A solvent for preparing high-quality coal-based needle coke, its preparation method and its application

A needle coke and solvent technology, applied in coking ovens, coking carbonaceous materials, tar processing through distillation, etc., can solve the problem of coal-based needle coke raw materials with low QS-TI and QI content, coal-based needle coke raw materials Problems such as high QI content and high production cost of coal-based needle coke achieve the effects of environmental protection, easy separation, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

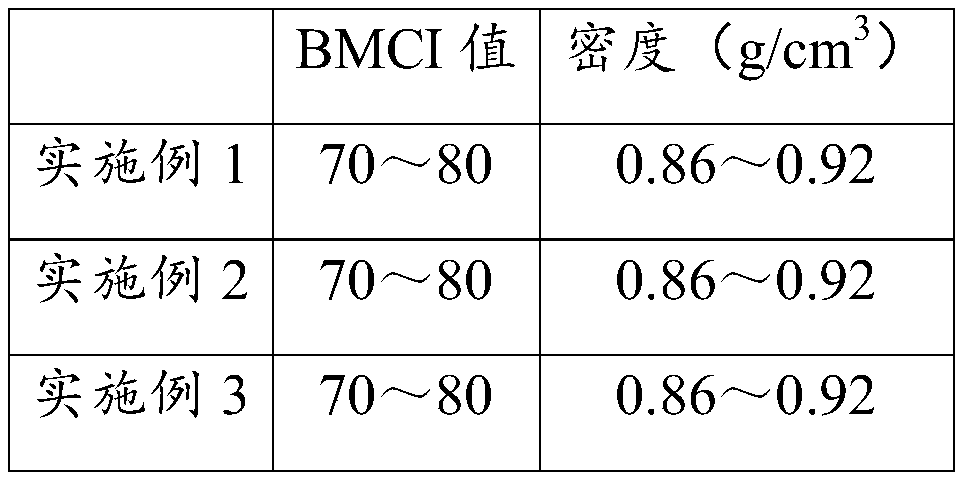

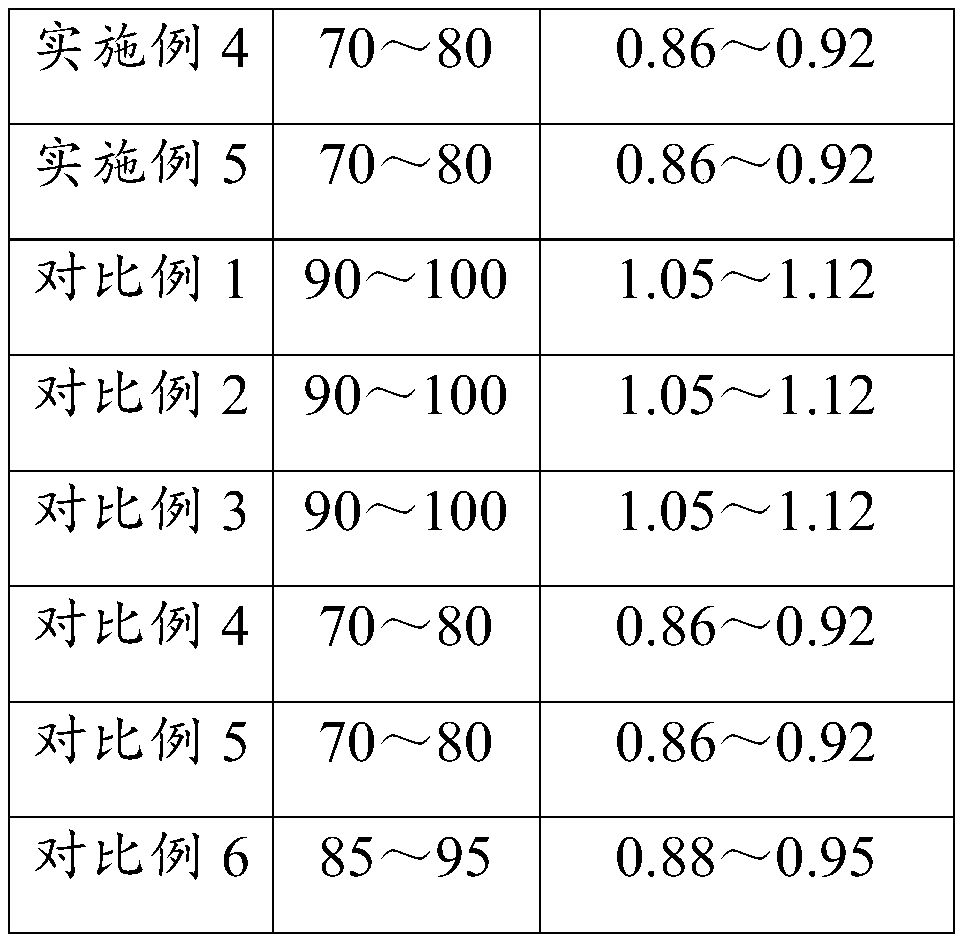

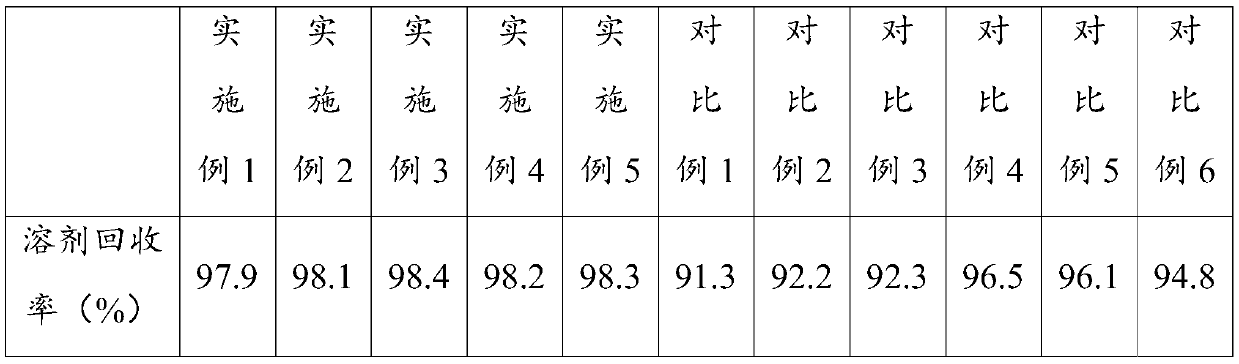

Embodiment 1

[0028] Mix medium and low temperature coal tar and coker oil gas, preheat it and send it to the first fractionation tower, and fractionate to obtain the top oil gas, the first line distillate (150-270°C), the second line distillate (270-360°C) ℃), coal tar pitch, and collect the distillate oil of the first measuring line to obtain the aromatic solvent. Mix the oil gas at the top of the first fractionation tower with the second line distillate (270-360°C), preheat and send it to the hydrogenation reactor, set the temperature at 320°C, and the pressure at 14MPa. The mixture of oil gas and second line distillate oil is subjected to hydrotreating, and the product obtained after hydrotreating is sent to the second fractionating tower, and the distillate oil at 130-310°C obtained by fractional distillation is an aliphatic solvent. The above-mentioned aromatic solvent and aliphatic solvent are mixed online according to a mass ratio of 7:3 to obtain a solvent for preparing coal-based ...

Embodiment 2

