Method for simultaneously extracting high-purity beta-methylnaphthalene and indole from coal tar

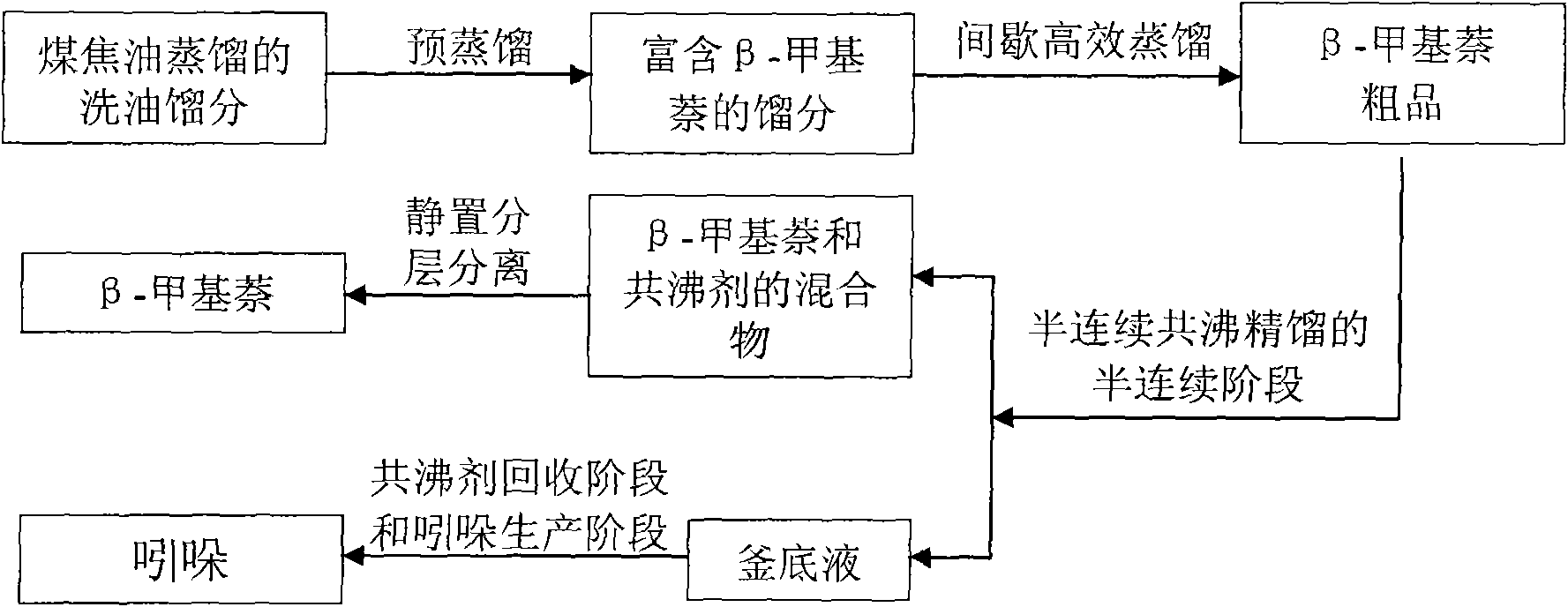

A technology of methylnaphthalene and coal tar, which is applied in the field of simultaneously extracting high-purity β-methylnaphthalene and indole, and extracting high-purity β-methylnaphthalene and indole, which can solve problems such as corrosion, polluted equipment, and single products , to achieve the effect of convenient and simple operation, complete separation and excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 300 tons of β-methyl naphthalene content of 35.24%, indole content of 4.12% of coal tar distillation wash oil fraction as raw material (DMNO-1) through pre-distillation (vacuum distillation column is a 60-layer plate Sieve tray tower, the pressure at the top of the tower is controlled at -66kPa, the cut-off temperature is 205-215°C, the reflux ratio is controlled at 8, and the recovery rate of the distillate rich in β-methylnaphthalene extracted from the upper side line is controlled at 36%) to obtain β - 155 tons of β-methylnaphthalene-rich fraction (DMNO-2) with a methylnaphthalene content of 76.67wt% and an indole content of 3.01wt%; Distillation in a high-efficiency stainless steel-packed batch distillation tower (the packing height of a high-efficiency stainless steel-packed batch distillation tower is equivalent to 110 layers of trays, the pressure at the top of the tower is controlled at -80Pa, the temperature in the effective production section is about 181°C, an...

Embodiment 2

[0043] The β-methylnaphthalene content is 38.07%, the indole content is 3.79% of the coal tar distillation wash oil fraction as raw material (DMNO-1) through pre-distillation (vacuum distillation column is a sieve plate with 100 layers tower, the pressure at the top of the tower is -20kPa, the cut-off temperature is 215-225°C, the reflux ratio is 12, and the recovery rate of the fraction rich in β-methylnaphthalene from the upper side stream is 50%) to obtain β-methylnaphthalene β-methylnaphthalene-rich fraction (DMNO-2) with a content of 77.8% and an indole content of 2.39%, the yield of β-methylnaphthalene was 70.5%; the fraction rich in β-methylnaphthalene ( DMNO-2) in the high-efficiency stainless steel packed batch distillation tower (the packing height of the high-efficiency stainless steel packed batch rectification tower is equivalent to 100 layers of trays, the top pressure of the tower is -20kPa, the temperature of the effective production section is about 195°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com