Injection molding machine having a platen for uniform distribution of clamping forces

a technology of injection molding machine and clamping force, which is applied in the direction of presses, manufacturing tools, food shaping, etc., can solve the problems of uncompensated mold face bending, possibility of flashing still exists, and the method and apparatus by which this is achieved are quite complex, and achieve the effect of reducing clamping pressure, light weight and quick mold cycle operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

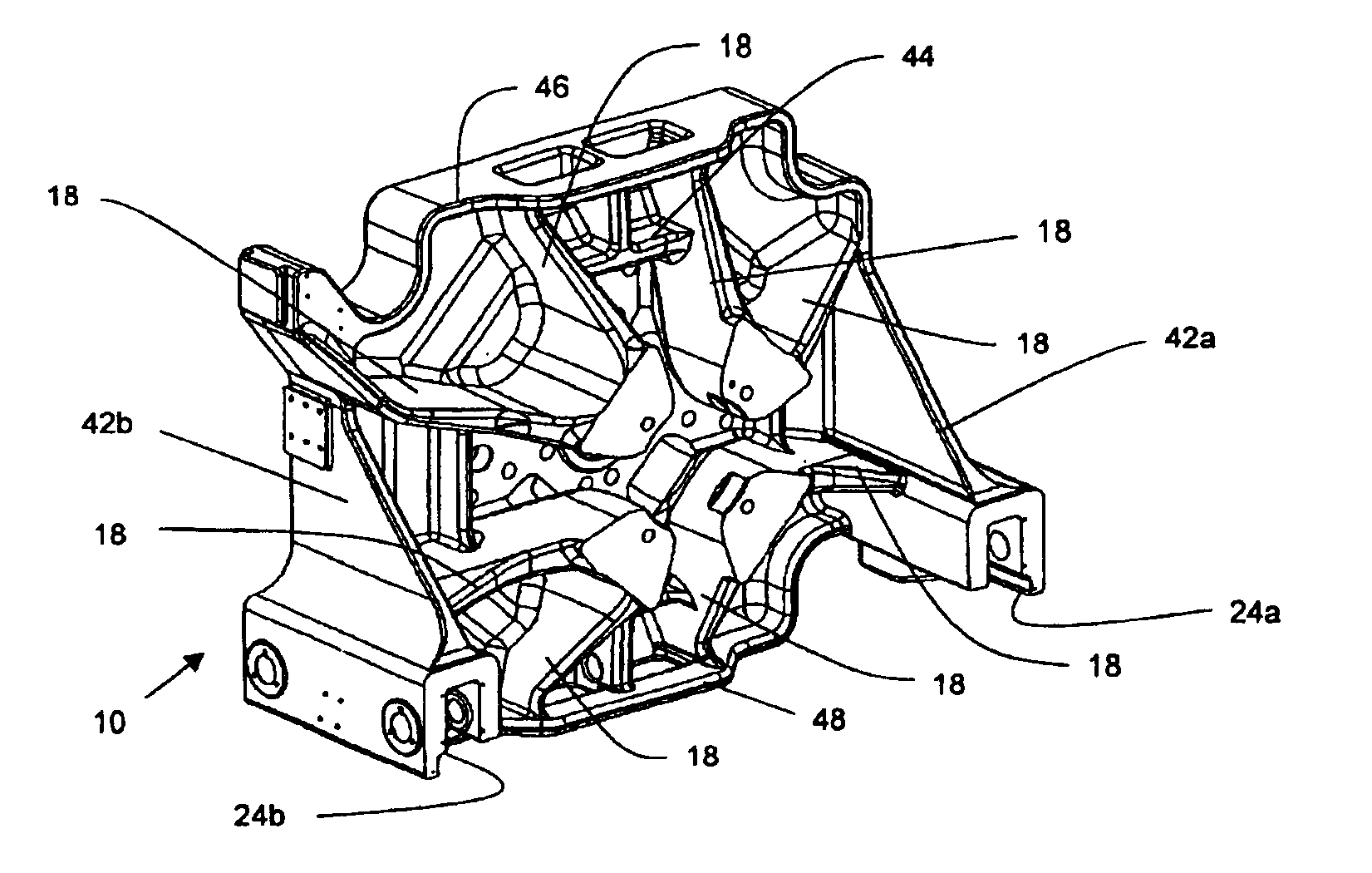