[0031]Mix medium and low temperature coal tar and coker oil gas, preheat it and send it to the first fractionation tower, and fractionate to obtain the top oil gas, the first line distillate (150-270°C), the second line distillate (270-360°C) ℃), coal tar pitch, and collect the distillate oil of the first measuring line to obtain the aromatic solvent. Mix the oil gas at the top of the first fractionation tower with the second line distillate (270-360°C), preheat and send it to the hydrogenation reactor, set the temperature at 250°C, and the pressure at 15MPa. The mixture of oil gas and second line distillate oil is subjected to hydrotreating, and the product obtained after hydrotreating is sent to the second fractionating tower, and the distillate oil at 130-310°C obtained by fractional distillation is an aliphatic solvent. The above-mentioned aromatic solvent and aliphatic solvent are mixed online according to a mass ratio of 6:4 to obtain a solvent for preparing coal-based n...

Embodiment 3

[0034] Mix medium and low temperature coal tar and coker oil gas, preheat it and send it to the first fractionation tower, and fractionate to obtain the top oil gas, the first line distillate (150-270°C), the second line distillate (270-360°C) ℃), coal tar pitch, and collect the distillate oil of the first measuring line to obtain the aromatic solvent. Mix the oil gas at the top of the first fractionation tower with the second line distillate (270-360°C), preheat and send it to the hydrogenation reactor, set the temperature at 390°C, and the pressure at 12MPa. The mixture of oil gas and second line distillate oil is subjected to hydrotreating, and the product obtained after hydrotreating is sent to the second fractionating tower, and the distillate oil at 130-310°C obtained by fractional distillation is an aliphatic solvent. Stir and mix the above aromatic solvent and aliphatic solvent in a tank at a mass ratio of 5:5 to obtain a solvent for preparing coal-based needle coke. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com