Patents

Literature

35results about How to "Reduce clamping pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

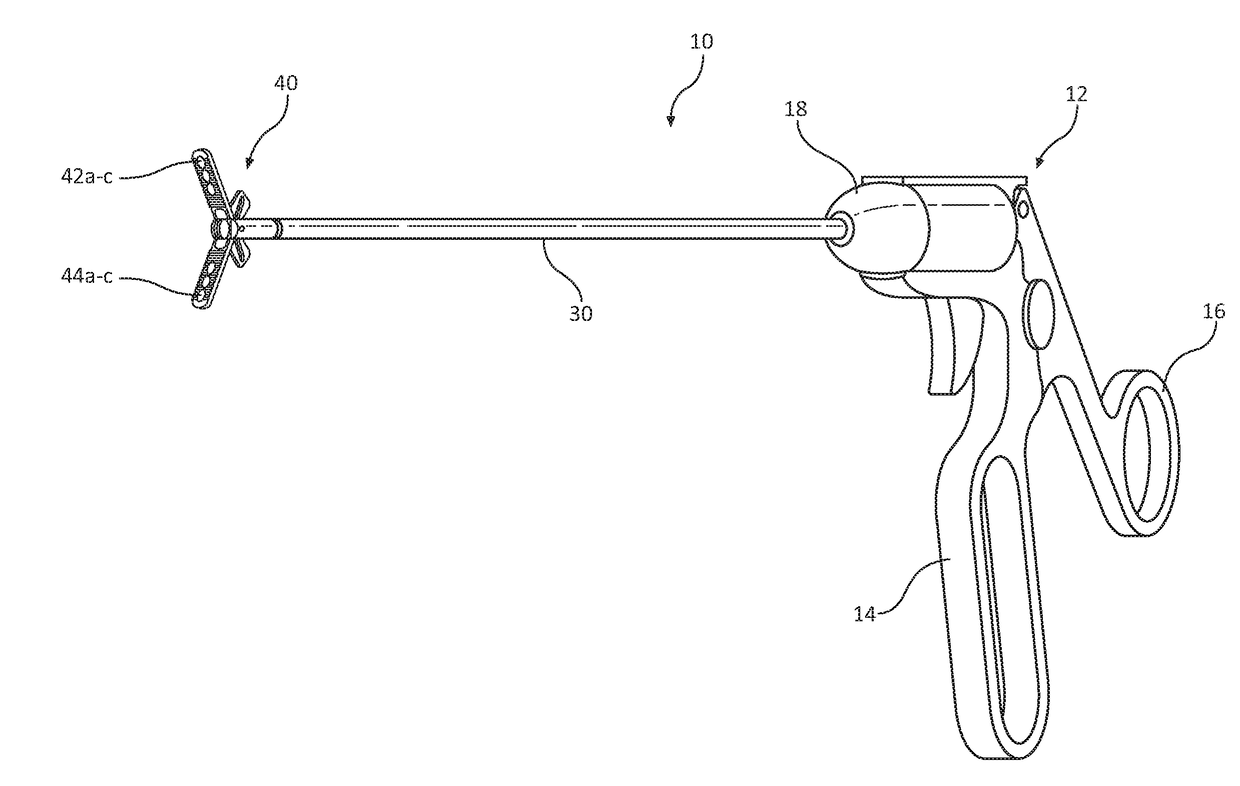

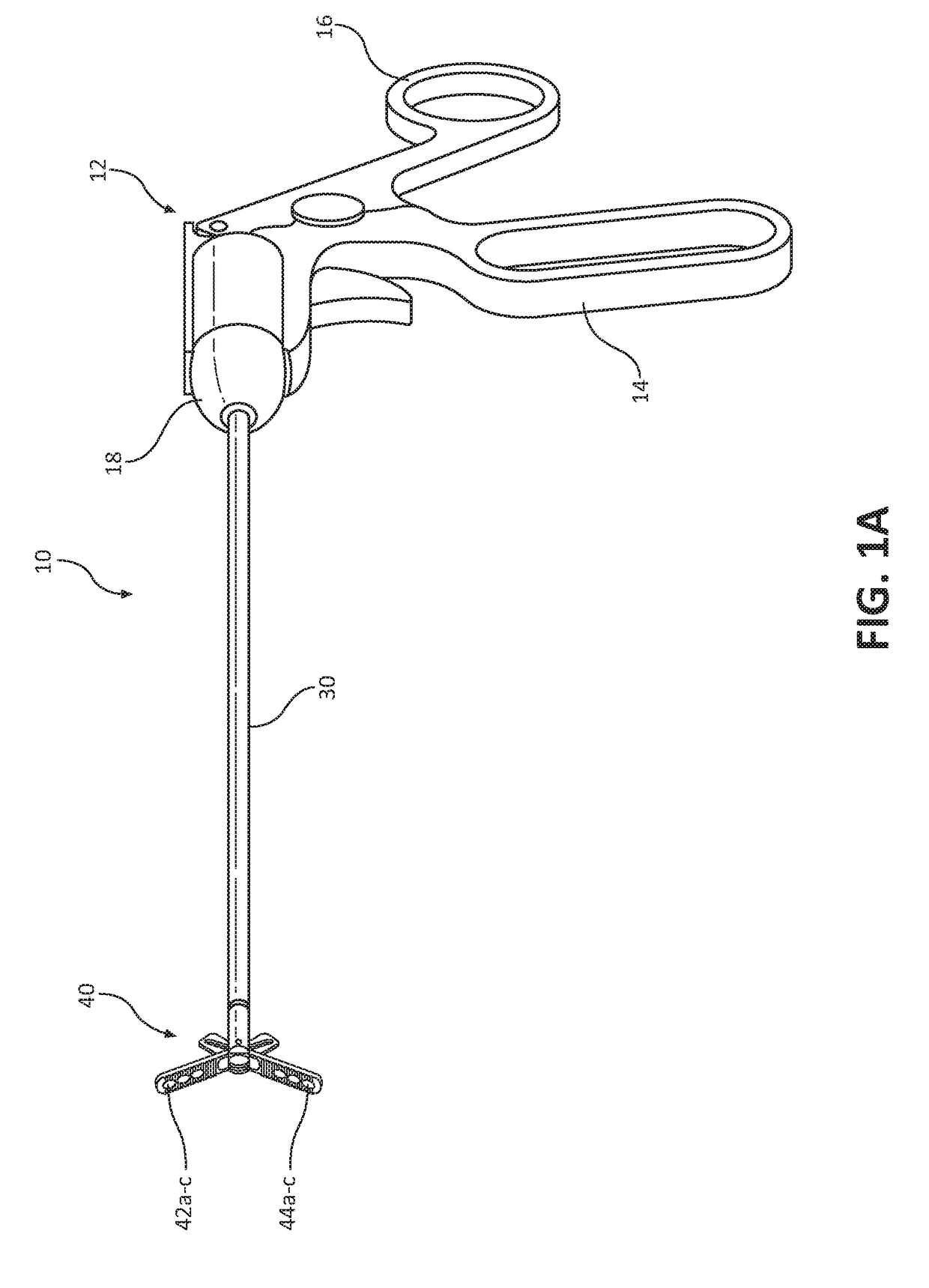

Surgical instruments including sensors

ActiveUS20170172550A1Reduce clamping pressureEvaluation of blood vesselsDead animal preservationMedicinePerfusion

A surgical instrument includes a handle portion, first and second jaw members operably coupled to the handle portion, and first and second sensors associated with the first or second jaw members. The first sensor is configured to measure local perfusion in tissue grasped between the first and second jaw members, and the second sensor is configured to measure a pressure applied to the tissue by the first and second jaw members.

Owner:TYCO HEALTHCARE GRP LP

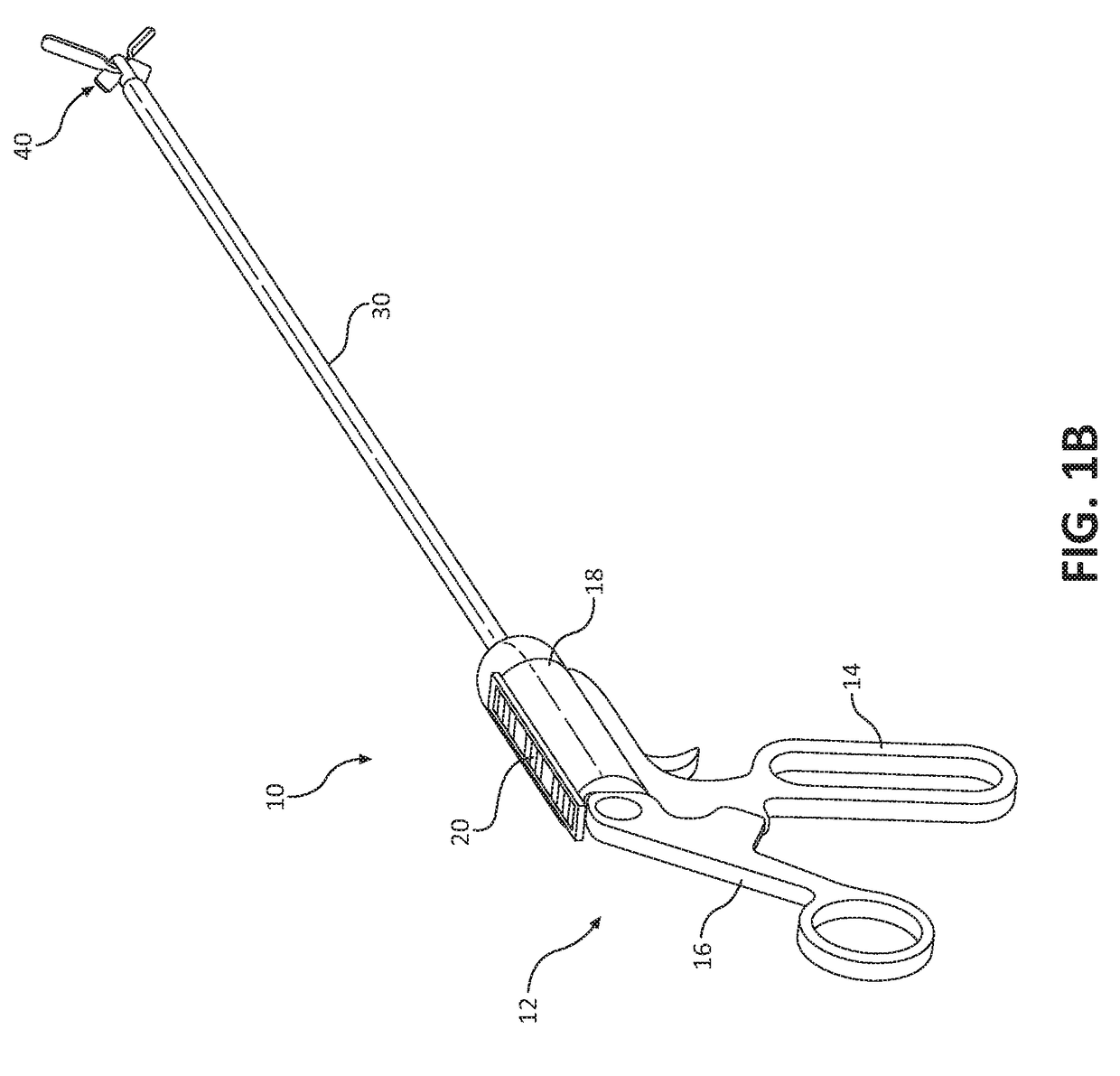

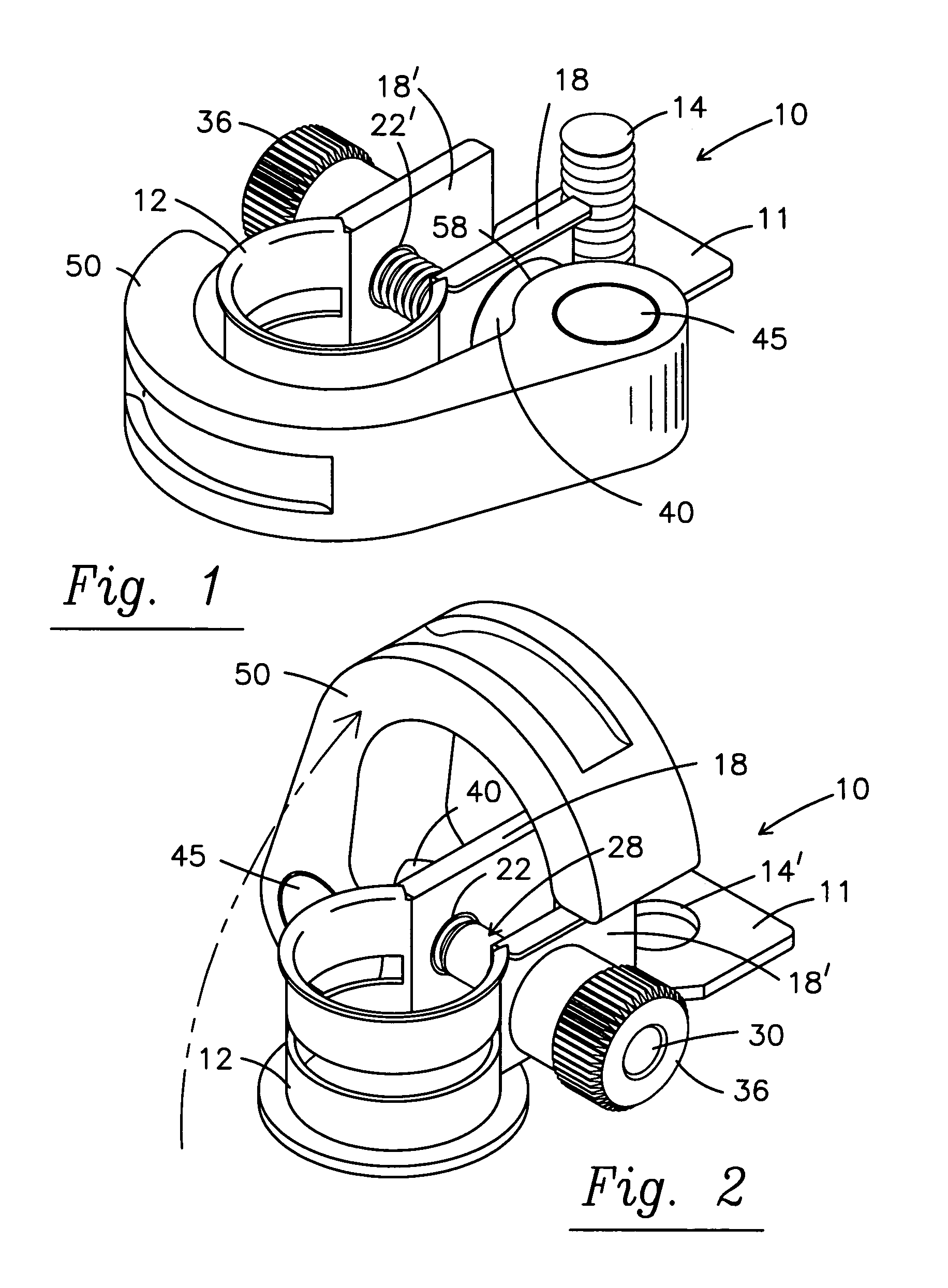

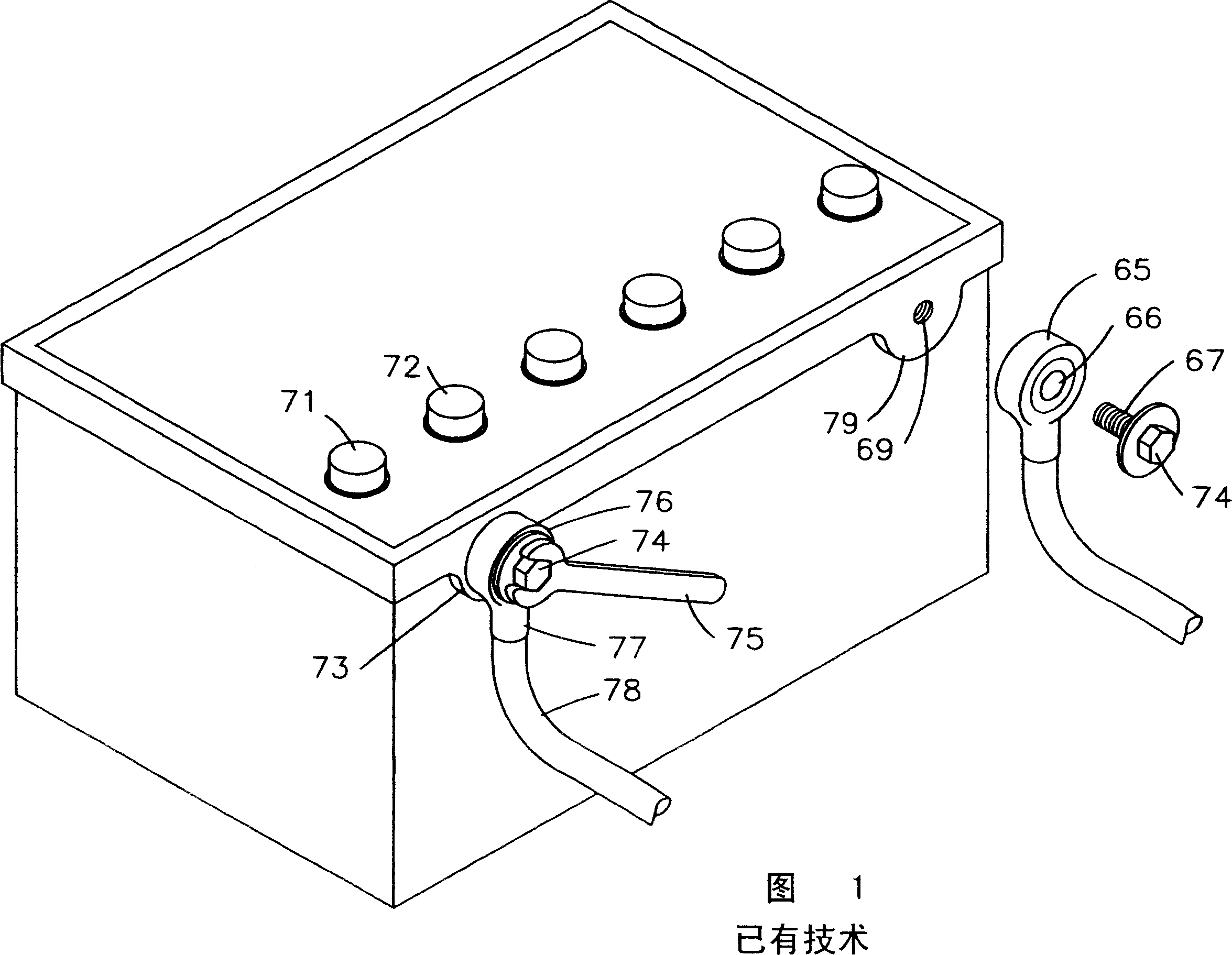

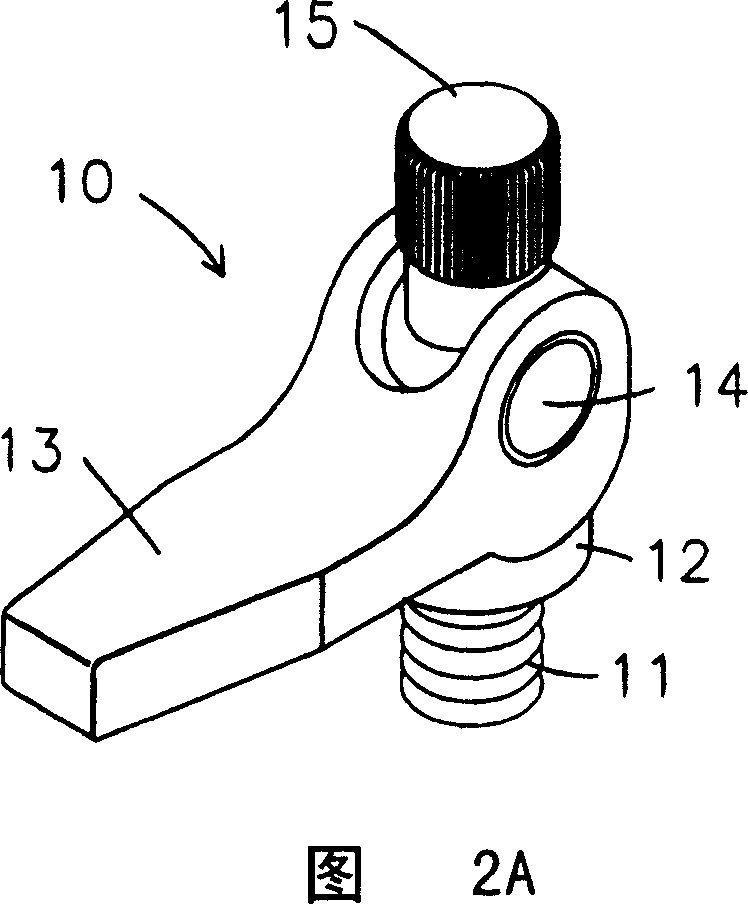

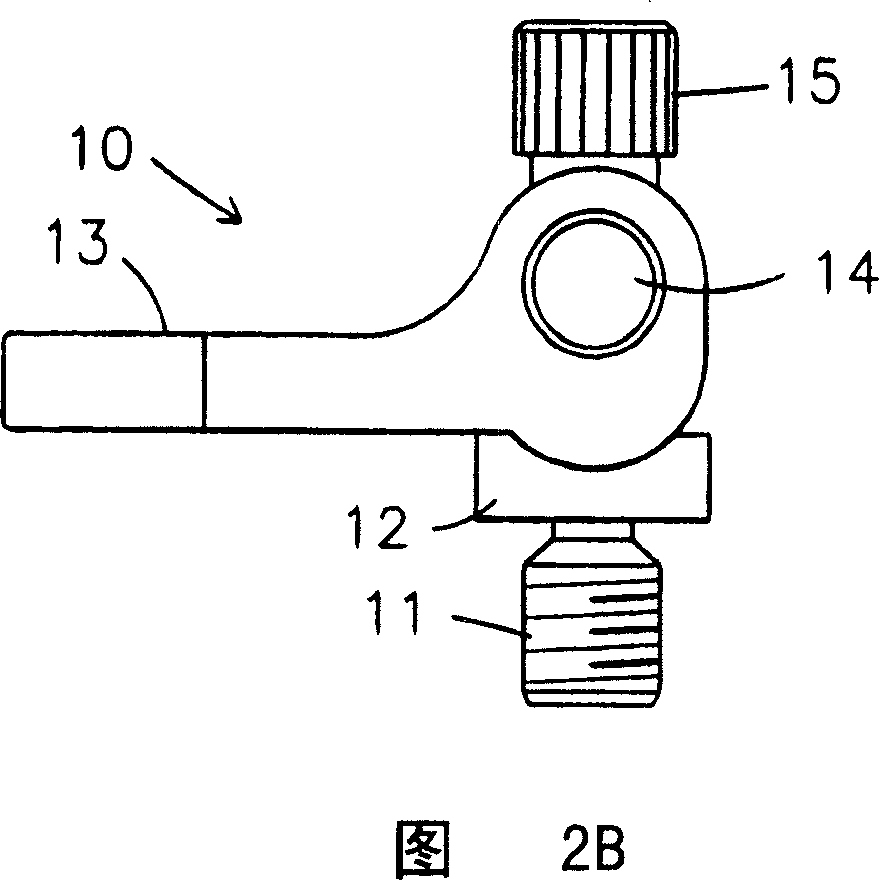

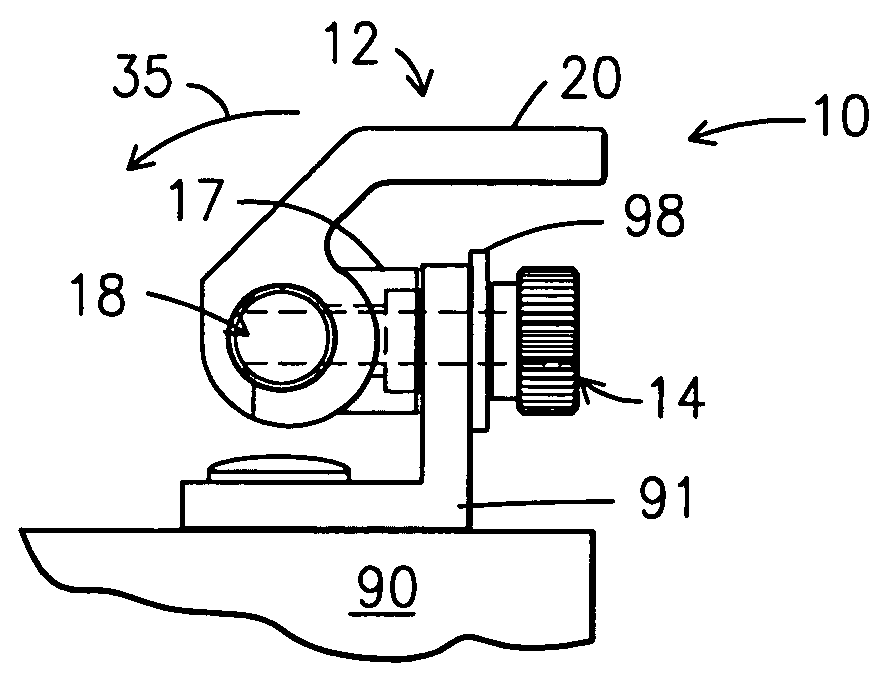

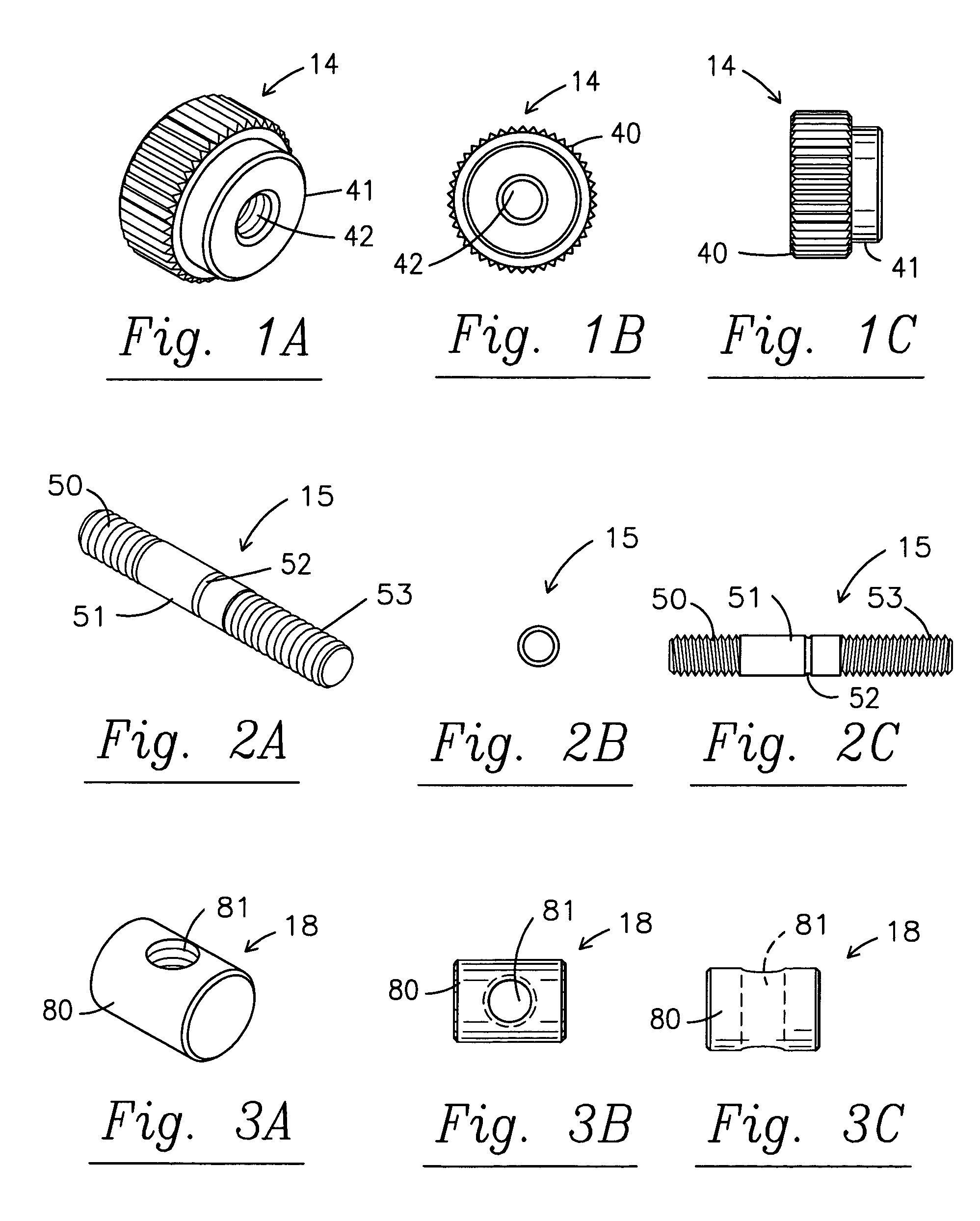

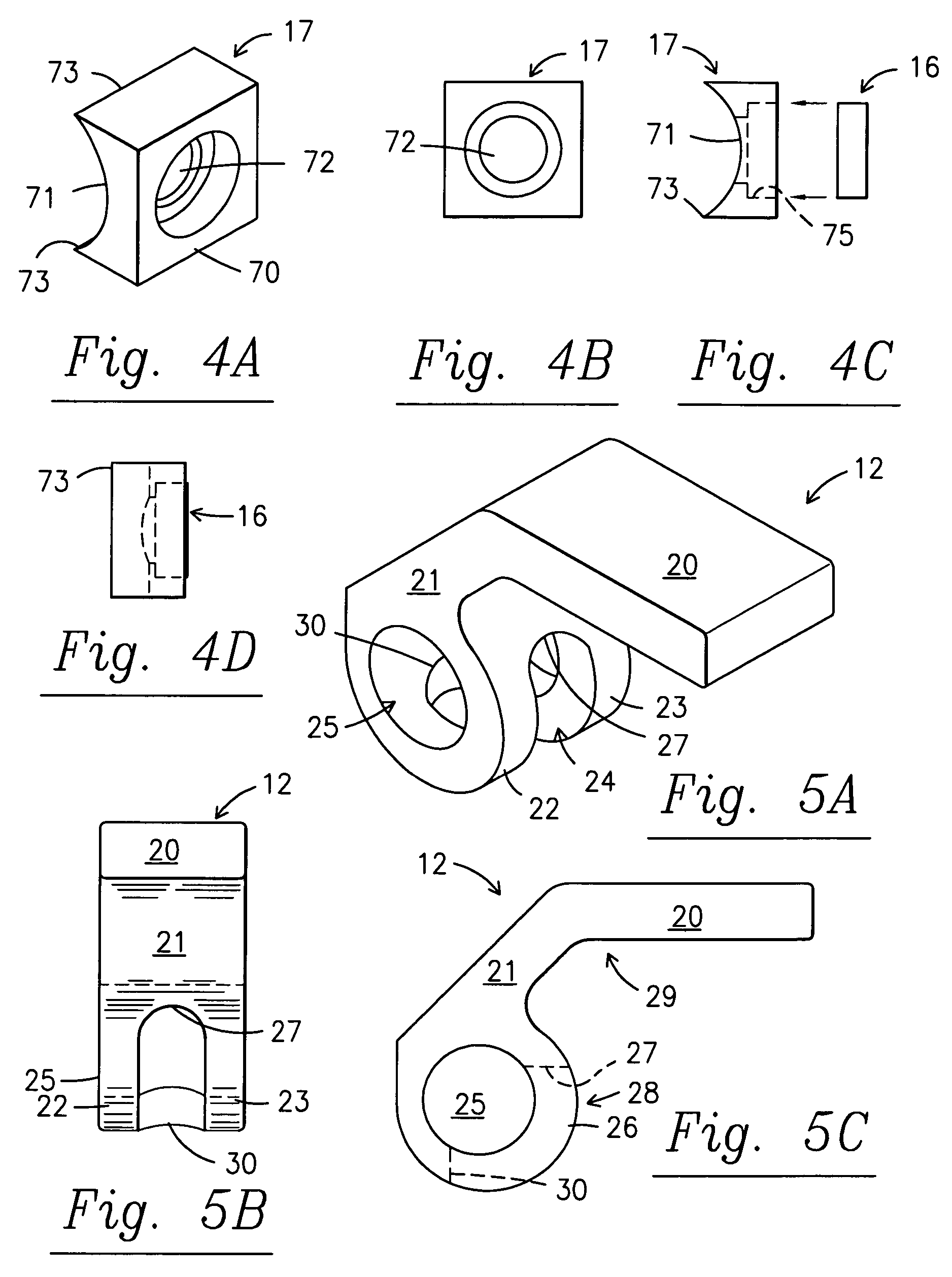

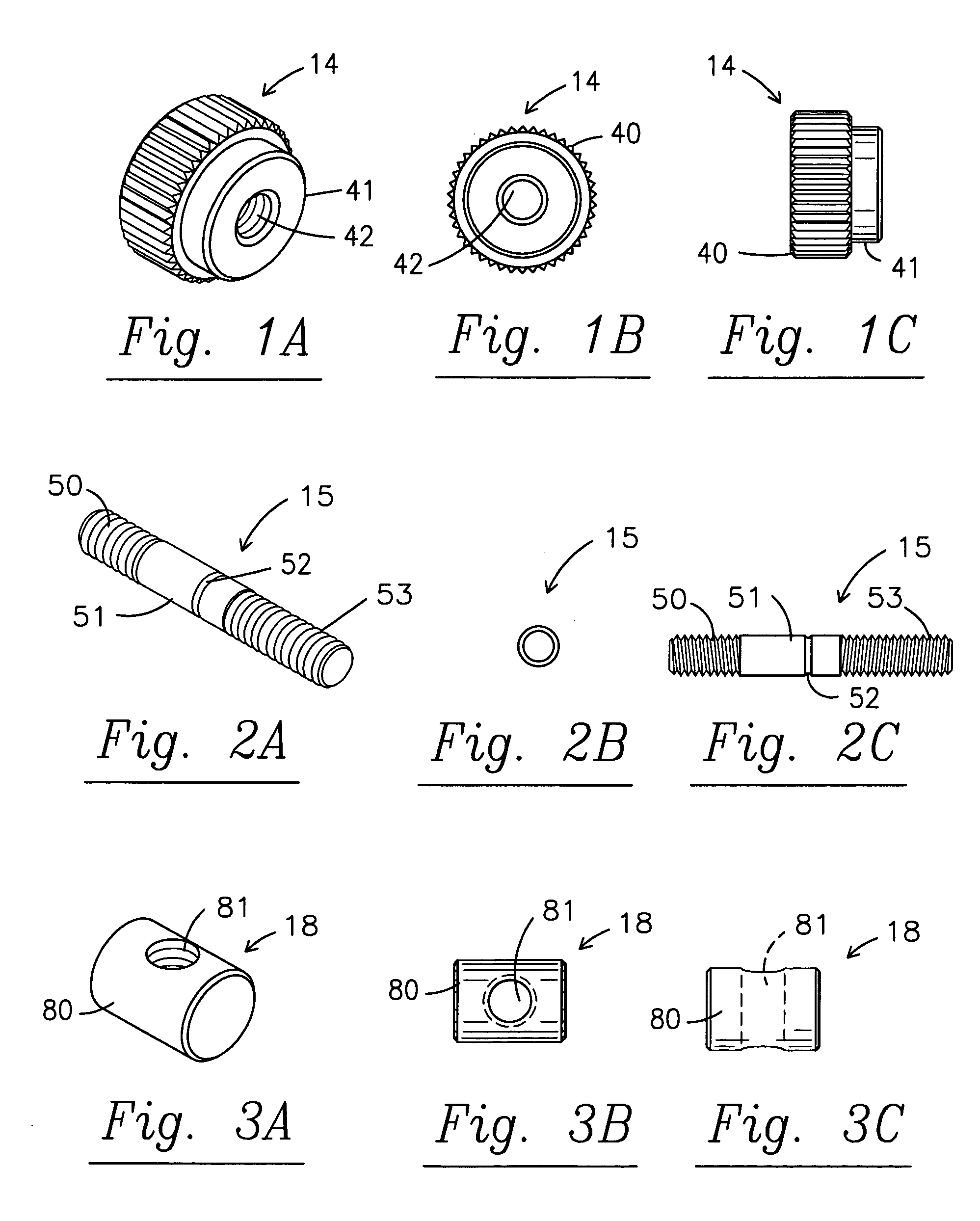

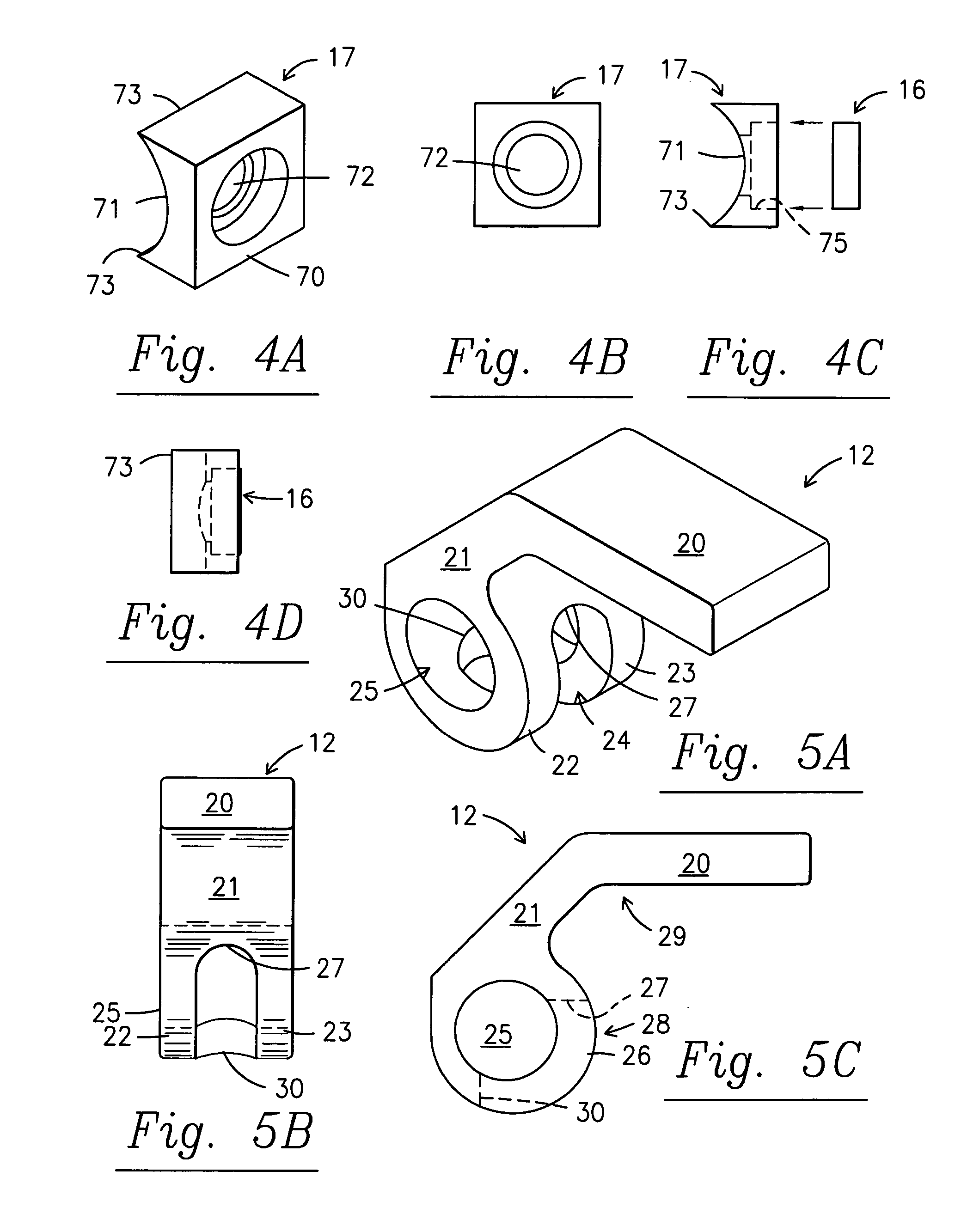

Rotatable connector for a battery cable clamp

InactiveUS6971925B1Increase pressureIncrease clamping pressureElectric connection basesClamped/spring connectionsEngineeringElectrical and Electronics engineering

An improved rotatable battery cable clamp connector is designed for use with applying pressure to legs of the clamp intermediate the cable section and post section of the clamp. Self-lubricating and non-corrosive materials are also used to advantage in the manufacture of the connector.

