Non-quinoline dispersant MF and production process

A production process and dispersant technology, applied in the field of quinoline-free dispersant MF configuration and production process, can solve problems affecting product quality, large equipment investment, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

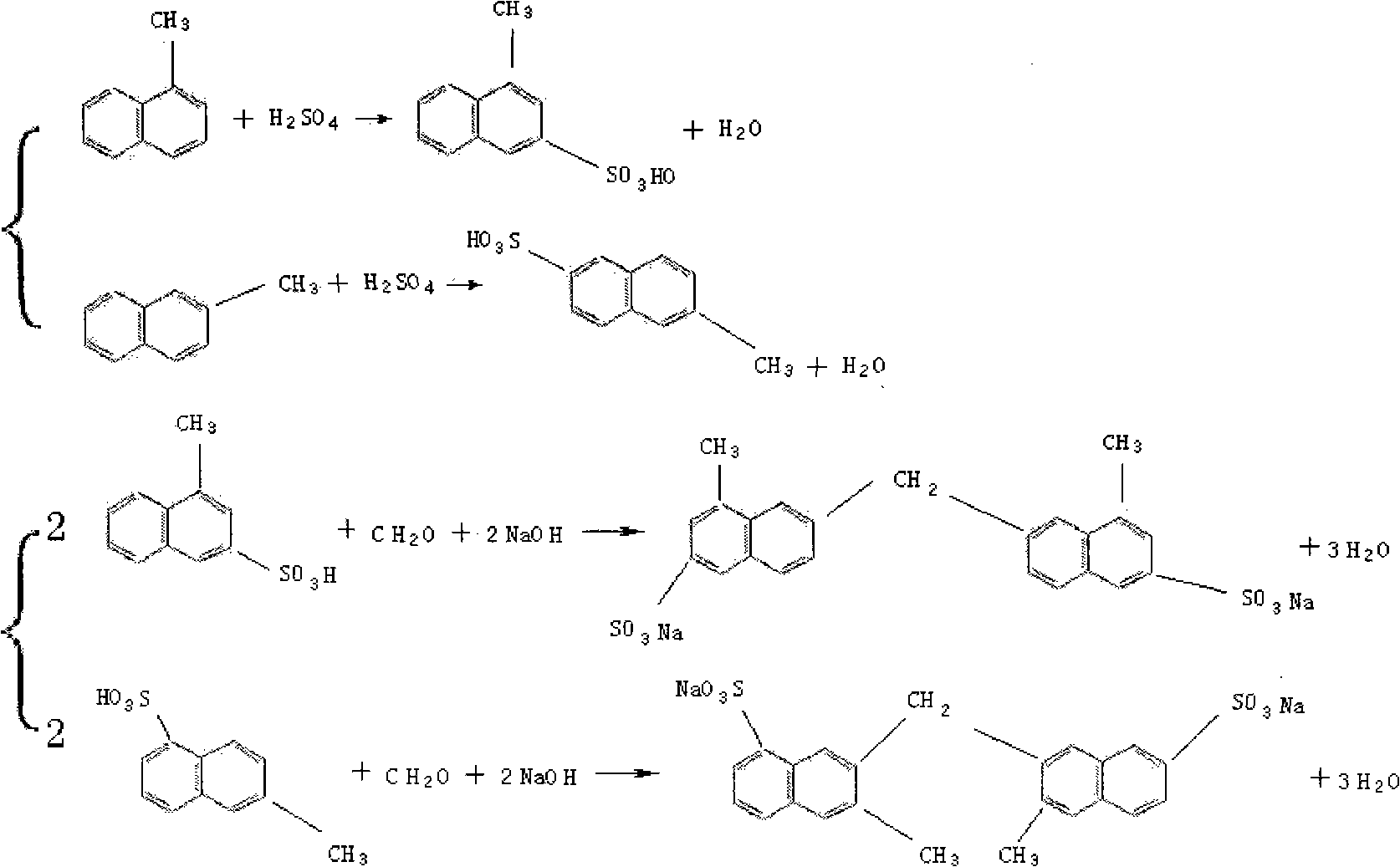

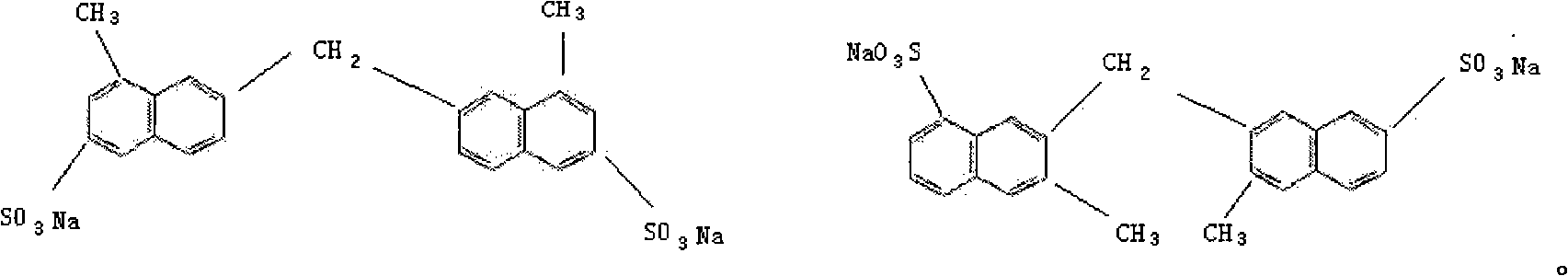

Method used

Image

Examples

Embodiment 1

[0034] A kind of production technique without quinoline dispersant MF, described production technique comprises the following processing steps:

[0035] The first step: put 560kg of hexadecylmethylnaphthalene into the reactor, and then heat the raw materials in the reactor to 50°C;

[0036] Second step: after the first step is completed, add 80kg of dilute sulfuric acid in the reactor, and stir for 1 hour, then separate the added dilute sulfuric acid slag to obtain refined hexadecyl methyl naphthalene;

[0037] The third step: heating up the refined hexadecylmethylnaphthalene to 110°C;

[0038] The 4th step: add 610kg in the reactor after the 3rd step is finished, the concentrated sulfuric acid that weight percentage concentration is 98%, then the temperature of raw material in the reactor is raised to 130 ℃, carry out sulfonation reaction under normal pressure, and Keep warm for about 4 hours;

[0039] The fifth step: After the fourth step is completed, the temperature of t...

Embodiment 2

[0052] A kind of production technique without quinoline dispersant MF, described production technique comprises the following processing steps:

[0053] The first step: put 560kg of hexadecylmethylnaphthalene into the reactor, and then heat the raw materials in the reactor to 60°C;

