Nanofiber 3D porous aerogel and preparation method and application thereof

A technology of porous airgel and nanofibers, which can be used in pharmaceutical formulations, prostheses, and drug delivery. It can solve problems such as accelerated cell growth and unstable electrical activity, and achieve accelerated cell growth, easy processing, and easy access. The effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

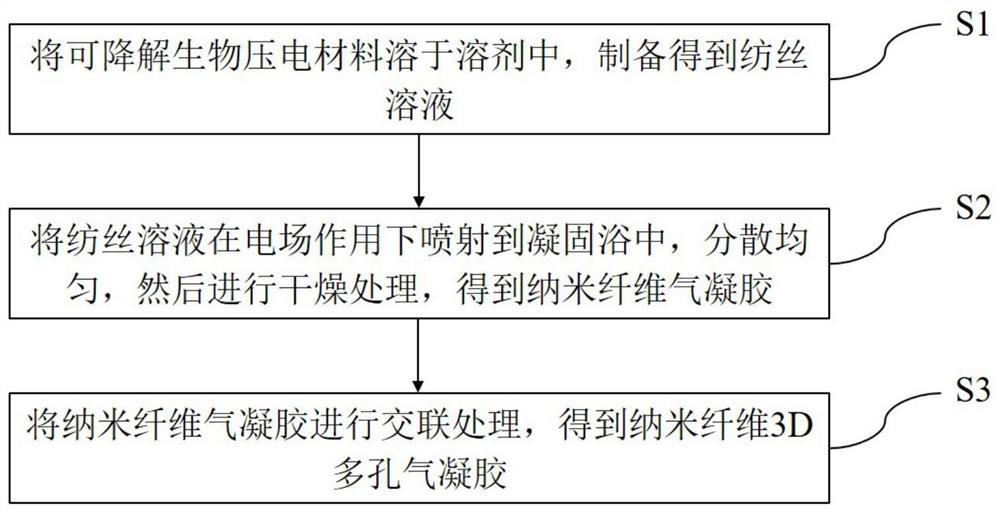

[0027] Such as figure 1 Shown, the preparation method of a kind of nanofiber 3D porous airgel provided by the present invention, it comprises the steps:

[0028] S1. Using degradable bio-piezoelectric materials as raw materials, dissolving them in a benign solvent to prepare a homogeneous spinning solution;

[0029] S2, spray the spinning solution obtained in step S1 into the coagulation bath under the action of an electric field, the degradable bio-piezoelectric material in the spinning solution is insoluble in the coagulation bath, and the coagulation bath and the benign solvent in the spinning solution are more miscible Strong, extract the benign solvent in the spinning solution to form a two-phase structure with the degradable bio-piezoelectric material as the continuous phase and the solvent as the dispersed phase, disperse evenly, and then dry to obtain nanofiber airgel;

[0030] S3, subjecting the nanofiber airgel obtained in step S2 to cross-linking treatment to gener...

Embodiment 1

[0040] 1. Dissolve PHB and chitosan by ultrasonic dispersion in isopropanol solution to prepare 8% (m / v) spinning solution, transfer the spinning solution to a 10mL syringe, the ambient temperature is 25°C ± 3°C, and the humidity is 50%±5%, the spinning voltage is 15kV, the spinning speed is 8mL / min, and the receiving distance is 15cm for spinning, and the coagulation bath adopts tert-butanol:water (v / v)=1:1 to collect nano fiber.

[0041] 2. Transfer the collected nanofibers to a beaker, and ultrasonically disperse them in an ice bath for 1 hour.

[0042] 3. The nanofiber mixture obtained by ultrasonic dispersion was frozen with liquid nitrogen, put into a freeze dryer, and freeze-dried for 48 hours to prepare a 3D porous airgel.

[0043] 4. The aerogel soaked with 1% genipin was cross-linked for 2 hours at 50° C. to obtain a nanofiber 3D porous aerogel.