Owner:FENELON MARGARET FENE +1

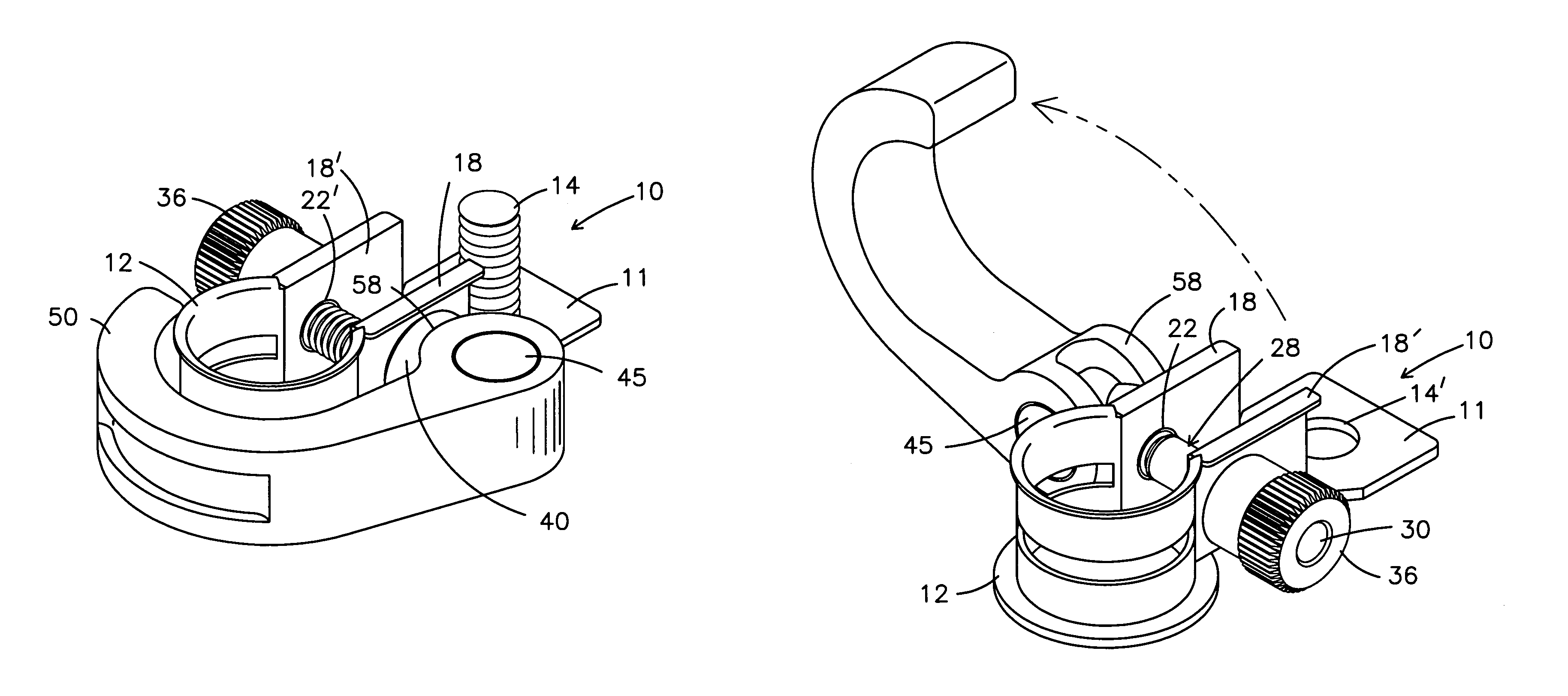

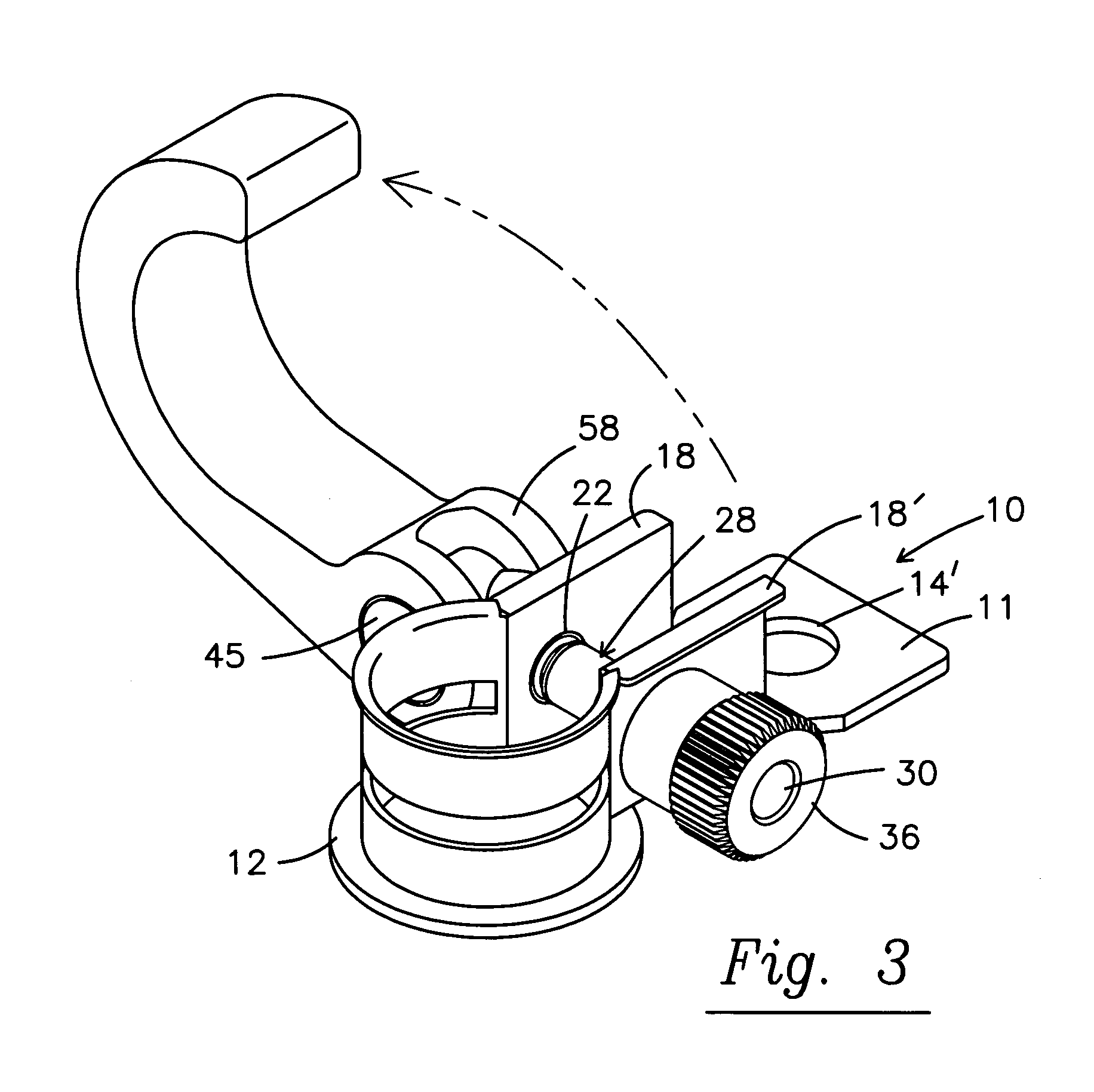

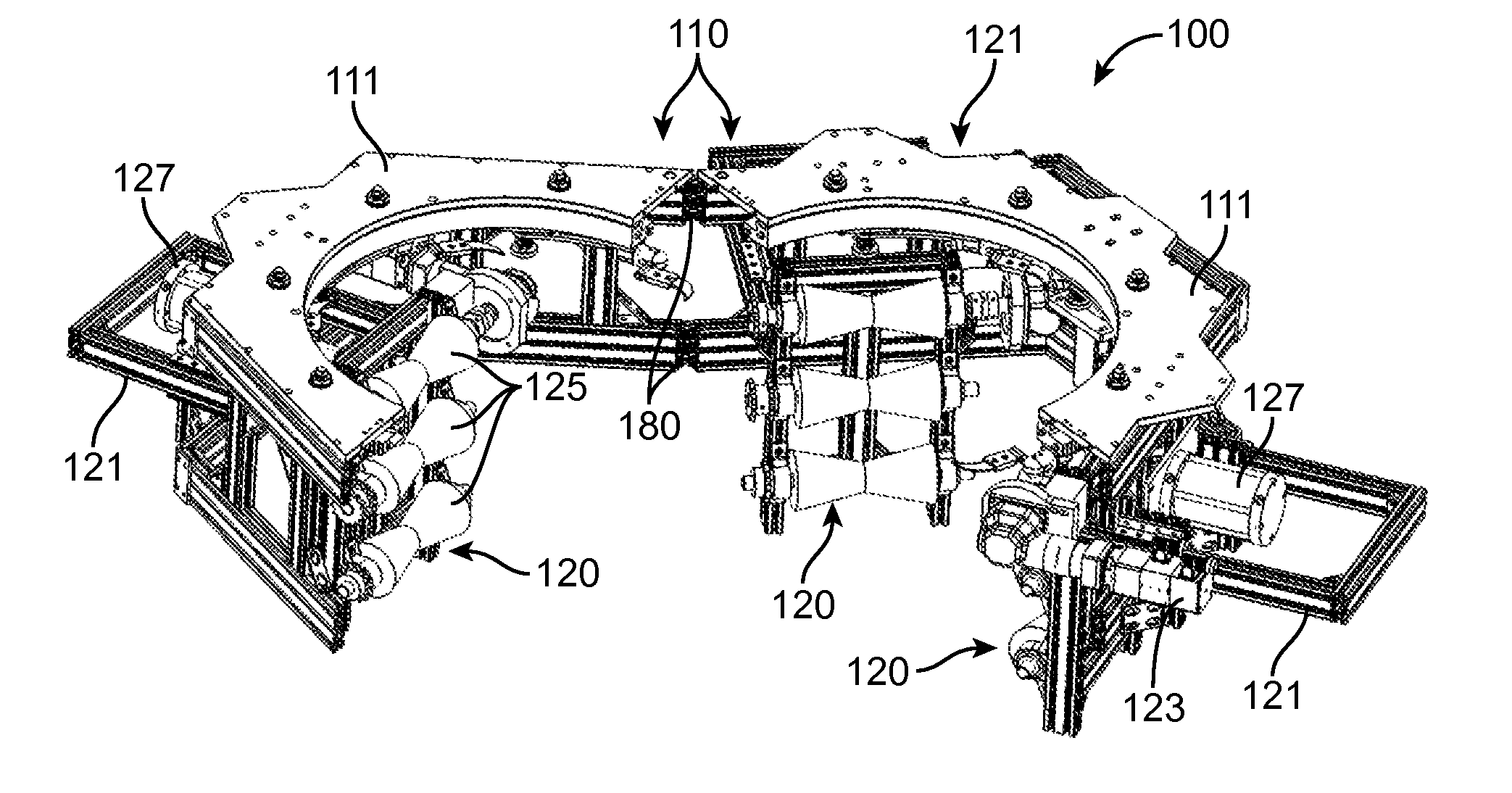

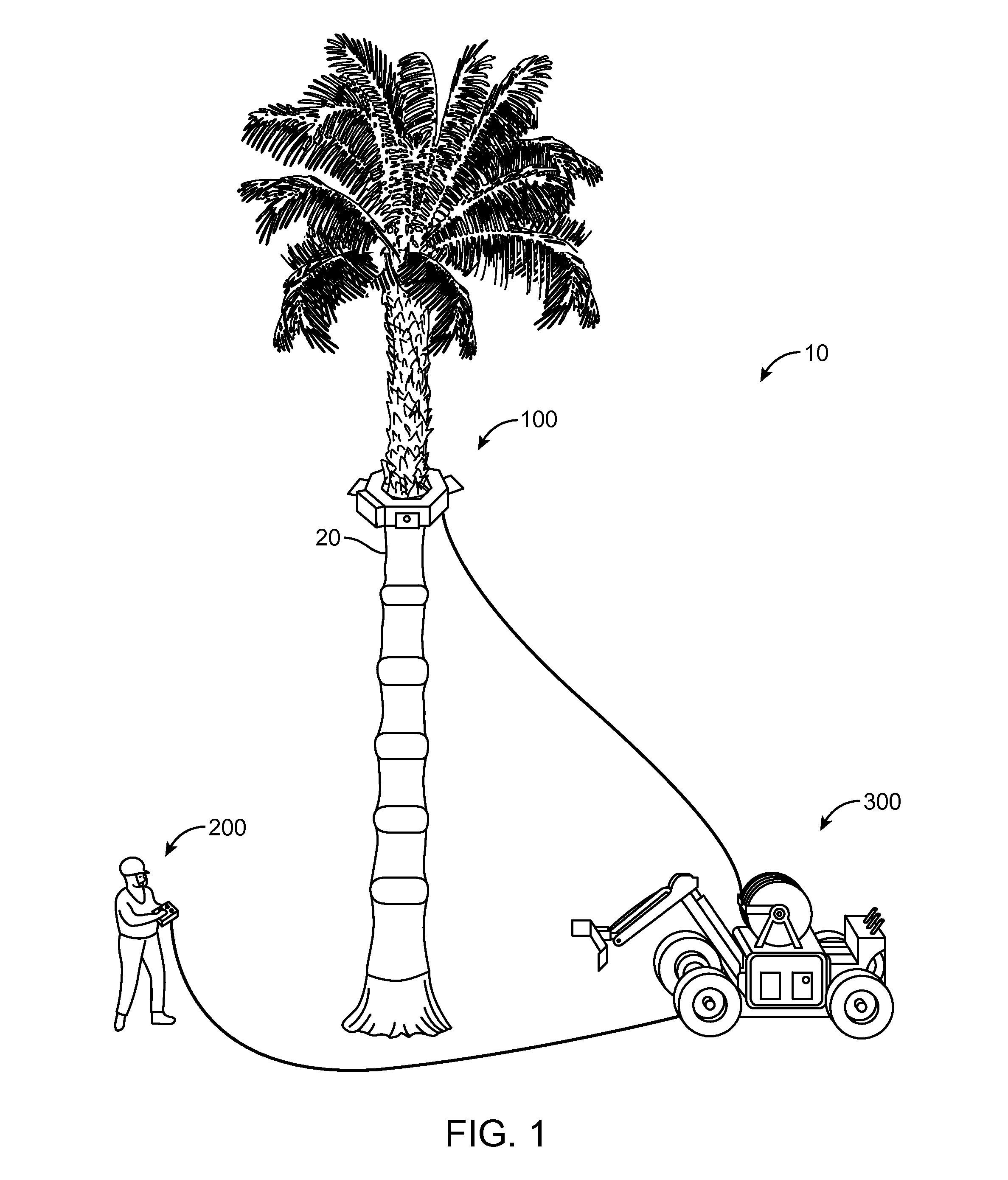

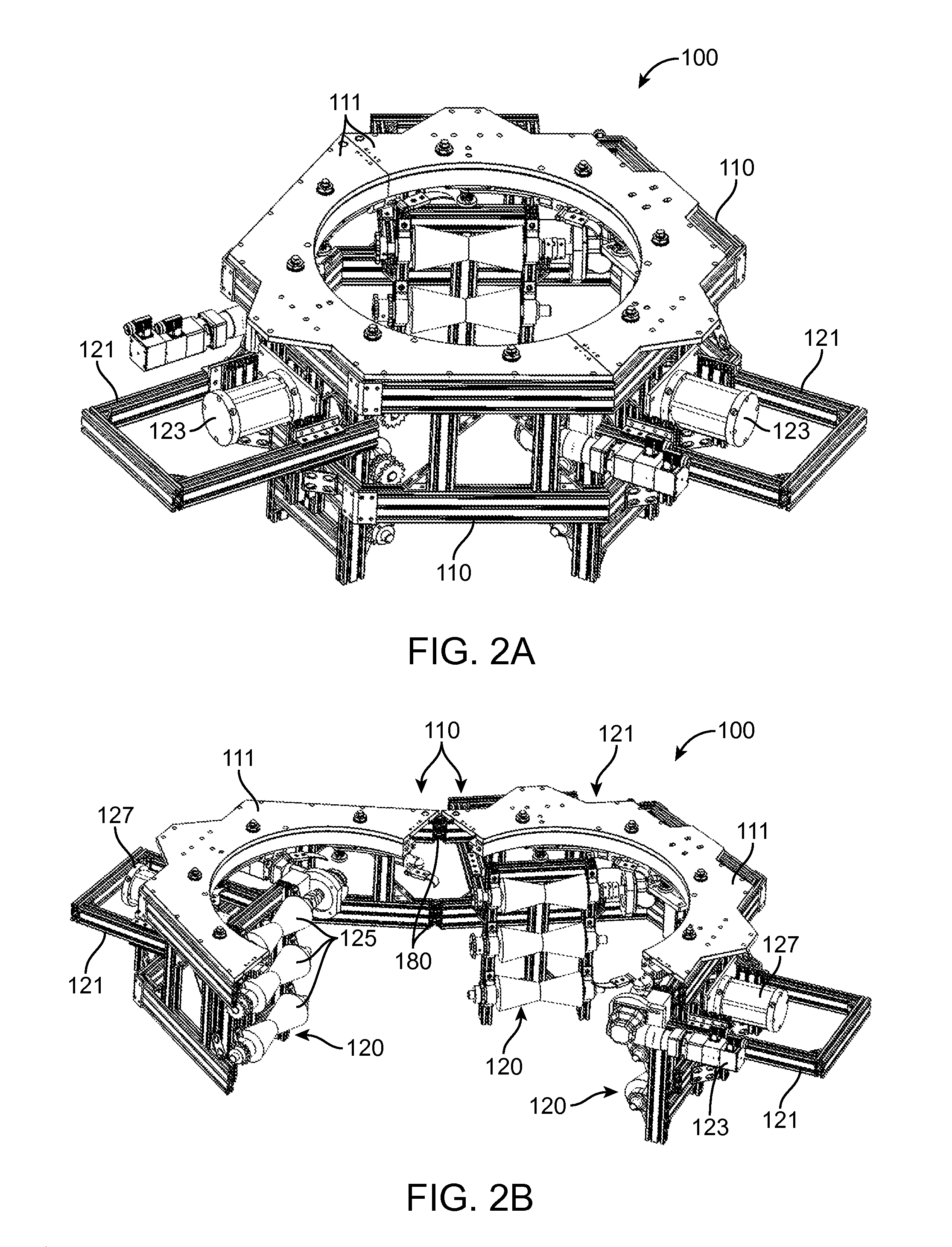

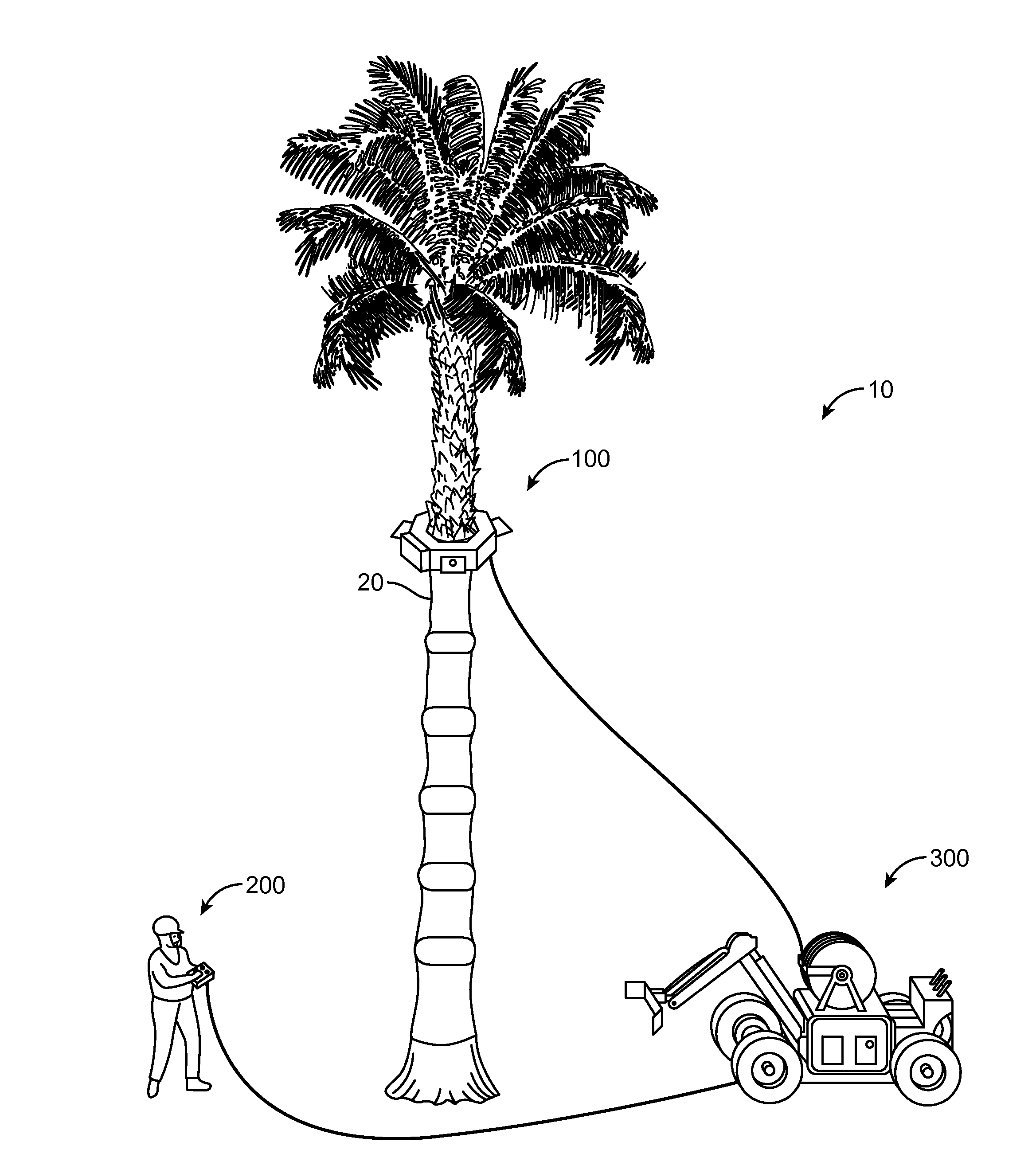

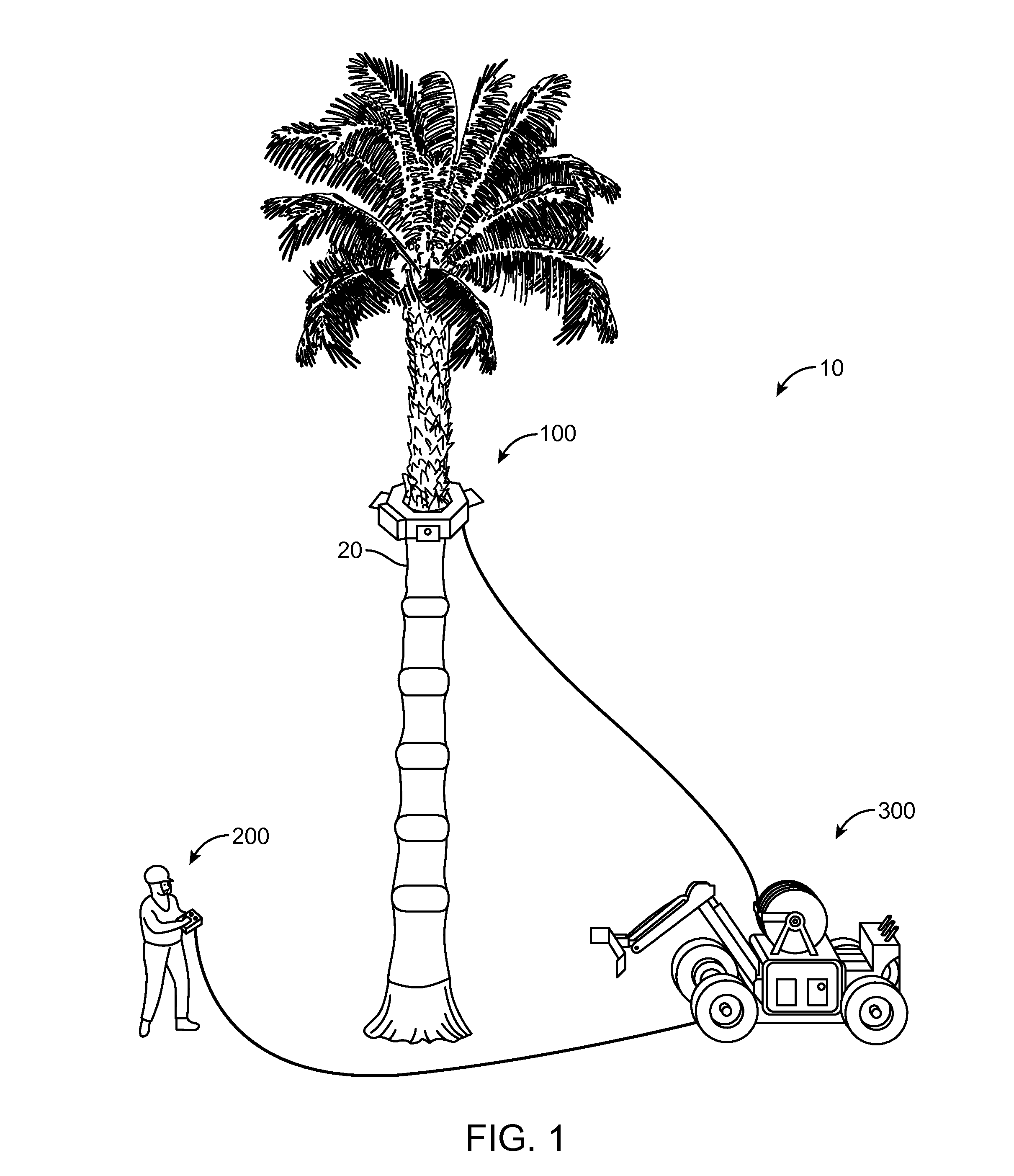

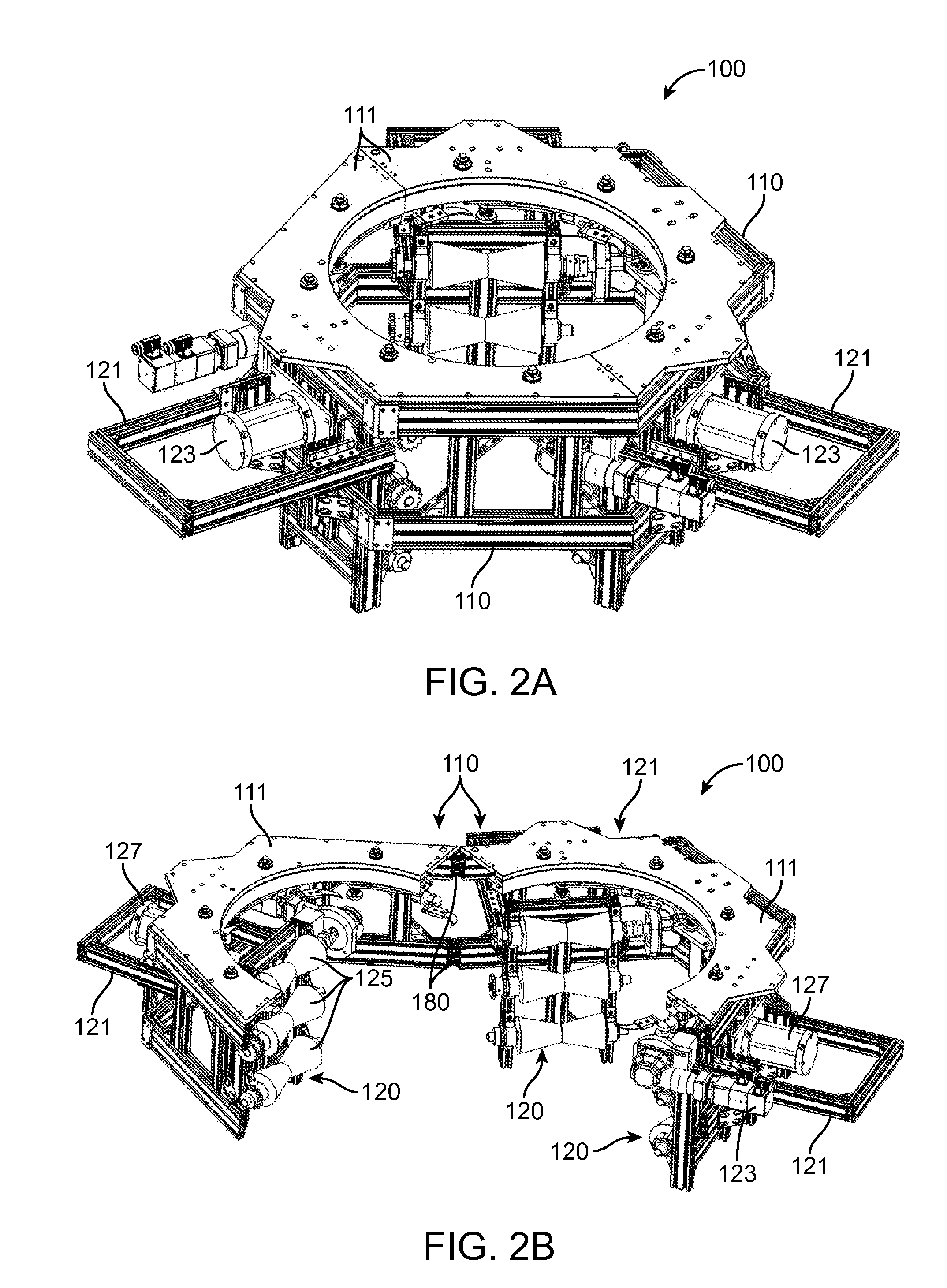

Multi-axis controlled self-climbing tree trimmer

A multi-axis controlled self-climbing tree trimmer used for shaping and severing peripheral growth from a tree is provided herein. The trimmer typically includes a structural segment hinged together to form a rigid chassis that surrounds a tree trunk climbing segment and a trimming portion. The climbing portion is retained within the structural segment in the form of a number of inward-extending carriages containing one or more rollers for gripping the tree trunk during climbing, and the trimming portion may include a rotatable split ring gear containing centrifugally rotating trimming blade members and / or a cutting tool on a positionable arm. When rotated, the blade members unlatch and pivot, into the trunk of the tree to effect controlled trimming. The system may utilize a multi-axis control system that uses linear interpolation, circular interpolation and coordination of all axes to enable the trimmer to follow an XYZ contour selected by a user.

