Method and special equipment for production of high-purity beta-methylnaphthalene by wash oil

A methyl naphthalene, high-purity technology, used in chemical instruments and methods, distillation purification/separation, hydrocarbon purification/separation, etc., can solve the problem of increasing investment and energy consumption, labor intensity of workers, increasing acid-base waste liquid, and difficulty in operation. major problems, to achieve the effect of saving equipment investment, reducing pickling wastewater, and reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

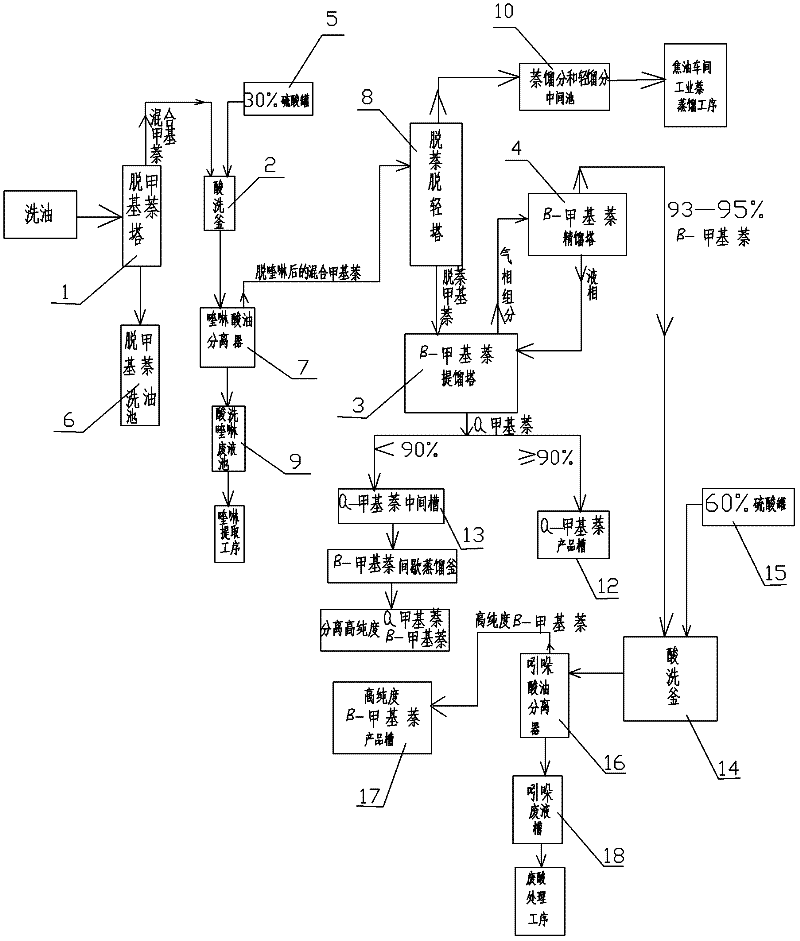

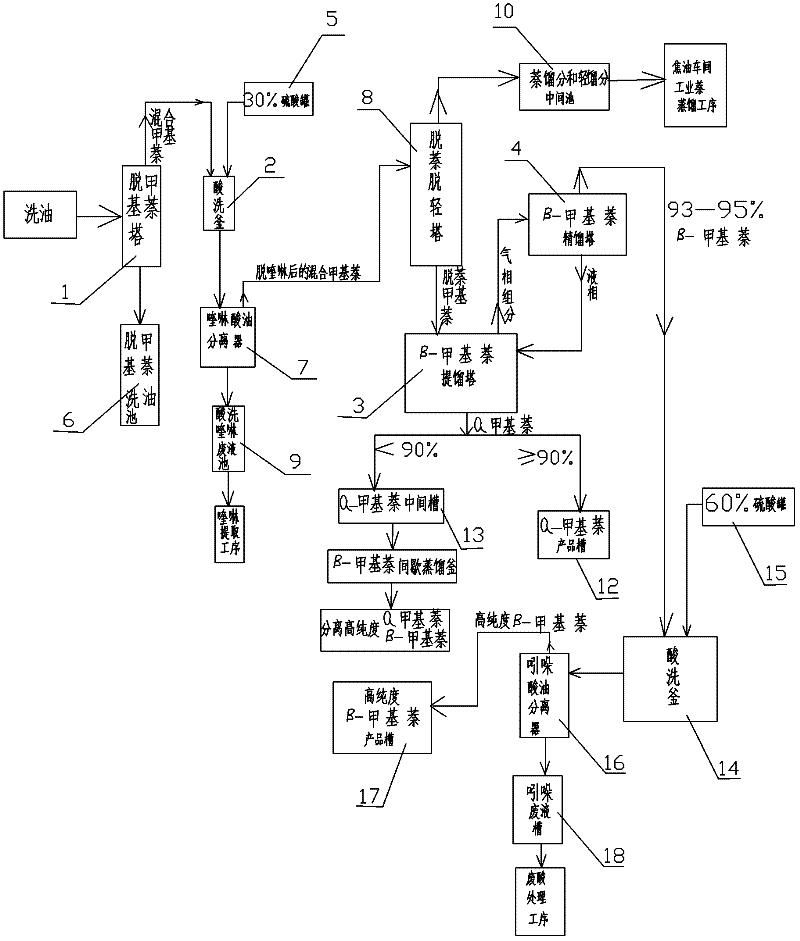

[0019] Reference figure 1 , On the basis of the company's original production process and equipment, carry out transformation and implementation. The method for producing high-purity β-methylnaphthalene from the washing oil is characterized in that the production steps are as follows:

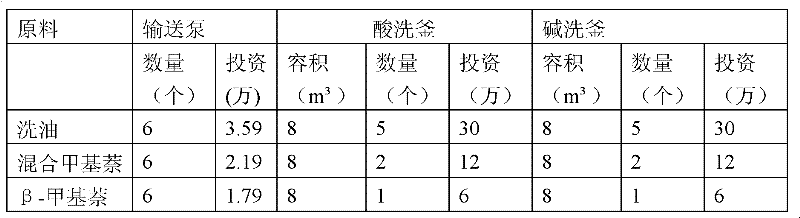

[0020] (1) One-step preparation of mixed methyl naphthalene from the washing oil: the washing oil is directly injected into the demethyl naphthalene tower, heated and distilled in the demethyl naphthalene tower, and the temperature at the top of the tower is controlled at 235-237℃. Produce mixed methyl naphthalene from the top of the tower, and produce demethyl naphthalene wash oil from the bottom of the tower;

[0021] (2) Use acid to elute the quinoline in methyl naphthalene: The mixed methyl naphthalene containing light components obtained in step (1) is placed in an acid washing tank with a stirrer, and the concentration is 30% sulfuric acid is used for pickling. The test shows that the mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com