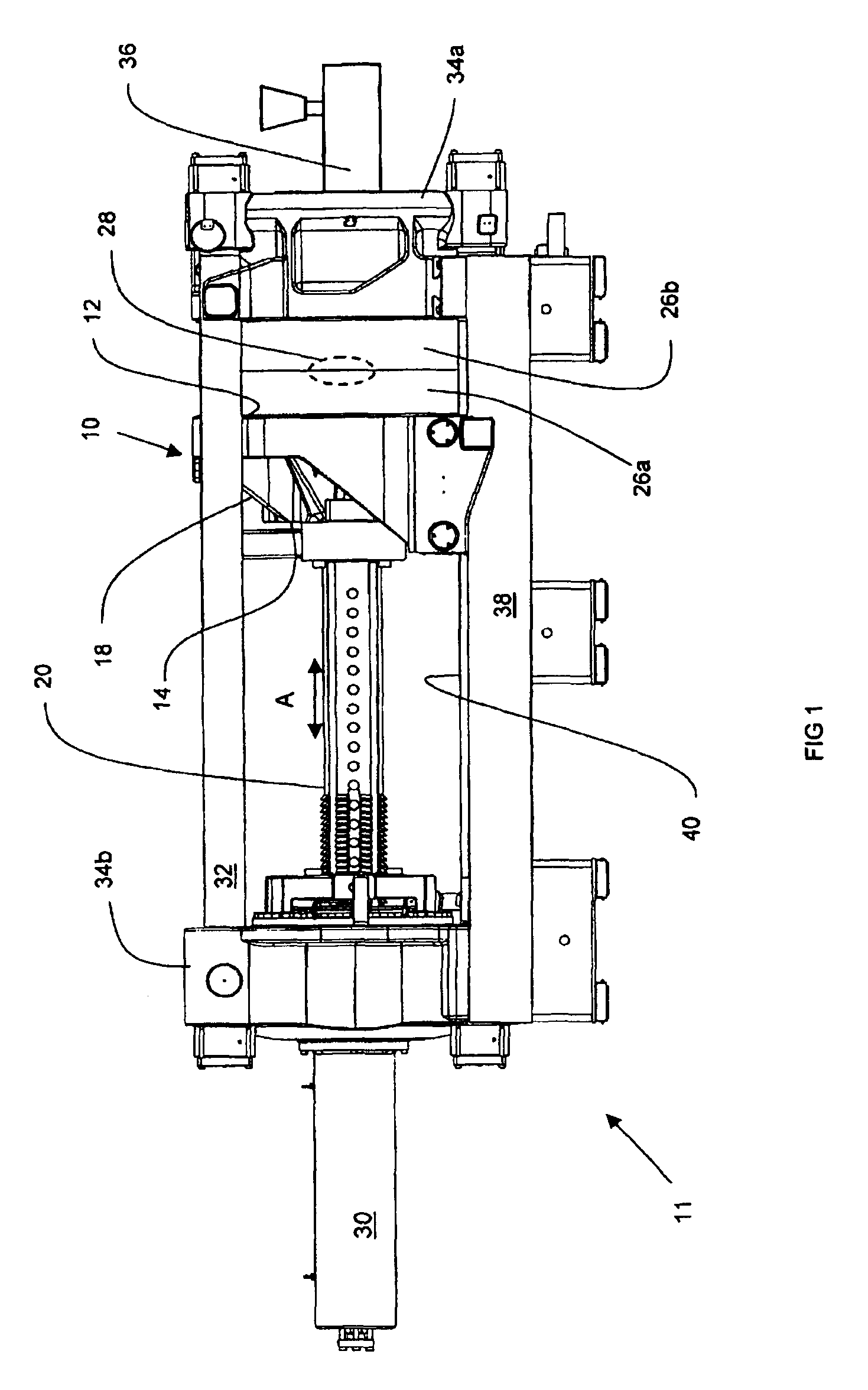

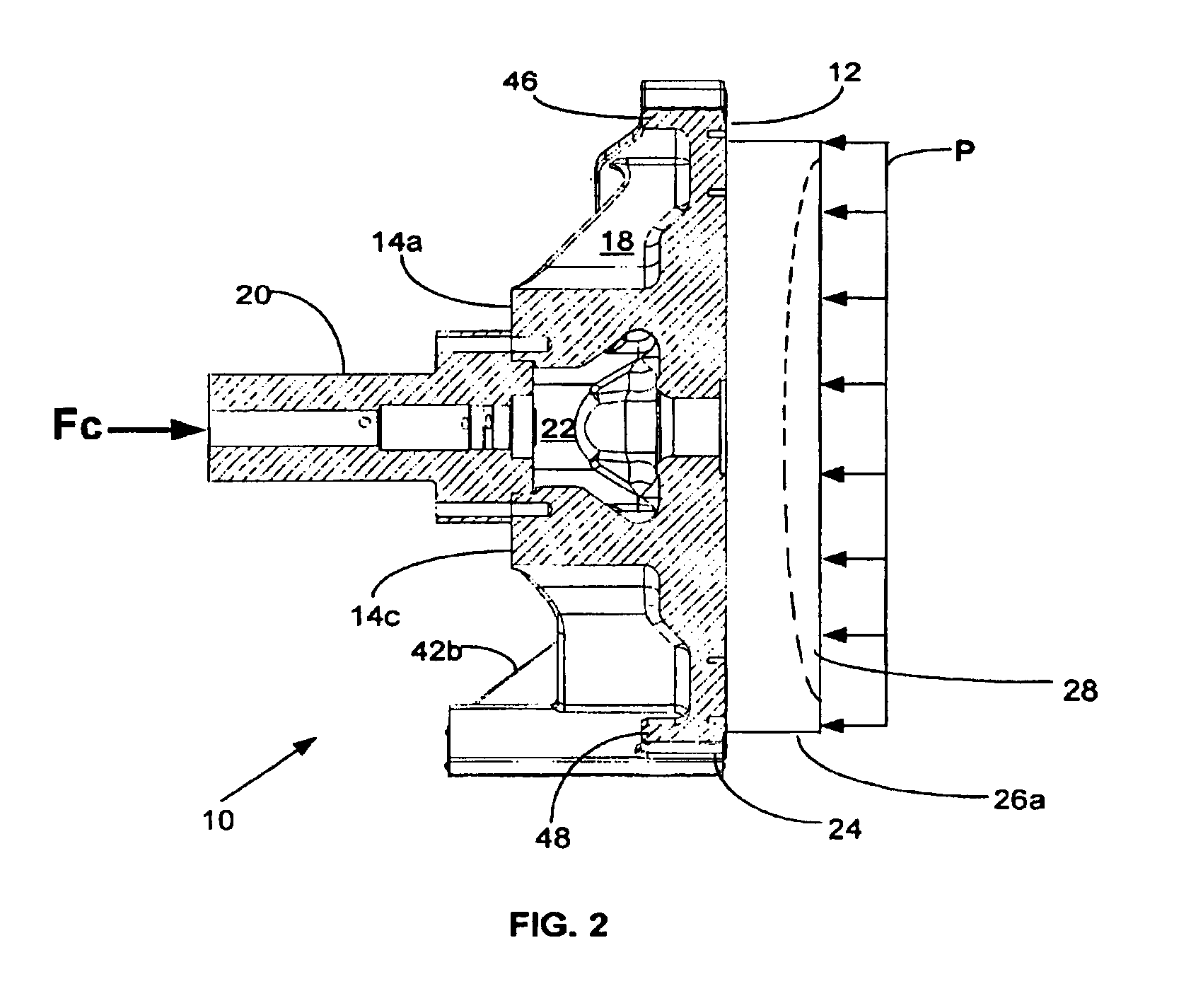

[0024]Referring to FIG. 1, an injection molding machine 11 is generally shown which uses at least one movable platen 10 in accordance with the present invention. Rigidly affixed to a central location of a back face 14 of the movable platen 10 is at least one clamp column 20 which allows the platen to be opened and closed (arrow A) by a hydraulic cylinder 30. The movable platen 10 rides along a rail 40 affixed to a machine base 38. A plurality of tie bars 32 run the length of the machine 11 and connect to spaced apart first and second stationary platensplaten 34a and clamp block 34b respectively.

[0025]A first mold half 26a is removably attached to a front face 12 of the movable platen 10. A second mold half 26b is removably mounted to second stationary platenclamp block 34b such that mold halves 26a and 26b form a mold cavity 28 therein when brought into contact during clamp-up by clamp column 20. Attached to the first stationary platen 34a and in communication with mold cavity 28 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com