Owner:VANDYPALM

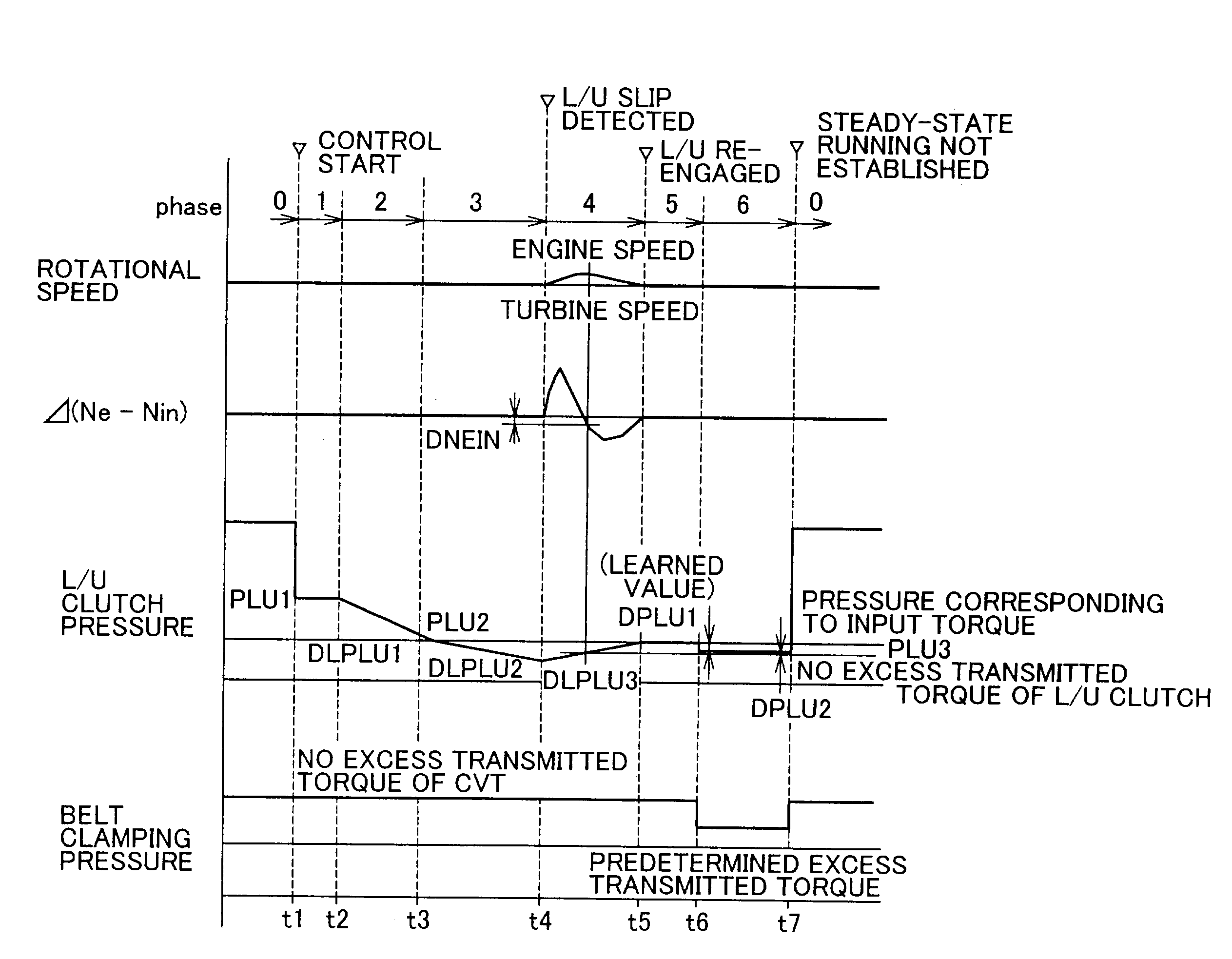

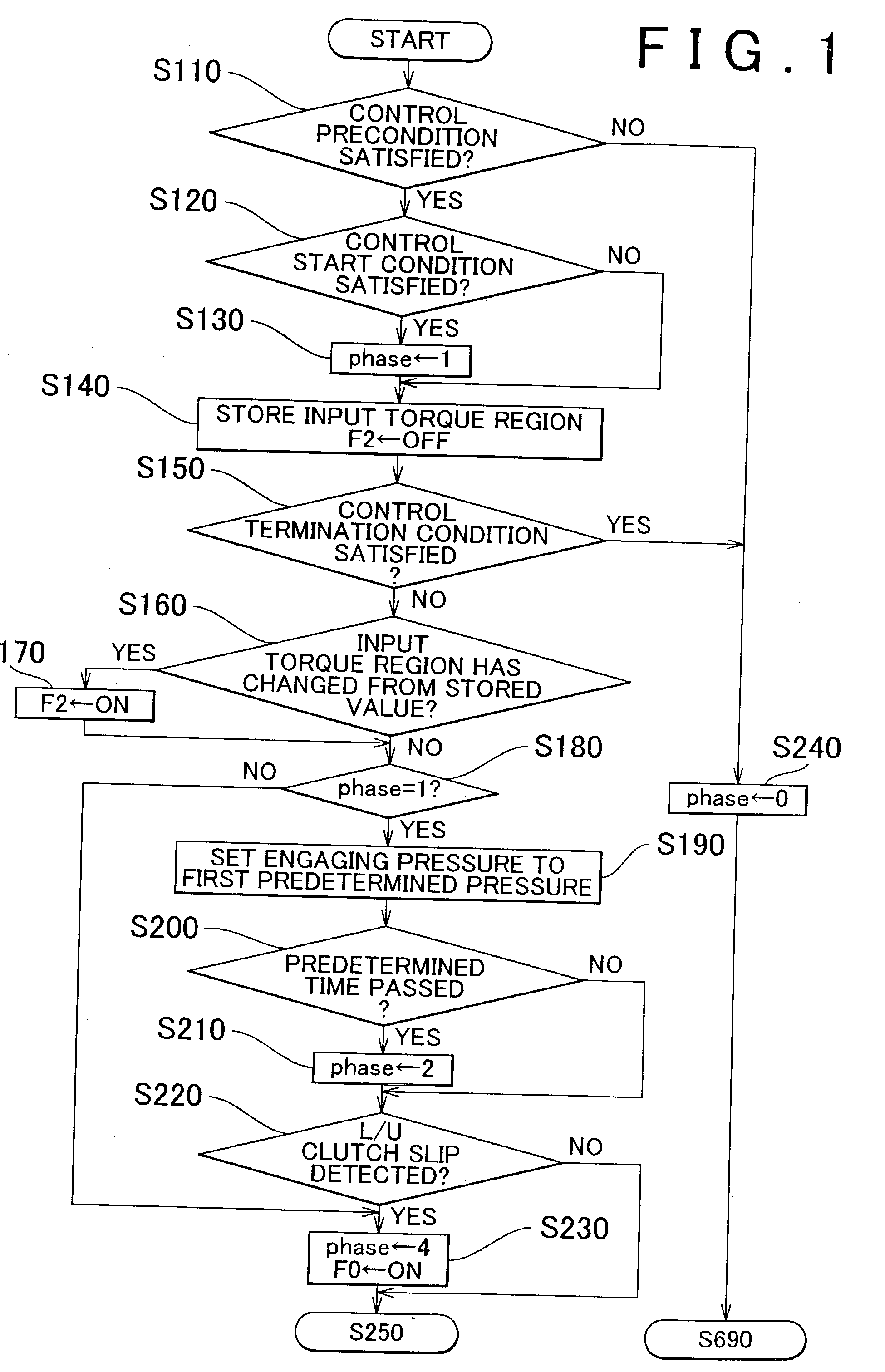

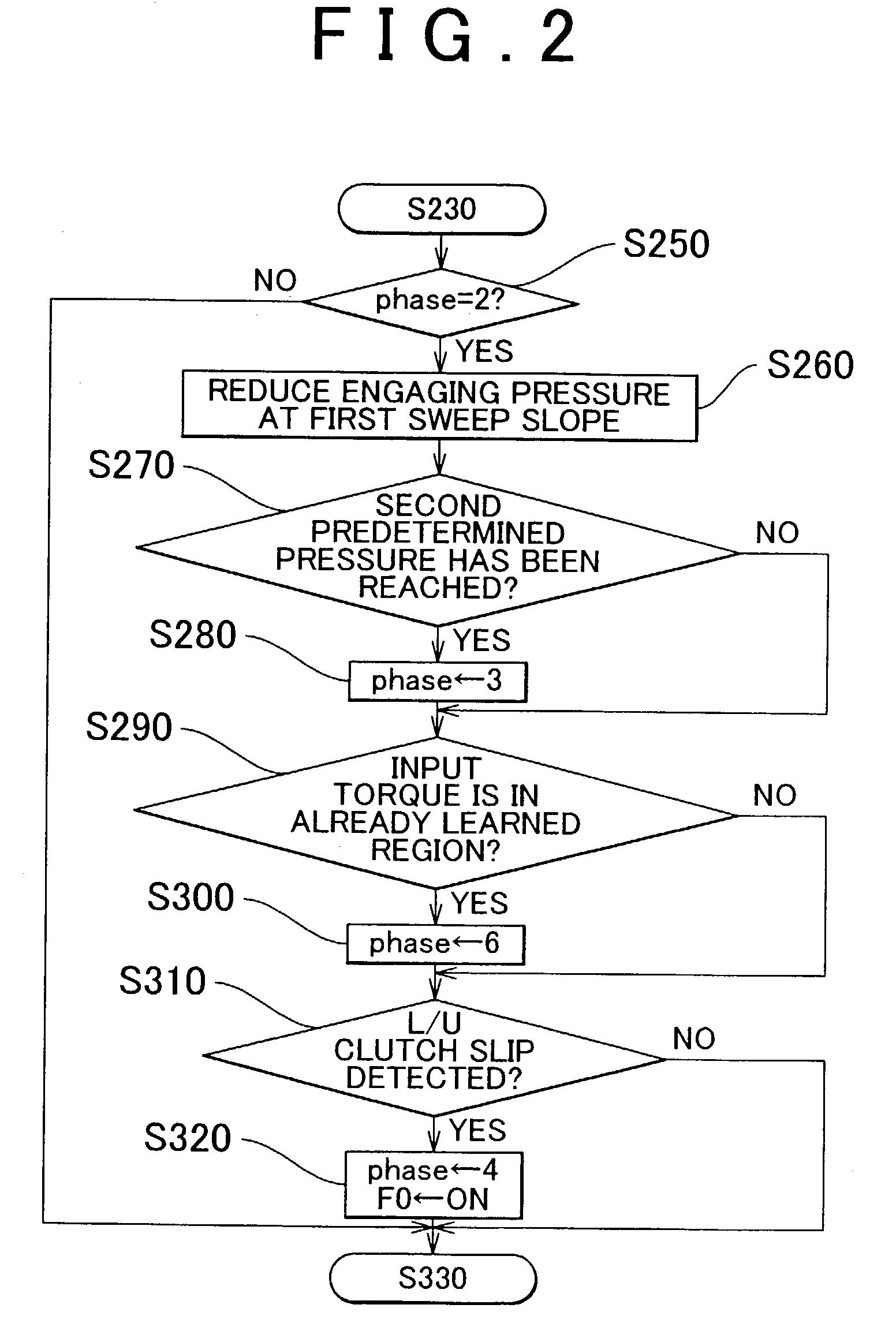

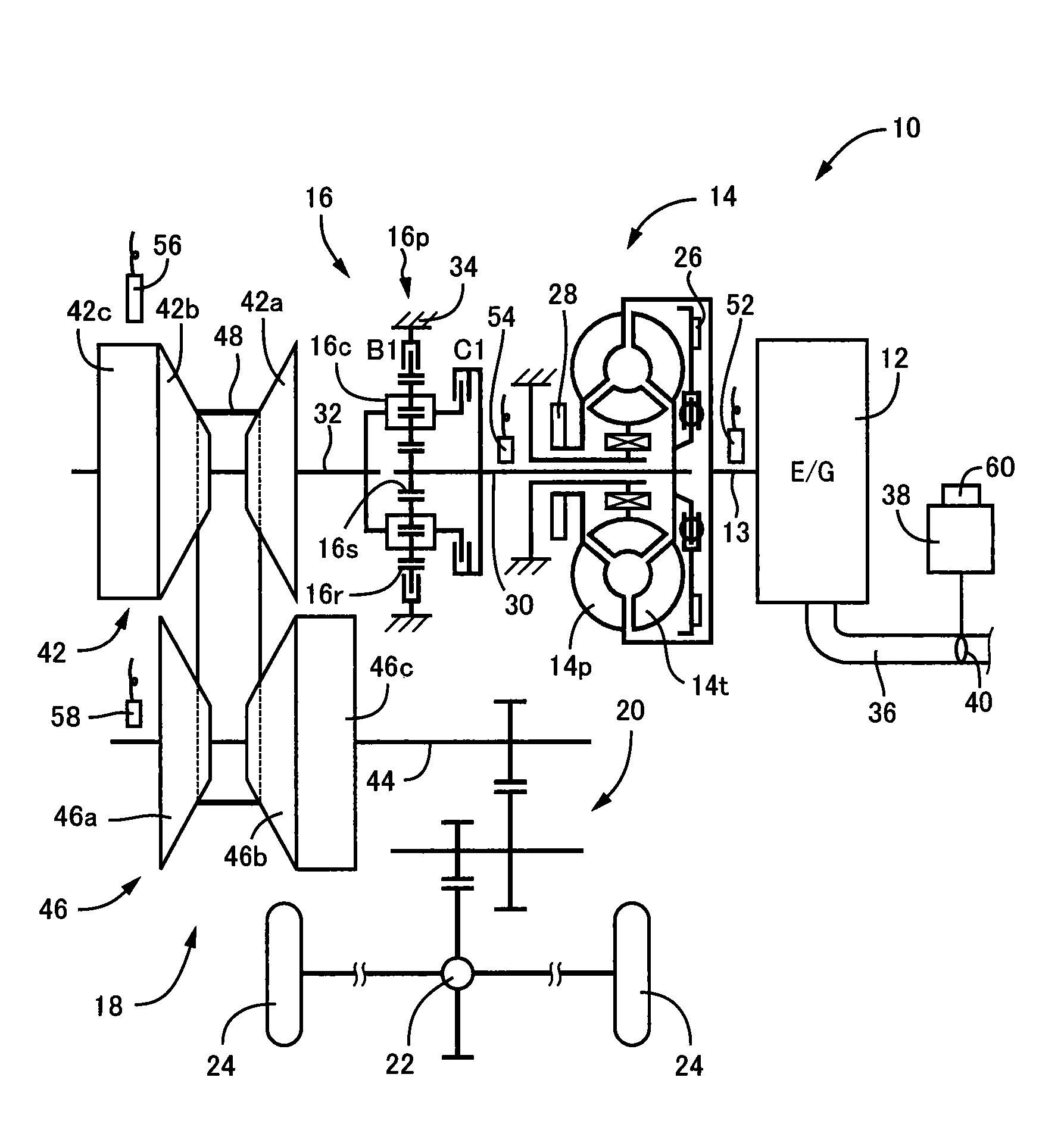

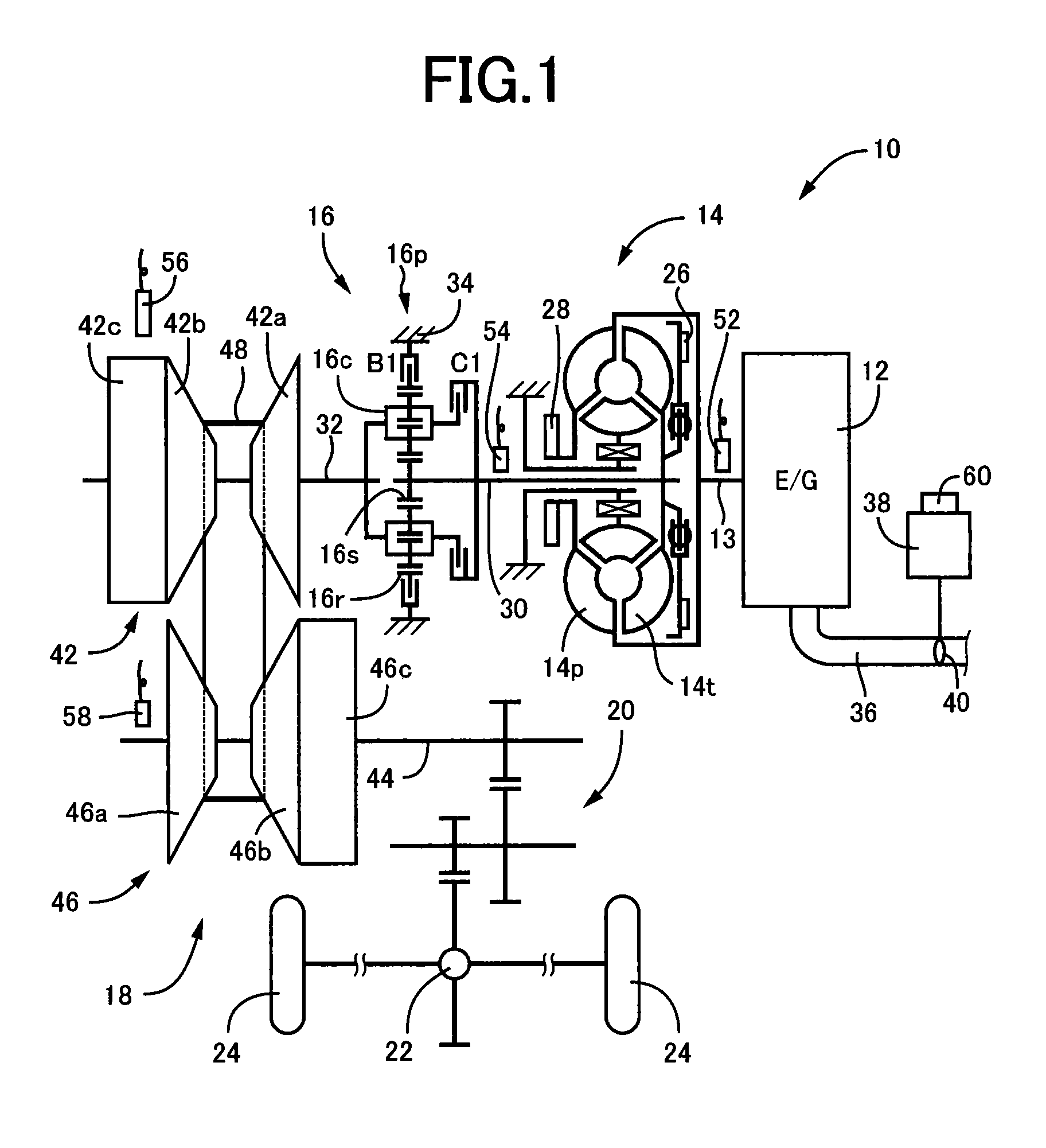

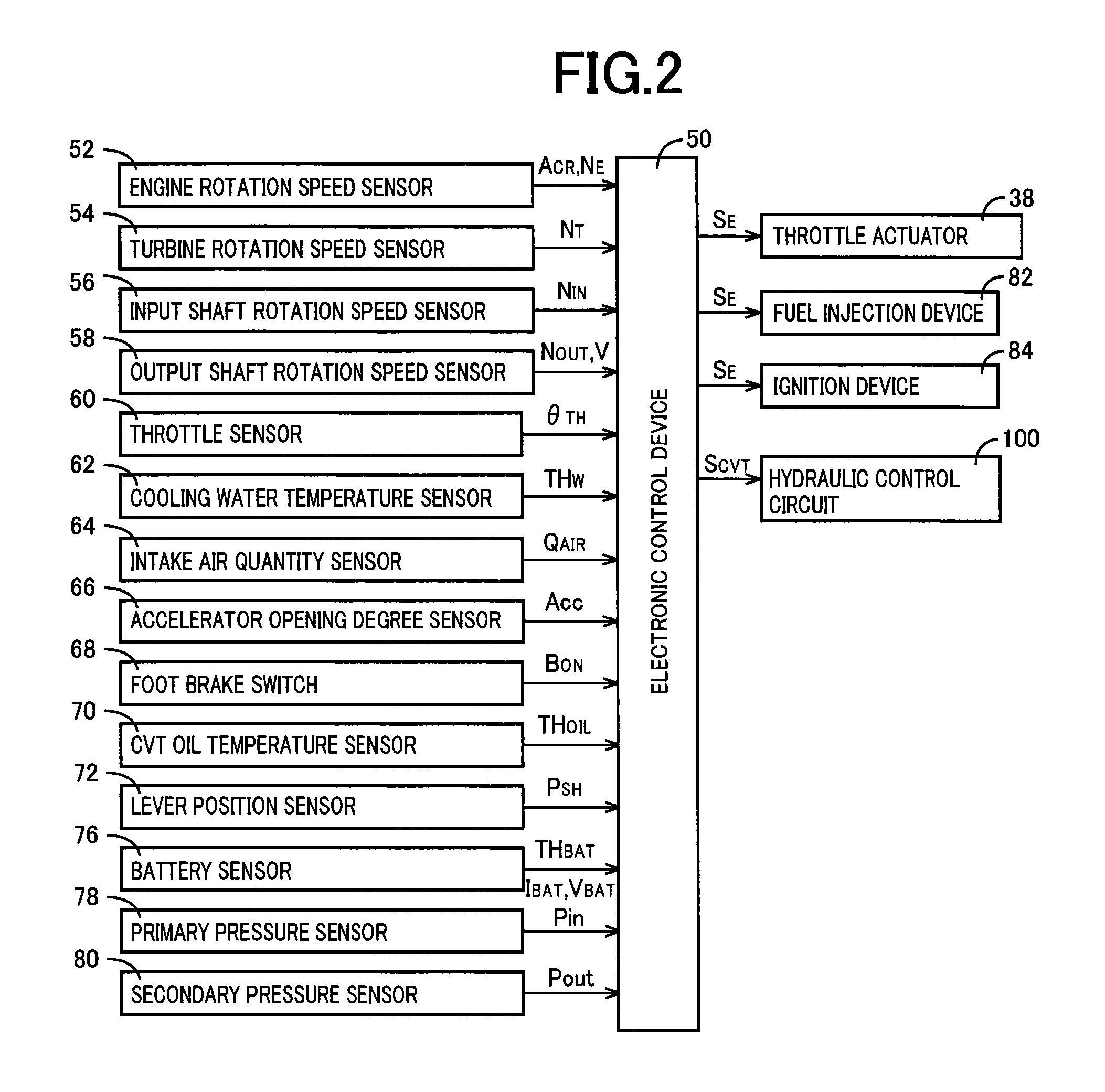

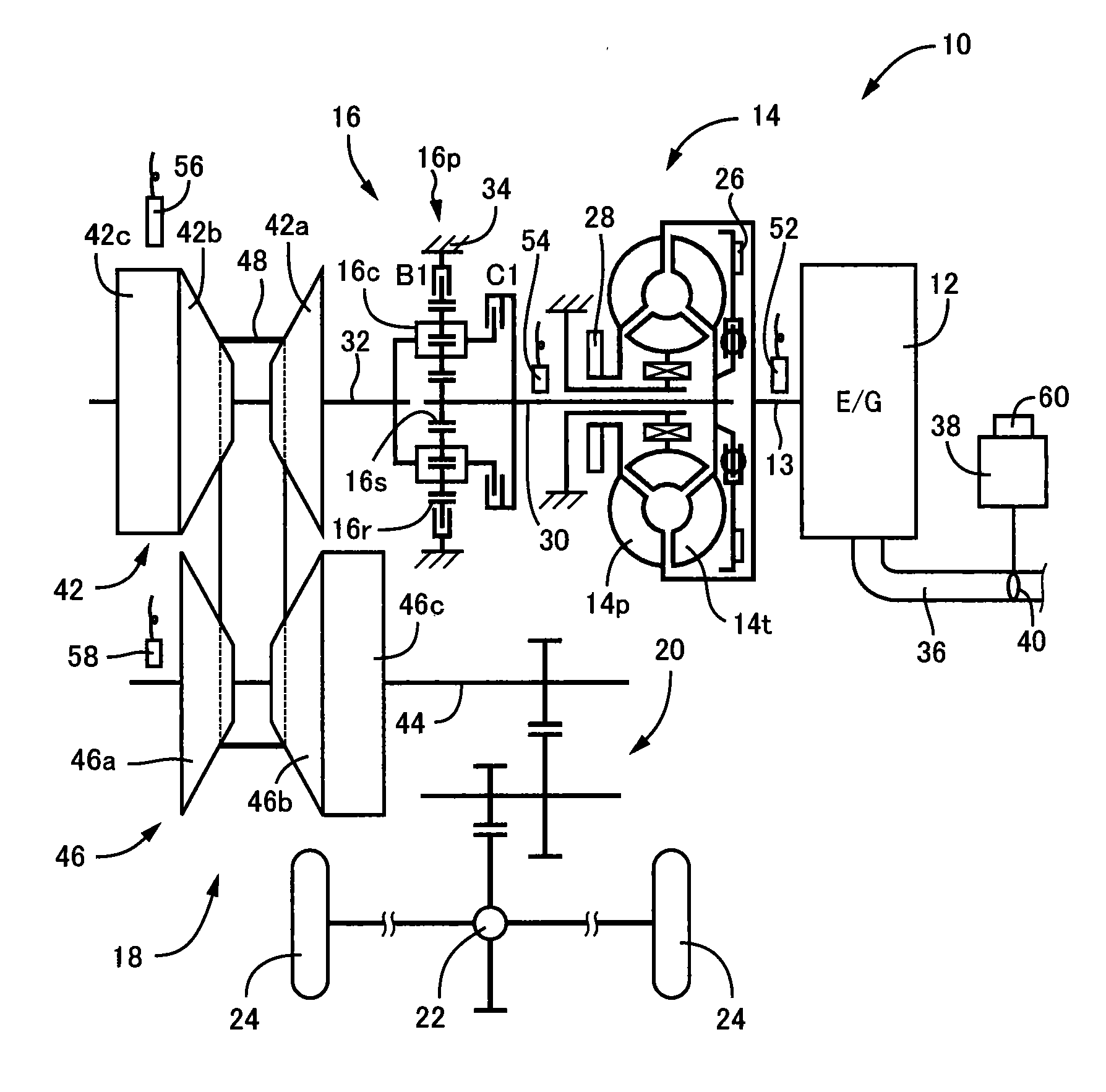

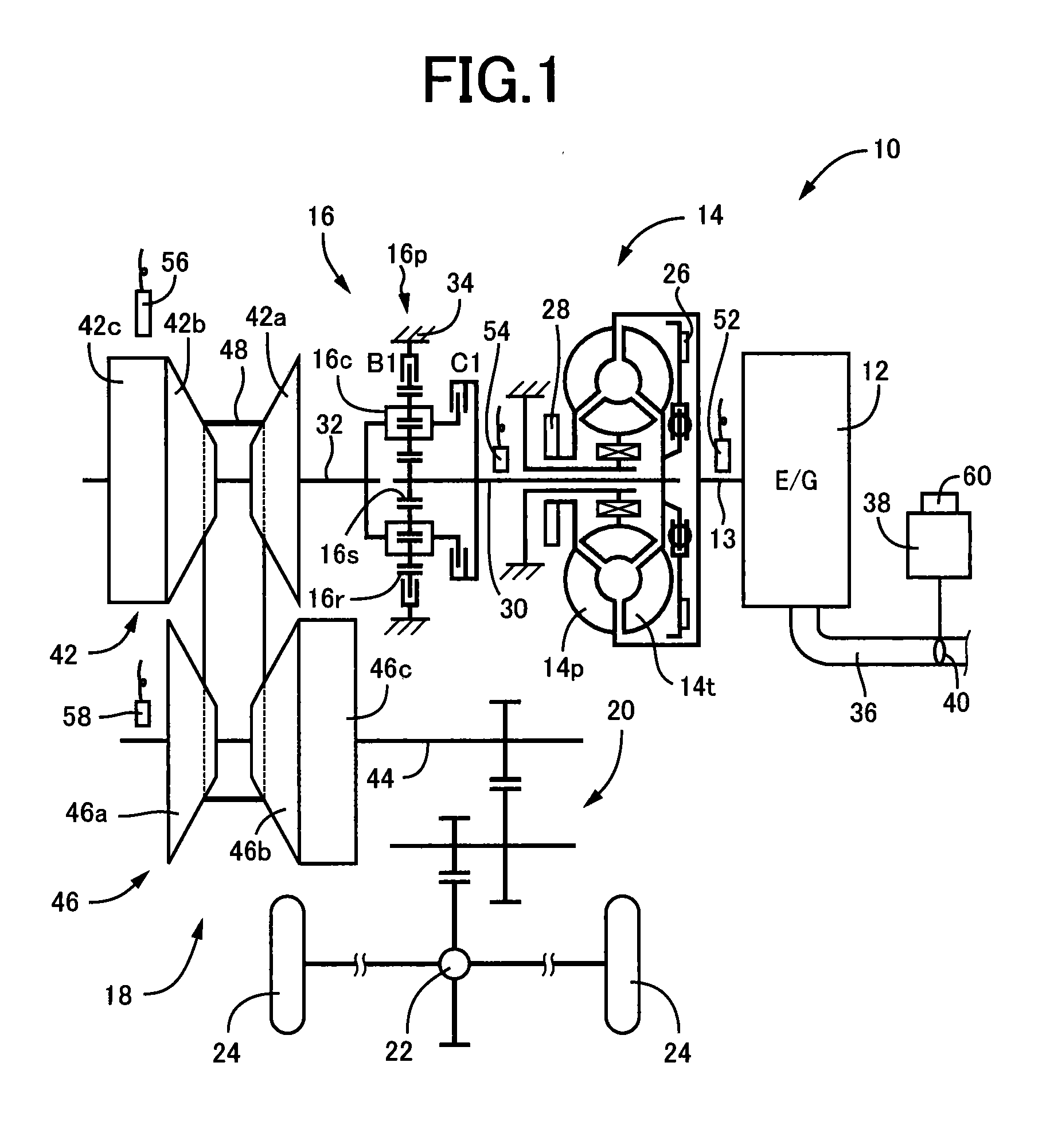

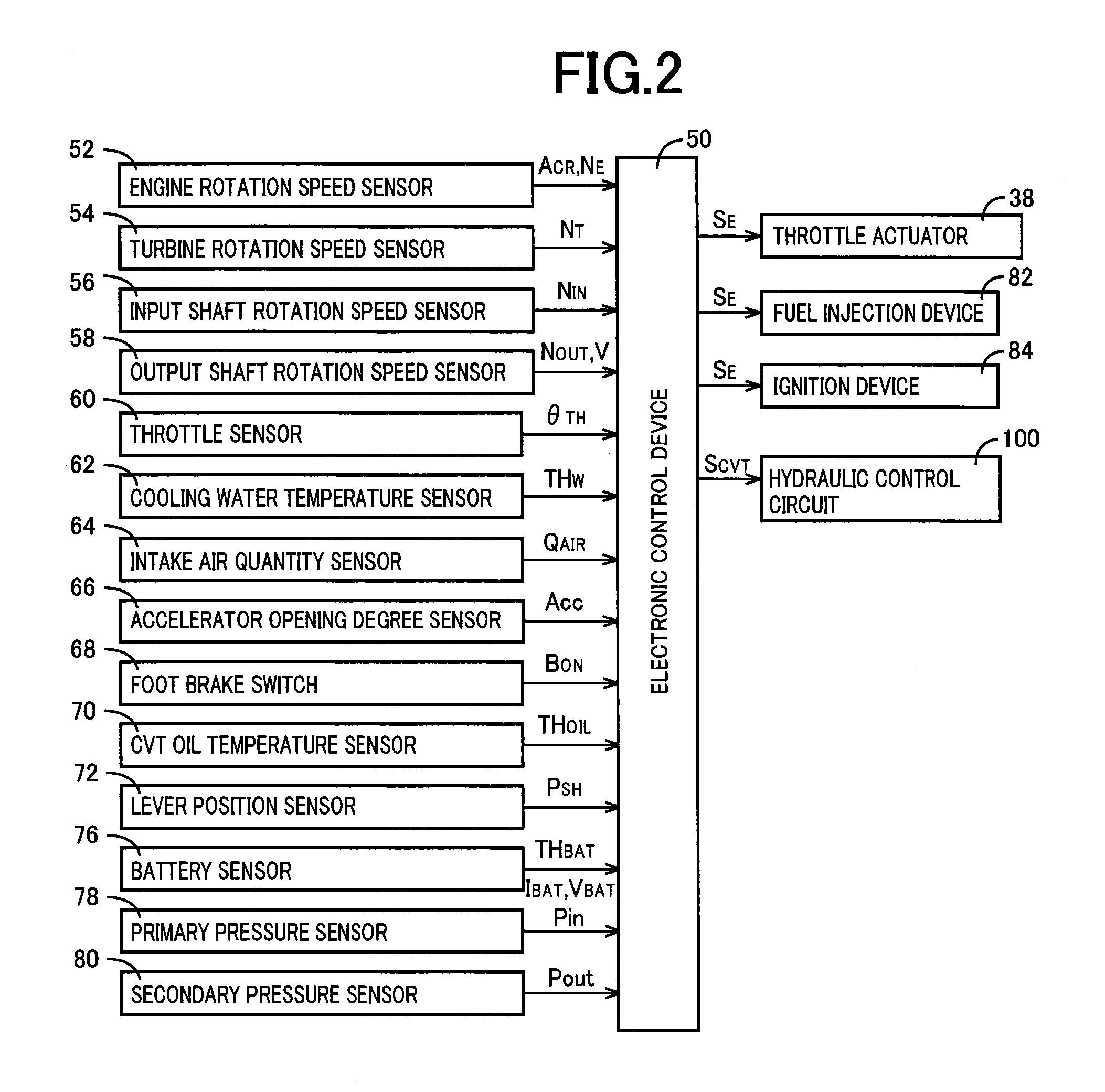

Control apparatus for power train including continuously variable transmission

InactiveUS20030150683A1Improve fuel economyEngage with obstructionMechanical actuated clutchesSlip couplingEngineeringControl theory

A control apparatus for a power train including a continuously variable transmission and a clutch arranged in series with the continuously variable transmission is provided in which an engaging pressure of the clutch is first reduced until a slip occurs, and is then increased after detection of the slip so as to re-engage the clutch, and an engaging pressure of the clutch to be established is calculated by giving an excess pressure to the engaging pressure at which the clutch is re-engaged, such that an excess amount of the transmitted torque of the clutch is set smaller than that of the continuously variable transmission. The control apparatus is adapted to determine a learned value as a correction value of the engaging pressure that is set in advance in accordance with an input torque applied to the clutch, based on the engaging pressure calculated by giving the excess pressure to the engaging pressure at which the clutch is re-engaged.