[0054] Second step: after the first step is completed, add 80kg of dilute sulfuric acid in the reactor, and stir for 1.5 hours, then separate the added dilute sulfuric acid slag to obtain refined hexadecyl methylnaphthalene;

[0055] The third step: heating up the refined hexadecylmethylnaphthalene to 120°C;

[0056] Step 4: After the completion of the third step, add 610 kg of sulfuric acid with a concentration of 98% by weight in the reactor, then raise the temperature of the raw materials in the reactor to 140°C, carry out the sulfonation reaction under normal pressure, and keep it warm about 4 hours;

[0057] The fifth step: After the fourth step is completed, the temperature of the raw materi...

Embodiment 3

[0070] A kind of production technique without quinoline dispersant MF, described production technique comprises the following processing steps:

[0071] The first step: put 560kg of hexadecylmethylnaphthalene into the reactor, and then heat the raw materials in the reactor to 55°C;

[0072] Second step: after the first step is completed, add 80kg of dilute sulfuric acid in the reactor, and stir for 1.5 hours, then separate the added dilute sulfuric acid slag to obtain refined hexadecyl methylnaphthalene;

[0073] The third step: heating up the refined hexadecylmethylnaphthalene to 115°C;

[0074] Step 4: After the completion of the third step, add 610 kg of sulfuric acid with a concentration of 98% by weight to the reactor, then raise the temperature of the raw materials in the reactor to 135°C, carry out sulfonation reaction under normal pressure, and keep it warm about 4 hours;

[0075] The fifth step: After the fourth step is completed, the temperature of the raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com