Mechanical centrifugal atomization device centrifugal pan

A centrifugal atomization and centrifugal disc technology, applied in the field of powder metallurgy machinery, can solve the problems affecting the normal use of the mechanical centrifugal atomization device, large centrifugal force, increase the working load, etc., and achieve the effect of improving the centrifugal atomization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

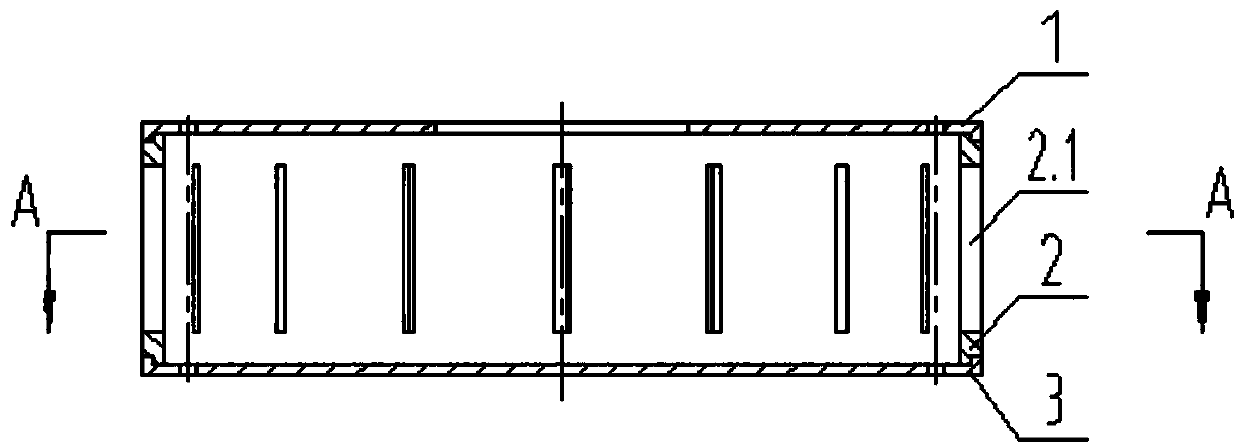

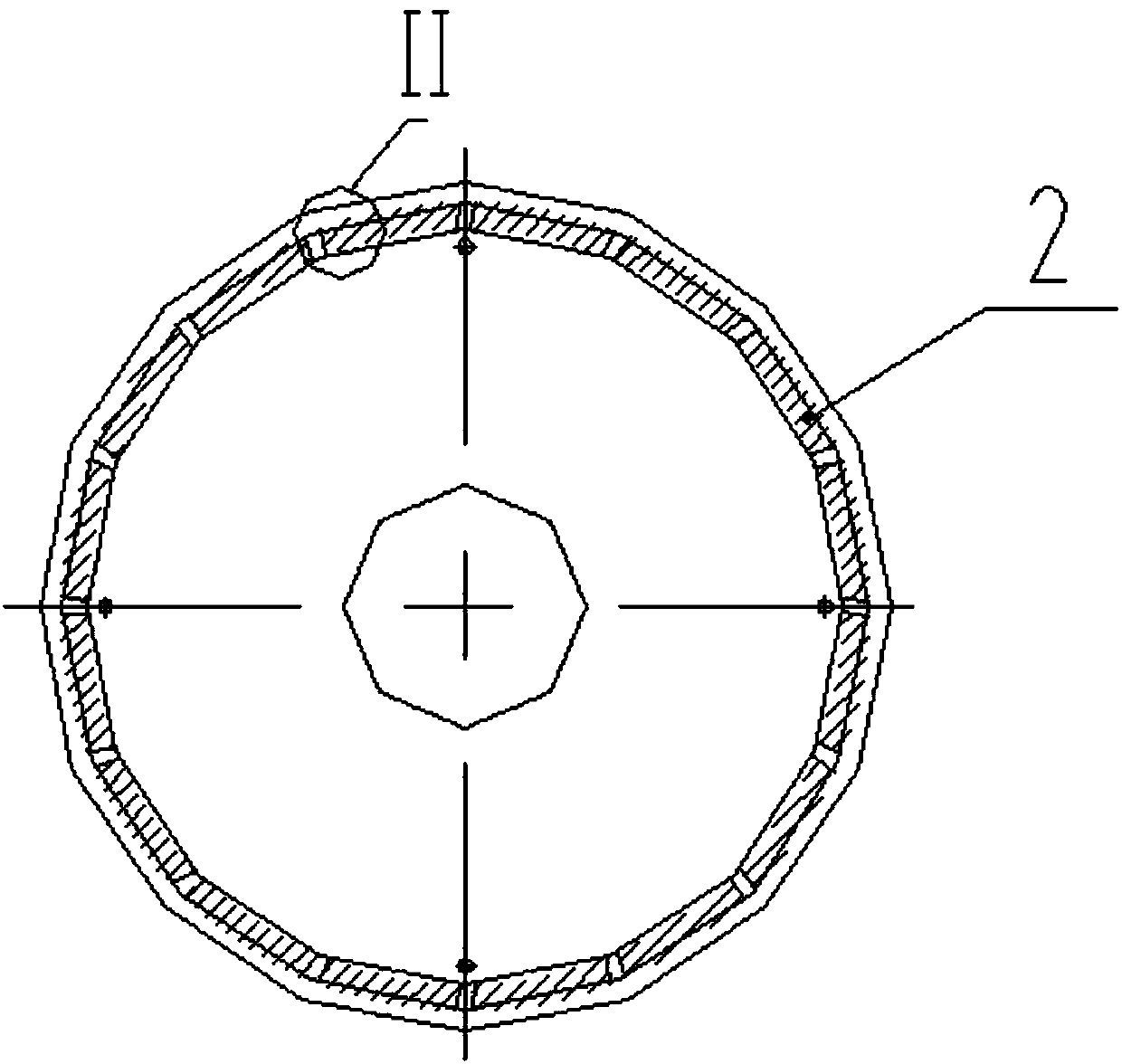

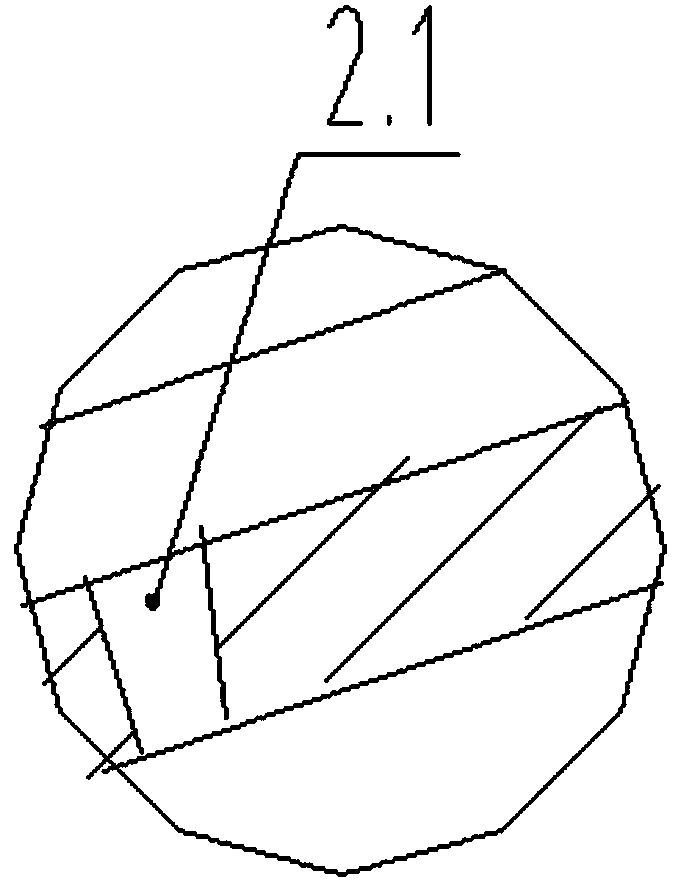

[0014] The centrifugal disk of the mechanical centrifugal atomization device shown in the accompanying drawings is set on the mechanical centrifugal atomization device, including a disk upper cover 1, a disk body 2, and a disk lower cover 3; the disk body 2 is a sleeve-shaped member with a vertical central axis, The outer wall of the circumference is provided with a number of axially elongated grooves 2.1 radially penetrating, and the axially elongated grooves 2.1 deviate from the central axis of the disc body 2. In this embodiment, the axially elongated grooves 2.1 are perpendicular to the central axis of the disc body 2. The inside of the cross-section is a tapered shape with a large outside and a small inside.

[0015] The disc upper cover 1 and the lower disc cover 3 sandwich the disc body 2 in the middle to form a hollow disc struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com