Owner:TOYOTA JIDOSHA KK

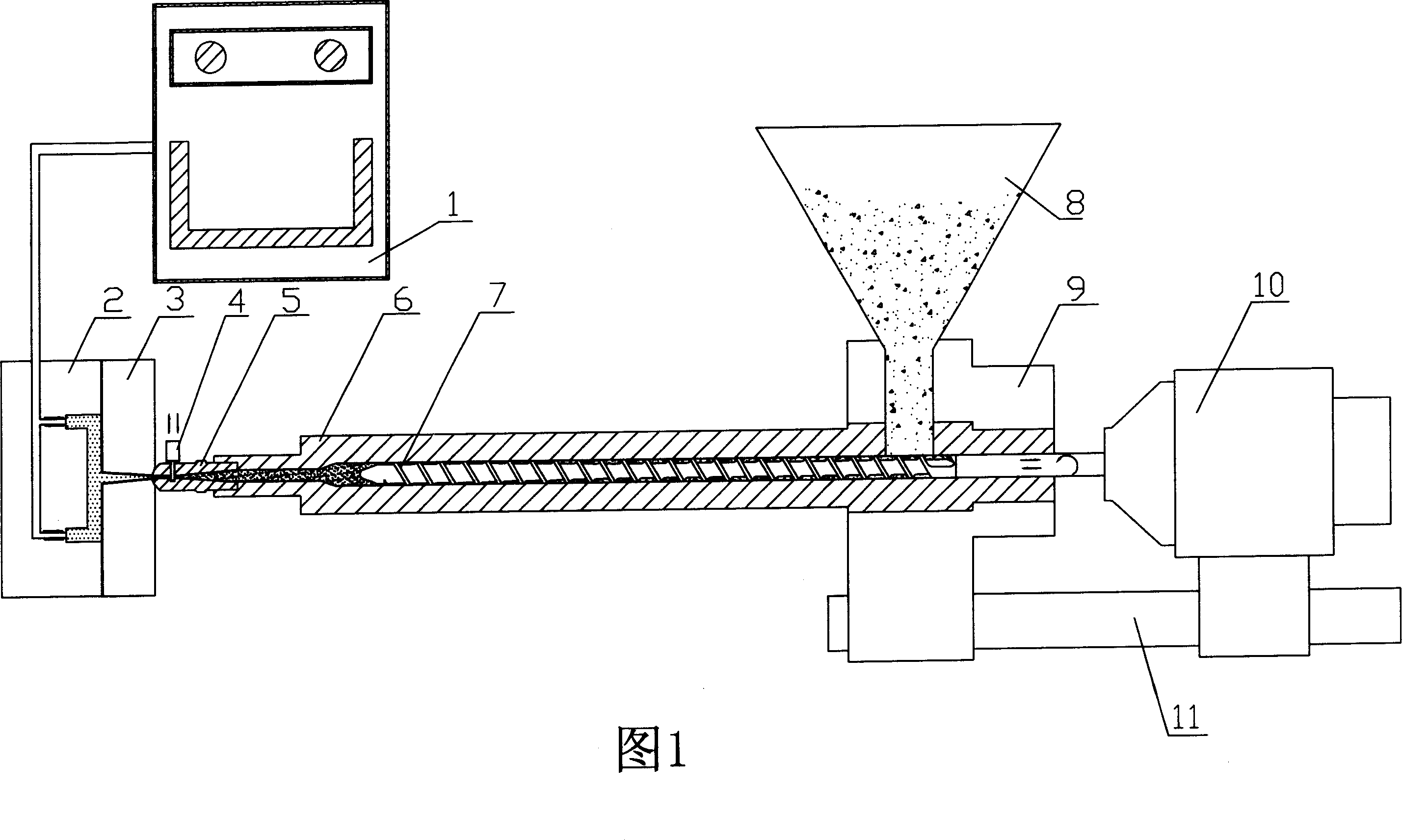

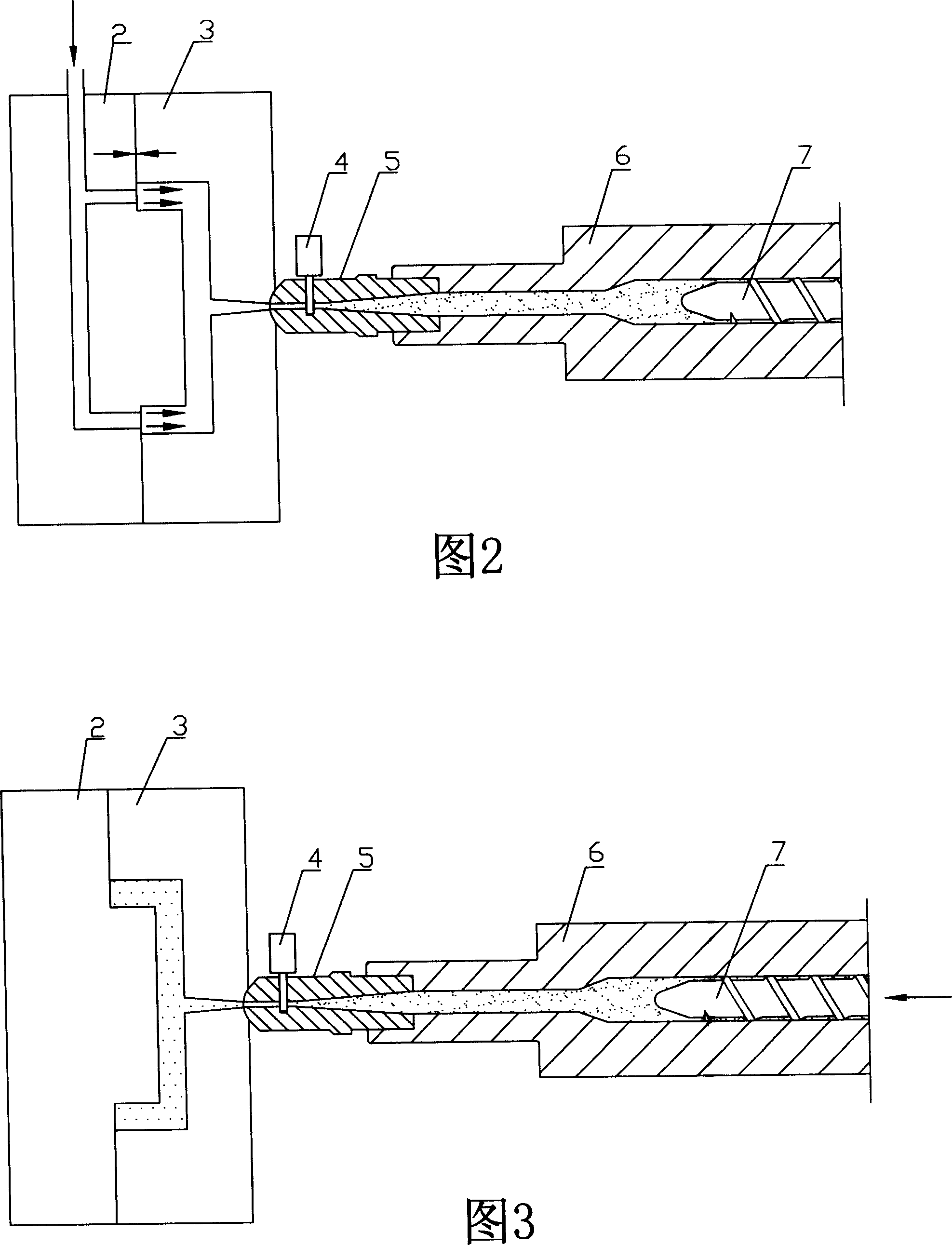

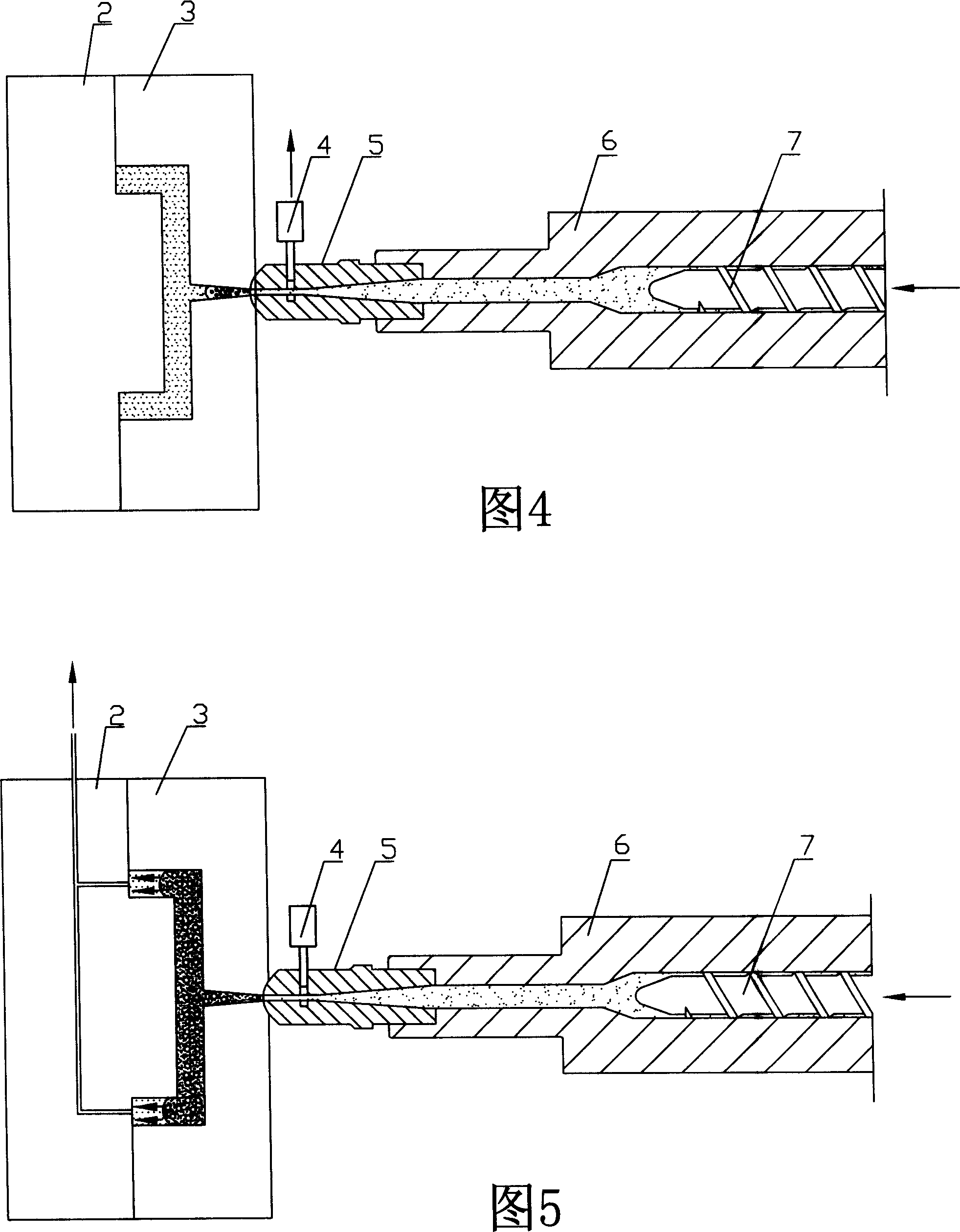

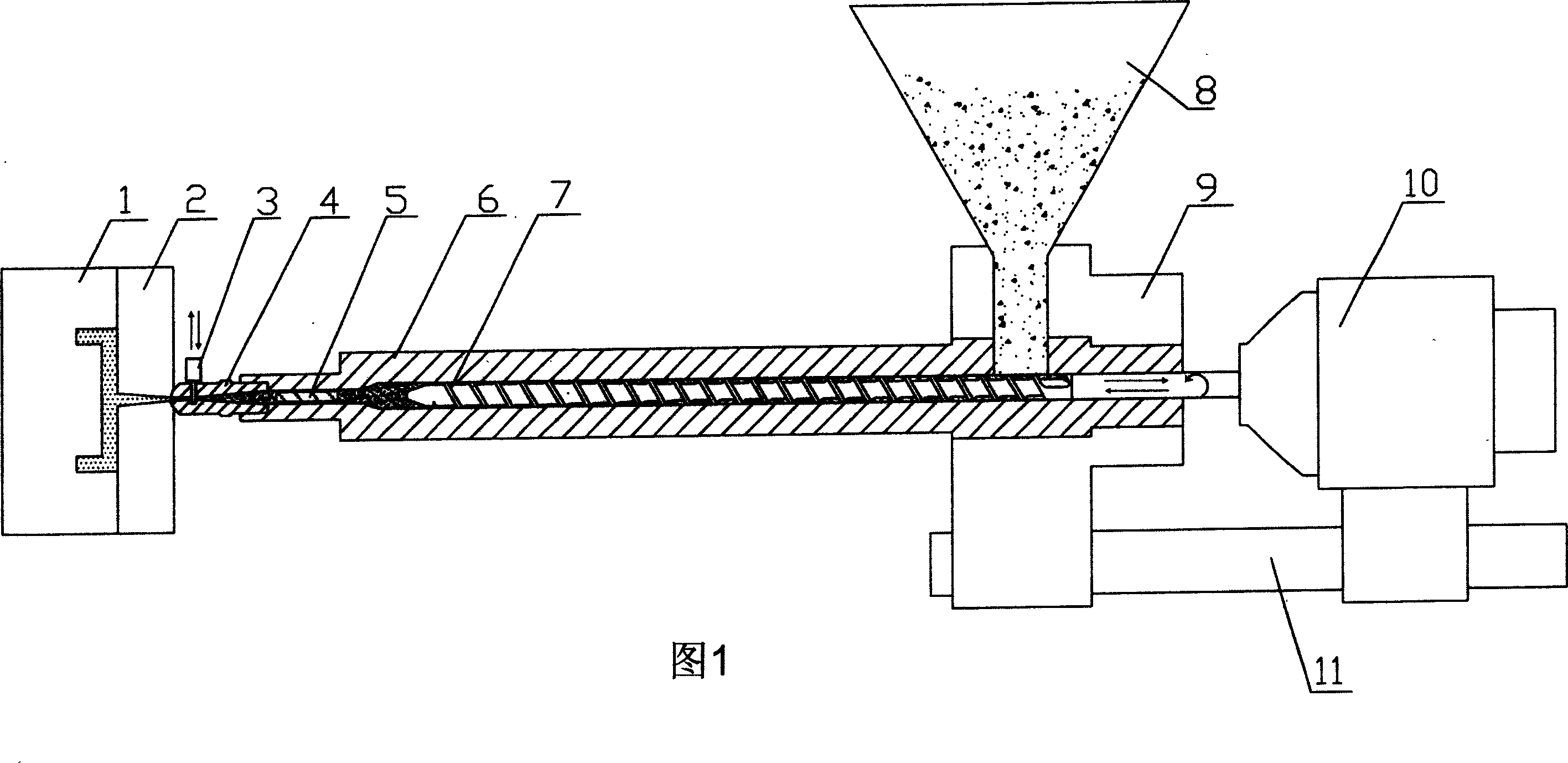

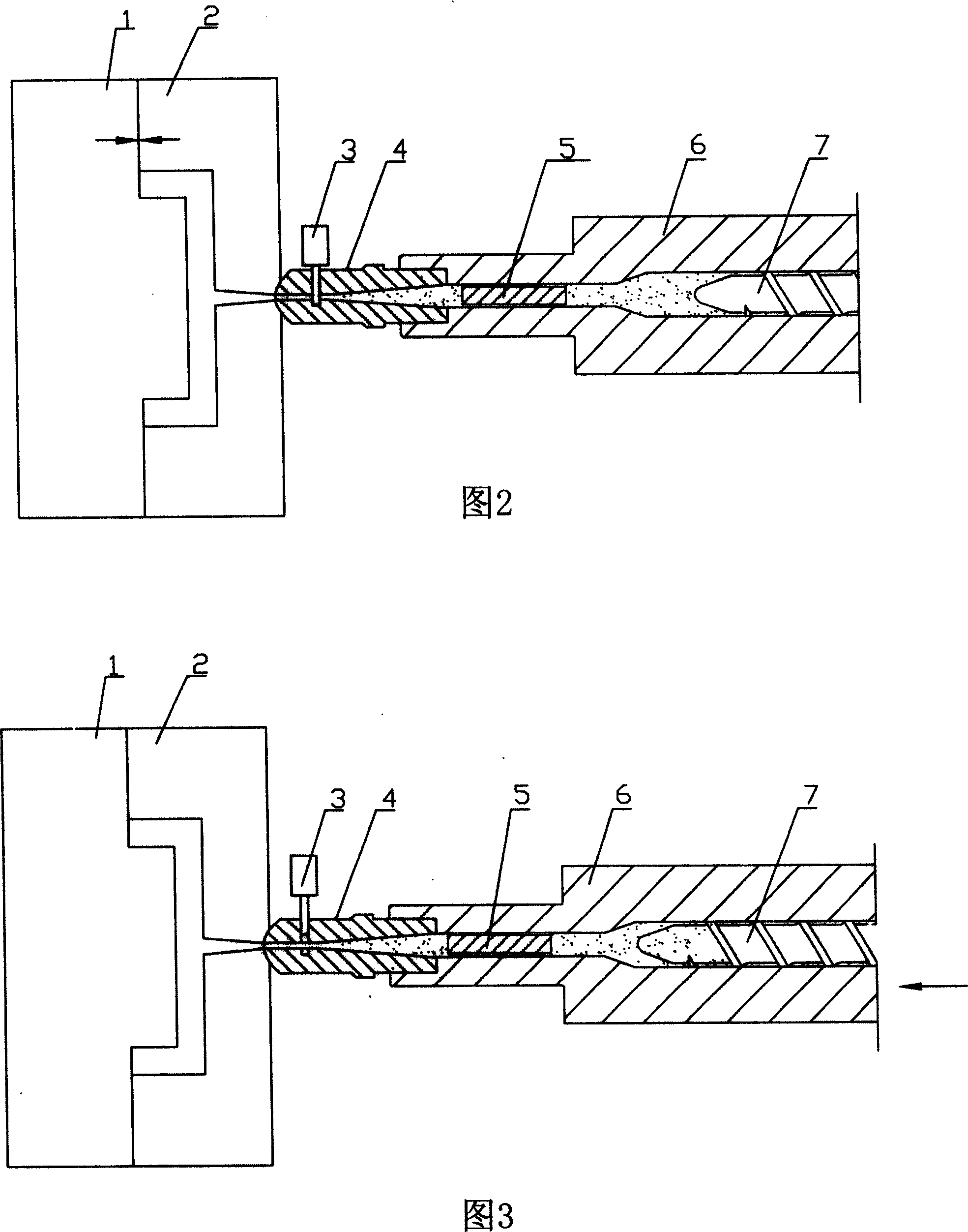

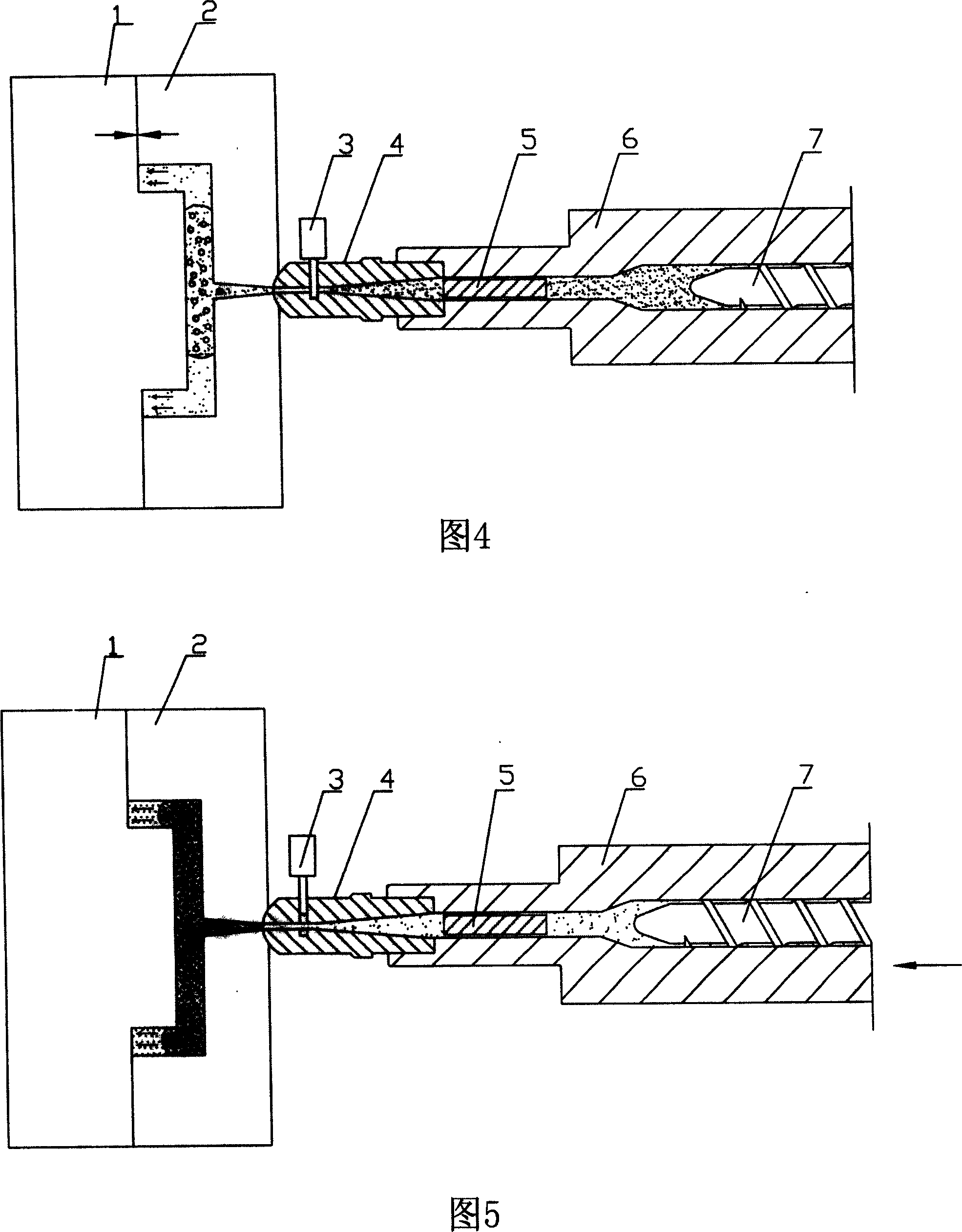

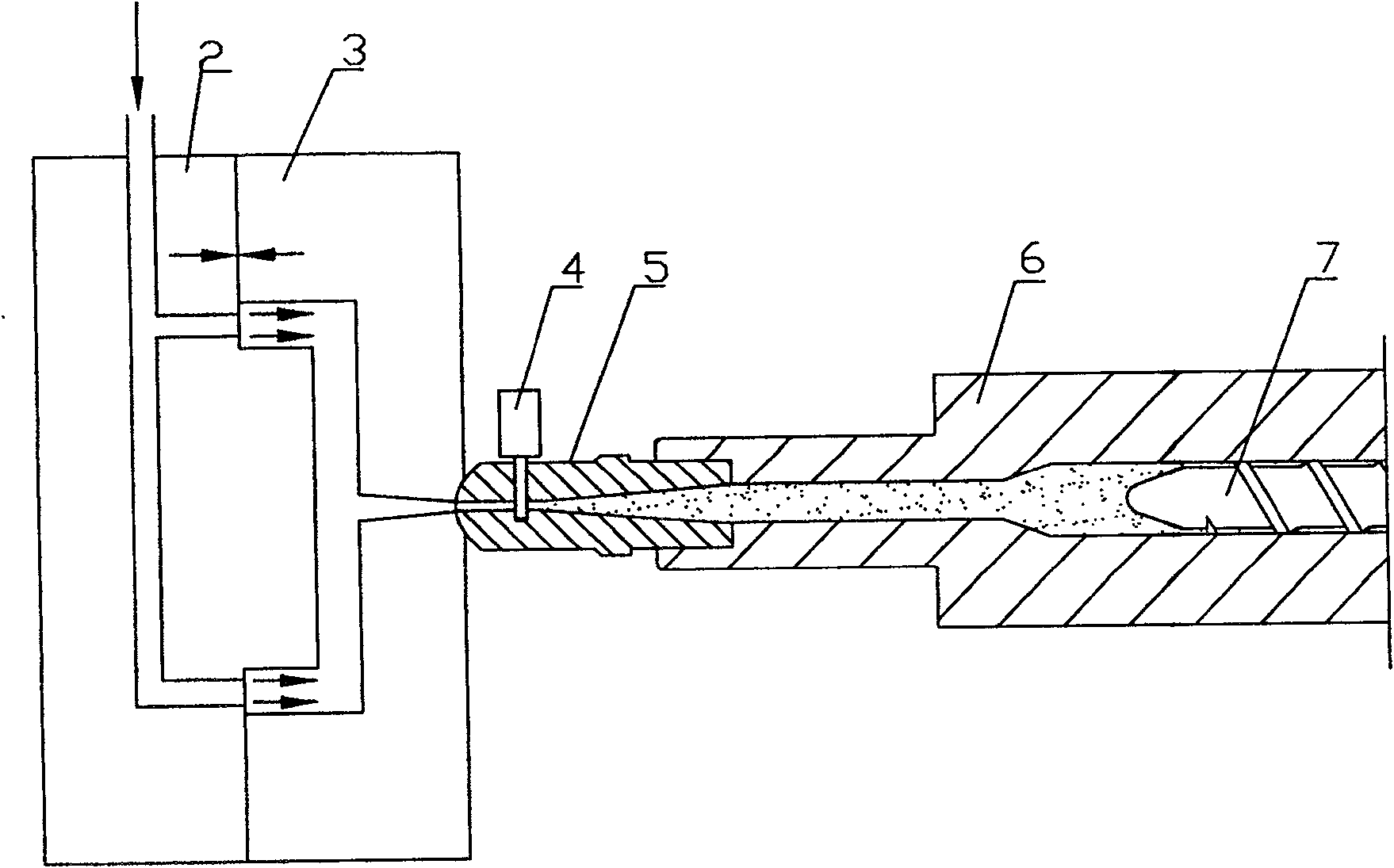

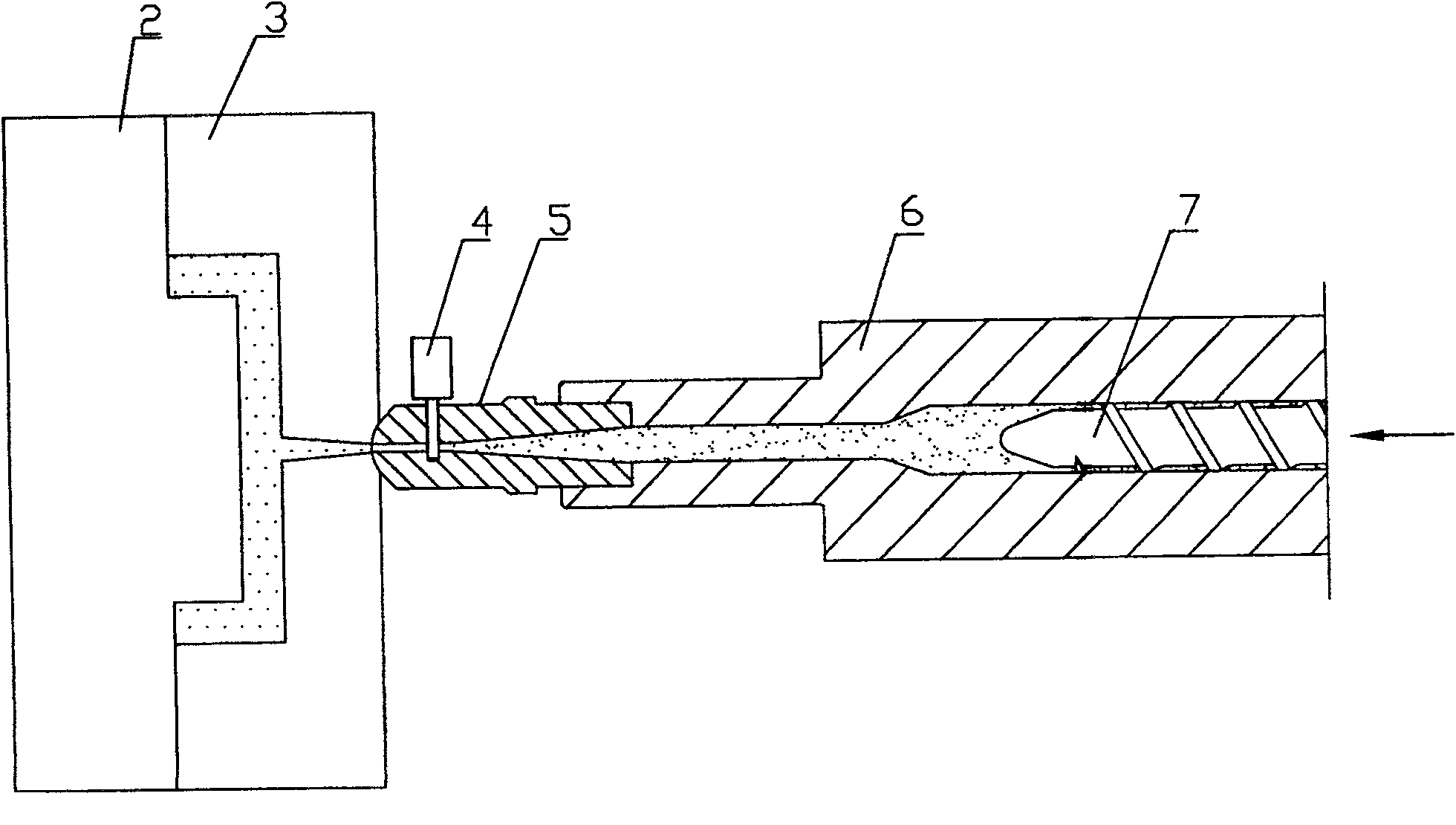

High speed injecting molding method by counter pressure method and chemical foaming method

The invention involves a counter-pressure chemical foaming high speed injection moulding shaping method. The invention provides a method which utilizes injection moulding shaping machine equipment, and dies, general gas energy, plastic raw materials and other system resources comprehensively, produces thick-wall plastic-foam product high speed and high effectively. The invention first closes the die and injects gas into die cavity, then injects molten material into die cavity, the welding fluid is full of die cavity after inner foaming, the molten material surface is closed to the metal wall-surface of die cavity, the molten material in die cavity is solidified and shaped after cooled, then opens the moving mold and static mold, the plastic products are prepared which surface is smooth and dense and inner is distributed with uniform foam. The invention can eliminate or reduce the converging cave and warping deformation of product surface, reduces injection moulding pressure, thereby reduces the lock-mode pressure of injection machine; reduces equipment operating costs, thereby improves the size accuracy and strength of products, can reduces 15% ~ 35% raw material consumption effectively, products have higher mechanical property and weight proportion.

Owner:DONGHUA MACHINERY

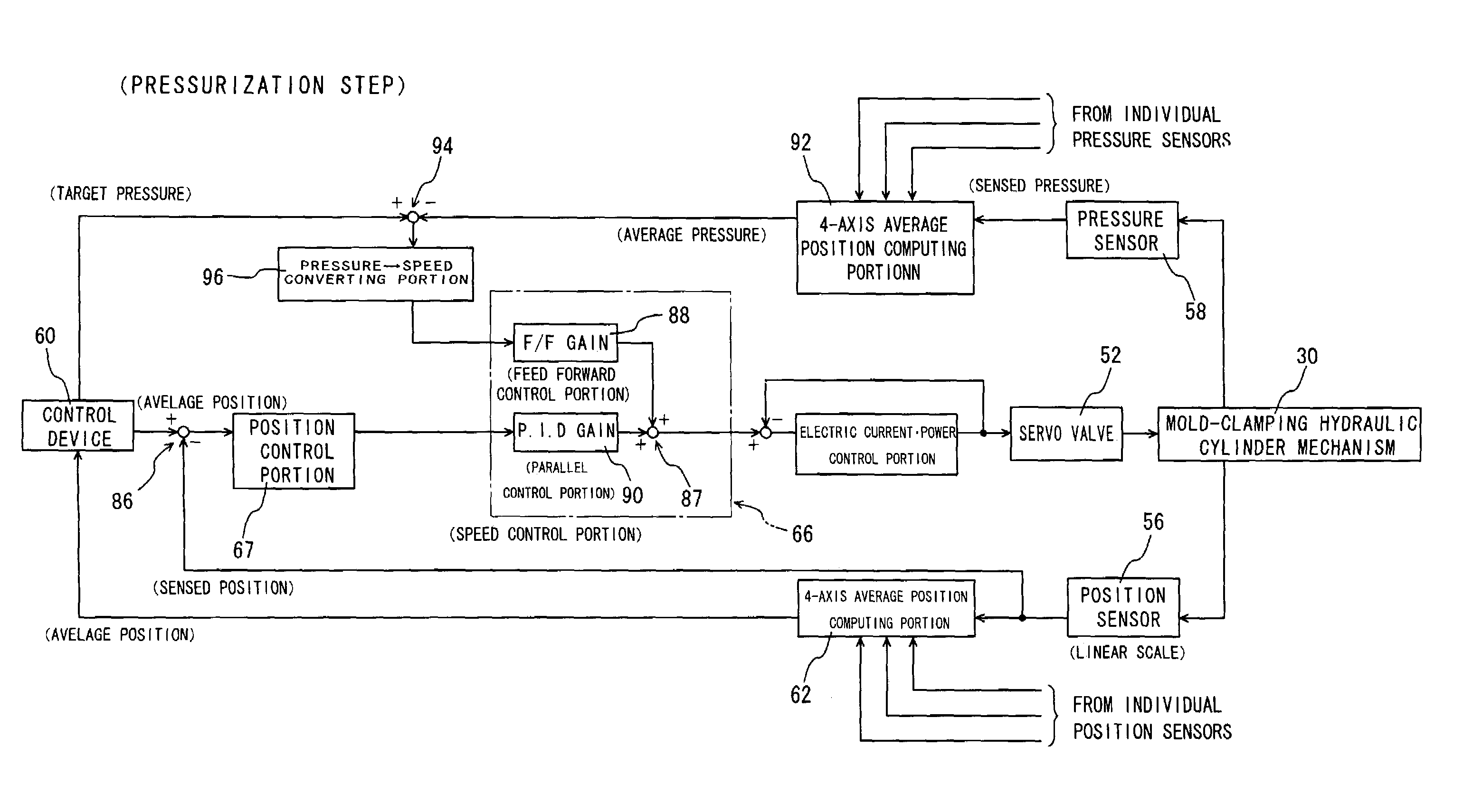

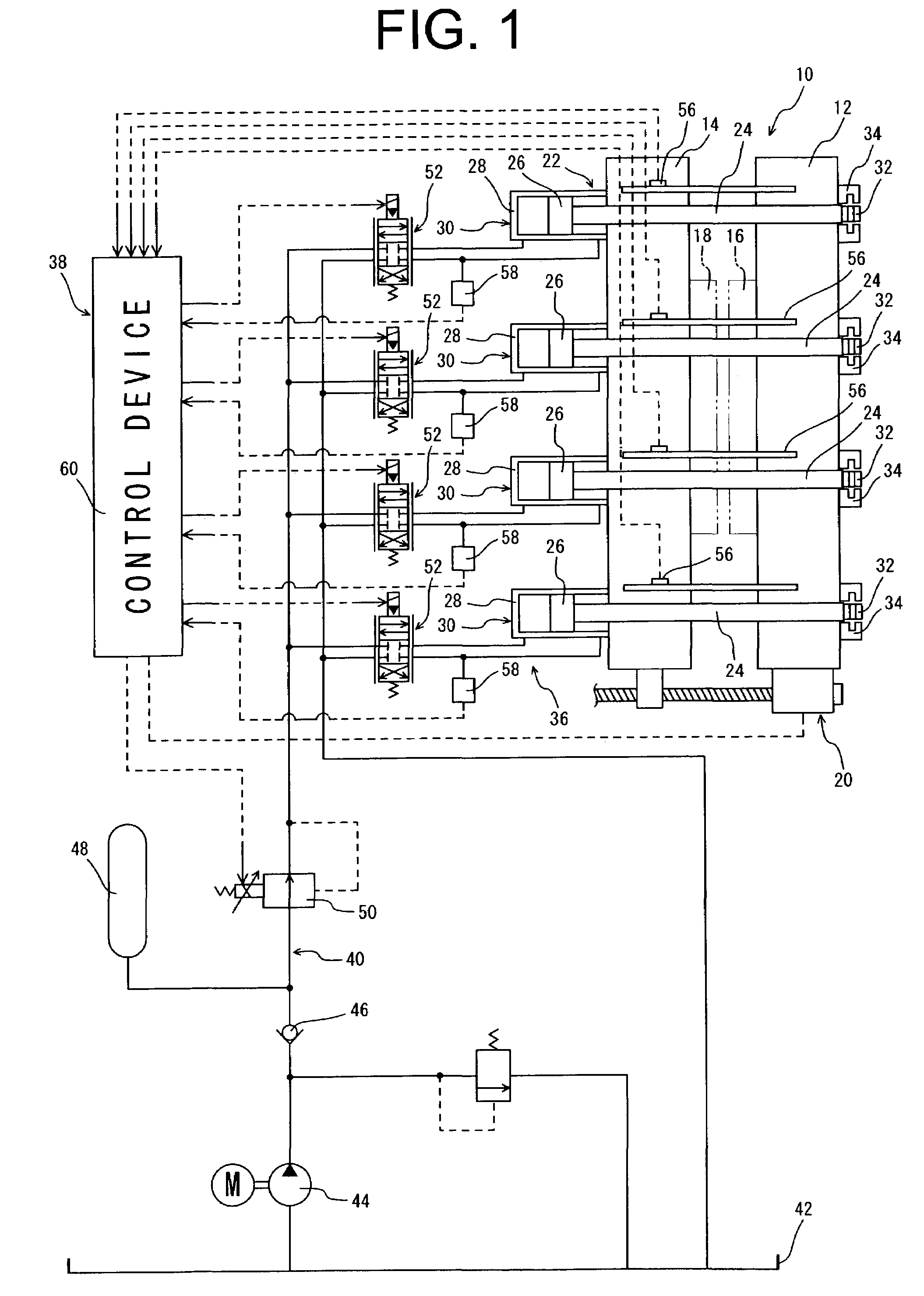

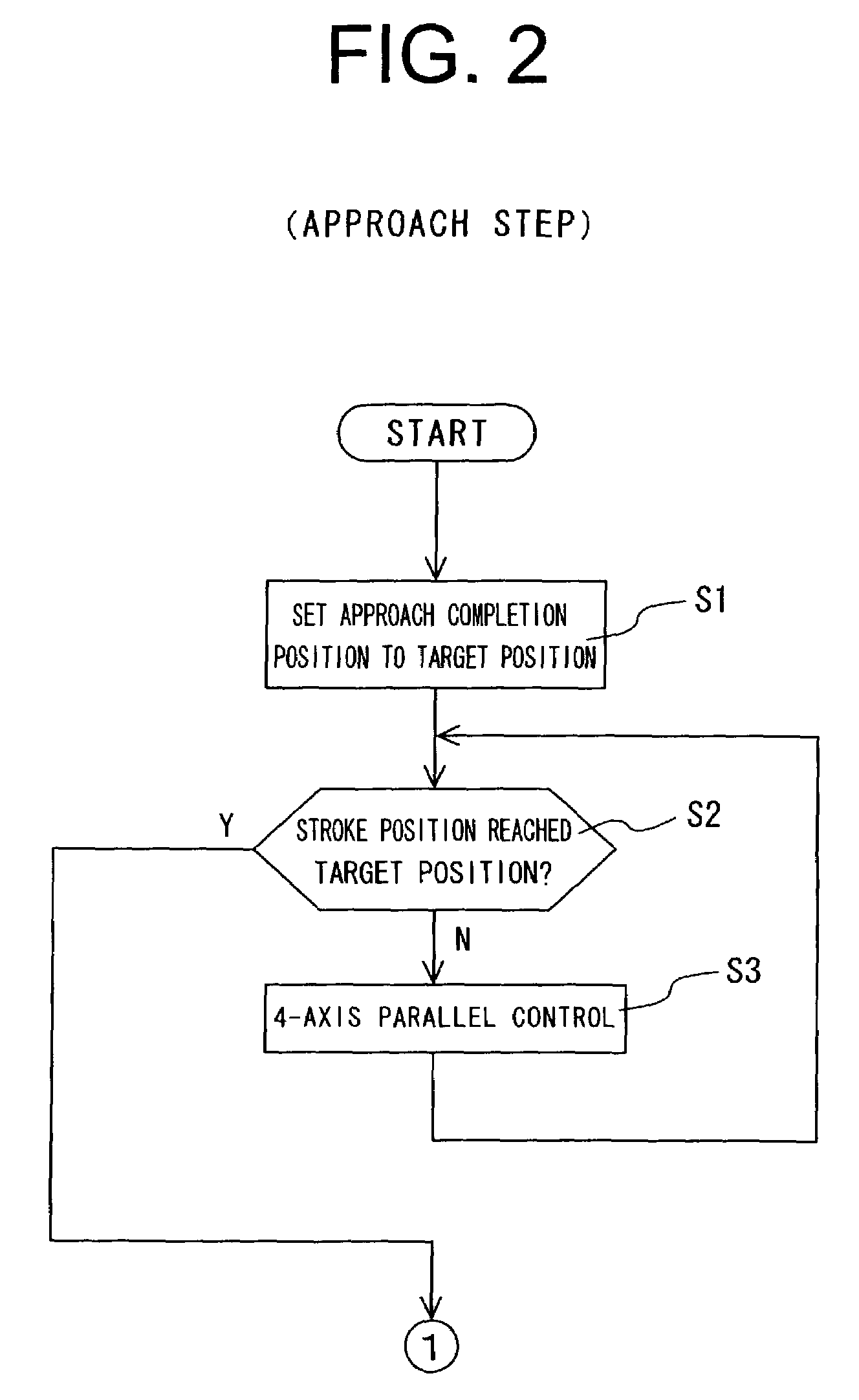

Compression molding method and mold clamping apparatus

ActiveUS7001545B2High precisionQuantity minimizationAuxillary shaping apparatusFood shapingCompression moldingControl signal

Disclosed is a compression molding method comprising the steps of: calculating an average value of mold clamping forces sensed in a plurality of mold clamping mechanisms for clamping a stationary and a movable mold half; obtaining a first control signal on the basis of deviation between a preset target mold clamping force and an average value of sensed mold clamping forces; sensing positions of movable members of the mold clamping mechanisms; obtaining an average value of sensed positions; setting the average value as a successive target position; obtaining a second control signal on the basis of deviation between each of the sensed positions and the successive target position; and obtaining a clamping control signal for each of the clamping mechanisms by adding the first control signal and the second control signal. An apparatus suitable for implementing the method is also disclosed.

