A conduction cooling superconducting magnet refrigerator structure and its installation and disassembly method

A superconducting magnet and conduction cooling technology, applied in superconducting magnets/coils, coolers, refrigerators, etc., can solve problems such as weakening maintenance effects, reduce equipment downtime, shorten on-site maintenance and repair time, The effect of high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

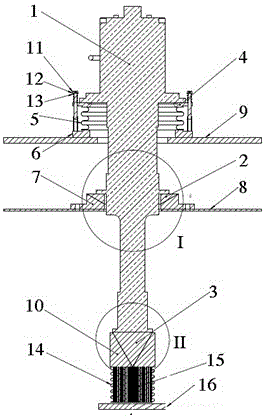

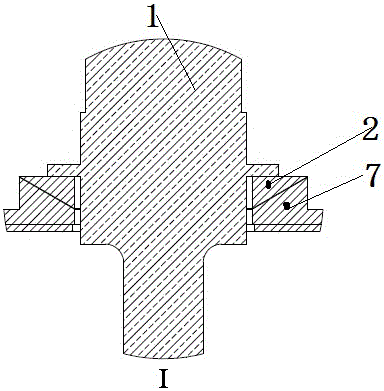

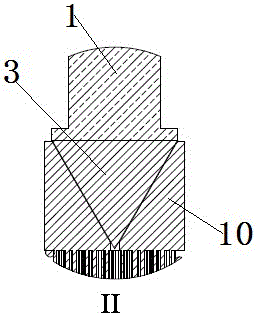

[0026] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] see figure 1 , a conductive cooling superconducting magnet refrigerator structure, including a connecting flange 4 connected with the refrigerator 1, the connecting flange 4 is connected with the supporting flange 6 through the bellows 5, and the magnet outer Dewar 9 is respectively connected with the supporting flange 6 connected, the first-stage cold head of the refrigerator 1 is connected with the upper assembly 2 of the heat transfer component, the lower end of the upper assembly 2 of the heat transfer component and the upper end of the lower part 7 of the heat transfer component are tightly combined by pressure, and the lower end of the lower part 7 of the heat transfer component is closely connected with the The magnet cold shield flange 8 is connected, the secondary cold head of the refrigerator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com