Separation purification process for 2-methylnaphthalene

A technology for separation and purification of methylnaphthalene, applied in the field of separation and purification of 2-methylnaphthalene, which can solve problems such as difficult acquisition of starting materials, difficulty in separation, and increased investment in equipment

Inactive Publication Date: 2008-10-29

EAST CHINA UNIV OF SCI & TECH +1

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of this method is that (1) the starting material is difficult to obtain, (2) when the temperature of the operating environment is high, it is quite difficult to separate the 2-methylnaphthalene crystal from the mother liquor, and it is necessary to reclaim the alcohol simultaneously Also increase investment in equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

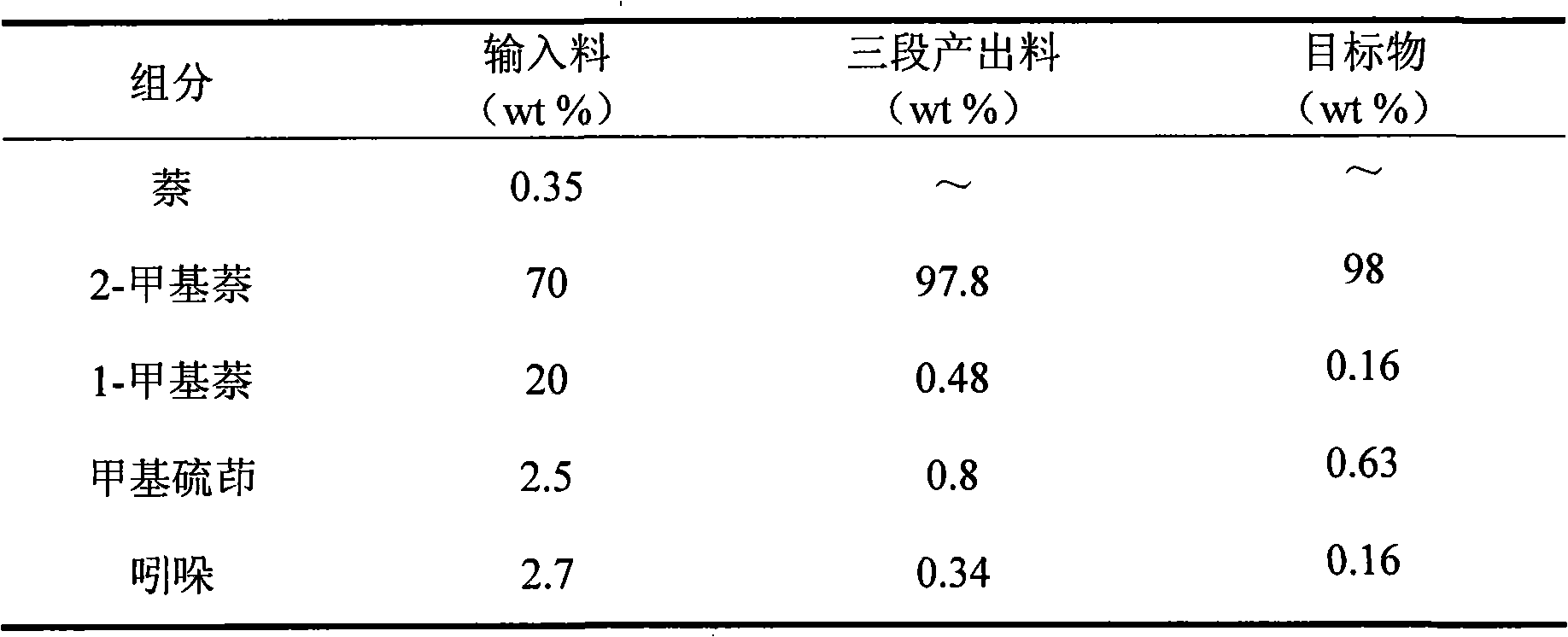

The invention relates to a method for separating and purifying 2-methylnaphthalene (Beta-methylnaphthalene). The method comprises the main steps: 70 wt% of 2-methylnaphthalene fraction is used as original material, and is subjected to fused crystallization at 34 DEG C to -15 DEG C for at least four times to obtain a target product. The method has the advantages of easily-accessible material, simple operation, low energy consumption, environment friendliness, etc.

Description

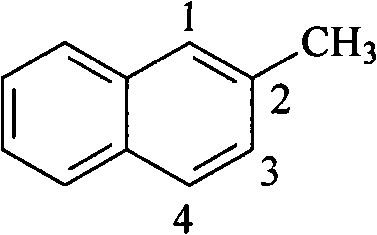

Separation and purification method of 2-methylnaphthalene Technical field The invention relates to a method for separating and purifying 2-methylnaphthalene (also known as β-methylnaphthalene), in particular to a washing oil fraction from coal tar (the content of 2-methylnaphthalene is about 70% by weight) The method for separating and purifying 2-methylnaphthalene. Background technique 2-Methylnaphthalene (β-methylnaphthalene) is an important chemical raw material and intermediate. For example, 2-methylnaphthalene can be used to prepare 2,6-naphthalenedicarboxylic acid (the carboxylic acid is a key component in the production of high-temperature polymers); it is used to synthesize vitamins K1, K3 and K4. In addition, 2-methylnaphthalene can also be used in the production of spices and other fine chemicals. Therefore, its commercial preparation has attracted much attention from chemists. US 3,219,719 discloses a method for isomerizing and purifying 2-methylnaphthalene. Under th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C15/24C07C7/14

Inventor 沈永嘉魏玲张妤朱建明戎大明

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com