Owner:MEIKI

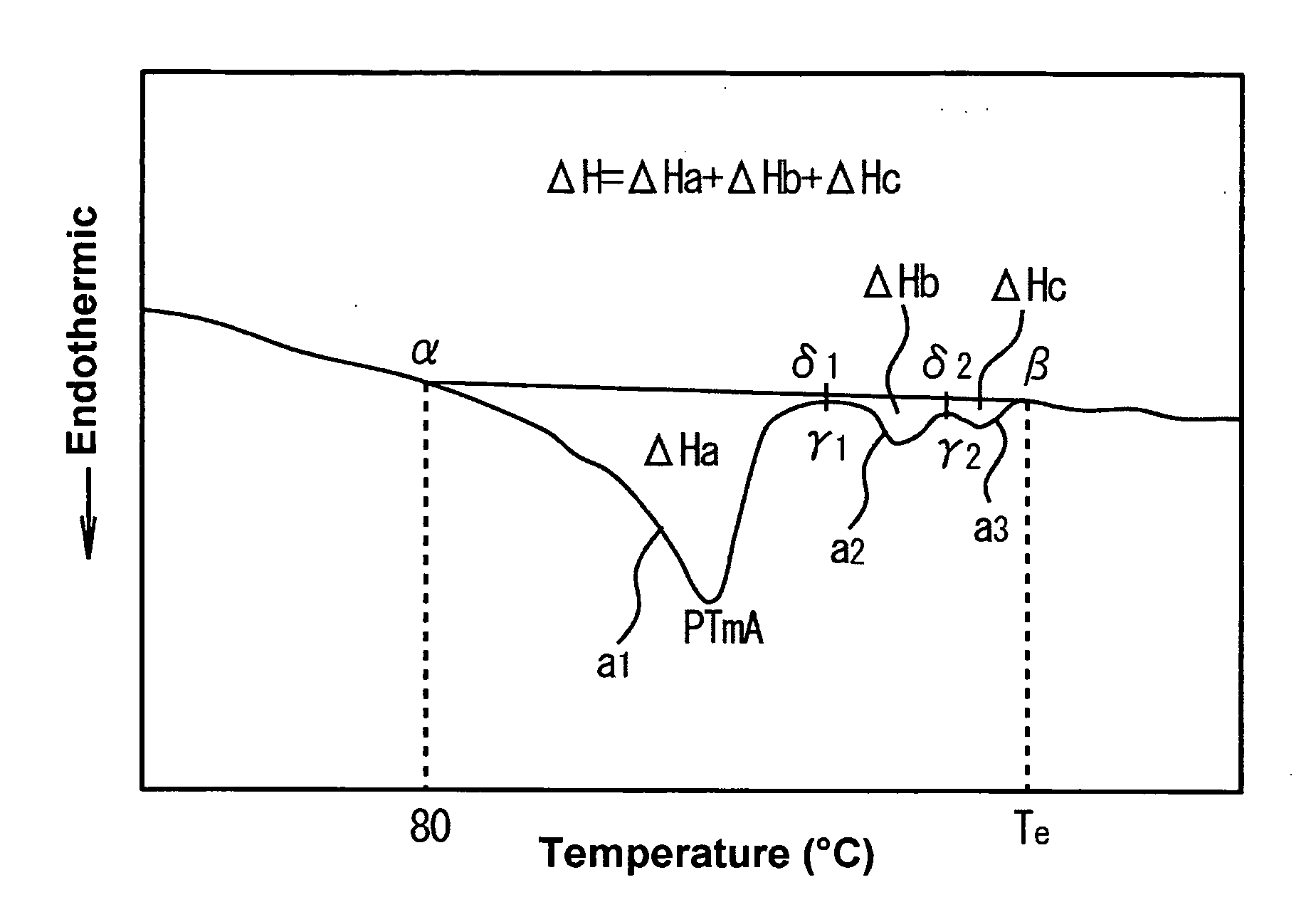

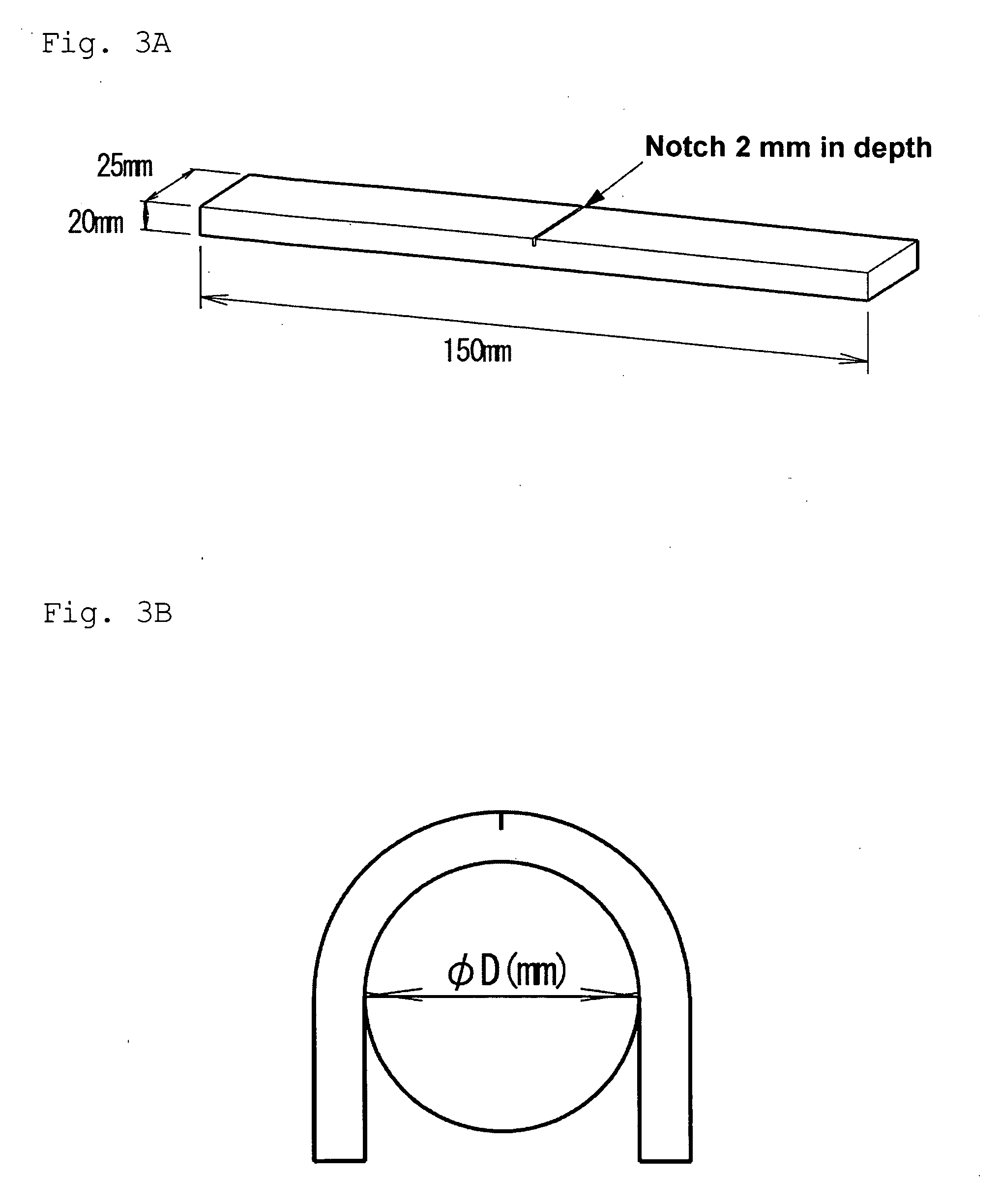

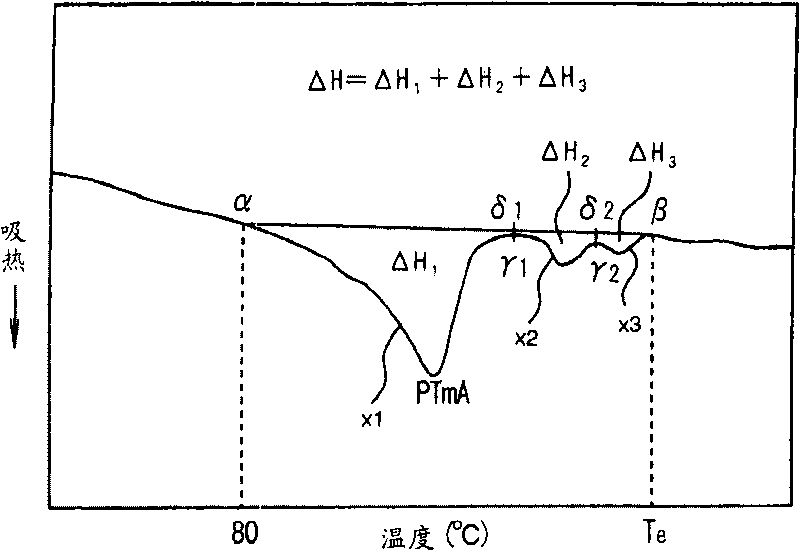

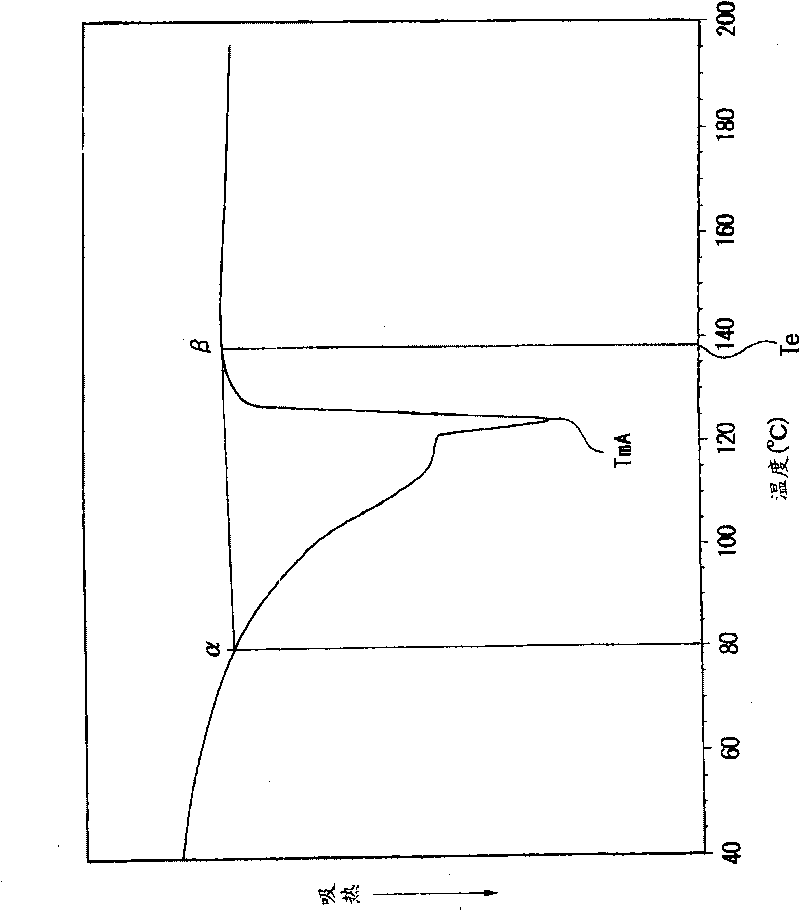

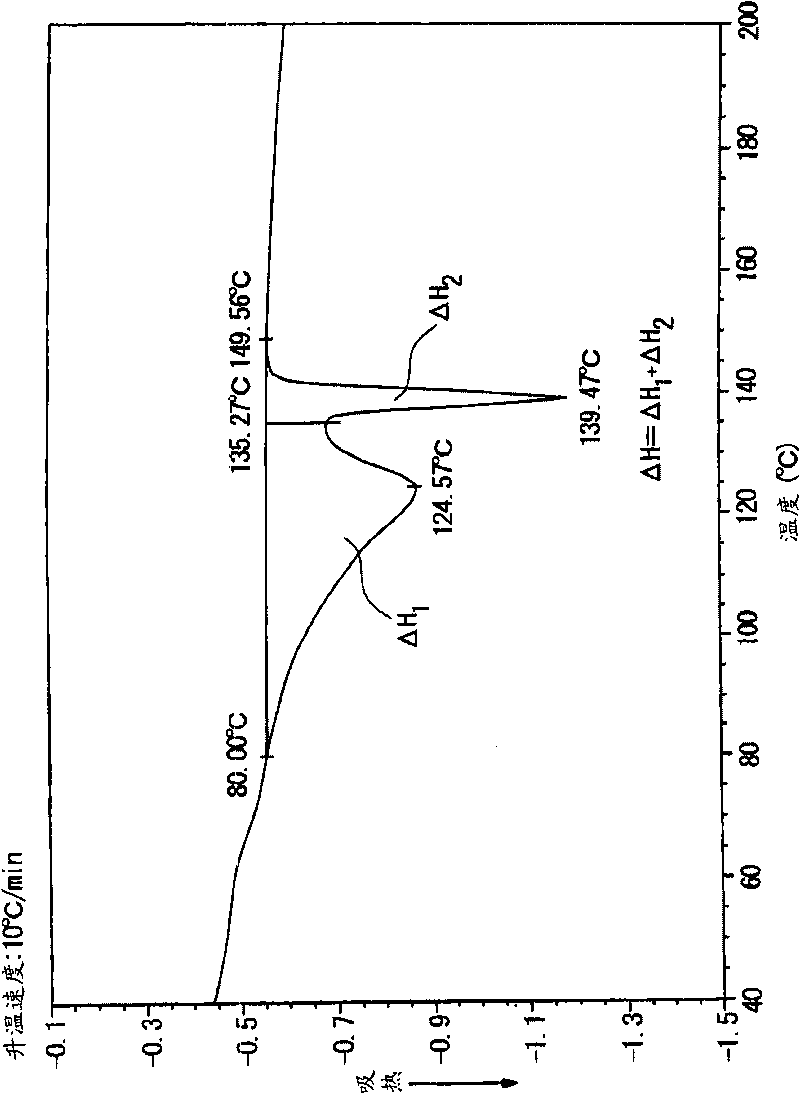

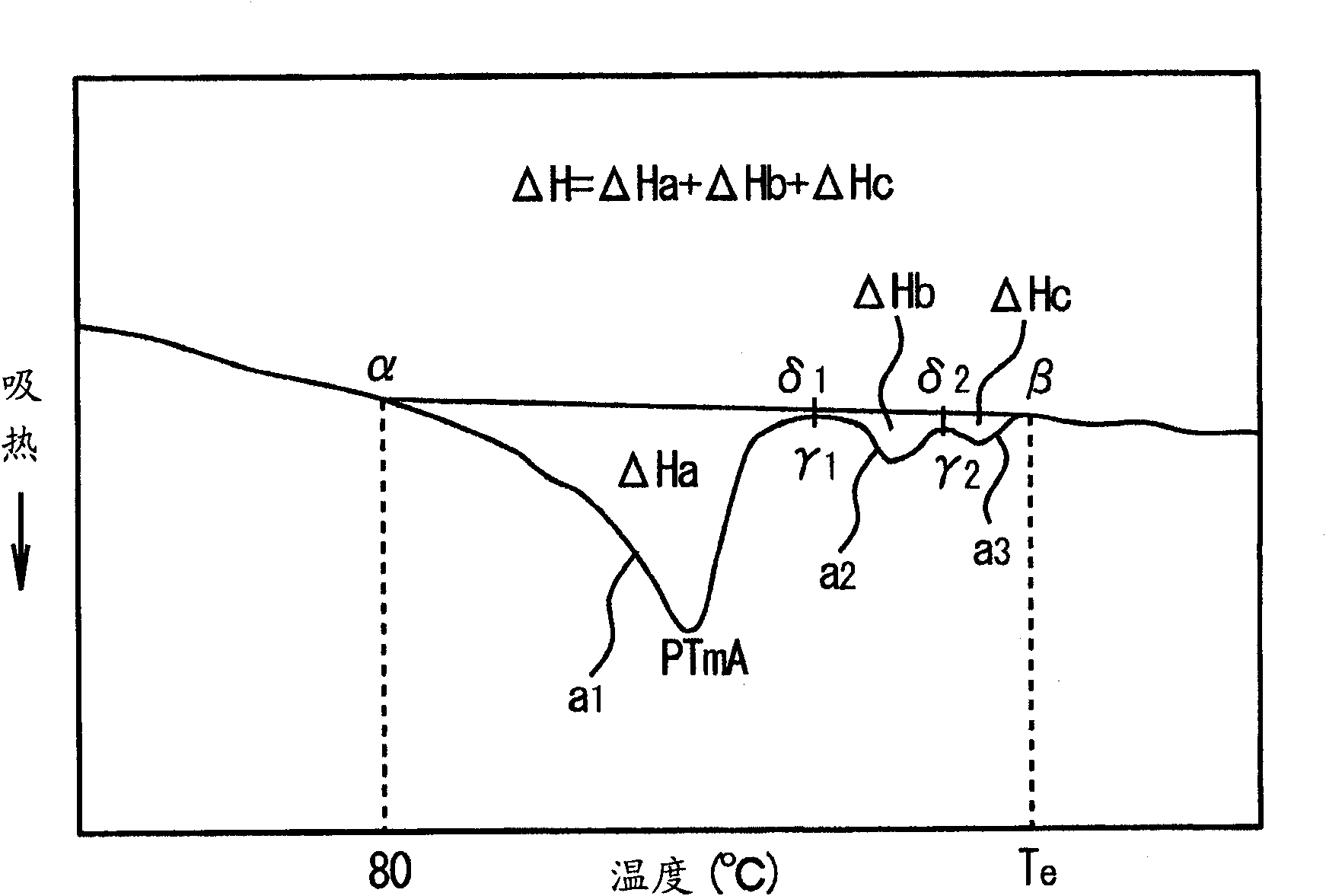

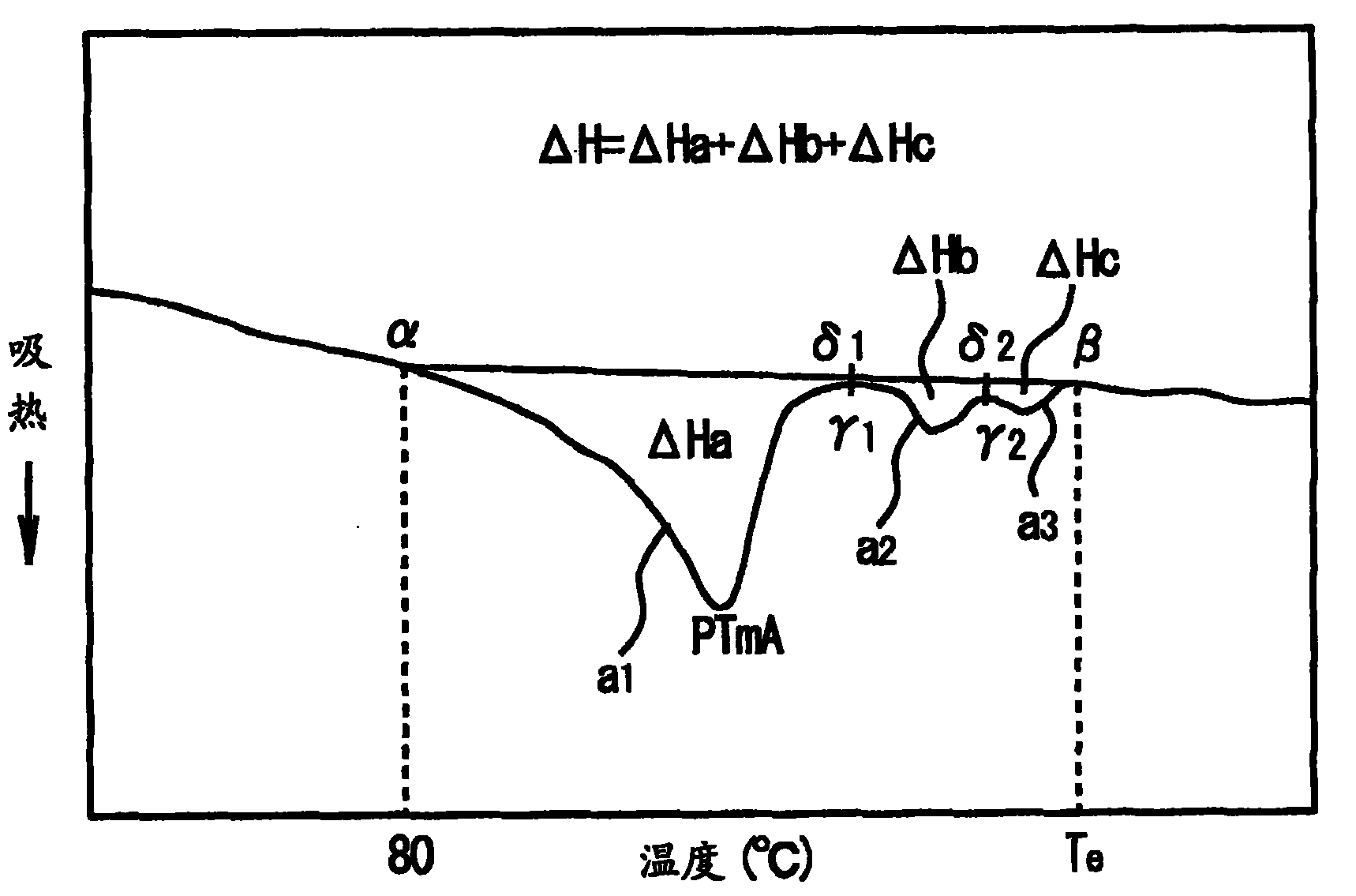

Polypropylene resin foam particle and molding thereof

ActiveUS20100105787A1Excellent appearance and mechanical propertiesExtended temperature rangeRise ratePolypropylene

A polypropylene resin foamed bead from which a foamed bead molded article excelling in appearance, heat resistance and mechanical properties can be obtained at the molding temperature lower than that for conventional polypropylene resin foamed beads; and a foamed bead molded article obtained by molding the same. The polypropylene resin foamed bead is characterized by having such a crystal structure that in the first DSC curve obtained when the temperature of the foamed bead sample is raised from ordinary temperature to 200° C. at a temperature rising rate of 2° C / min by a differential scanning calorimetry, there appear a main endothermic peak of 100° to 140° C. endothermic peak apex temperature exhibiting 70 to 95% endothermic peak calorific value based on the total endothermic peak calorific value and two or more endothermic peaks exhibited on the high temperature side with respect to the main endothermic peak.

Owner:JSP CORP

Control device of continuously variable transmission for vehicle

ActiveUS8798877B2Prevent slippingImprove fuel efficiencyV-beltsDigital data processing detailsLow speedTransmission belt

A control device of a continuously variable transmission for a vehicle has a pair of variable pulleys and a transmission belt, and the control device respectively controls input-side and output-side thrust forces of input-side and output-side variable pulleys to set an actual gear ratio to a target gear ratio, prevents a slip of the transmission belt, and determines a lowest-speed-side gear ratio. When it is determined that a detection value of a rotation speed for calculating the actual gear ratio does not reflect an actual rotation speed, target input-side and output-side thrust forces are set to be target thrust forces for maintaining the lowest-speed-side gear ratio and preventing the slip of the transmission belt, and based on whether the actual gear ratio is already the lowest-speed-side gear ratio, values of the input-side and output-side thrust forces are changed for obtaining the target thrust forces.

Owner:TOYOTA JIDOSHA KK

Control device of continuously variable transmission for vehicle

ActiveUS20130218429A1Improve fuel efficiencyReduce clamping pressureDigital data processing detailsGearing controlVariatorEffective diameter

A control device of a continuously variable transmission that controls an input-side thrust force of an input-side variable pulley and an output-side thrust force of an output-side variable pulley to set an actual gear ratio to a target gear ratio and prevent a slip of the transmission belt. The continuously variable transmission having a lowest-speed-side gear ratio determined by mechanically preventing movement of an input-side rotating body moved in an axial direction for varying an effective diameter of the input-side variable pulley, if it is determined that a detection value of a rotation speed for calculating the actual gear ratio does not reflect an actual rotation speed, a target input-side thrust force and a target output-side thrust force being set to be target thrust forces for maintaining the lowest-speed-side gear ratio and preventing a slip of the transmission belt, and, based on whether the actual gear ratio is already the lowest-speed-side gear ratio, the control device differentiating control methods of the input-side thrust force and the output-side thrust force each of which is independently controllable to adjust a pressure in order to obtain the target thrust.

Owner:TOYOTA JIDOSHA KK

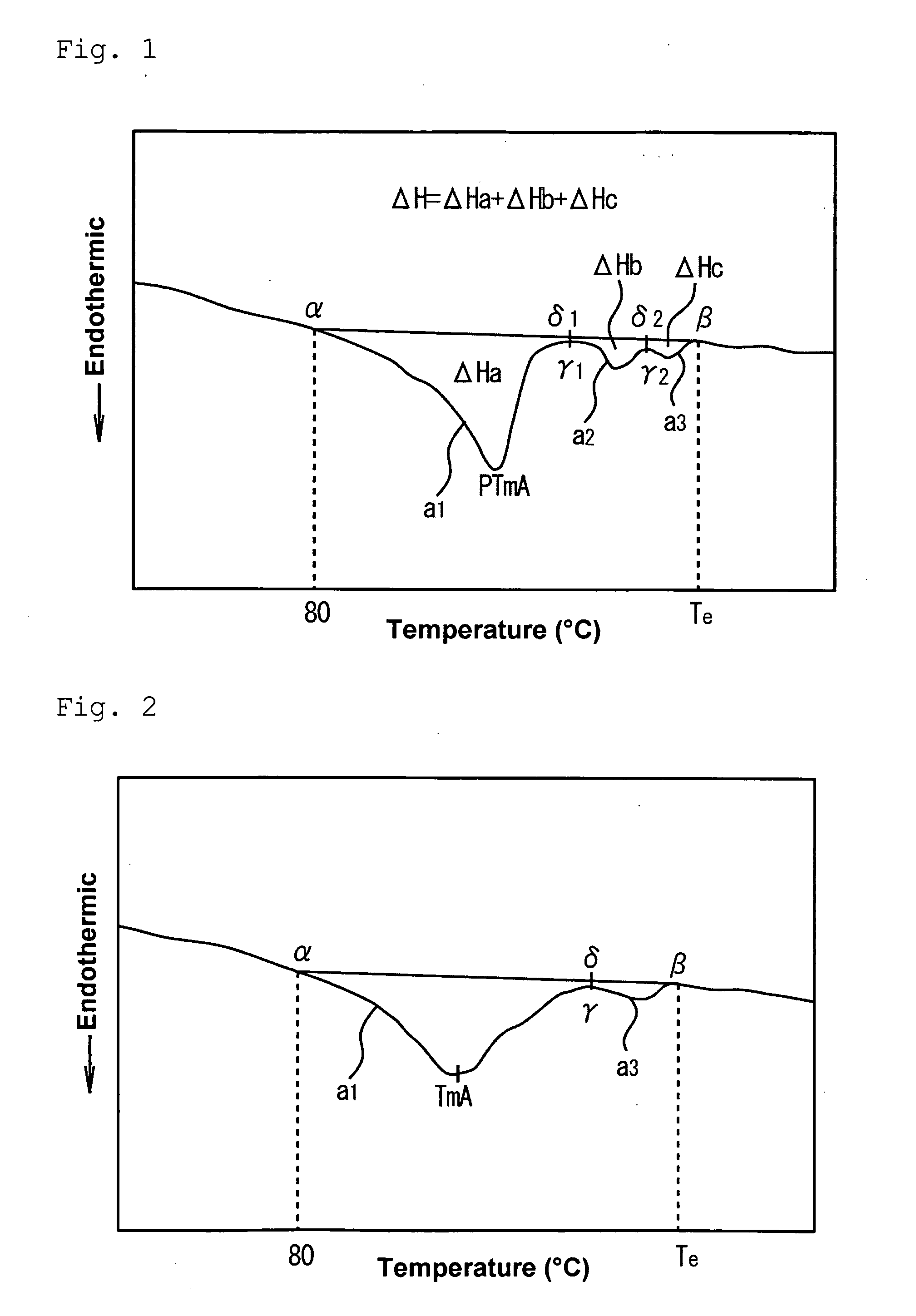

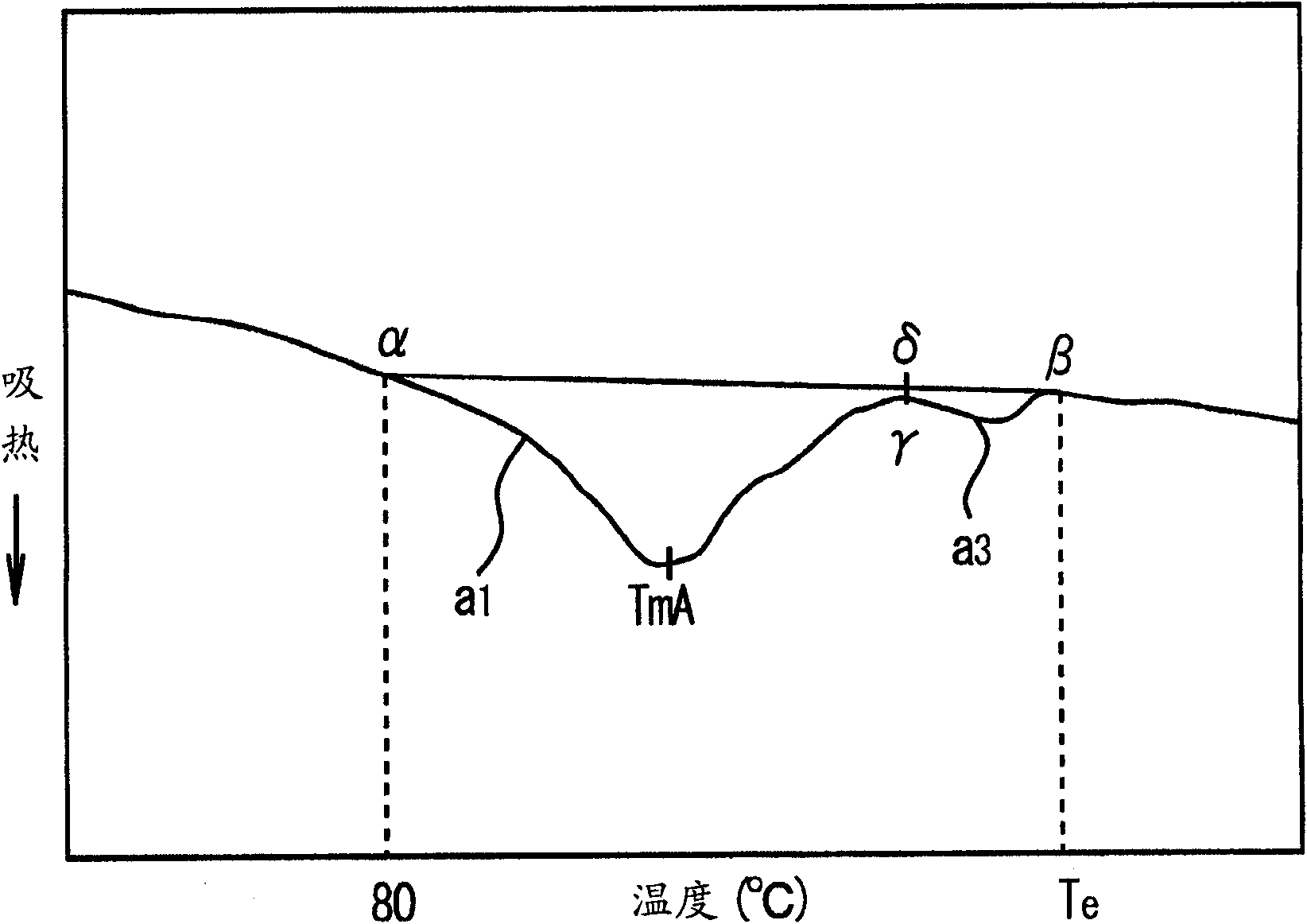

Expanded polypropylene resin beads and foamed molded article thereof

The polypropylenic resin foamed particles are provided, which have a melting point of 120[deg.]C or higher and lower than 140[deg.]C, wherein the melting point is determined from a DSC curve determined by heat flux differential scanning calorimetry in accordance with JIS K7121-1987 in which a test piece of 1 to 3 mg of the polypropylene resin foamed particles is heated to 200[deg.]C at a heating rate of 10[deg.]C / min, then cooled to 30[deg.]C at a rate of 10[deg.]C / min, and again heated from 30[deg.]C to 200[deg.]C at a heating rate of 10[deg.]C / min, to determine the DSC curve. The polypropylenic resin foamed praticles have an apparent density ratio [(the apparent density before heated) / (the apparent density after heated)] of not greater than 1.5 when heated for 10 s by saturated steam at a temperature higher by 5[deg.]C than the melting point thereof in a pressure vessel.

Owner:JSP CORP

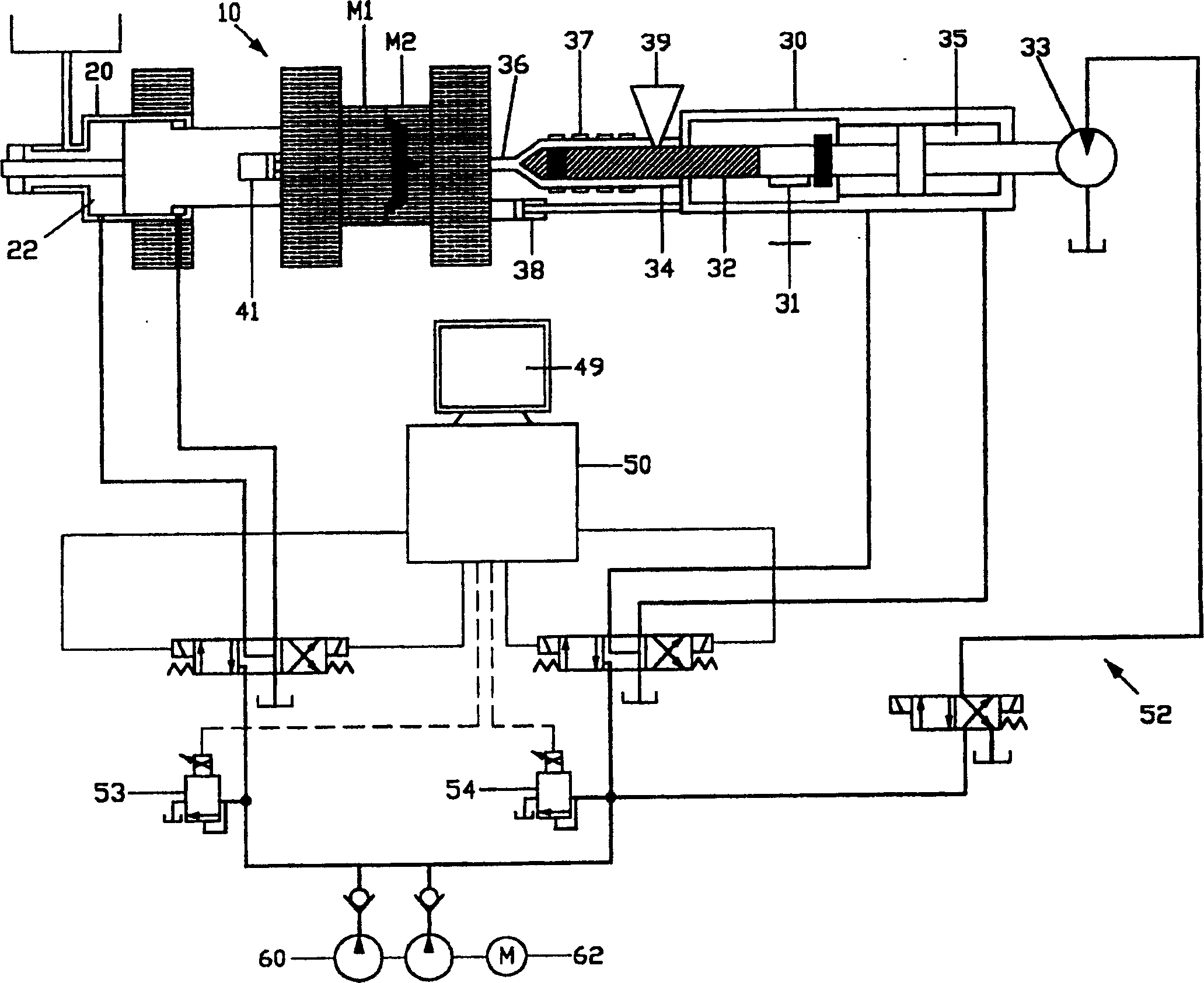

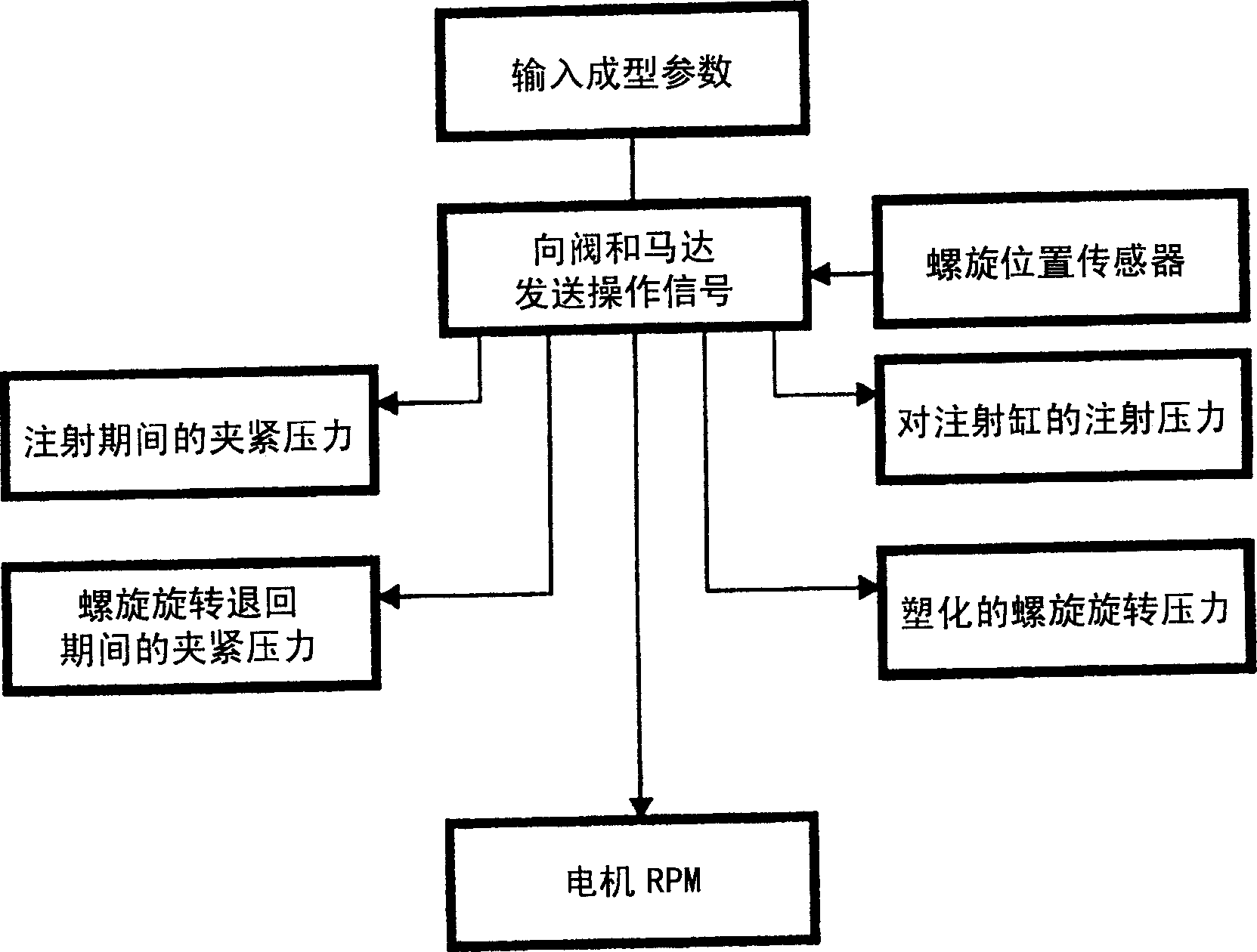

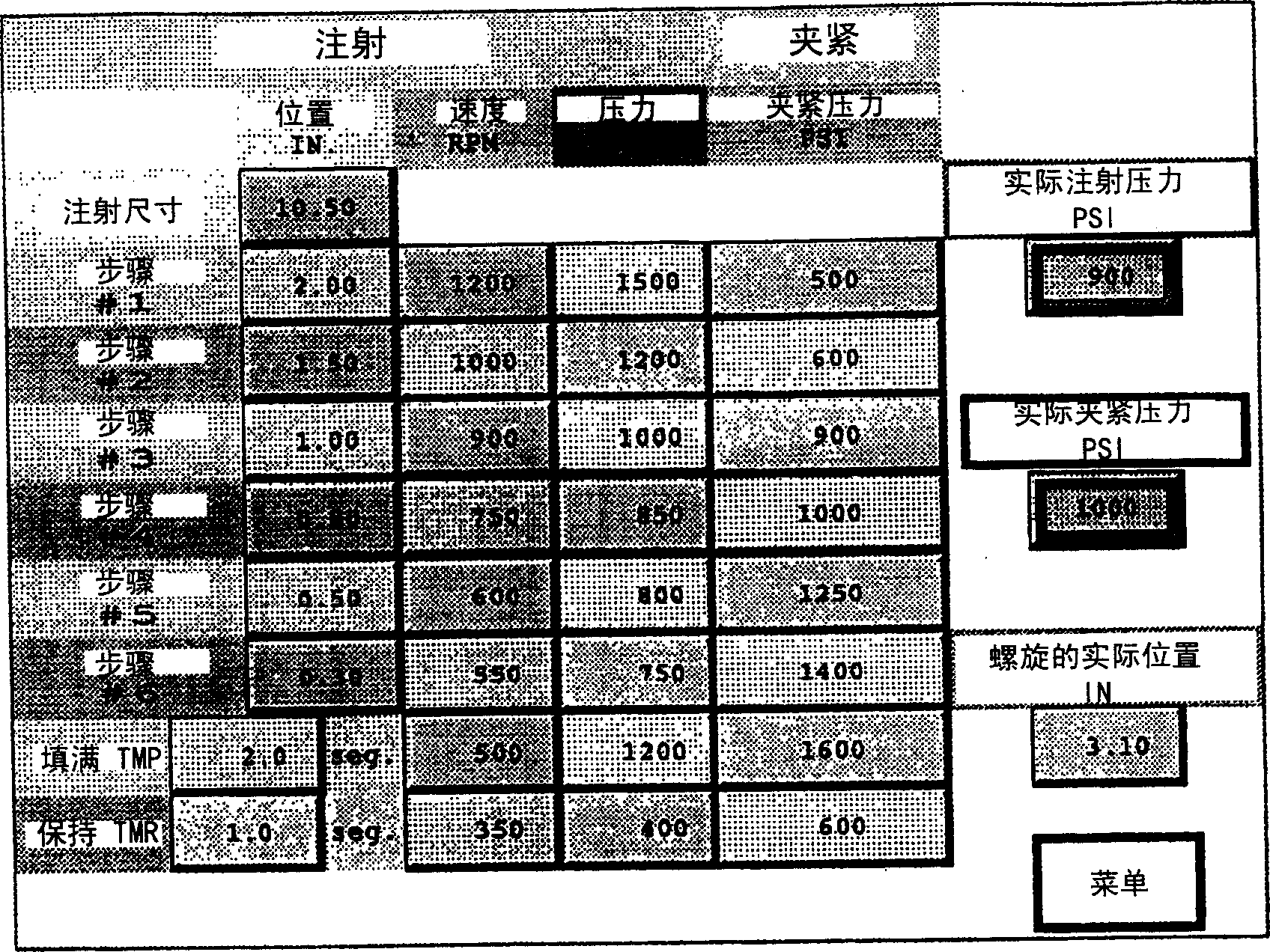

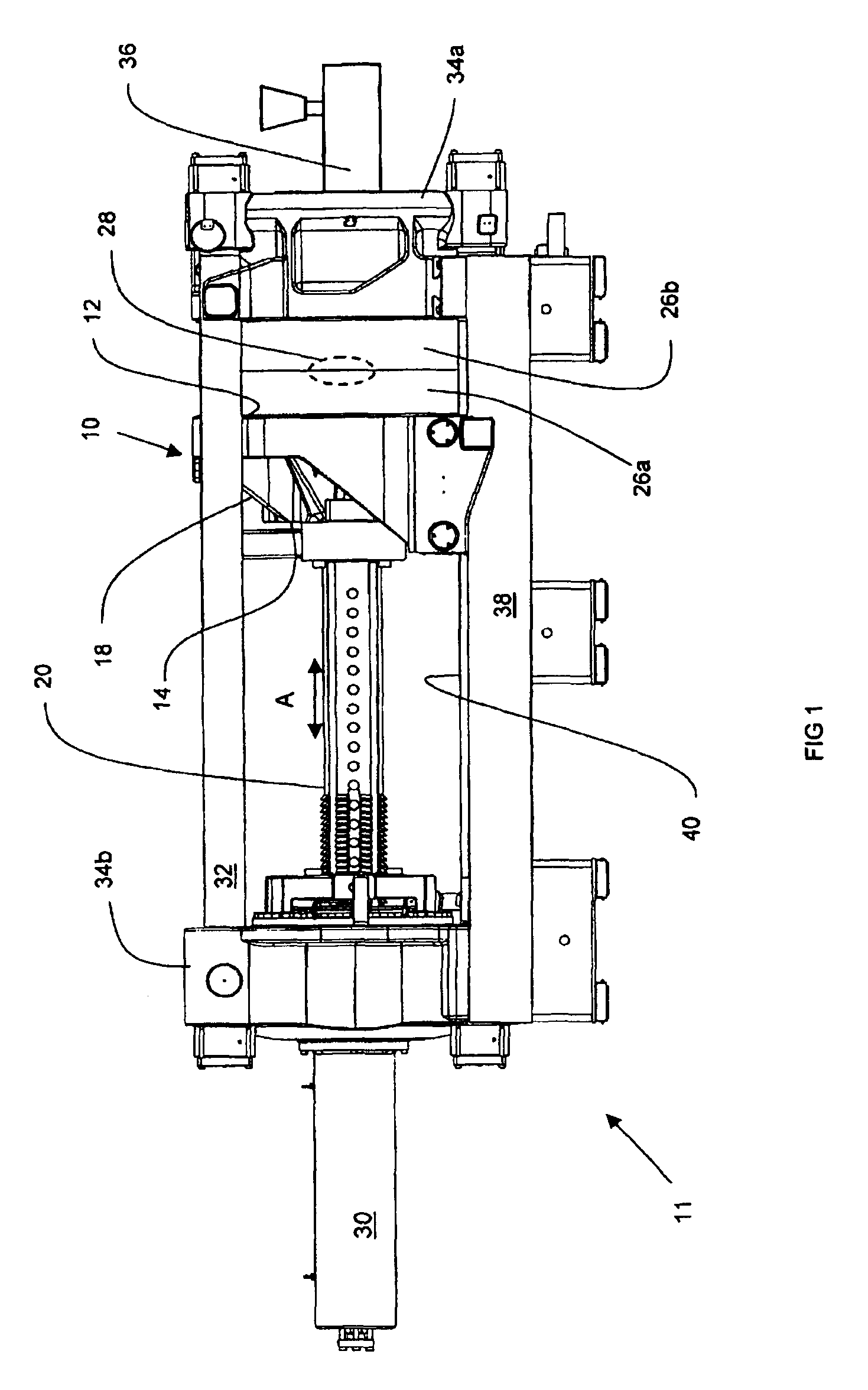

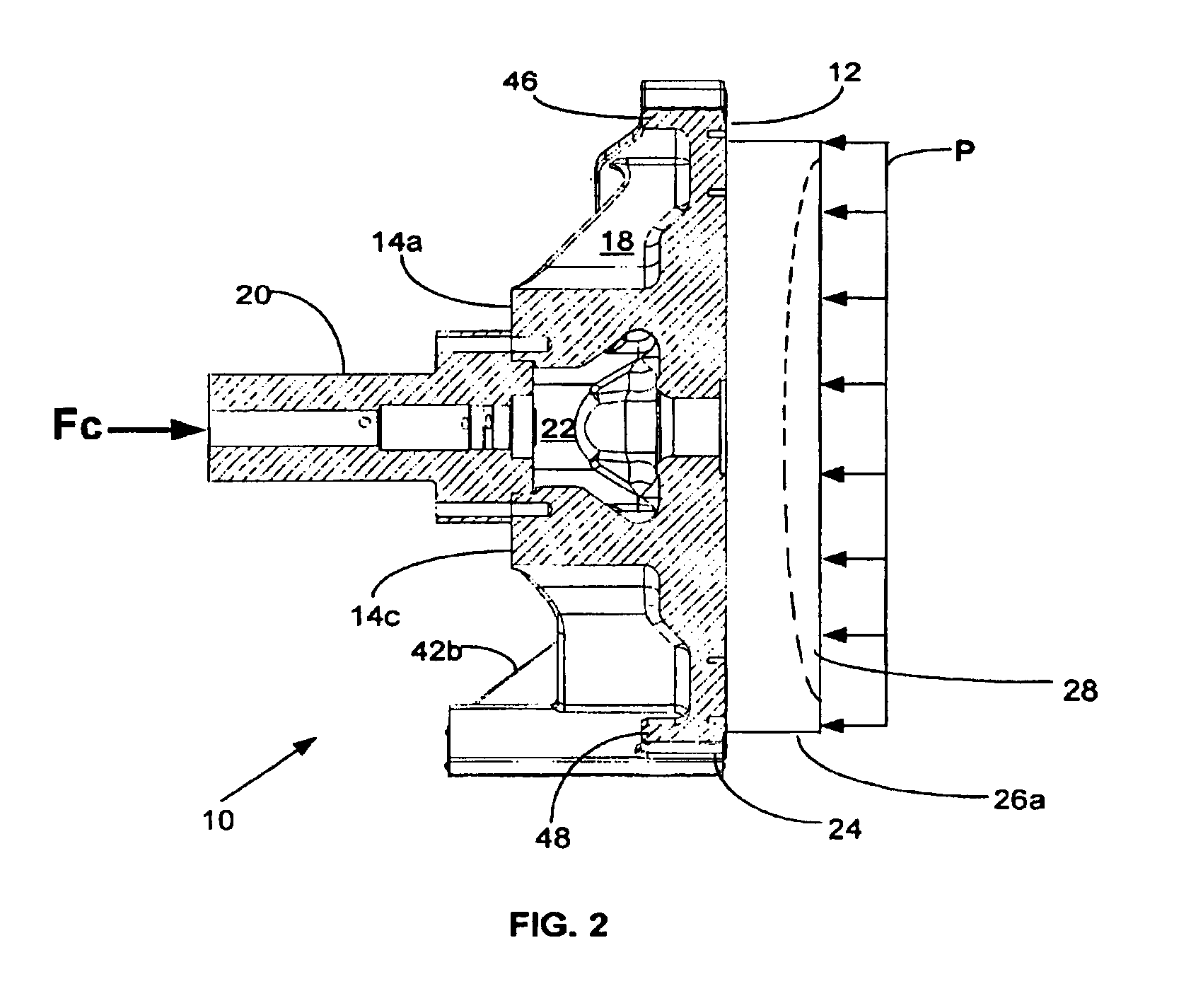

Injection molding machine and controller

An injection molding machine 10 utilizes a two part mold to produce a molded part. A machine includes a clamping mechanism 20 including one or more clamping cylinders 22 for applying a mold clamping force to the two part mold, an injection mechanism 30 for plasticizing material and injecting the plasticized material into the closed mold, and a controller 50 for powering the molding machine hydraulic system 52. In one embodiment, clamping pressure is automatically increased or decreased to allow air to escape as plasticized material flows into the mold cavity. In another embodiment, the controller provides a minimum clamp pressure to maintain the plasticized material within the mold as a function of fluid injection pressure to the screw member of the injection system.

