Green circular economy technology with coal coking as the main part

A coal coking and process technology, applied in the field of green circular economy process, can solve the problems of corroded equipment, complex components, equipment scaling and blockage, etc., and achieve the effect of reducing the degree of corrosion, significantly reducing consumption, and improving calorific value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

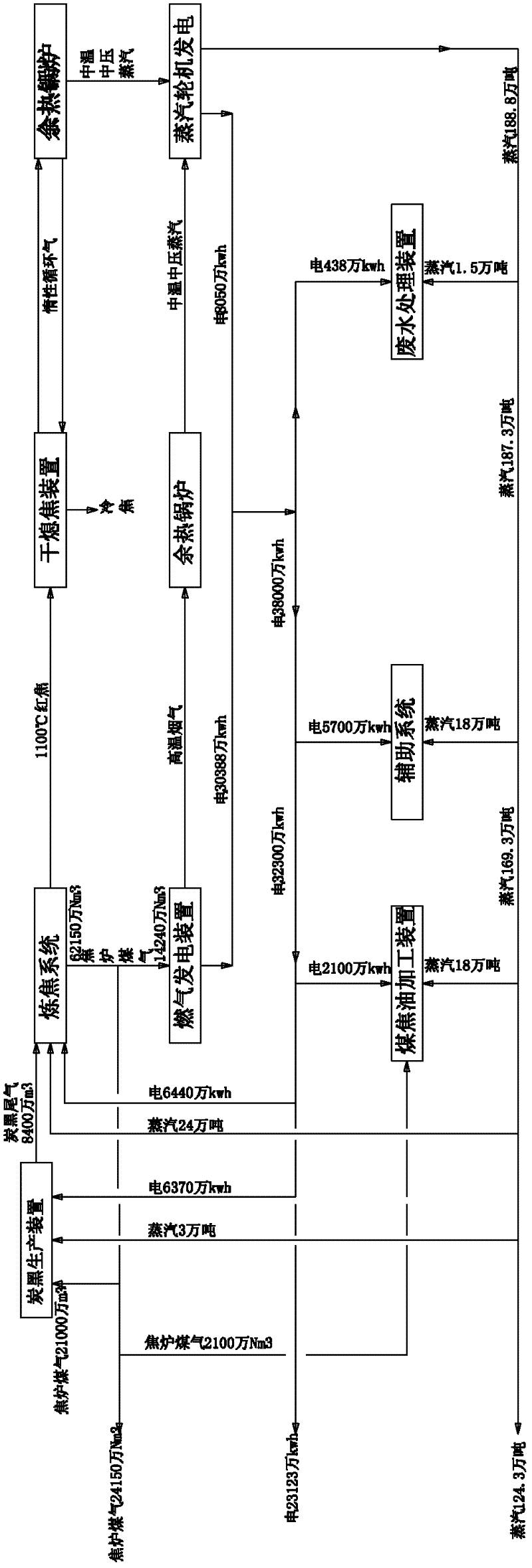

[0073] Equipment supporting form: 2.3 million tons / year coal coking unit (with 300 tons / hour CDQ unit) + 300,000 tons coal tar processing unit + 300,000 tons carbon black unit + 40MW gas power generation cogeneration unit + sewage treatment Device + Auxiliary System.

