Method and device for removing indole from beta-methylnaphthalene

A technology of methylnaphthalene and indole, which is applied in the field of removing indole from β-methylnaphthalene, can solve the problems of low product purity, not conforming to the concept, and not being available for export, and achieves simple equipment and process, improved energy consumption and low cost. Large, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

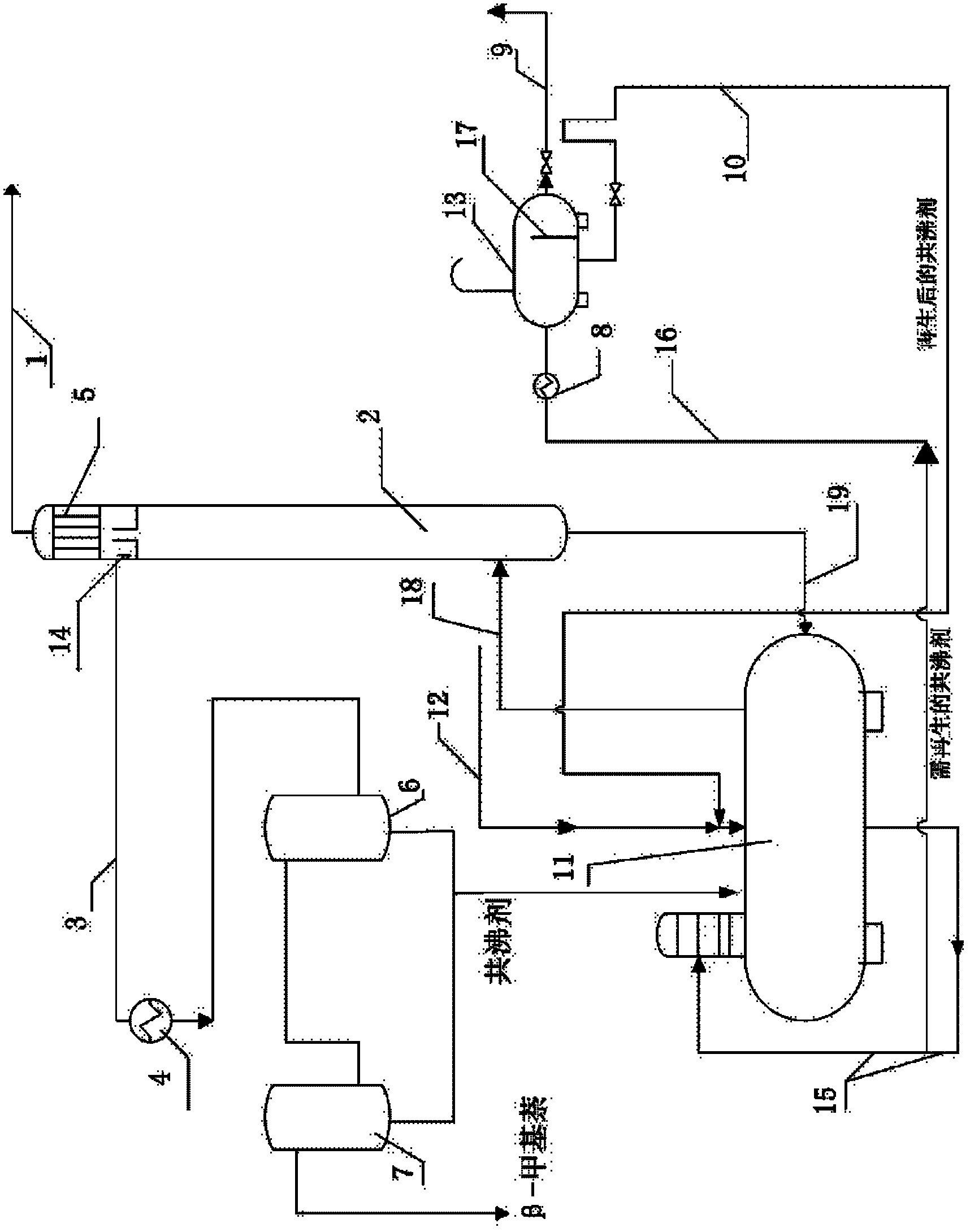

[0034] equipment such as figure 1 As shown, its structure comprises distillation still 11 and azeotropic distillation tower 2; Still kettle and the steam pipeline 18 of bottom of azeotropic distillation tower and the reflux liquid pipeline 19 of bottom form loop;

[0035]A top cooler 5 is installed on the top of the azeotropic distillation tower, and the top extraction pipeline 3 is connected to the azeotropic distillation tower through the top extraction outlet, and the top extraction outlet is below the top cooler, and an overflow extraction baffle is provided 14; The tower top production line 3 is connected to the cooler 4, the separation tank A 6 and the separation tank B 7 in sequence; the lower part of the separation tank A 6 is connected to the upper part of the separation tank B 7, and the tail gas discharge line 1 is arranged in the azeotropic distillation tower 2 the top to ensure the negative pressure of the azeotropic distillation column;

[0036] A still still re...

Embodiment 2

[0049] The device is the same as in Example 1.

[0050] The difference of raw material component has difference with embodiment 1, and in the raw material, beta-methyl naphthalene content is 96.23%, and indole content is 0.78%. The β-methylnaphthalene raw material and the entrainer are added in a ratio of 1:1.2, and the temperature and pressure control parameters of the tower body are the same. All the other method conditions and processing steps are basically the same as the above examples, the only difference is. The purity of the obtained product is 98.0%, the content of ethylene glycol is 0.10%, and the content of indole is not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com