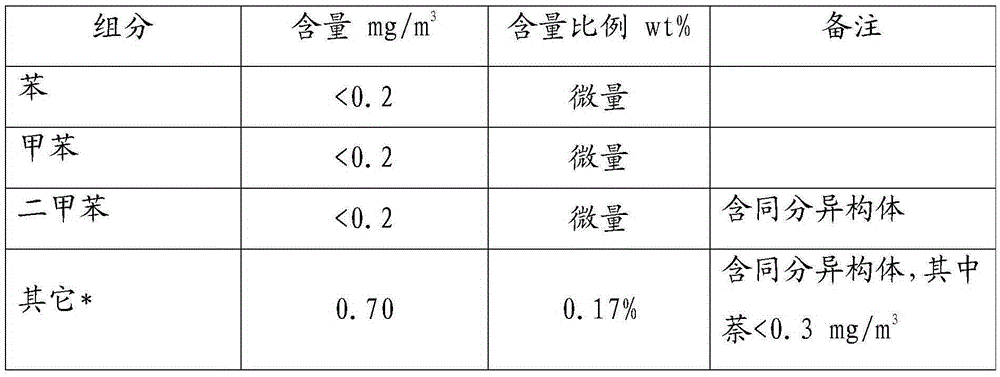

[0027] The coke oven gas in a factory still contains aromatic components after desulfurization, deammonification and other processes. According to the needs of the follow-up section, the aromatics should be removed to 3 , the main volume percentage components and impurity content of the feed gas are as follows:

[0028] CO 2 : 2%, CO: 8%, H 2 : 65%, CH 4 : 25%, water content 31g / Nm 3 , aromatics and others: 35g / m 3 . The main components of impurities such as aromatic hydrocarbons are as follows:

[0029] Table 1 Composition of impurities such as aromatics in raw gas

[0030] components

Content g / m 3

Content ratiowt%

Remark

benzene

24.395

69.7

5.915

16.9

1.575

4.5

Contains isomers

trimethylbenzene

0.735

2.1

Contains isomers

unsaturated aliphatic hydrocarbon

0.42

1.2

0.21

0.6

0.1...

Embodiment 2

[0043] The treatment gas source is the same as in Example 1, and the absorption solvent is a mixed solvent of 80wt% N-formylmorpholine + 20wt% N-acetylmorpholine, which also contains simethicone oil with a mass of 5ppm, and the gas to be treated enters the absorption tower The temperature is 30°C, and the pressure at the top of the tower is 0.15MPa, a. The content of aromatics in the liquid entering the absorption tower is less than 0.5%, without water.

[0044] After purification, the content of aromatics in the purified gas from the absorption tower is reduced to 5mg / m 3 Hereinafter, its main composition is the same as that of Example 1.

[0045] The operating temperature of the recovery column is about 202° C., the temperature at the top of the tower is 80° C., the pressure at the top of the tower is 0.04 MPa, and the reflux ratio is 2. Other conditions and results are the same as in Example 1.

[0046] The operating temperature of the regenerating tower kettle was 177° C...

Embodiment 3

[0048] The gas source is the same as in Example 1, and the absorption solvent is N-formylmorpholine and N-acetylmorpholine. Prepare a mixed solvent with a mass ratio of 1:1, and the mixed solvent also contains simethicone with a mass of 5ppm . The temperature of the gas to be treated entering the absorption tower is 30°C, and the pressure at the top of the tower is 0.12MPa, a. The content of aromatics in the liquid entering the absorption tower is less than 0.5%, and does not contain water. The working condition liquid-gas volume ratio is 1:530-580, and the rest of the conditions are the same as in Example 1.

[0049] The benzene content in the purified gas exiting the absorption tower after purification is 1.9mg / m 3 , toluene, xylene less than 0.2mg / m 3 , other aromatic components totaled 6.34g / m 3 .

[0050] The operating temperature of the recovery column is about 205° C., the temperature at the top of the tower is 80° C., the pressure at the top of the tower is 0.11 MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com