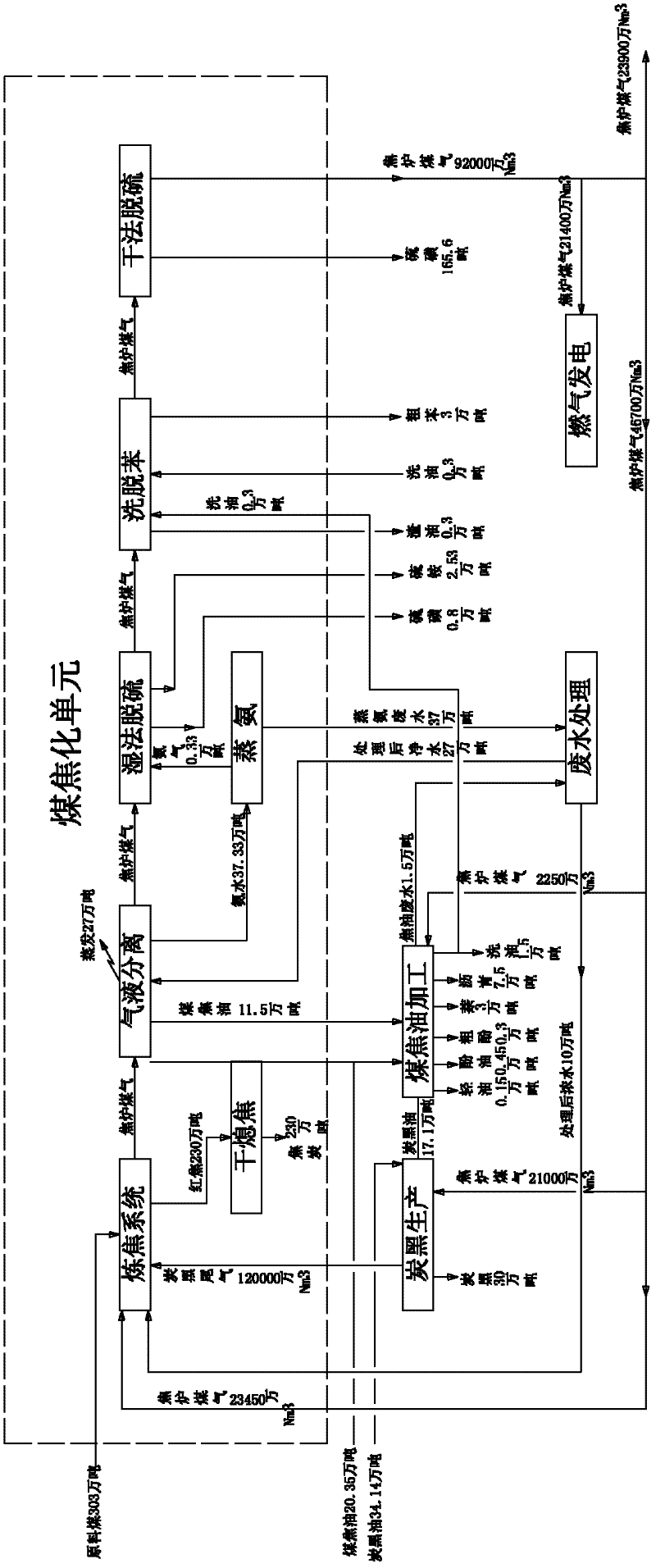

[0074] See figure 1 As shown, the green circular economy process with coal coking as the main body in this embodiment is mainly provided with a coal coking unit (including a CDQ process), a coal tar processing unit, a carbon black unit, a gas-fired power generation cogeneration unit, etc.; mainly include:

[0075] In the coal coking unit, a reheated coke oven is used, and the coking coal is used as the raw material, and the coking coal is loaded into the coke oven carbonization chamber, and is isolated by coke oven gas, dehydrated carbon black tail gas and high-pressure atomized mixed waste oil. The air is heated for dry distillation, so that the volatile crude coke oven gas overflows and is collected and proc...