Owner:乔斯・R・马拉齐塔

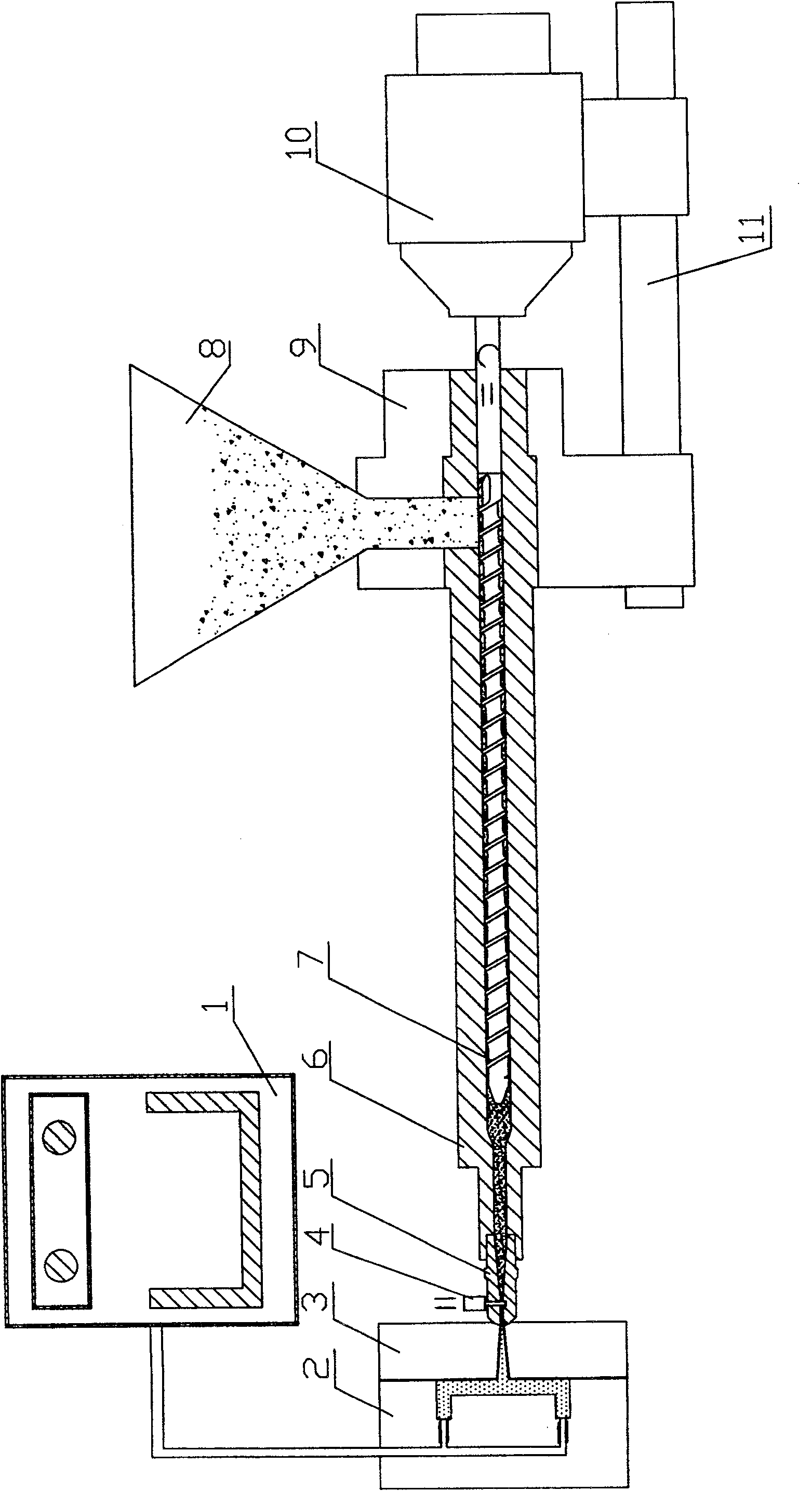

Chemical foaming prepressing high speed injection molding method

InactiveCN101011850AReduce consumptionImprove yieldDomestic articlesInjection pressurePlastic materials

The invention relates to a pre compression chemical foaming high speed injection mold forming. It synthetically uses the resources like injection molding equipment, molds, plastic materials and so on. It starts with the tight closing of the mold, injecting the precompressed melt material into the mold cavity, filling the cavity through inside foaming with the melt material closely attached to the metal wall of the cavity, solidification of the material after cooling, opening the male mold and the female mold to get the smooth, tight, and evenly allocated plastic parts. It can eliminate or reduce the shrink dent or warpage of the part, reducing injection pressure and the mold locking pressure, with low running cost, improved product dimension precision and strength, effectively reducing material consumption by 15%-35%, with higher mechanical feature and weight proportion.

Owner:DONGHUA MACHINERY

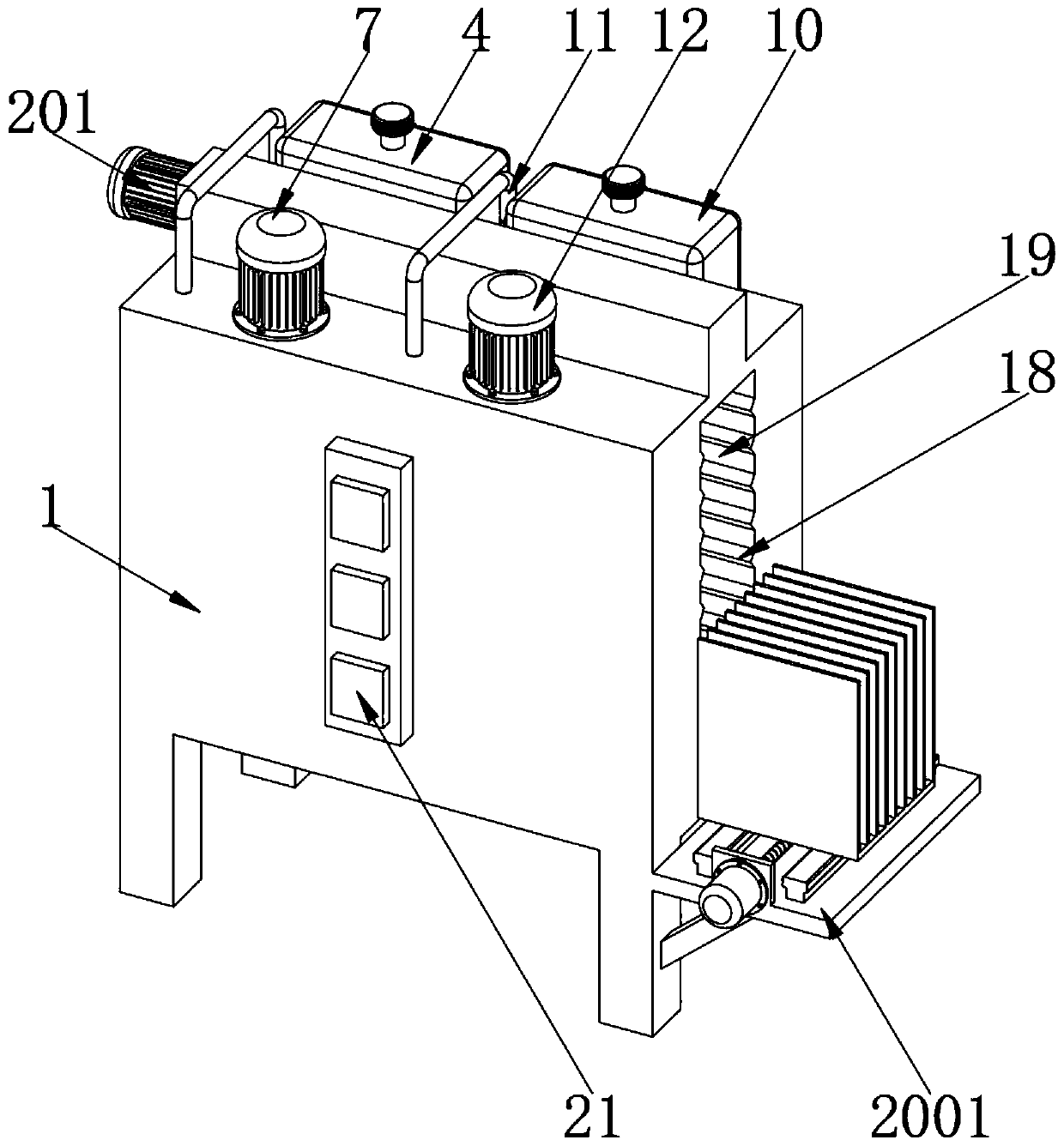

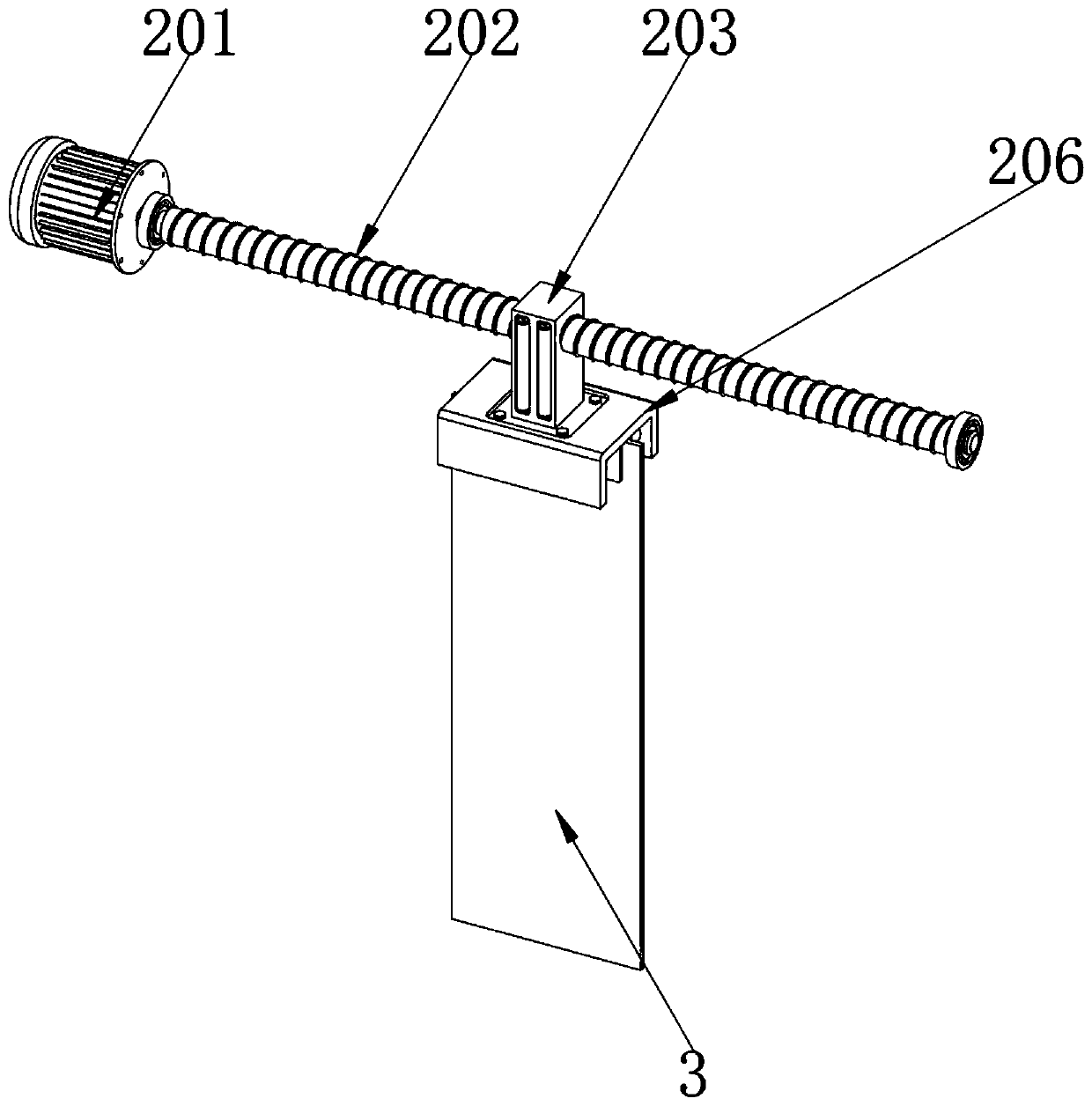

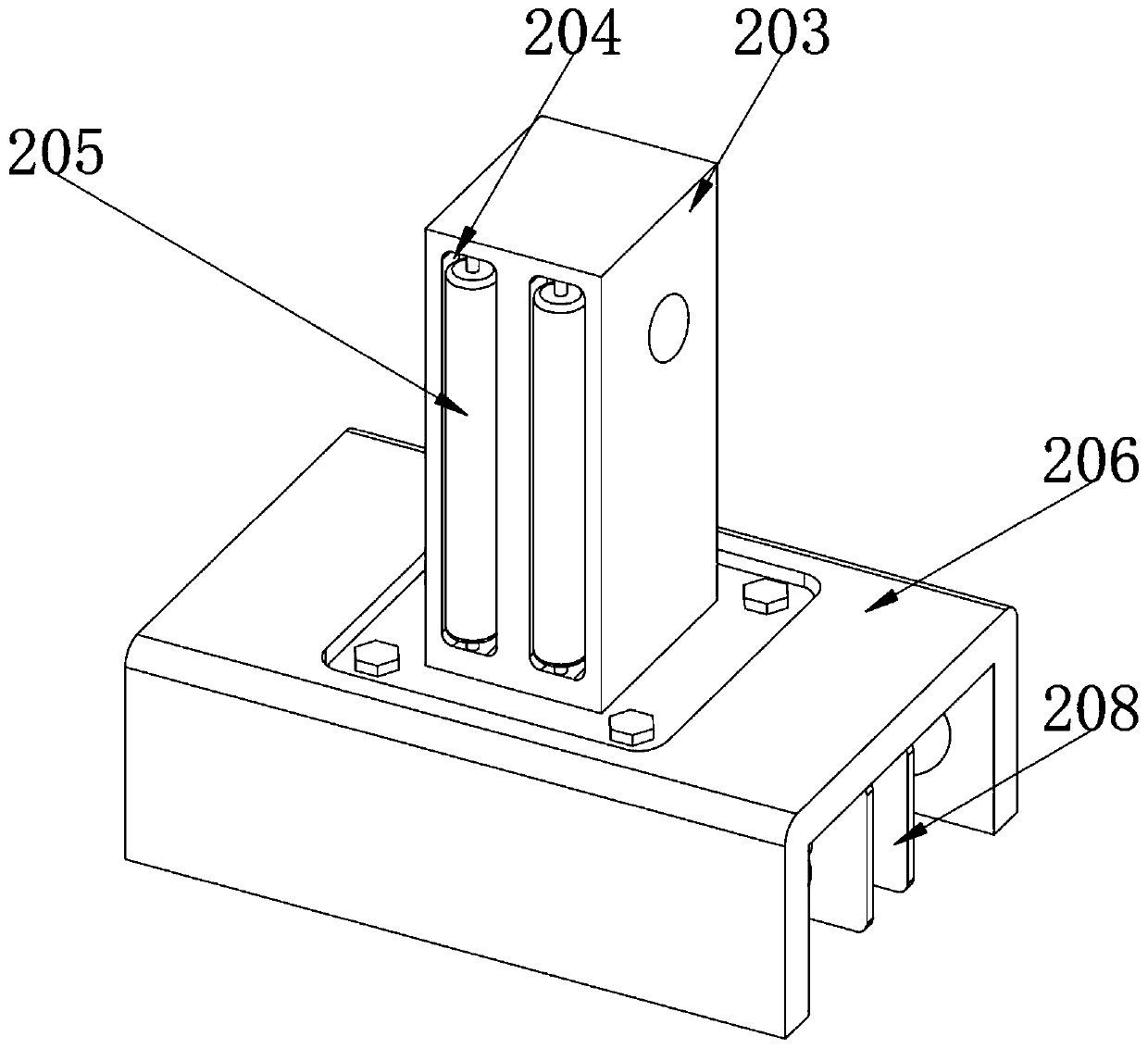

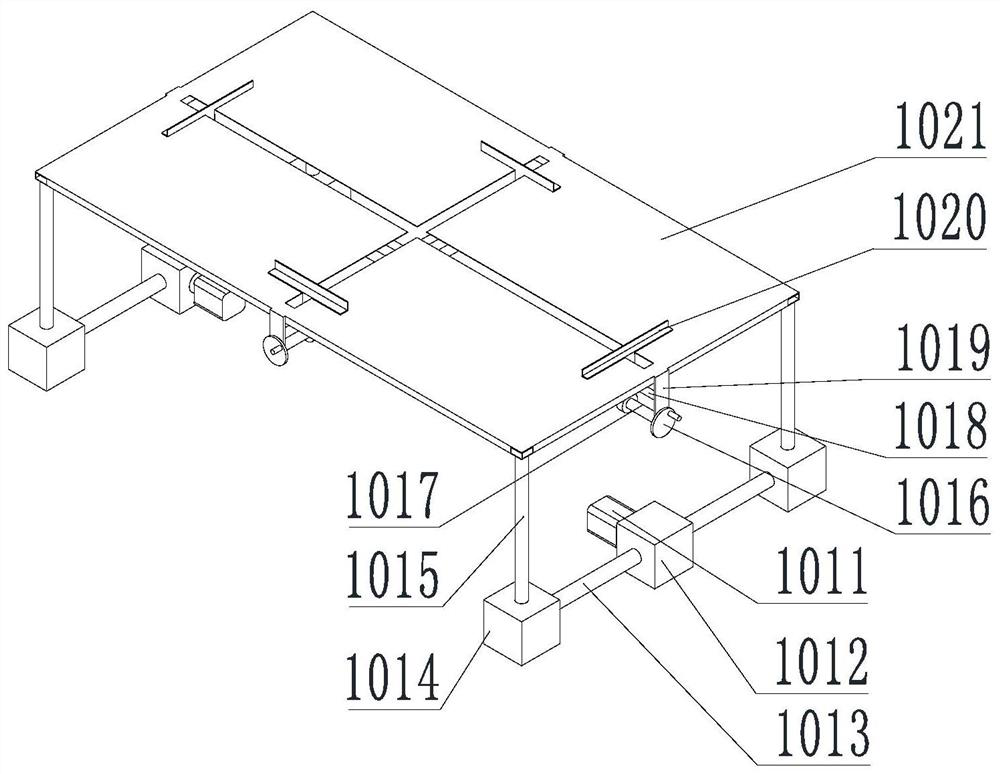

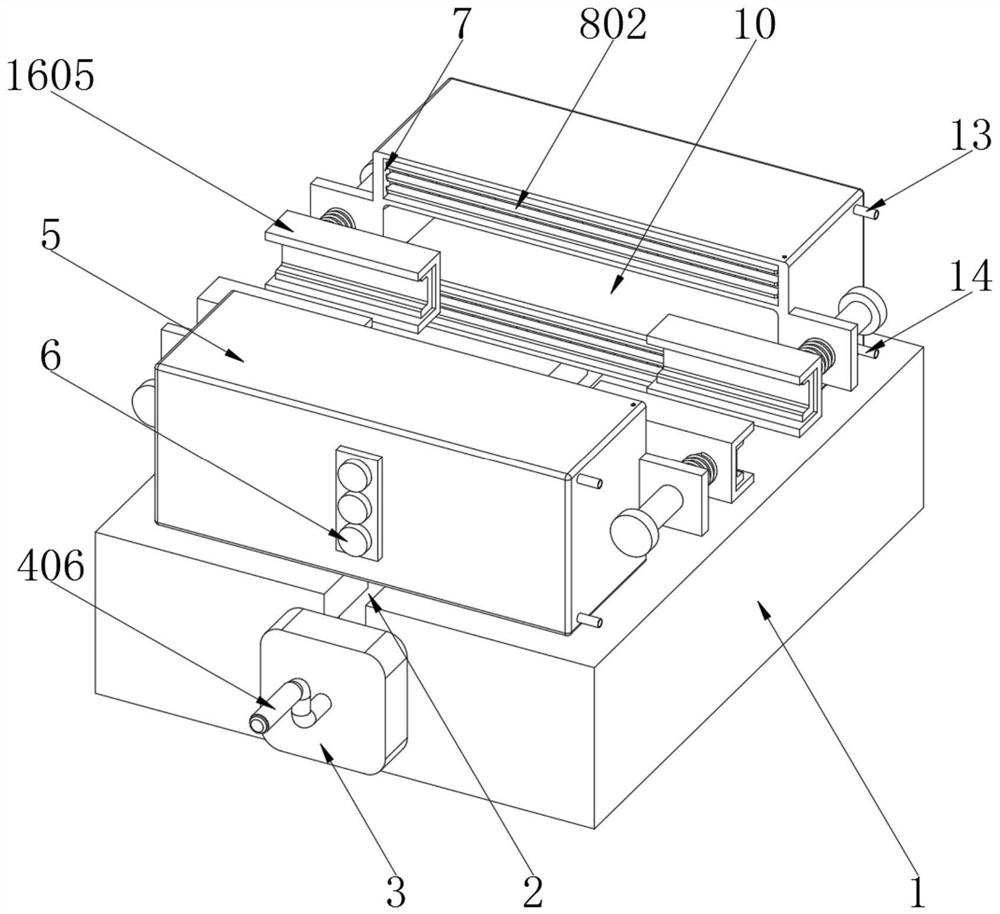

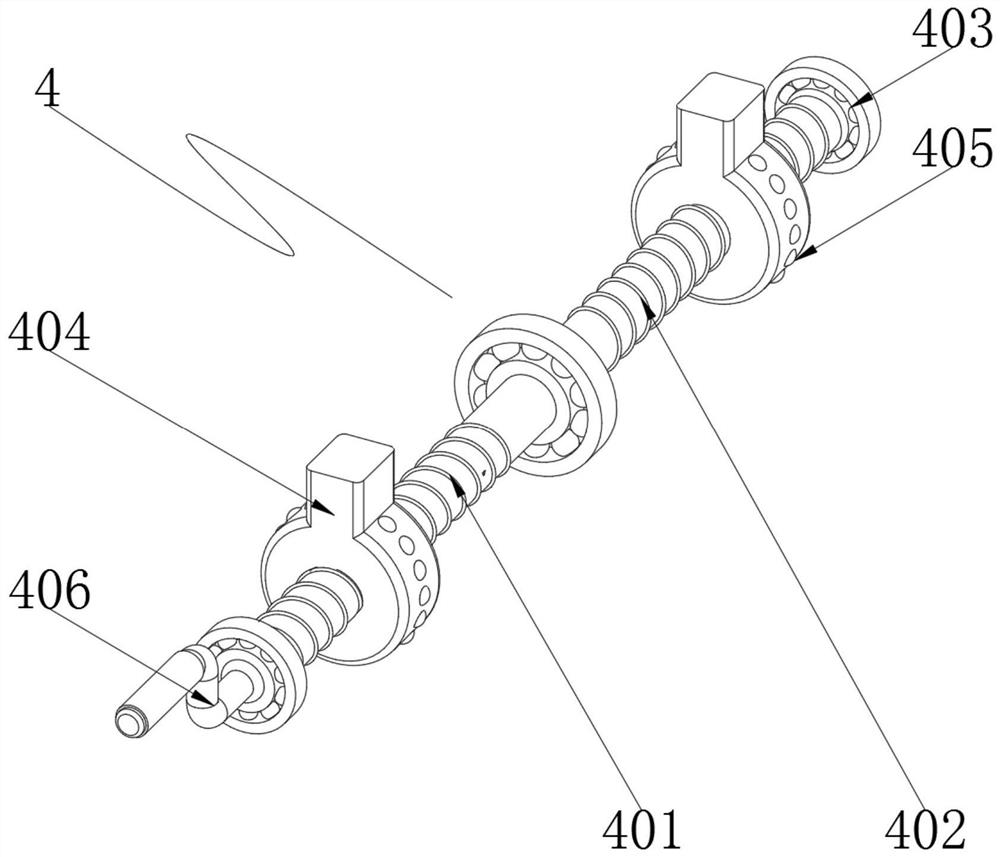

Cleaning device for LCM backlight source structural part

ActiveCN110434107ASmooth slidingRelieve pressureDrying solid materials without heatDrying gas arrangementsFriction forceEngineering

The invention discloses a cleaning device for a LCM backlight source structural part. The cleaning device comprises a cleaning box and a transferring and clamping assembly, wherein the middle of the top end of the cleaning box is fixedly provided with the transferring and clamping assembly, the transferring and clamping assembly can clamp and transfer the structural part. The cleaning device is scientific and reasonable, and the use is safe and convenient; by utilizing the transferring and clamping assembly, and the structural part can be clamped, the clamped structural part is integrally operated such as cleaned, washed, wiped, dried and the like, so that the cleaning efficiency of the structural part is greatly improved, and in addition, the friction force between a threaded sliding block and the cleaning box can be effectively reduced by using a moving roller, so that the cleaning and transferring of the structure are more smooth. The clamping pressure of a first clamping plate to the structural part can be effectively reduced through a first clamping rubber gasket, damage to the structural part caused by too large clamping pressure is avoided, meanwhile, the friction force between the structural part and the first clamping plate is increased, and the structural part is prevented from being damaged due to falling in the cleaning process.

Owner:重庆智兴伟科技有限公司

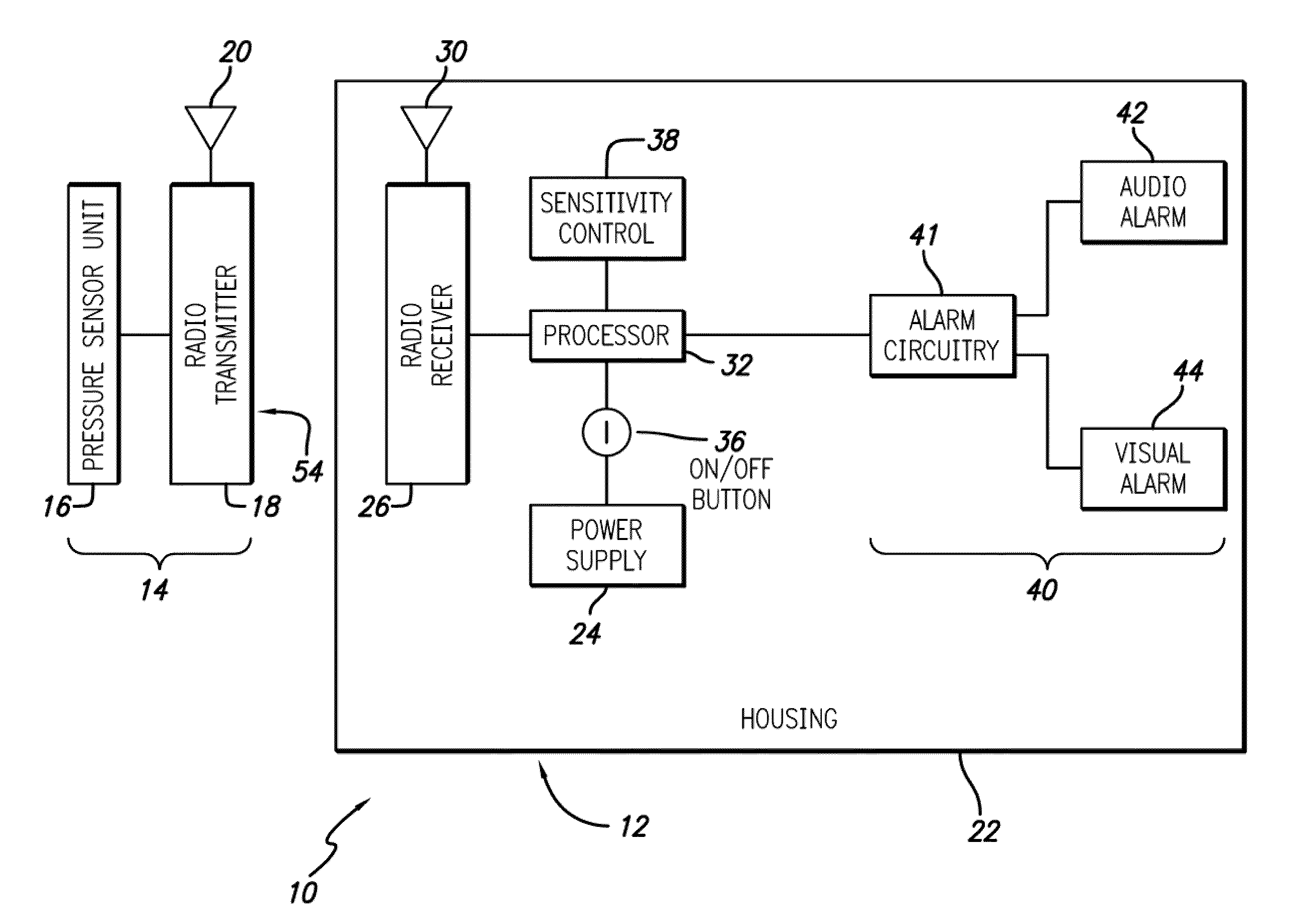

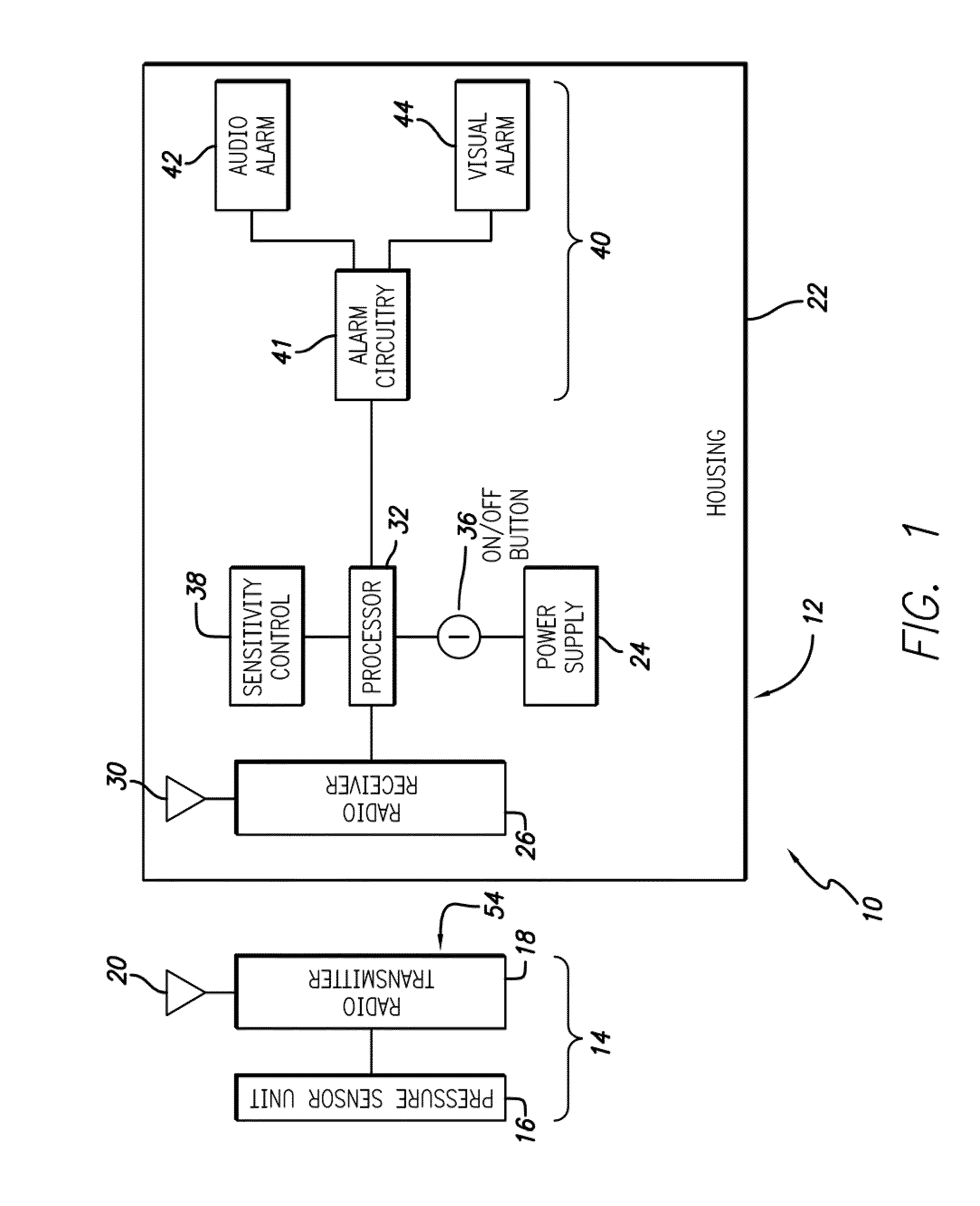

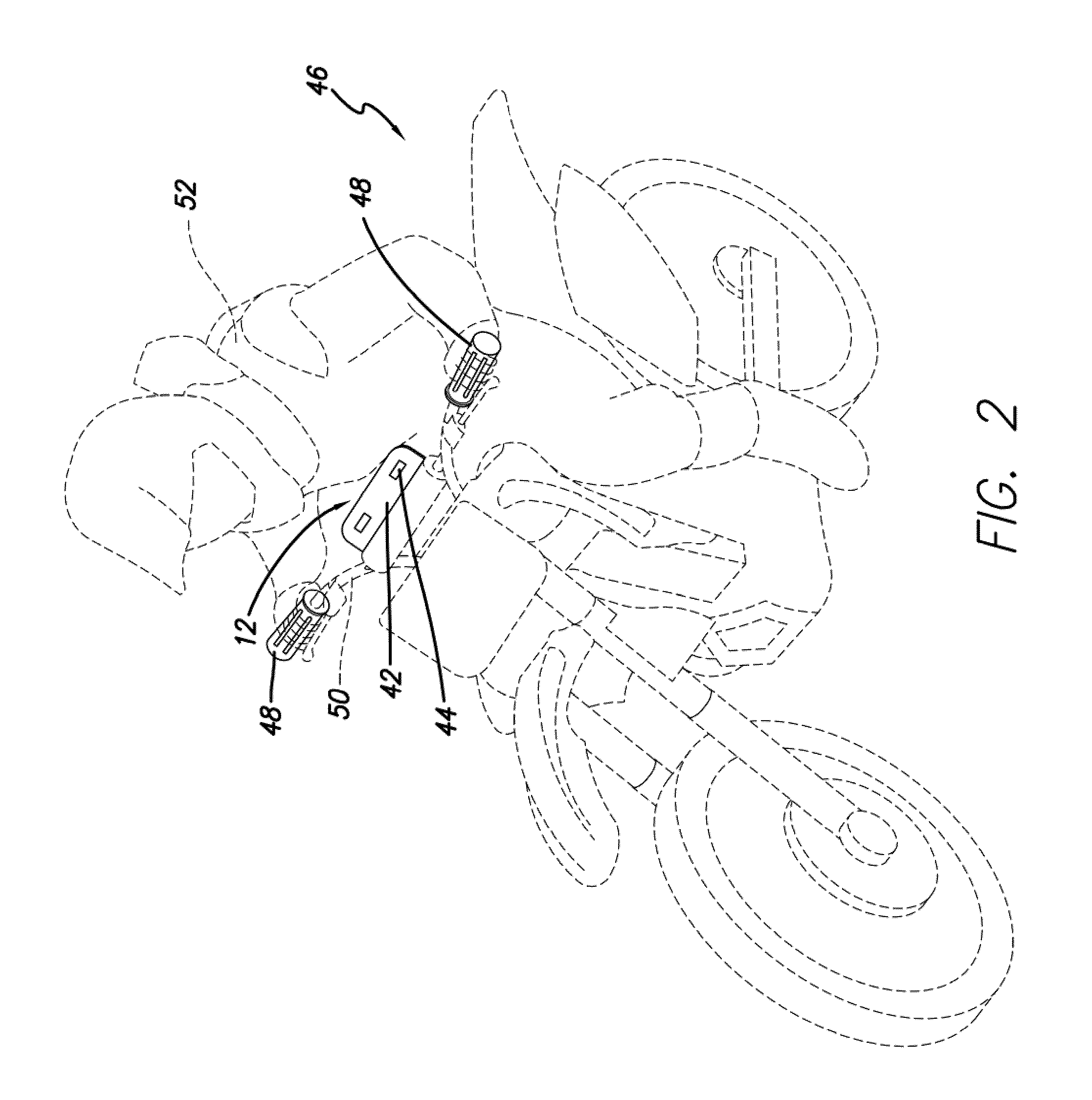

Motorcycle grips with pressure sensors and alarm system

InactiveUS20110063120A1Reduce clamping pressureFrequent problemSteering deviceCycle sensorsPressure sensitiveEngineering

A pressure sensitive alarm system for solving the problem of arm pump commonly experienced by competitive motocross riders is provided. The system comprises motorcycle grips which incorporate one or more pressure sensors. The pressure sensors provide a signal to a control unit which compares the magnitude of the pressure sensor signal to a predetermined threshold value. When the predetermined threshold value is exceeded the control unit activates an alarm and maintains the alarm until the rider's grip pressure falls below the predetermined threshold value. The predetermined threshold value is a pressure magnitude which when exceeded by a rider is likely to lead the onset of arm pump. Means are provided for individually tailoring the predetermined threshold value to the specific needs of an individual rider.

