Process for purifying feedstocks of carbon black

A technology of tar and crude coal, which is applied in the field of refining carbon black raw material oil, can solve the problems of environmental safety hazards, increase operating costs, increase the amount of extraction solvent, etc., and achieve the effect of low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

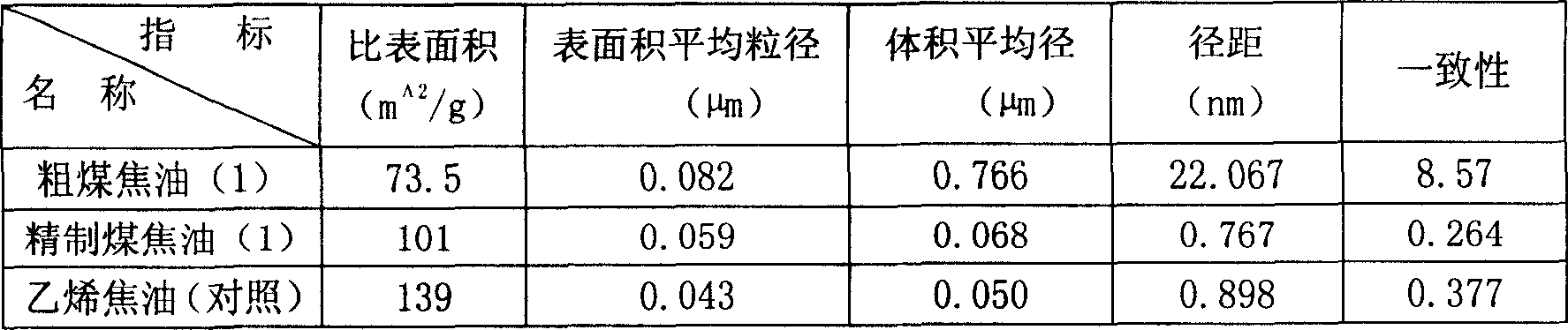

[0021] The crude coal tar (1) provided by a factory (see Table 1 for its main physical parameters) and the positive solvent composed of 50wt% benzene, 20wt% toluene and 30wt% α-methylnaphthalene are placed in the container, and the crude coal tar (1) The weight ratio with the forward solvent is 1: 0.2. After 0.5 hours, add 20wt% ethanolamine, 50wt% acetone, 20wt% isopropanol and 10wt to the above-mentioned crude coal tar (1) and the forward solvent mixed solution The reverse solvent composed of % styrene, the weight ratio of crude coal tar (1) to the reverse solvent is 1:0.05. Keep the temperature at 30°C and the pressure at 0.1Mpa for 0.5 hours, and obtain refined coal tar (1) after solid-liquid separation. Refined coal tar (1) was analyzed by laser particle size scattering, and the results are shown in Table 2.

[0022] Carbon black oil (crude coal tar)

(1)

(2)

relative density d 50 / 4

1.16

1.16

Asphalt wt%

6.7...

Embodiment 2

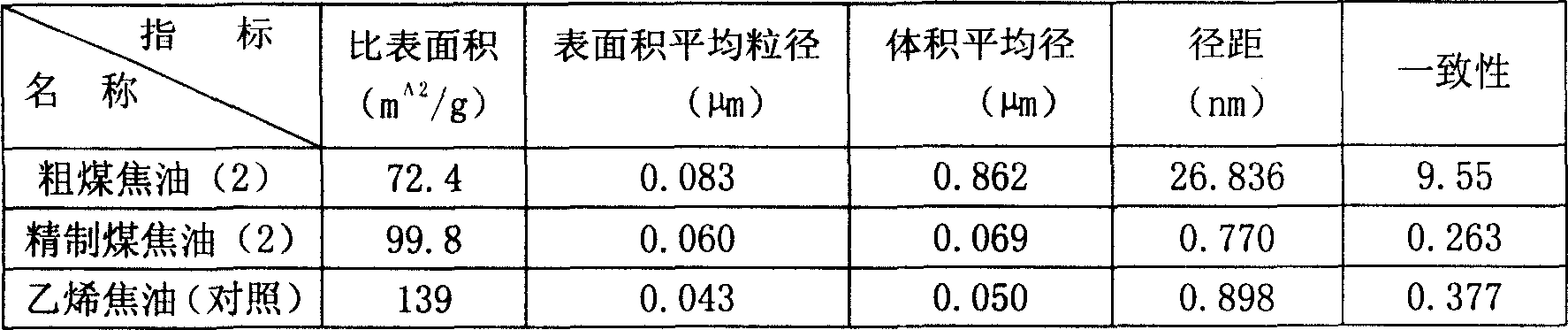

[0026] The crude coal tar (2) provided by a factory (see Table 1 for its main physical parameters) and the positive solvent composed of 30wt% benzene, 50wt% toluene and 20wt% β-methylnaphthalene are placed in the container, and the crude coal tar (2) The weight ratio with the forward solvent is 1: 2. Add 15wt% ethanolamine, 50wt% acetone, 15wt% isopropanol and 20wt% ethanolamine to the above-mentioned crude coal tar (2) and forward solvent mixed solution after 1 hour The reverse solvent composed of % styrene, the weight ratio of crude coal tar (2) to the reverse solvent is 1:0.5. Keep the temperature at 50°C and the pressure at 0.2Mpa for 2 hours, and obtain refined coal tar (2) after solid-liquid separation. Refined coal tar (2) was analyzed by laser particle size scattering, and the results are shown in Table 3.

[0027] Table 3. Comparison of main quality indicators of crude coal tar (2) before and after refining and with ethylene tar

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com