Automatic fiber arranging device

A sorting device and fiber technology, which is applied to the parts and components of the strapping machine, can solve the problems of not being able to carry out tight strapping in time, easy to loose during storage, etc., and achieve stability, high efficiency, strong continuity, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

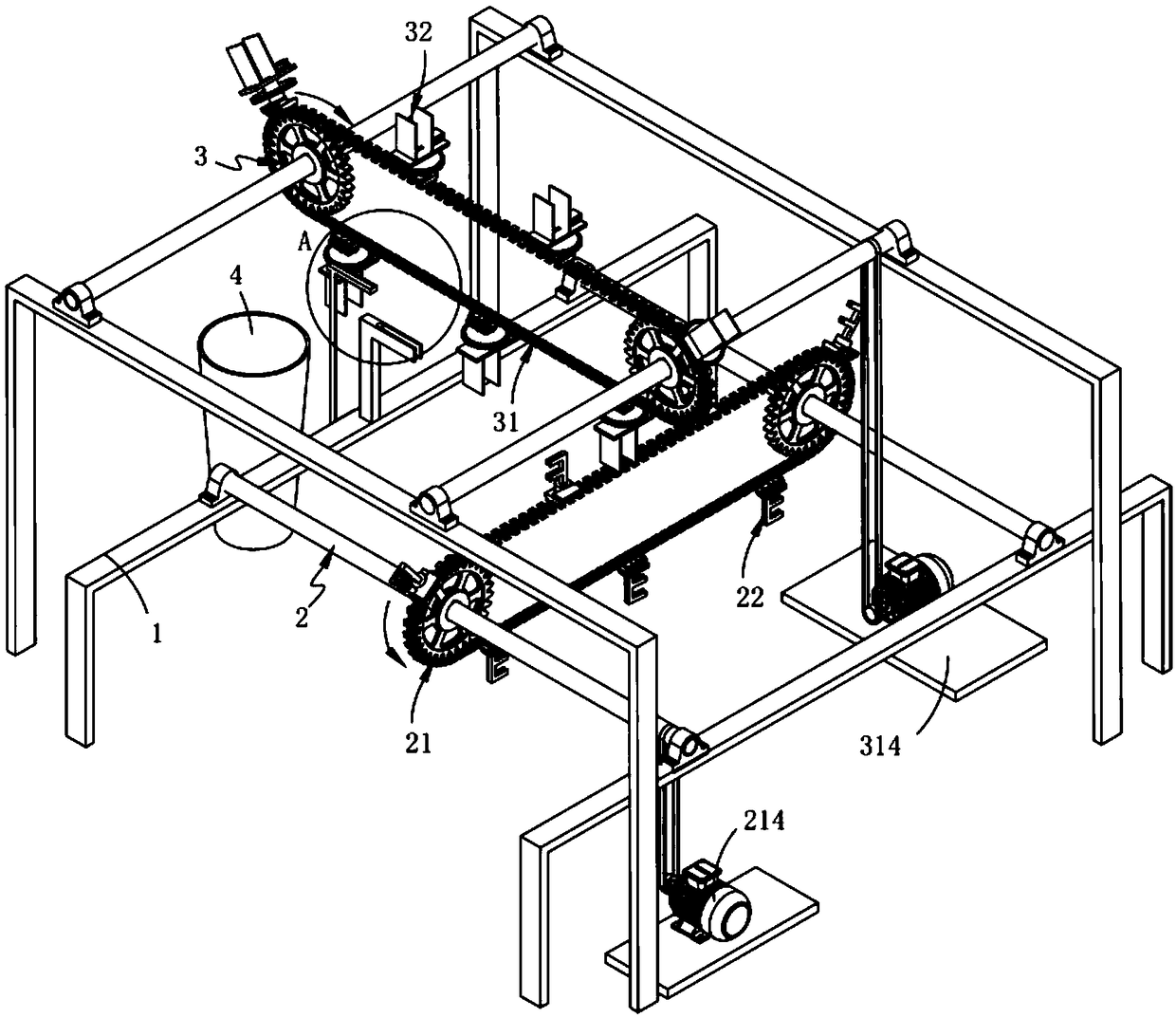

[0062] Such as figure 1 Shown, a kind of automatic fiber finishing device comprises:

[0063] Rack 1;

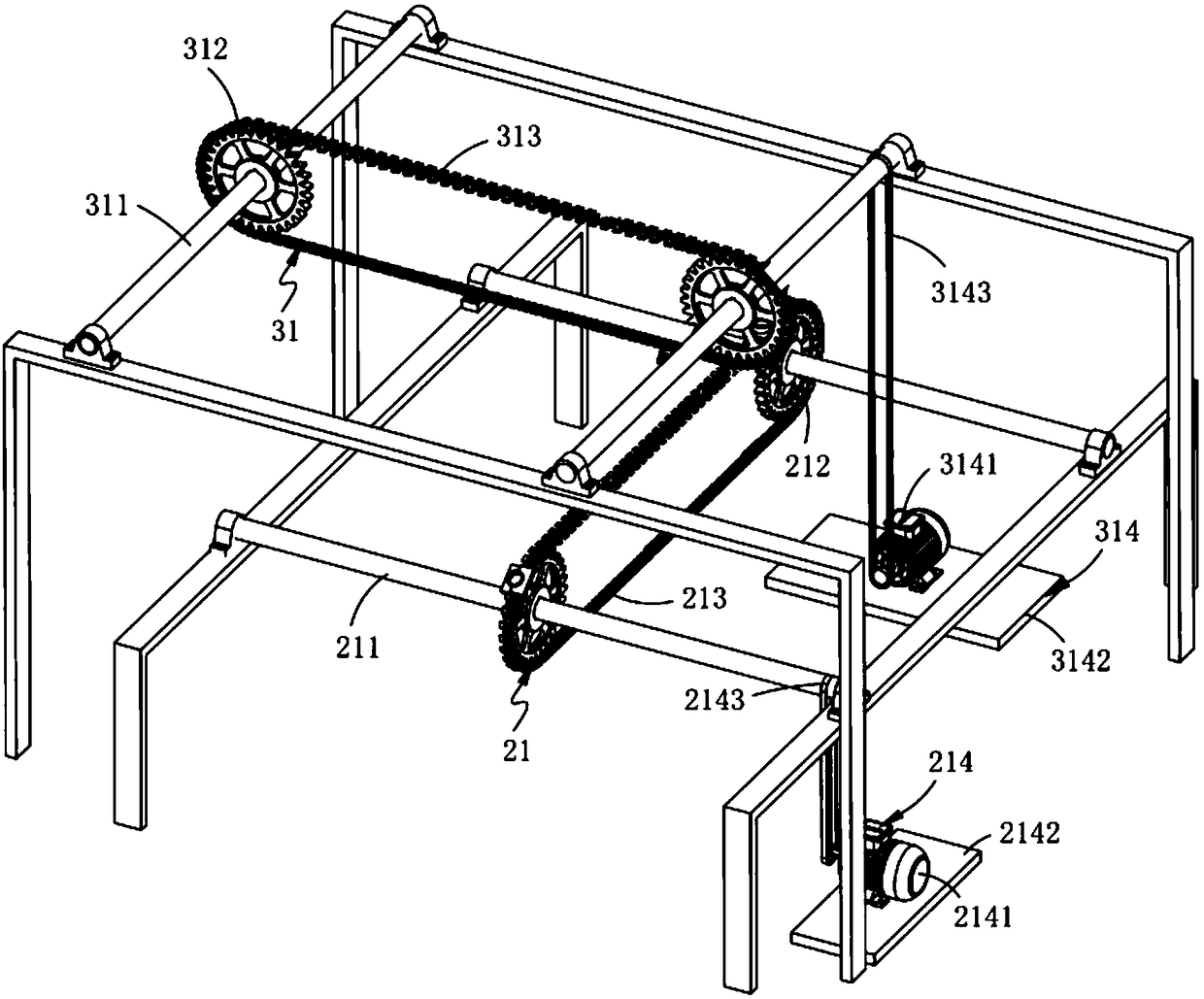

[0064] The first transmission mechanism 2, the first transmission mechanism 2 is fixedly arranged on the frame 1, which includes a lateral drive assembly 21 and a feeding assembly 22 arranged on the lateral drive assembly 21;

[0065] The second transmission mechanism 3, the second transmission mechanism 3 is fixedly arranged on the frame 1 and arranged above the first transmission mechanism 2, which includes a longitudinal drive assembly 31 vertically arranged with the horizontal drive assembly 21 , a clamping component 32 arranged on the longitudinal drive component 31 and a tightening component 33 cooperating with the clamping component 32; and

[0066] The discharge bucket 4 is arranged on the frame 1 and located at the rear end of the longitudinal drive assembly 31 .