Embodiment 2

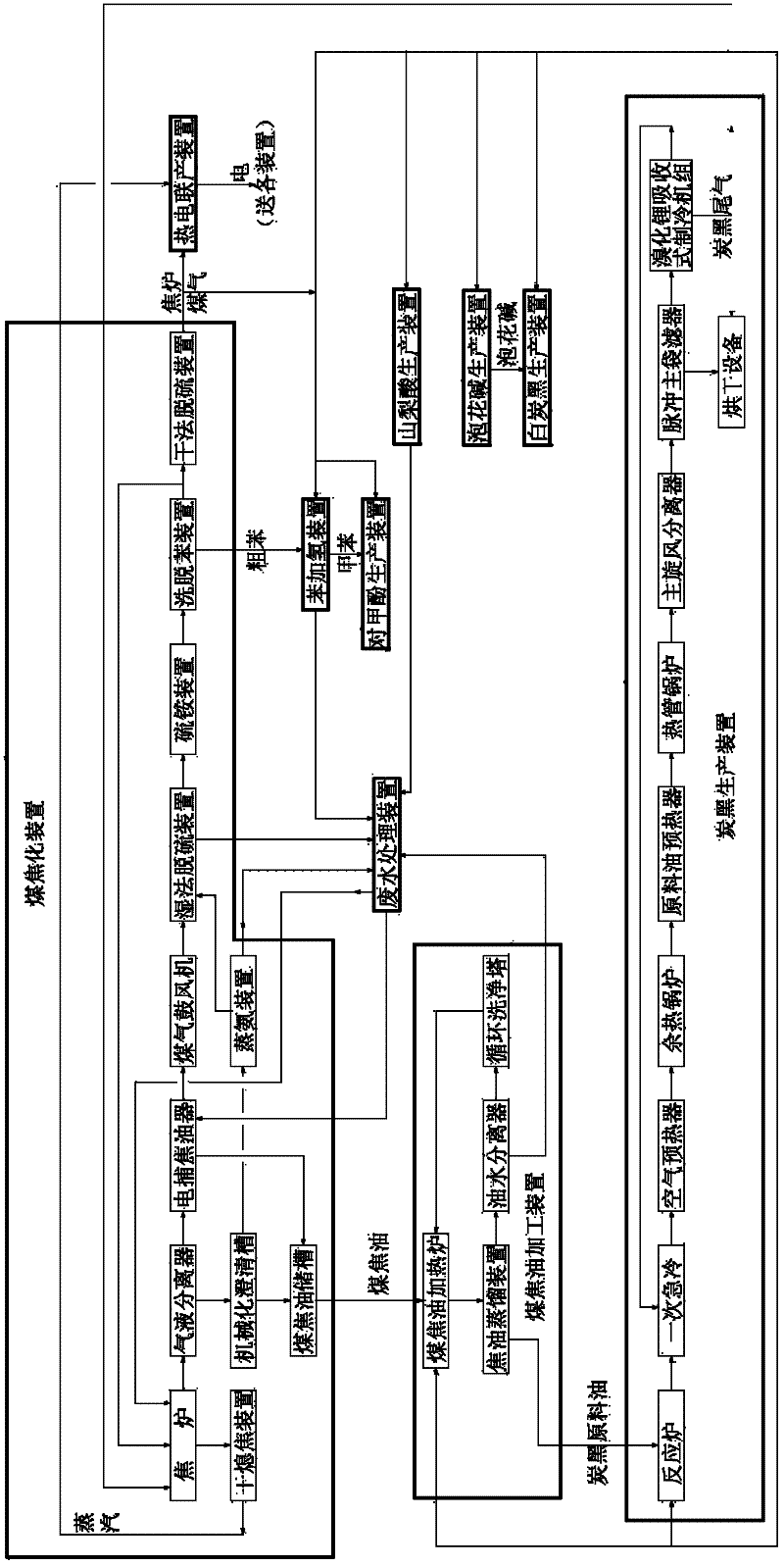

[0106]Process combination: 2.3 million tons / year coal coking unit (with 300 tons / hour CDQ unit) + 300,000 tons / year tar processing unit + 210,000 tons / year carbon black unit + 300,000 tons / year bubble flower Alkali unit + 200,000 tons / year silica unit + 100,000 tons / year benzene hydrogenation unit + 30,000 tons / year p-cresol unit + 25,000 tons / year sorbic acid unit + 29MW gas-fired cogeneration unit+ Sewage treatment plant + auxiliary system

[0107] See image 3 , Figure 4 , Figure 5 As shown, the green circular economy process with coal coking as the main body in this embodiment is mainly provided with a coal coking unit, a coke dry quenching unit, a carbon black unit, a gas-fired power generation cogeneration unit, a tar processing unit, a benzene hydrogenation unit, a Cresol unit, sorbic acid unit, Paohua alkali and silica unit, etc.;

[0108] The device for realizing the green circular economy process with coal coking as the main body in this embodiment includes:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com