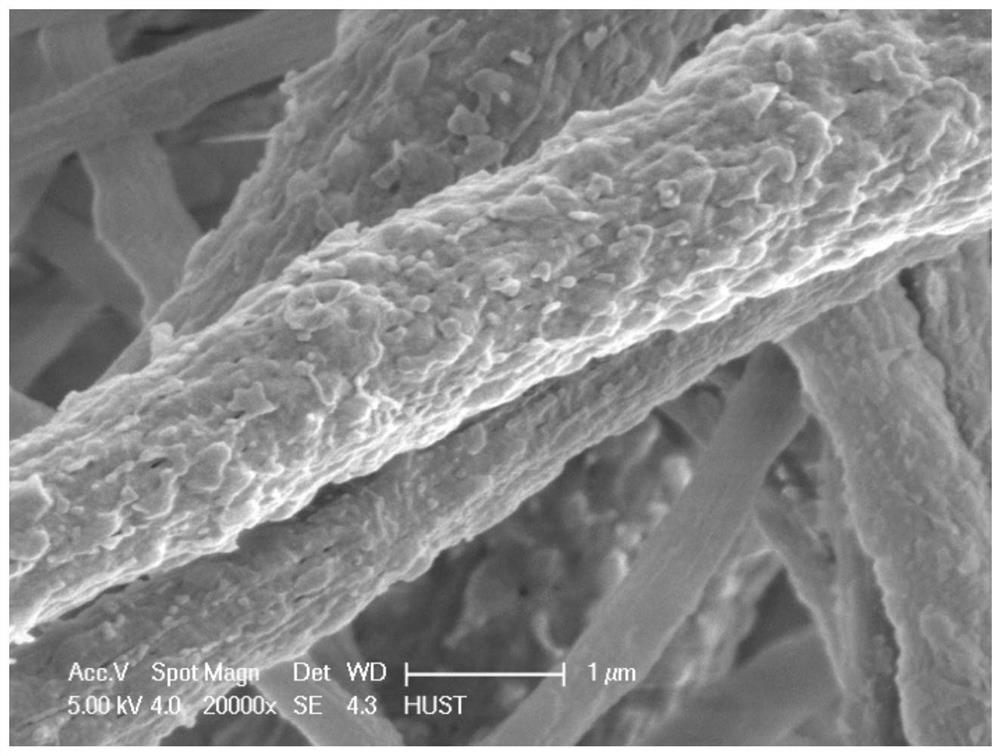

[0044] In this embodiment, PHB and chitosan are used as biodegradable piezoelectric materials, which have excellent bio...

Embodiment 2

[0047] 1. Dissolve PHB and chitosan ultrasonically in isopropanol solution to prepare a 10% (m / v) spinning solution, transfer the spinning solution to a 10mL syringe, the ambient temperature is 25°C ± 3°C, and the humidity is 50%±5%, the spinning voltage is 15kV, the spinning speed is 6mL / min, and the receiving distance is 15cm for spinning, and the coagulation bath adopts tert-butanol:water (v / v)=1:1 to collect nano fiber.

[0048] 2. Transfer the collected nanofibers to a beaker, and ultrasonically disperse them in an ice bath for 1 hour.

[0049] 3. The nanofiber mixture obtained by ultrasonic dispersion was frozen with liquid nitrogen, put into a freeze dryer, and freeze-dried for 48 hours to prepare a 3D porous airgel.

[0050] 4. The aerogel soaked with 1% genipin was cross-linked for 2 hours at 30° C. to obtain a nanofiber 3D porous aerogel.

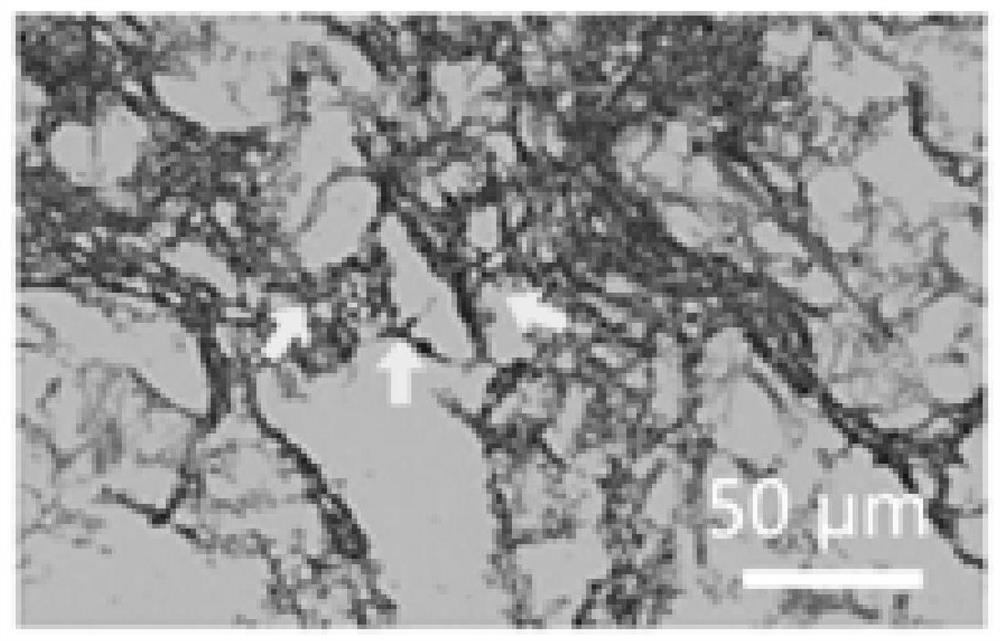

[0051] The airgel prepared in this example has a 3D structure of nanofibers, and the fibers are interlaced to form a porous ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com