Owner:EBNER RONNIE

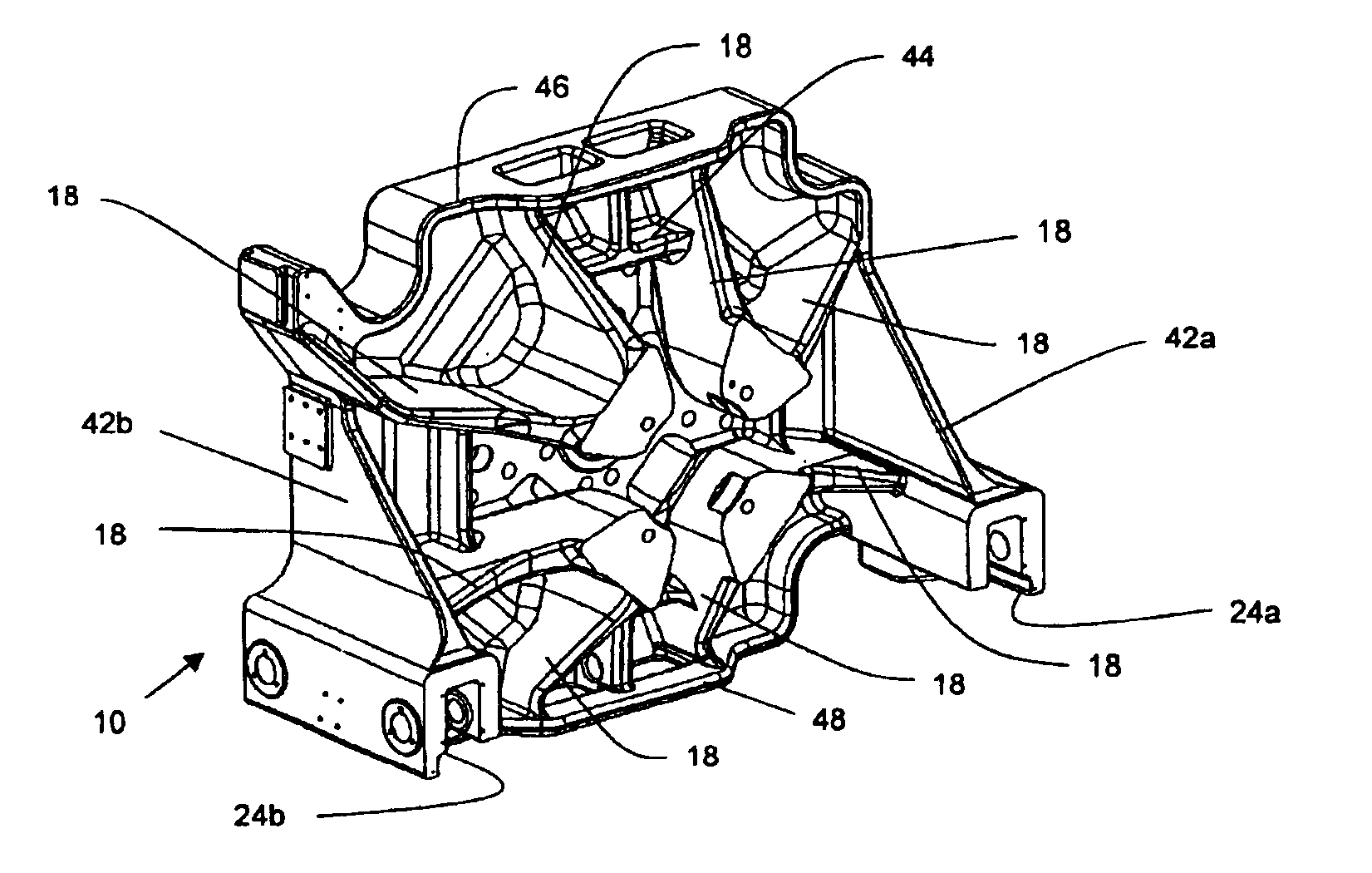

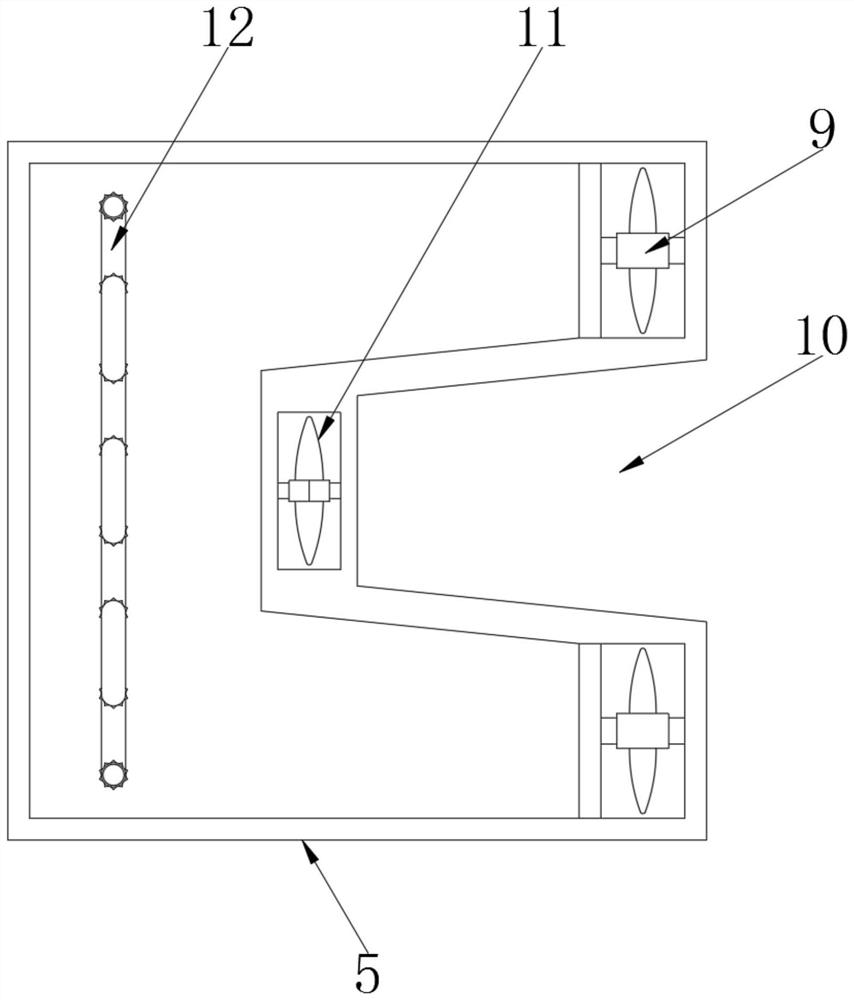

Multi-axis controlled self-climbing tree trimmer

ActiveUS20140060701A1Avoid damageReduce clamping pressureTree debarkingChemical debarkingControl systemSplit ring

A multi-axis controlled self-climbing tree trimmer used for shaping and severing peripheral growth from a tree is provided herein. The trimmer typically includes a structural segment hinged together to form a rigid chassis that surrounds a tree trunk climbing segment and a trimming portion. The climbing portion is retained within the structural segment in the form of a number of inward-extending carriages containing one or more rollers for gripping the tree trunk during climbing, and the trimming portion may include a rotatable split ring gear containing centrifugally rotating trimming blade members and / or a cutting tool on a positionable arm. When rotated, the blade members unlatch and pivot, into the trunk of the tree to effect controlled trimming. The system may utilize a multi-axis control system that uses linear interpolation, circular interpolation and coordination of all axes to enable the trimmer to follow an XYZ contour selected by a user.

Owner:VANDYPALM

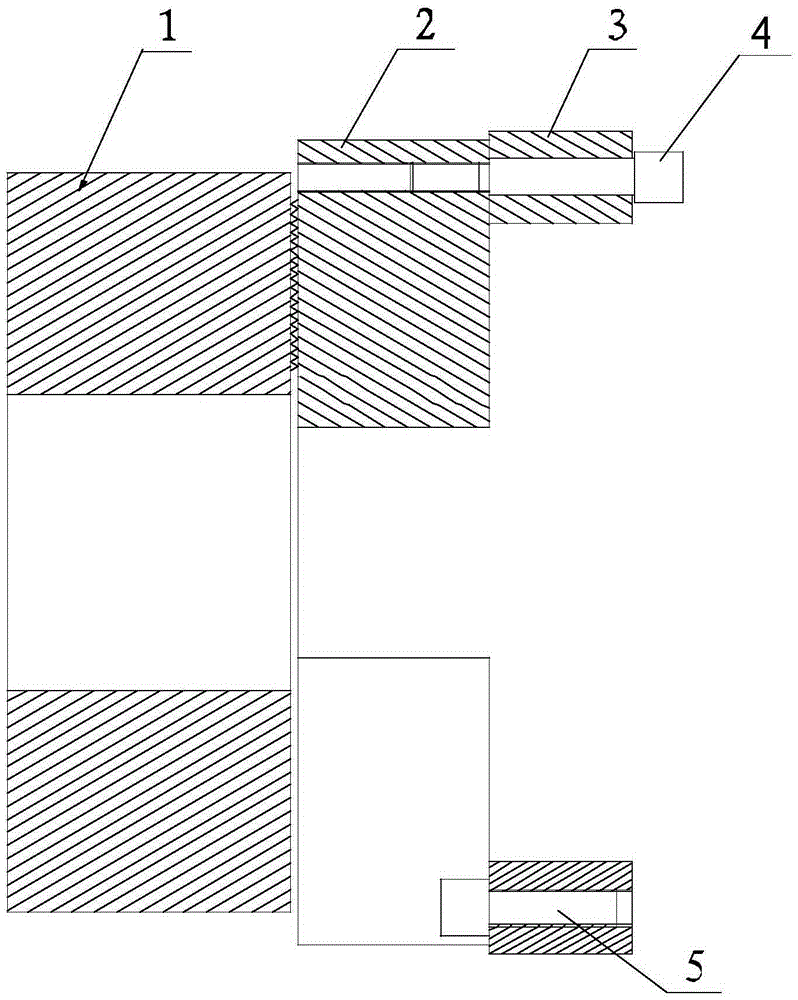

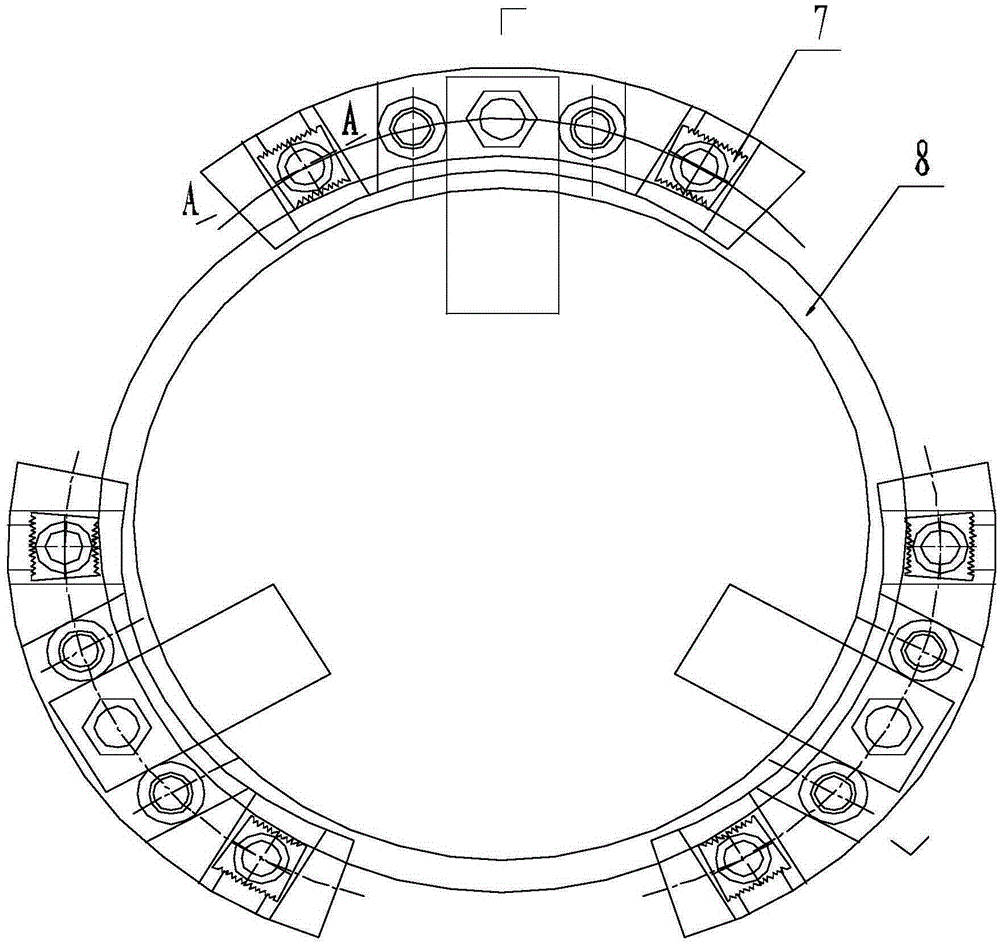

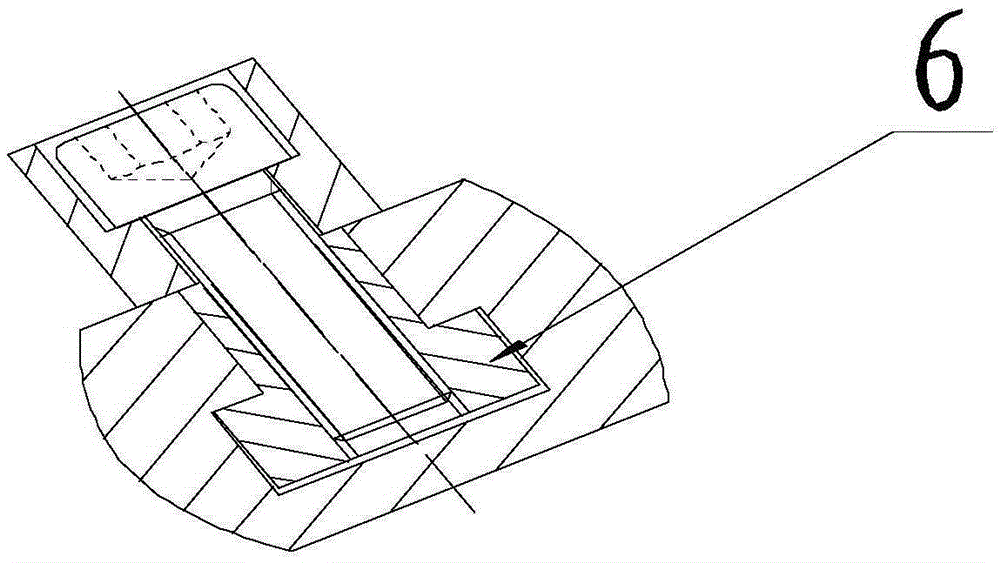

Floating fixture and method for processing inner and outer rings of single-row tapered roller bearing

InactiveCN105414584AShorten the inner and outer ring turning processFloating up and downBearing componentsChucksEngineeringMechanical engineering

The invention discloses a floating fixture and a method for processing inner and outer rings of a single-row tapered roller bearing. The floating fixture comprises a three-jaw chuck, three jaws, jaw clamping bodies, a floating connecting rod, and six clamping jaws. The three jaws are correspondingly connected with the three-jaw chuck. The number of the jaw clamping bodies is three. The three jaw clamping bodies are arranged respectively corresponding to the three jaws. The jaw clamping bodies are correspondingly connected with the three jaws through the floating connecting rod. Limiting screws are also connected between the jaw clamping bodies and the three jaws. The number of the limiting screws is two. The two limiting screws are respectively symmetrically arranged on two sides of the floating connecting rod. Each jaw clamping body is meshed and connected with the two clamping jaws through teeth. The three jaws and the jaw clamping bodies are connected through the floating connecting rod, and the limiting screws are connected between the jaw clamping bodies and the three jaws. Through the floating connecting rod, the limiting screws play certain up-down floating roles in a clamping process. In turning bearing forging, the fixture improves turning precision, and shortens a turnery process of the inner and outer rings of a single-row tapered roller bearing.

Owner:CHENGDU TIANMA RAILWAY BEARING

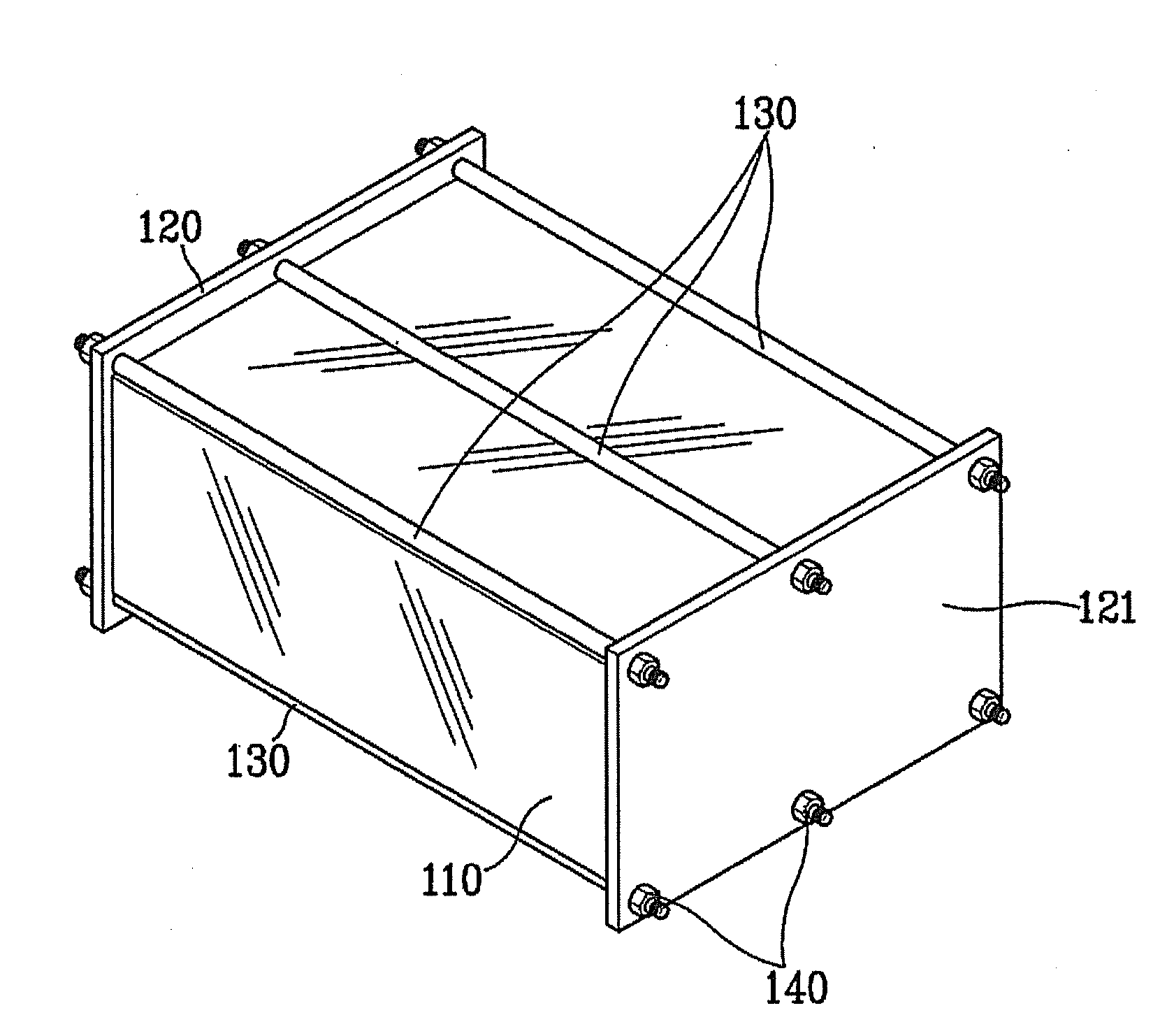

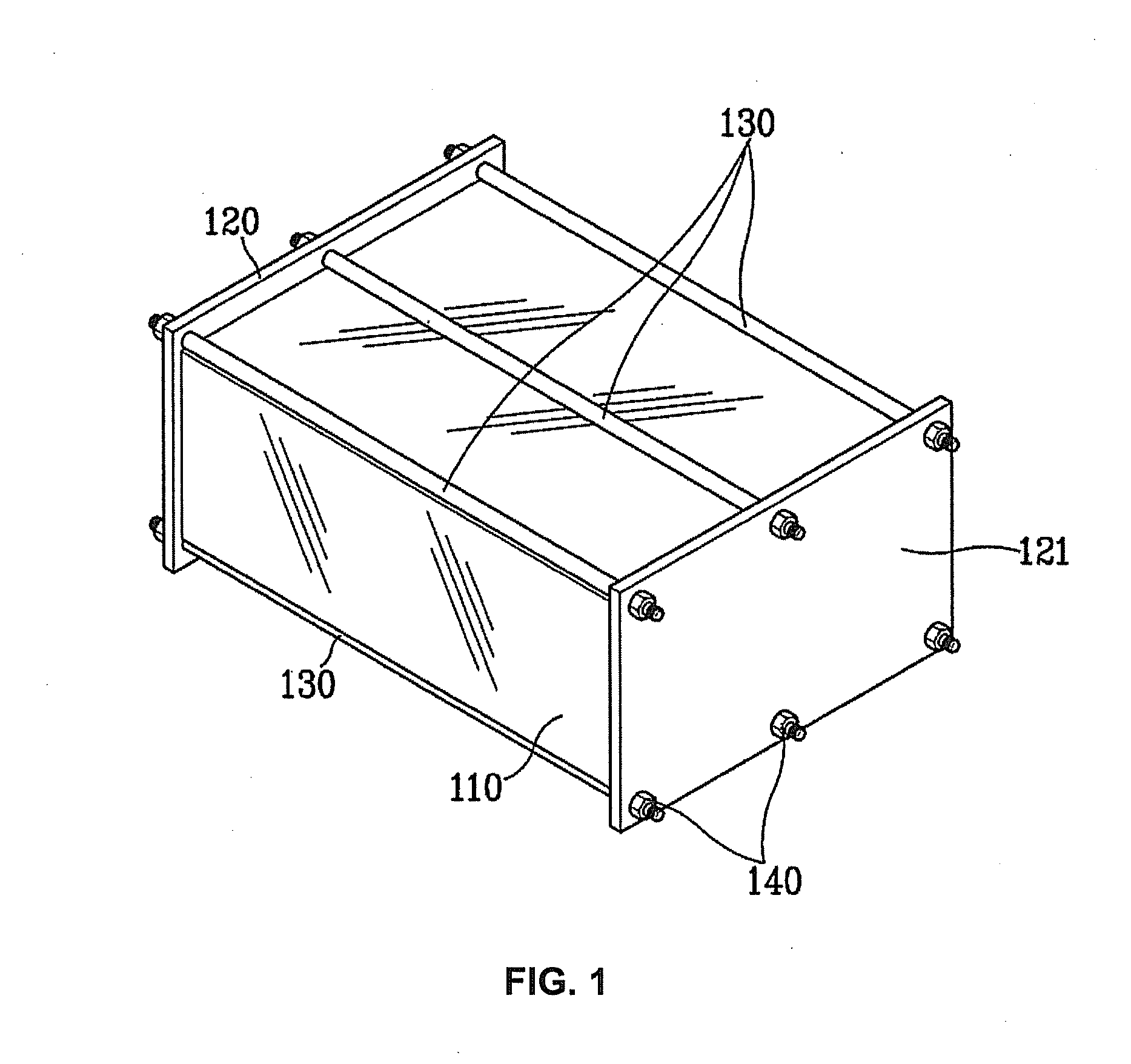

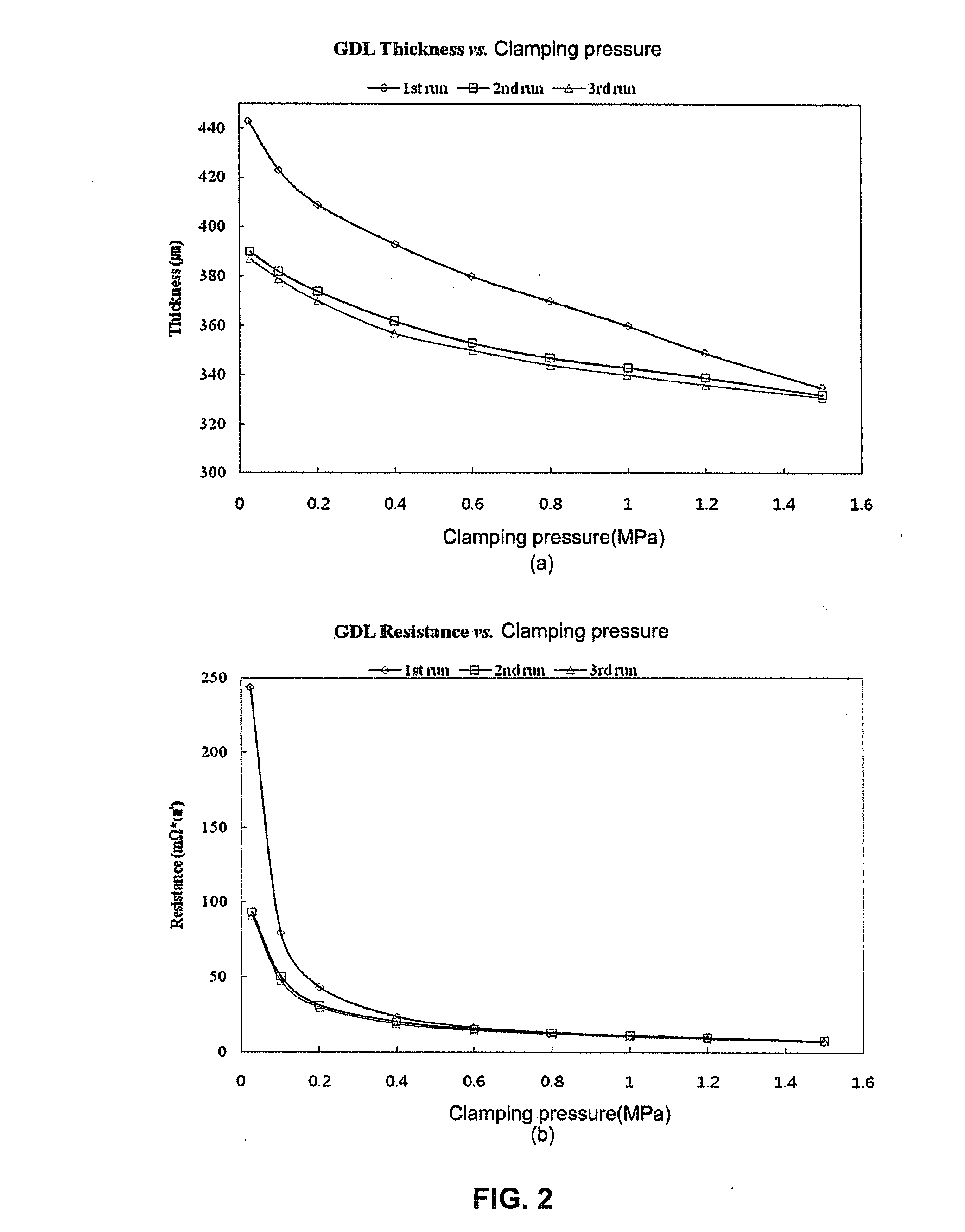

Method of clamping fuel cell stack

InactiveUS20120088179A1Stably and optimally clampReduce clamping pressureFuel cells groupingCell component detailsFuel cellsEngineering

A method of clamping a fuel cell stack includes a stack preliminary clamping step, a stack pre-treatment step of performing a gas flow rate variation cycle or a clamping pressure variation cycle, wherein the gas flow rate variation cycle repeatedly changes a flow rate of a gas supplied to an anode and a cathode included in the preliminarily clamped stack, and wherein the clamping pressure variation cycle repeatedly increases and decreases the clamping pressure by pressurization and pressure release of the preliminarily clamped stack using the pressure tool, and a stack main clamping step of correcting a variation in clamping pressure occurring due to a variation in thickness of a gas diffusion layer to mainly clamp the stack after the stack pre-treatment step.

Owner:HYUNDAI MOTOR CO LTD

Injection molding machine having a platen for uniform distribution of clamping forces

InactiveUSRE39193E1Reduce clamping pressureLight weightMeat processingCeramic shaping apparatusEngineeringInjection molding machine

An injection molding machine includes a movable platen specifically adapted to uniformly distribute a clamp force to the mold half surfaces thereby reducing localized deflections and unwanted flash on the molded article.

Owner:HUSKY INJECTION MOLDING SYST LTD

Molded product of a polypropylene-based resin expanded particle and method for producing the same

ActiveCN101875739ALow expansion ratioHigh compressive strengthApparent densityVolumetric Mass Density

The invention relates to a molded product of a polypropylene-based resin expanded particle and a method for producing the same. The object of the invention is to provide a molded product of a polypropylene-based resin expanded particle with a low expansion ratio having excellent fusibility between expanded particles mutually, small density difference between a surface part and an inner part of the molded product, better mechanical properties, such as compressive strength, compared with a conventional one, and also excellent appearance. In an in-mold molding method with the polypropylene-based resin expanded particle, the expanded particle has apparent density of 60-450 g / L, the welding rate of the polypropylene-based resin expanded particle is above 50%, the ratio between the apparent density of the expanded particle molded body to the inner density of the molded body is 1-2 and the molded product of the polypropylene-based resin expanded particle is preferably molded when satisfying the special conditions.

Owner:JSP CORP

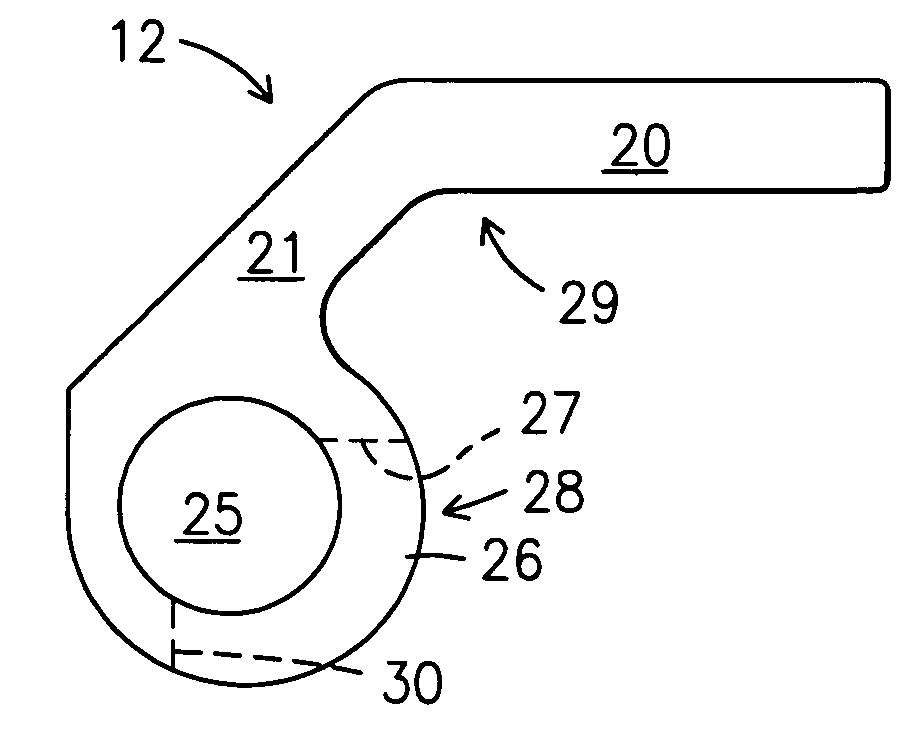

Releasable side terminal battery cable connector clamp

InactiveCN1960029AReduce clamping pressureElectric connection structural associationsCell component detailsCamMechanical engineering

A side terminal battery cable converter clamp is provided with a clamp shaft having a distal male threaded end adapted to mate with a female threaded side terminal, said clamp shaft carrying a cam seat, a cammed handle with pin, and a locknut, wherein the cammed handle is operable to frictionally engage and release the distal male threaded shaft end and female threaded side terminal.

Owner:BATLOK

Lawn and garden battery clamp

InactiveUS7189123B2Easy to looseEasy to disassembleSemiconductor/solid-state device manufacturingElectric connection structural associationsEngineeringCam

An improved battery cable clamp provides for toolless attachment of battery cable connectors to lawn and garden-type battery terminal posts utilizing a bossed handle, cam seat and thumbnut, preferably made of non-corrosive materials.