[0067] In this embodiment, the U-shaped iron wires equipped with fiber bundles are horizontally and...

Embodiment 2

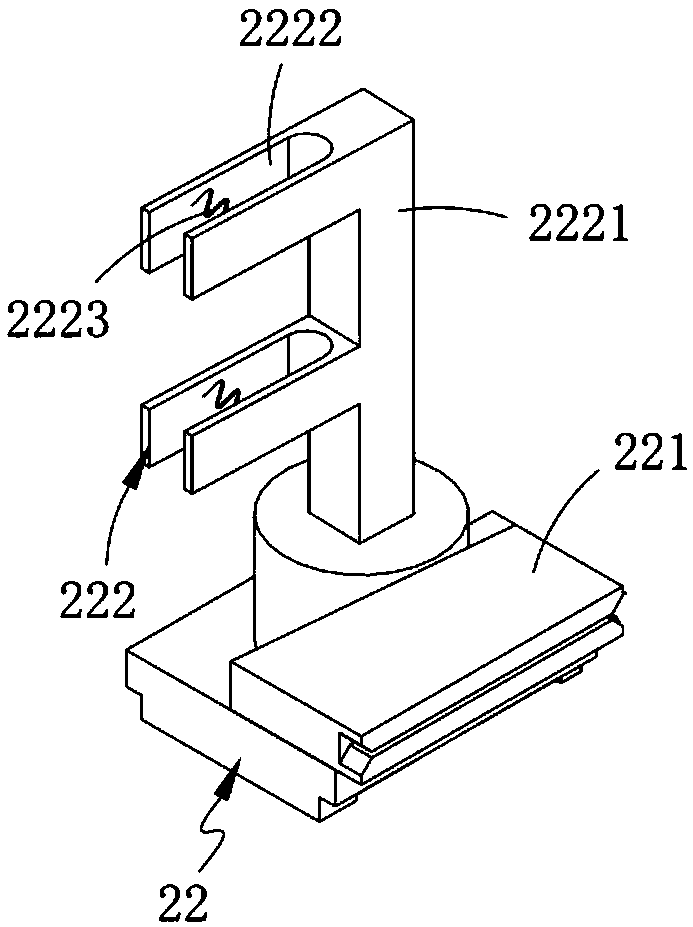

[0109] Such as image 3 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0110] further, such as image 3 As shown, the locking groove 2222 is further provided with a spring 2223 , and the spring 2223 is arranged along the width direction of the locking groove 2222 .

[0111] In this embodiment, by setting the spring 2223, on the one hand, the locking groove 2222 can fix the iron wire; During the process, it is in direct contact with the fiber bundle to ensure the quality of the fiber bundle.

[0112] work process:

[0113]Start the driving part 214, manually place the fiber bundle in the iron wire, and then manually continue to place the iron wire in the locking groove 2222, and with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com