Owner:SPC INT

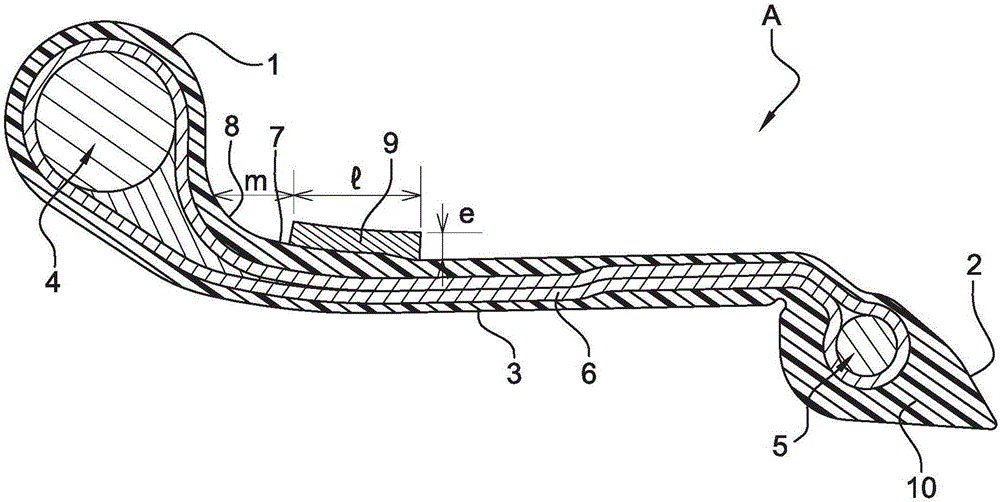

Adapter for a wheel assembly and a wheel assembly comprising same

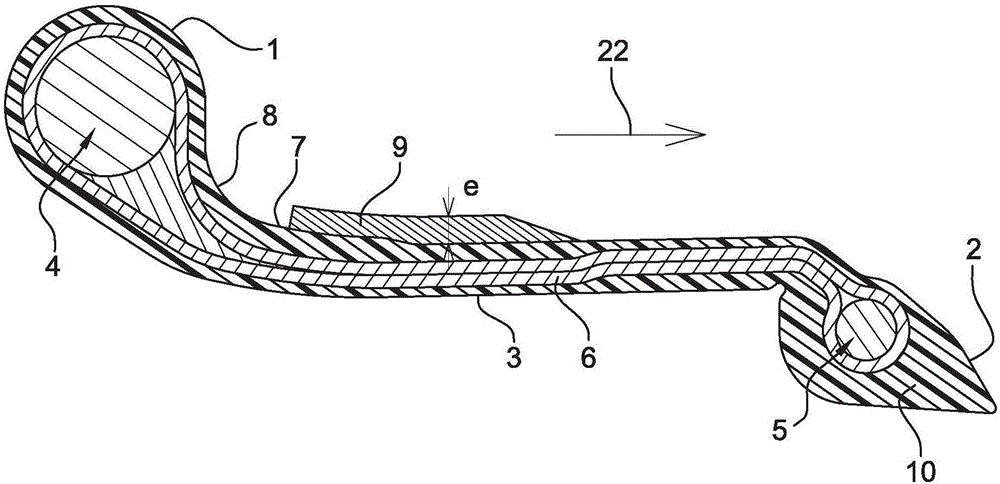

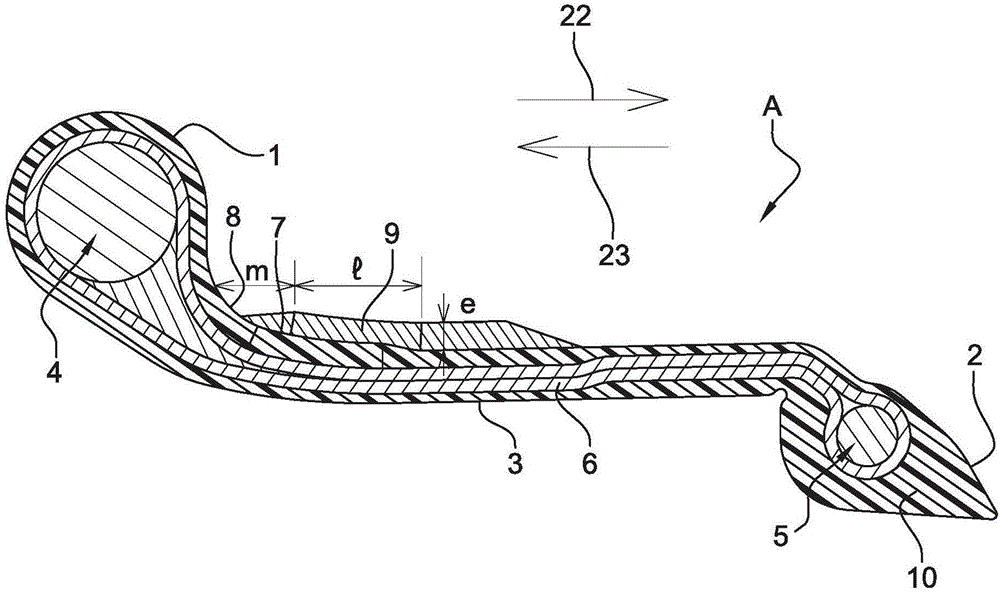

ActiveCN106715143ASimple designEasy to installWithout separate inflatable insertsRimsRotational axisTire bead

The invention relates to an adapter for a wheel assembly having a rotational axis and comprising a tire (P) with two beads (B), a wheel rim (J), where said adapter forms the junction between one of the beads and the wheel rim, where said wheel rim has two wheel-rim seats (20) and two wheel-rim hooks (12), where said adapter has an axially inner end (2) intended to be mounted on the wheel-rim seat and comprising an inner reinforcement element (5), an axially outer end (1) intended to be mounted on the wheel-rim seat and comprising an outer reinforcement element (4), a body (3) connecting said outer end (1) to said inner end (2) such as to form a single part comprising at least one main reinforcement frame that ensures the connection between said outer reinforcement element (4) and said inner reinforcement element (5), a substantially cylindrical adapter seat (7) intended to receive one of said beads, an adapter bearing surface (8) substantially in a plane perpendicular to the axis. This adapter is characterized in that the reinforcement element (4) of the axially outer end is entirely located axially outside the bearing surface (8), and in that the body (3) comprises a ring-shaped seat protuberance (9) opposite the adapter seat (7), where said protuberance (9) comprises at least one rubber composition.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

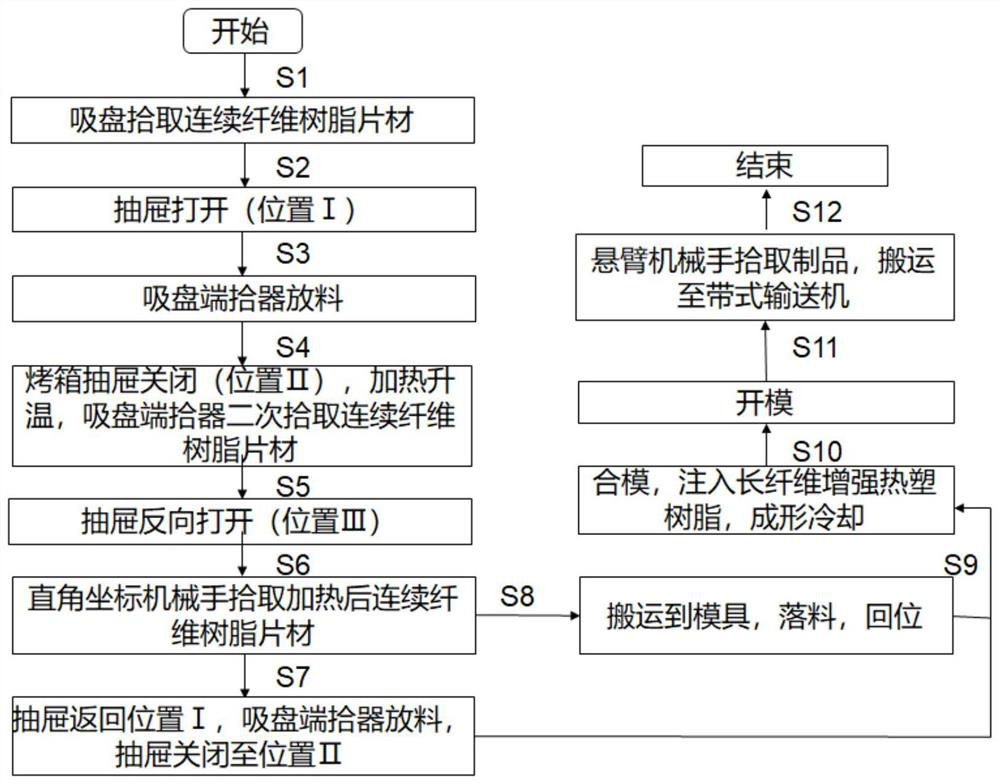

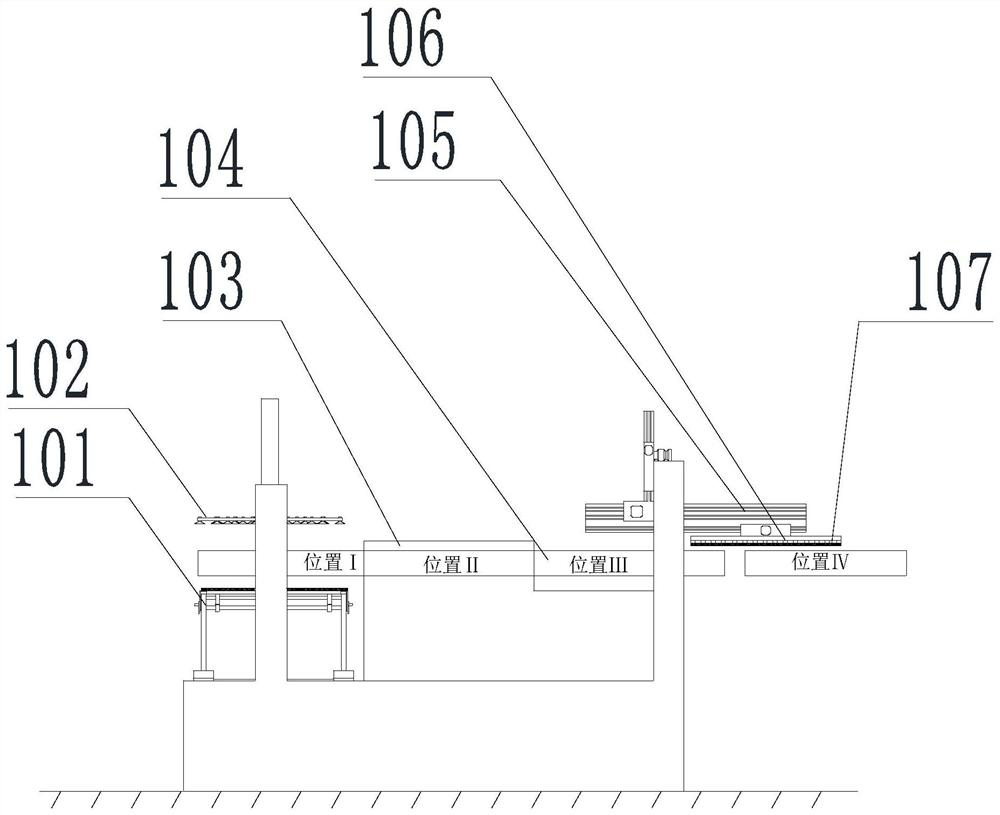

Composite material hot-press forming device

The invention relates to a composite material hot-press forming device. The composite material hot-press forming device comprises a suction cup end picker arranged on one side of the device, a feeding device, a manipulator mechanism, a hearth, a moving mechanism, a forming device and a discharging device, wherein the feeding device comprises a panel and a first driving mechanism, the panel is arranged below the suction cup end picker and used for providing resin fiber sheets, and the first driving mechanism is used for driving the panel to move upwards; the manipulator mechanism is arranged on the other side of the device and is used for grabbing the resin fiber sheets; the hearth is arranged in the middle of the device; one side of the moving mechanism is located on the lower side of the suction cup end picker, the other side of the moving mechanism is located on the lower side of the manipulator mechanism, and the moving mechanism is used for conveying away the resin fiber sheets placed in by the suction cup end picker through the manipulator mechanism after the resin fiber sheets are heated by the hearth; the forming device is arranged on one side of the manipulator mechanism and used for performing injection molding of the resin fiber sheets; and the discharging device is arranged on one side of the forming device, and is used for transporting formed products, and the carrying time is shortened. The composite material hot-press forming device has the advantages that the forming time can be shortened, the die assembly pressure can be reduced, the compatibility with injected resin can be improved, the product performance can be enhanced, and continuous operations can be achieved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Lawn and garden battery clamp

InactiveUS20060240676A1Easy to disassembleEasy to looseSemiconductor/solid-state device manufacturingElectric connection structural associationsEngineeringCam

An improved battery cable clamp provides for toolless attachment of battery cable connectors to lawn and garden-type battery terminal posts utilizing a bossed handle, cam seat and thumbnut, preferably made of non-corrosive materials.

Owner:SPC INT

Rapid formation method

PendingCN113675488AShorten the formation timeImprove wettabilityFinal product manufactureSecondary cells manufactureCharge currentEngineering

The invention discloses a rapid formation method, and belongs to the technical field of battery core manufacturing. The rapid formation method comprises the following steps: S1, pressurizing a battery core by controlling the clamping speed of two side plates of the battery core; S2, applying pressure to a clamping force critical value D1 for first formation charging, applying pressure to a clamping force critical value D2 for second formation charging, and reducing pressure to a clamping force critical value D3 for third formation charging; and S3, finishing charging, and releasing the battery core, wherein silica gel layers are arranged on the inner sides of the two side plates for clamping the battery core. According to the invention, the battery core is wrapped and clamped by the silica gel layer, so that the deformation of the battery core is reduced, and the hardness of the battery core is improved; the formation time is shortened by increasing the charging current in stages; and the infiltrating effect of the pole piece is improved by stepped pressurization.

Owner:NINGBO VEKEN BATTERY

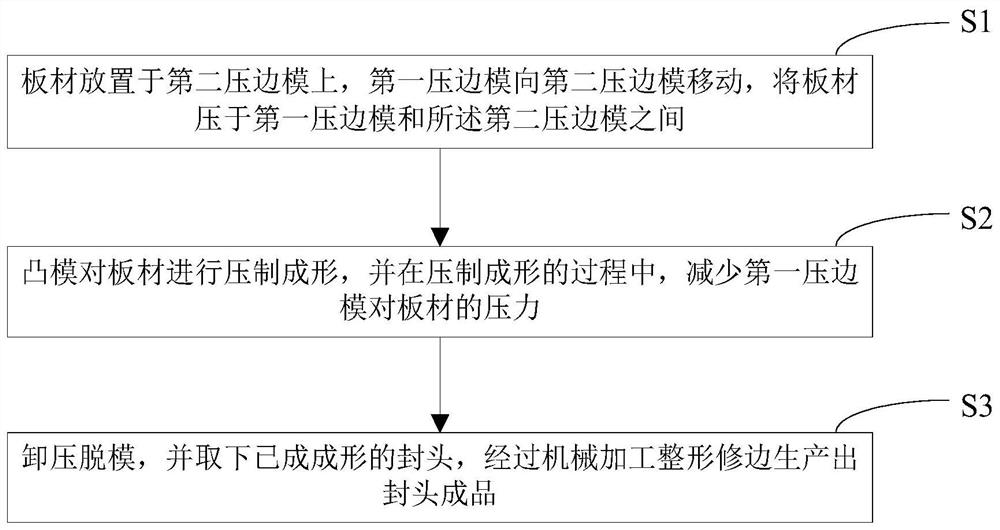

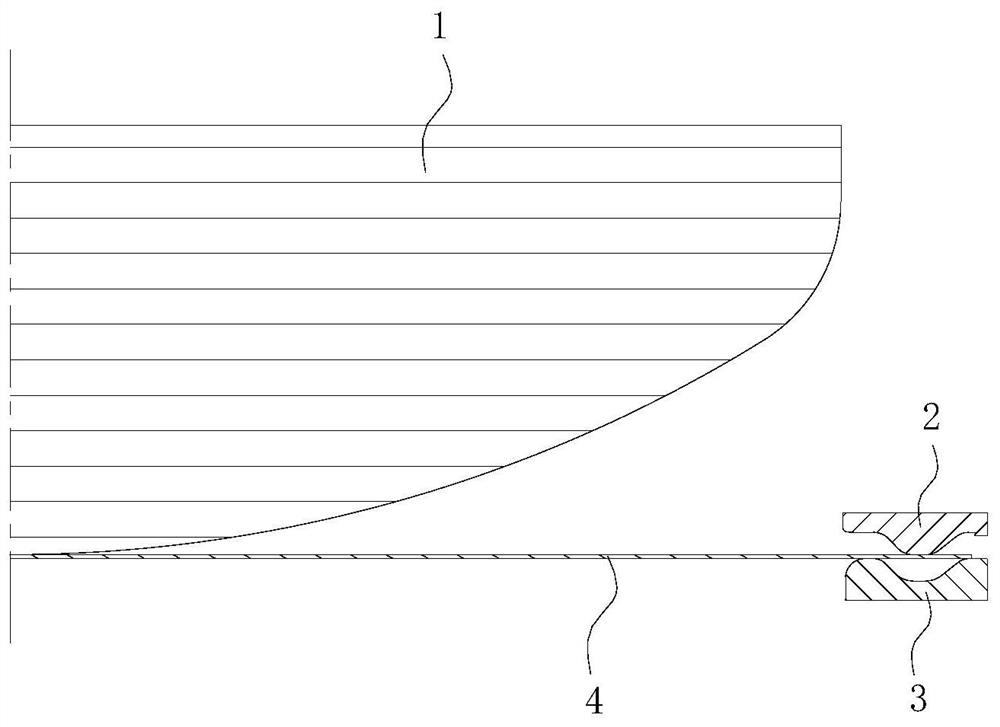

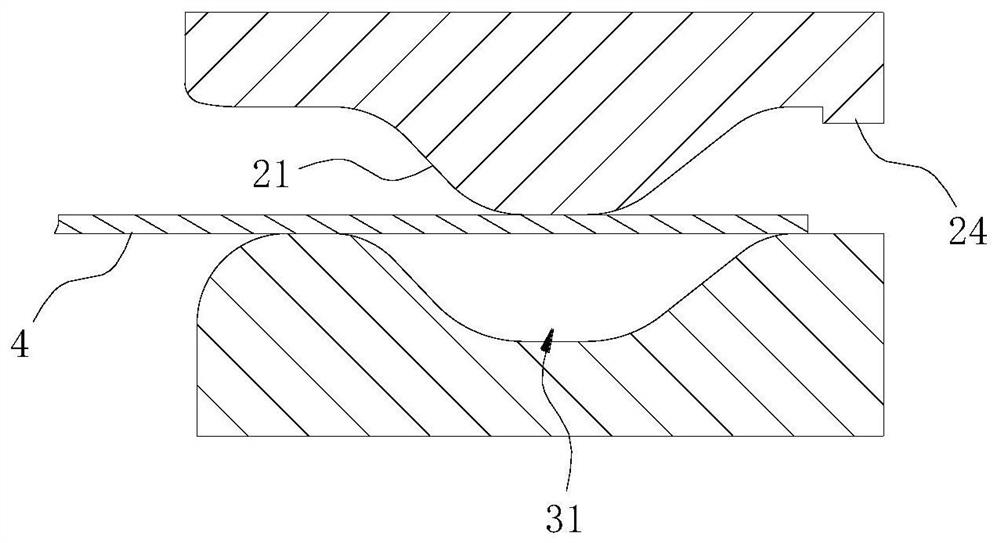

End socket forming die and end socket forming method

The invention provides an end socket forming die and an end socket forming method implemented through the end socket forming die. The end socket forming die comprises a male die, a first edge pressingdie and a second edge pressing die, the first edge pressing die is arranged around the outer side of the circumference of the male die, and the second edge pressing die corresponds to the first edgepressing die; the first edge pressing die moves towards the second edge pressing die to press a plate between the first edge pressing die and the second edge pressing die; and in the pressing formingprocess, the pressure of the first edge pressing die on the plate is reduced. The pressure of the first edge pressing die on the plate is reduced in the pressing forming process of the male die on theplate, that is, the clamping pressure of the first blank pressing die and the second blank pressing die on the plate is reduced, so that a plate raw material between the first edge pressing die and the second edge pressing die moves towards the male die / die cavity, and then the local stretching thinning speed is decreased, and the formed end socket is more uniform in thickness. Therefore, on thebasis of meeting the minimum thickness of each part of the end socket, the thickness of the plate raw material is reduced, and the raw material cost is reduced.

Owner:CIMC SAFEWAY TECH CO LTD

High speed injecting molding method by counter pressure method and chemical foaming method

The invention involves a counter-pressure chemical foaming high speed injection moulding shaping method. The invention provides a method which utilizes injection moulding shaping machine equipment, and dies, general gas energy, plastic raw materials and other system resources comprehensively, produces thick-wall plastic-foam product high speed and high effectively. The invention first closes the die and injects gas into die cavity, then injects molten material into die cavity, the welding fluid is full of die cavity after inner foaming, the molten material surface is closed to the metal wall-surface of die cavity, the molten material in die cavity is solidified and shaped after cooled, then opens the moving mold and static mold, the plastic products are prepared which surface is smooth anddense and inner is distributed with uniform foam. The invention can eliminate or reduce the converging cave and warping deformation of product surface, reduces injection moulding pressure, thereby reduces the lock-mode pressure of injection machine; reduces equipment operating costs, thereby improves the size accuracy and strength of products, can reduces 15% ~ 35% raw material consumption effectively, products have higher mechanical property and weight proportion.

Owner:DONGHUA MACHINERY

Auxiliary cooling device for liquid crystal display module production and processing

ActiveCN110455024BSpeed up the flowIncrease cooling rateDomestic cooling apparatusLighting and heating apparatusCold airThermodynamics

The invention discloses an auxiliary cooling device used for the production and processing of liquid crystal display modules, comprising a cooling table, a cooling box, an air outlet and an air suction port. The upper and lower ends are provided with air outlets, and the middle of one side of the cooling box is provided with an air intake. The invention is scientific and reasonable, safe and convenient to use, and is provided with a cooling box, which utilizes the cooling U-shaped pipe inside the cooling box to achieve heat exchange. At the same time, the air flow can be formed above the cooling table by using the outlet fan and the suction fan inside the air outlet and the air suction port, the cold air can be used to cool the liquid crystal display module, and the hot air can be sucked into the cooling box by the air suction port and the suction fan. On the one hand, the flow of air is accelerated, which effectively improves the cooling rate of the liquid crystal display module;

Owner:安徽世阳光电有限公司

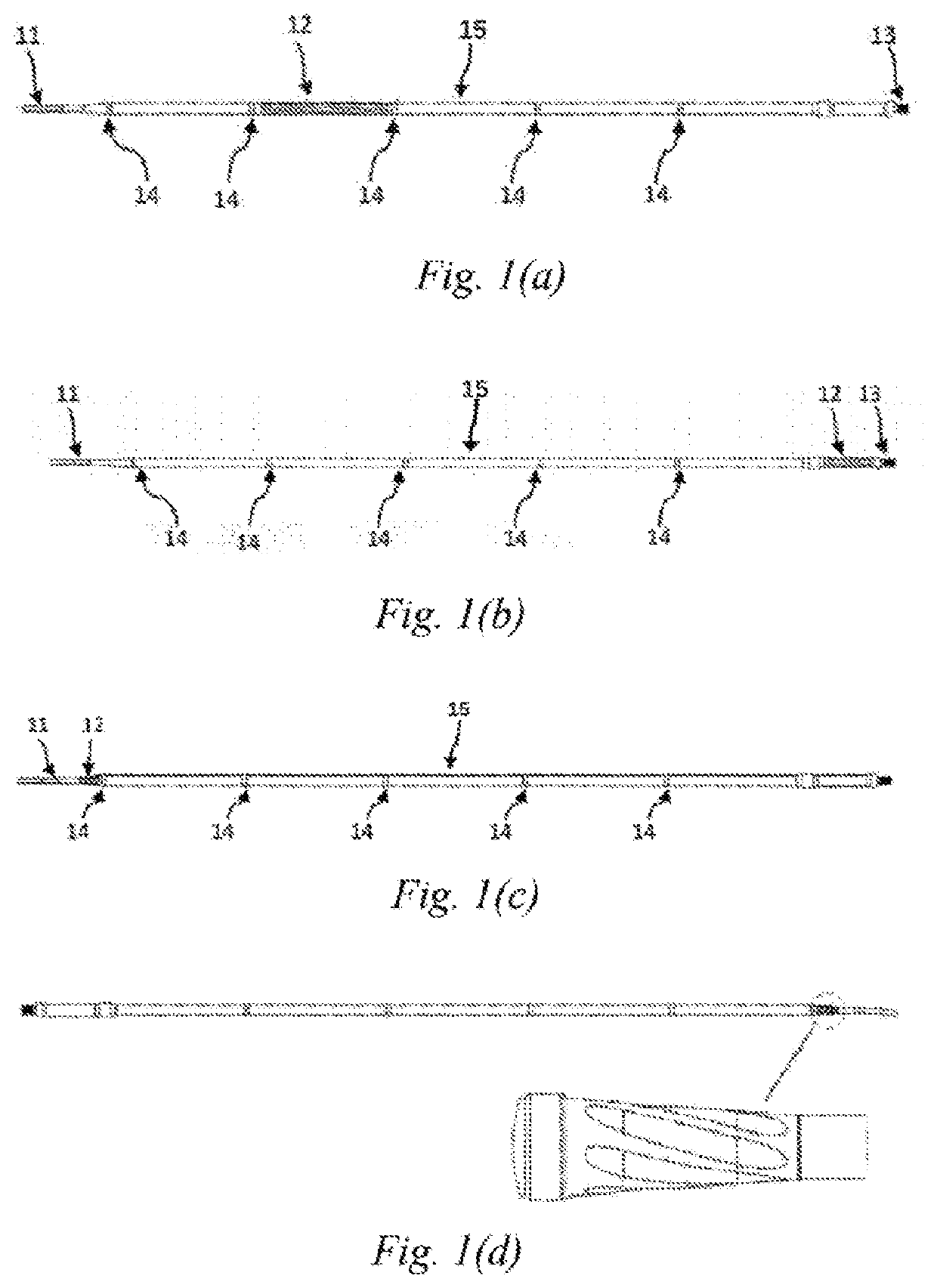

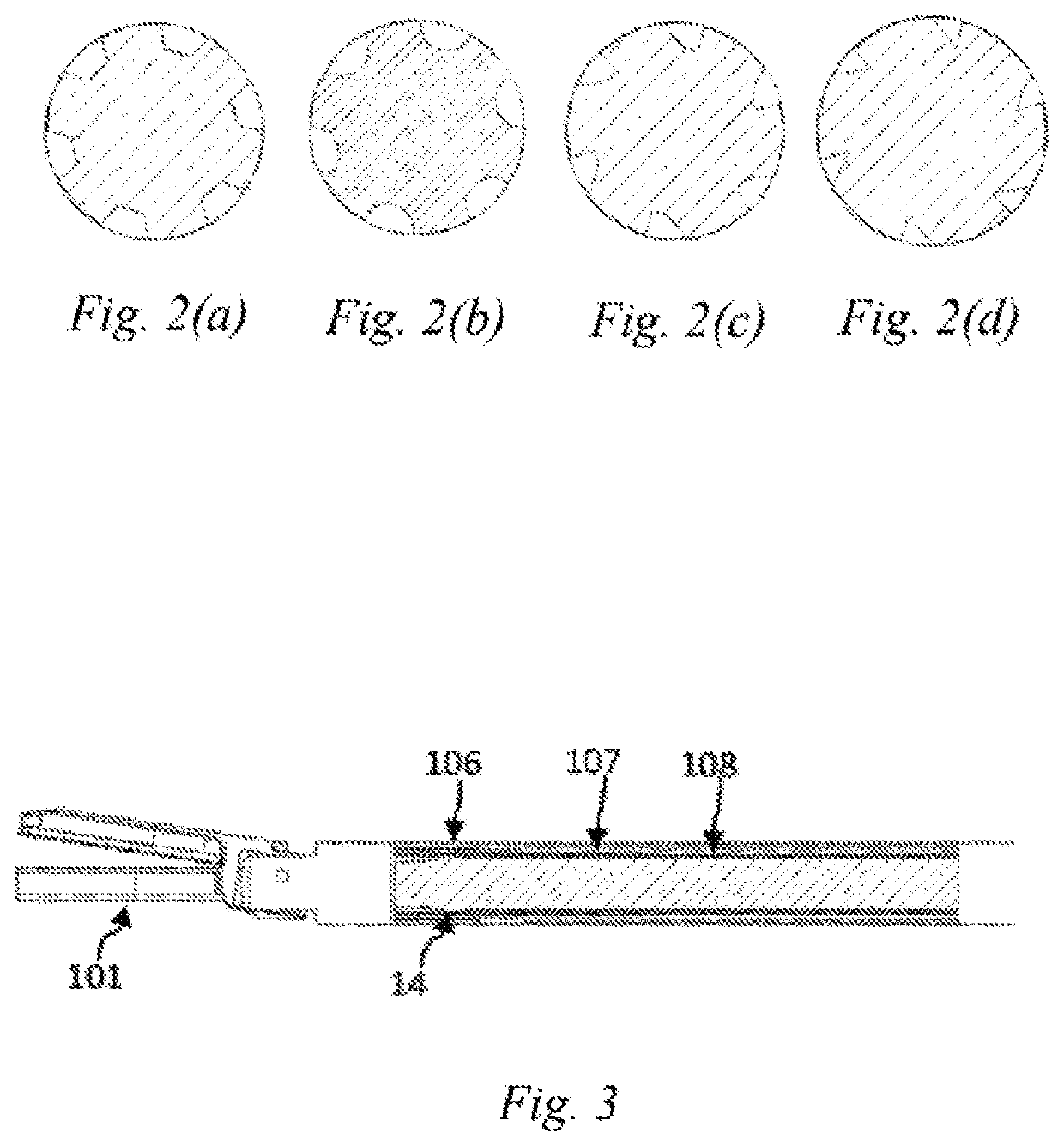

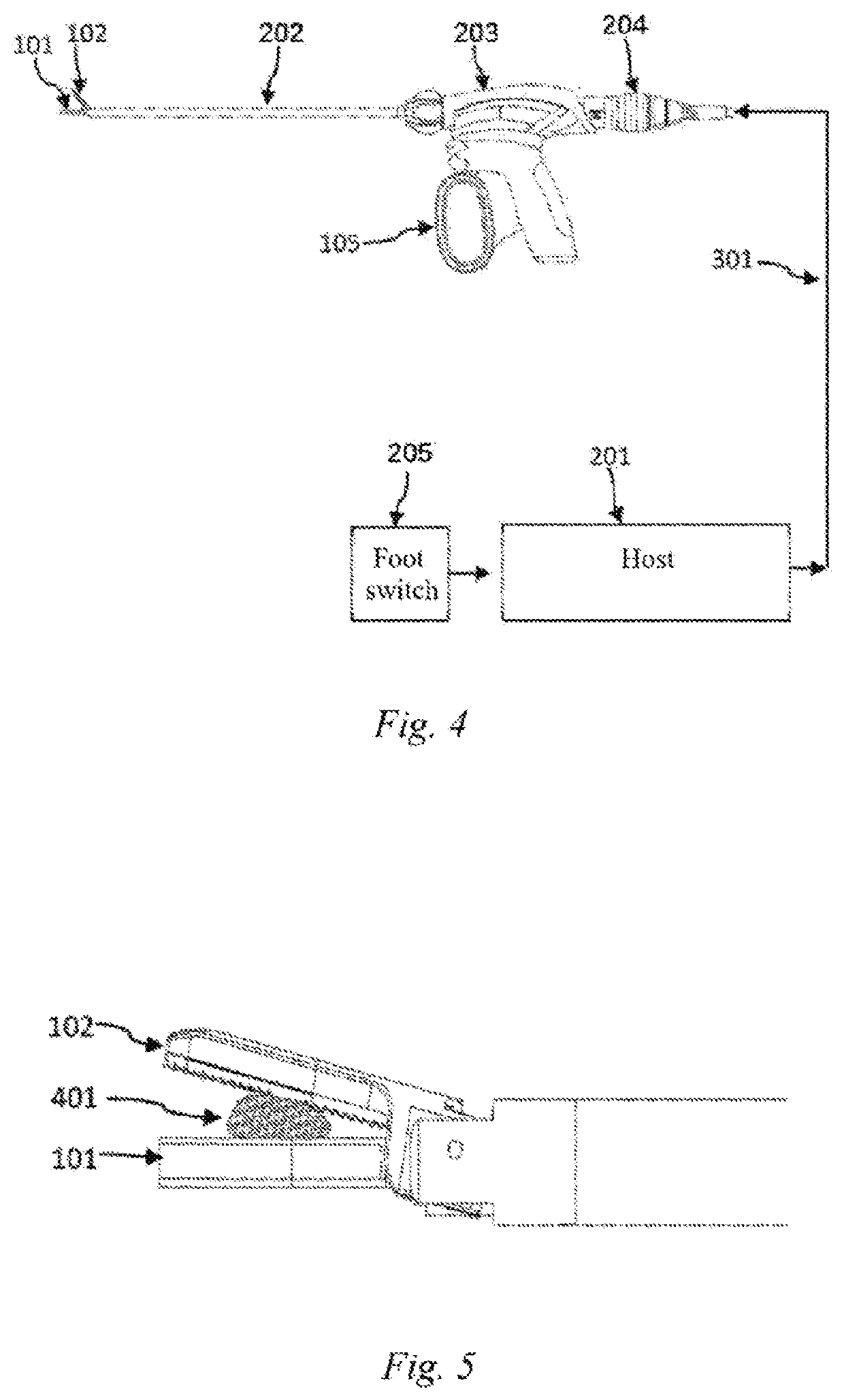

Ultrasonic scalpel bit, ultrasonic vibration propagation assembly and ultrasonic hemostasis and cutting system

InactiveUS20200022720A1Improve efficiencyImprove securityIncision instrumentsSurgical instruments for heatingUltrasonic vibrationWaveguide

Disclosed is an ultrasonic hemostasis and cutting system, comprising an ultrasonic vibration propagation assembly. An ultrasonic scalpel bit (101) of the ultrasonic vibration propagation assembly comprises an ultrasonic scalpel tip (11), a connection portion (13), vibration node bosses (14) and a waveguide (15), wherein the ultrasonic scalpel tip (11) is arranged in front of the waveguide (15), the connection portion (13) is arranged behind the waveguide (15), the vibration node bosses (14) are arranged on the waveguide (15), the ultrasonic scalpel tip (11) is laterally bent at a pointed end thereof, and a vibration guide groove (12) is further provided on the ultrasonic scalpel bit (101). By designing the ultrasonic scalpel bit in a bent shape and converting a longitudinal ultrasonic vibration into a longitudinal torsional composite vibration, temperature uniformity inside a tissue being cut or coagulated can be improved, thereby improving the efficiency and safety of hemostasis and cutting.

Owner:BEIJING SMTP TECH CO LTD

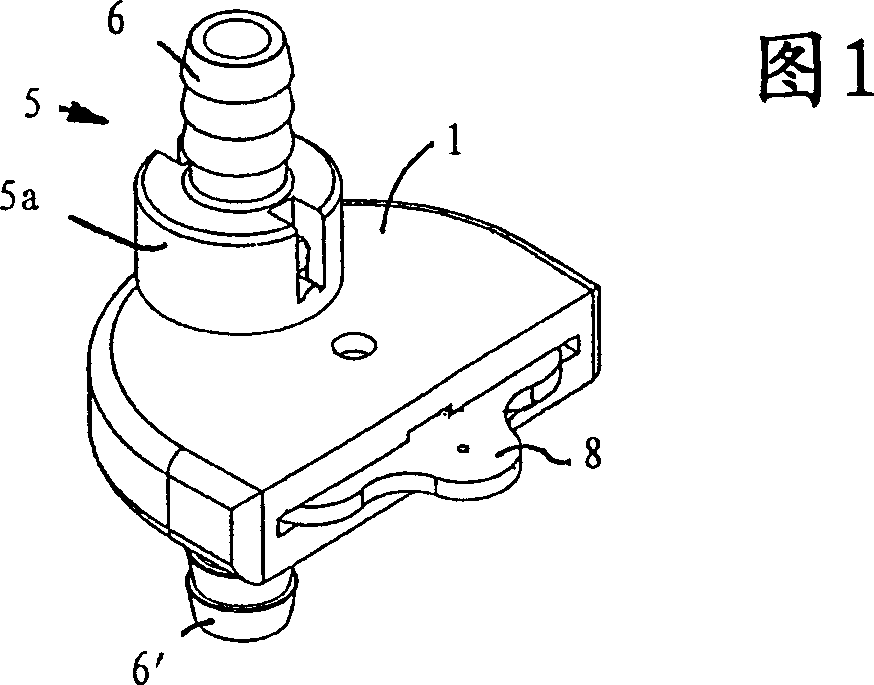

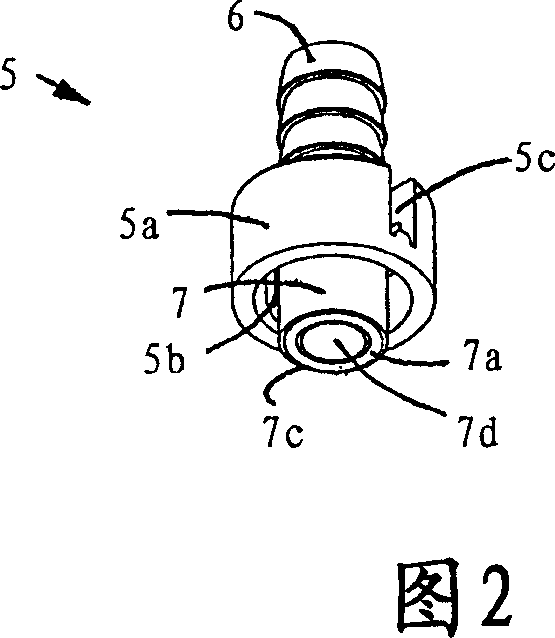

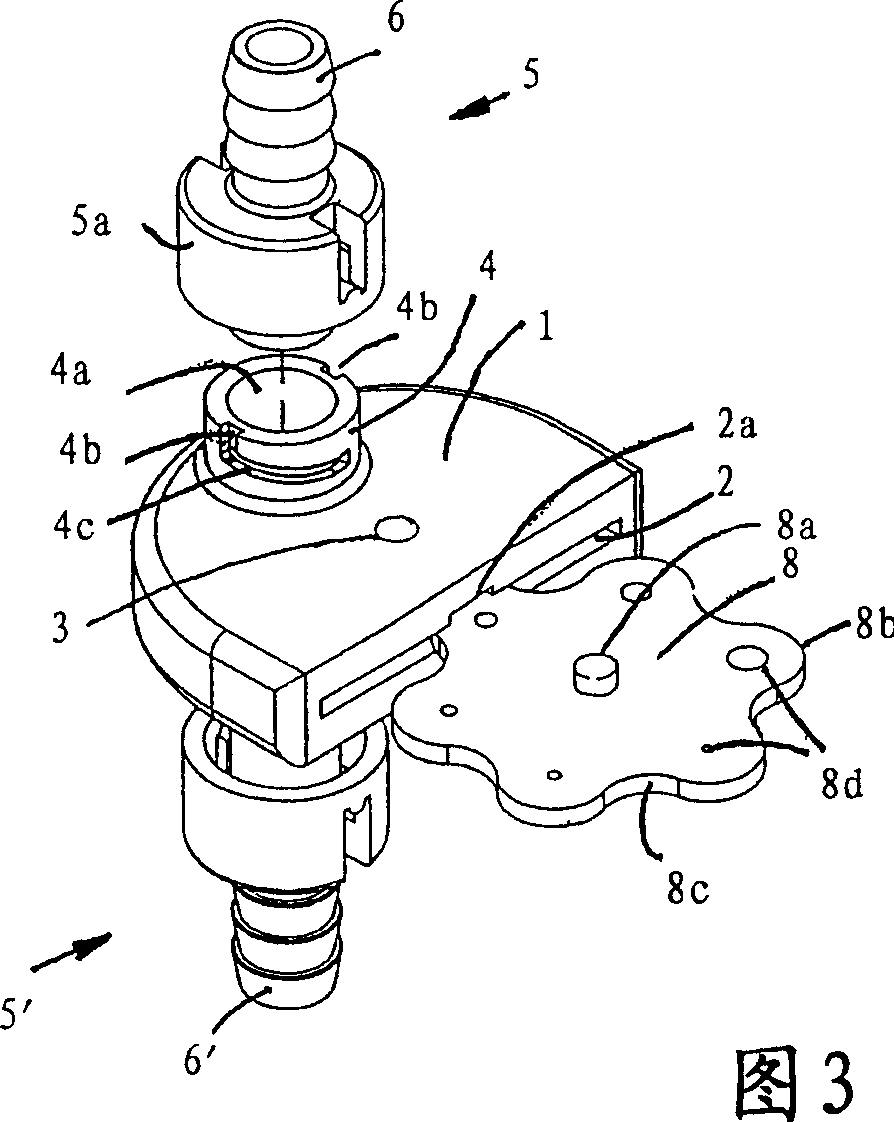

Flow restrictor

A liquid flow restrictor in the supply line of an eductor or other dilution or dispensing device has a rotatably mounted disc (8) with opposite faces and a plurality of apertures or holes (8d), which provide different flow restrictions between the faces, and a pair of flow conduits (5, 5') sealingly engaging against the faces, whereby on rotation of the member (8) the zones are selectively brought into communication with the conduits (5, 5') to provide a desired flow restriction.

Owner:JOHNSONDIVERSEY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com